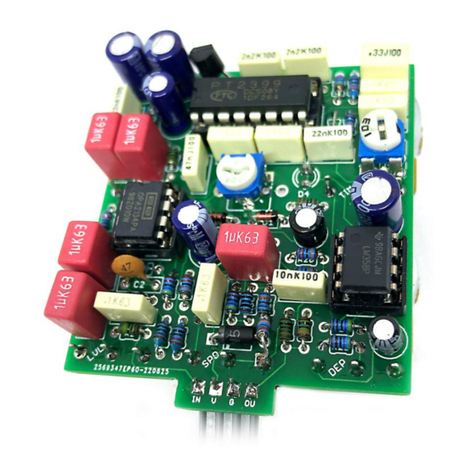

The power and signal pads on the PCB conform to the FuzzDog Direct Connection format, so can

be paired with the appropriate daughterboard for quick and easy offboard wiring.

Be very careful when soldering the diodes, ED and transistors. They’re very sensitive to heat. You

should use some kind of heat sink (crocodile clip or reverse action tweezers) on each leg as you

solder them. Keep exposure to heat to a minimum (under 2 seconds).

The long leg (anode) of the electrolytic capacitors go into the square pads. The striped leg (cathode)

of the diodes goes into the square pads.

Snap the small metal tag off the pots so they can be mounted flush in the box.

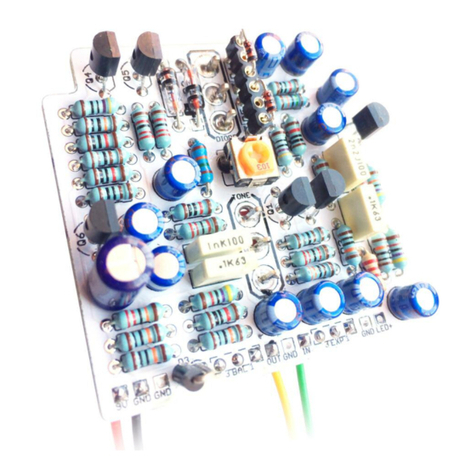

Pots and switches mount on the back side of the board. Red line in the image above shows the

direction of the switch tags. If you’re using board-mounted pots you’ll have to place these last as

they’ll restrict your access to the pads for the other components.

Ensure your switches and pots (if using board-mount) all line up before fully committing to

soldering them. The best way to do this is solder in the 3PDT switch first, as this is the deepest

component. Now place your SPDT switch and raise it slightly from the board until it aligns with the

first switch. Now do the same with the pots. The pins will only just poke out of the top of the board

when they’re high enough to line up with the switch. Only solder one pin of each pot for now, until

you ensure they’re all lined up. It’s easy enough to melt a single solder joint and reposition them.

When everything lines up, solder the other two pins of each pot.

A good way to go about lining them all up is to place the switches and pots into the PCB without

soldering, then place the enclosure on top, but upside down, i.e. the whole thing is sitting on the top

face of the box. The hole pattern is symetrical so it should still line up. That should make it much

easier to line things up.

PCB ayout ©2015 Pedal Parts td.