14 15

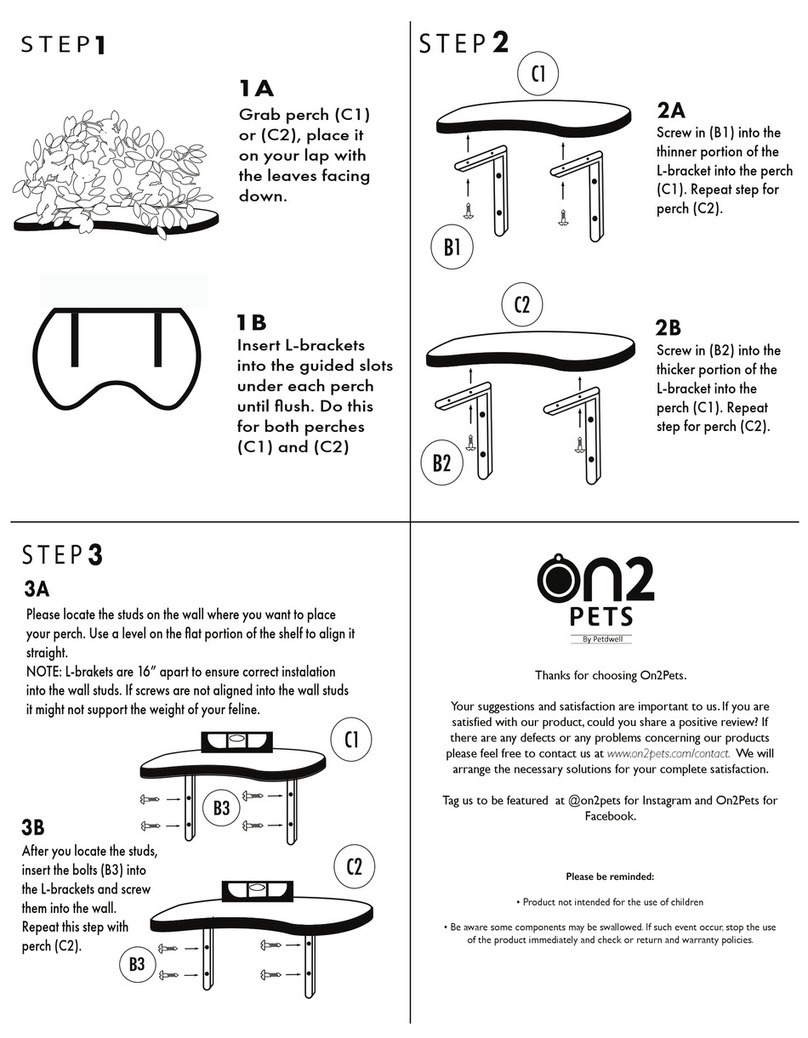

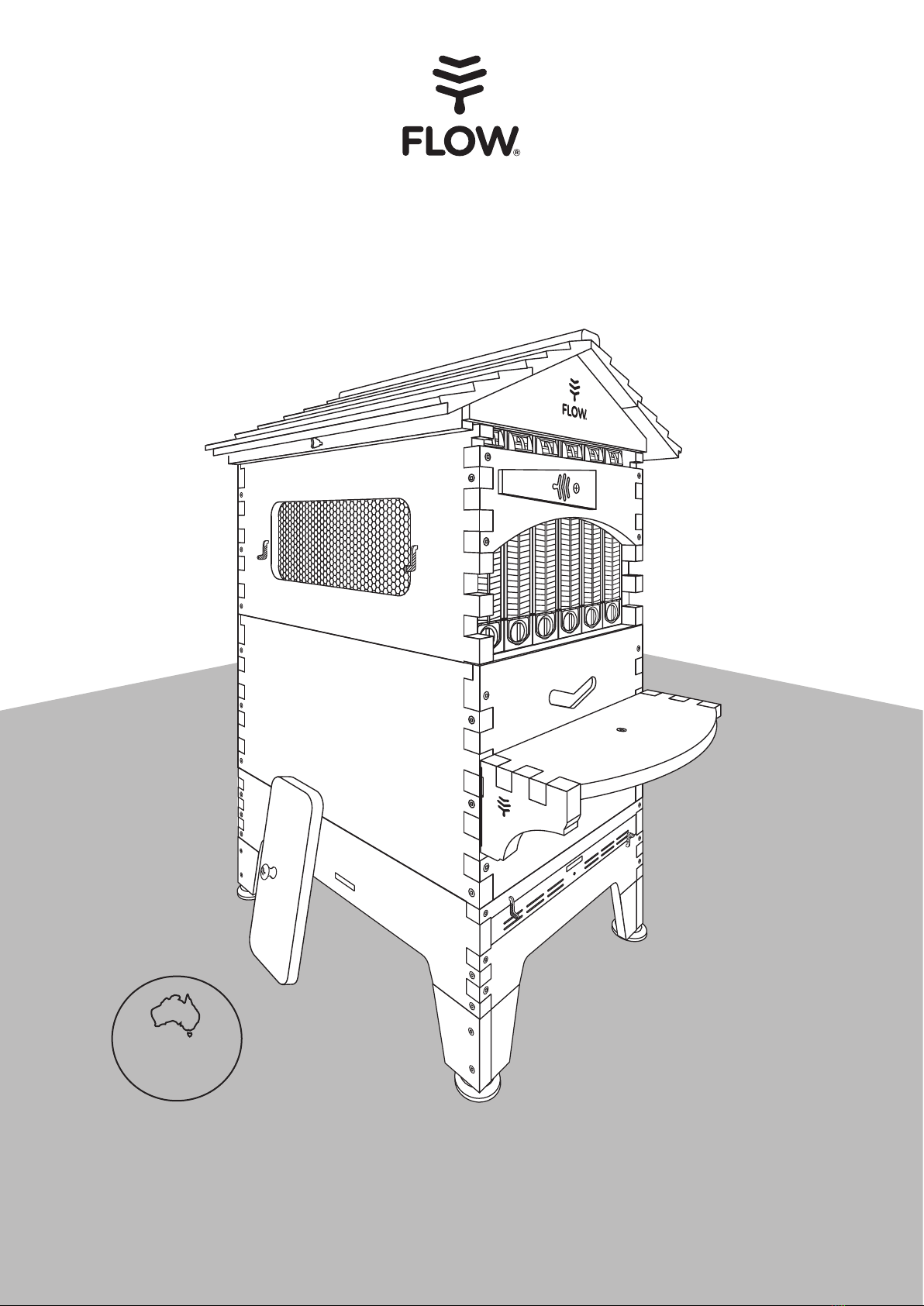

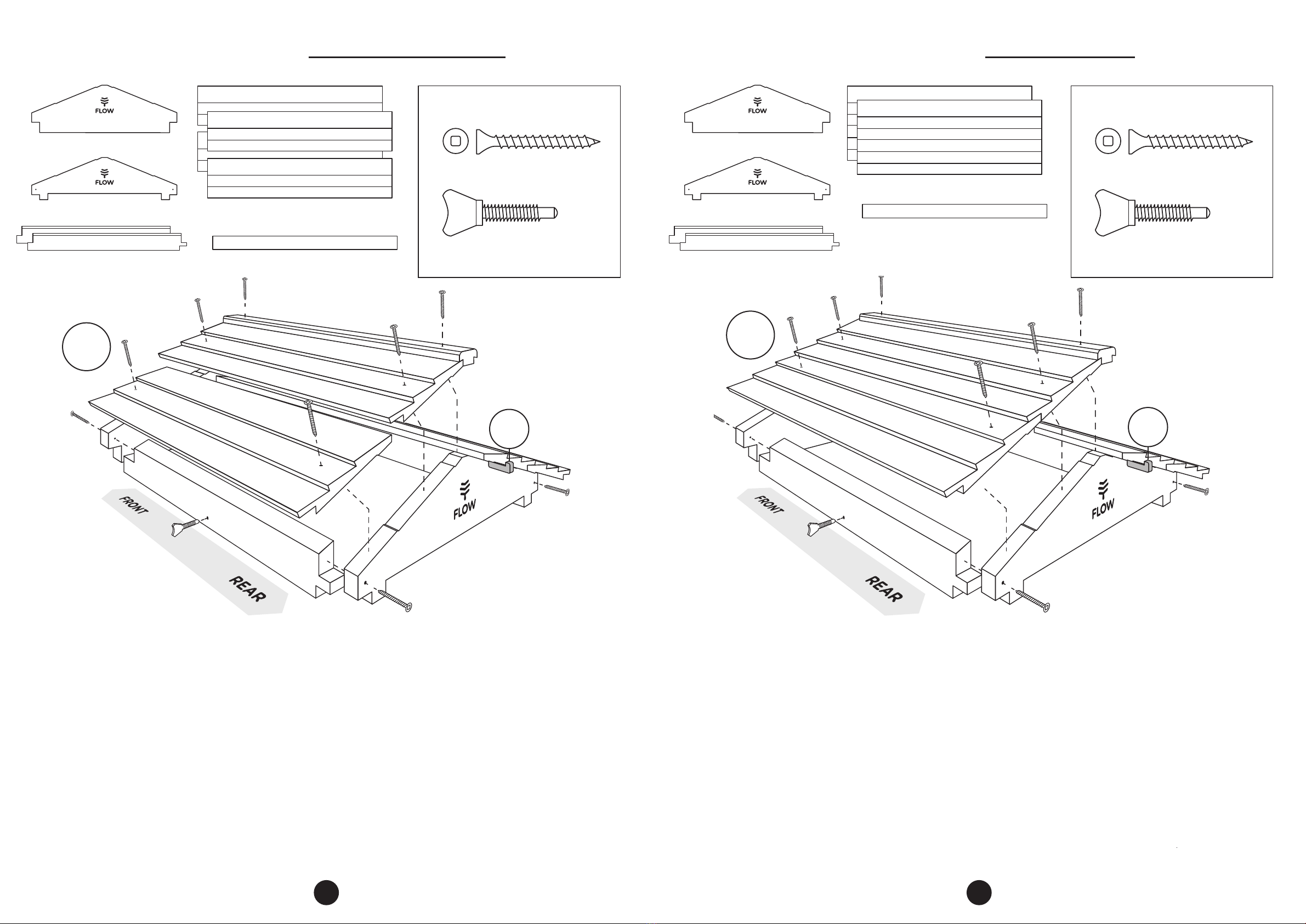

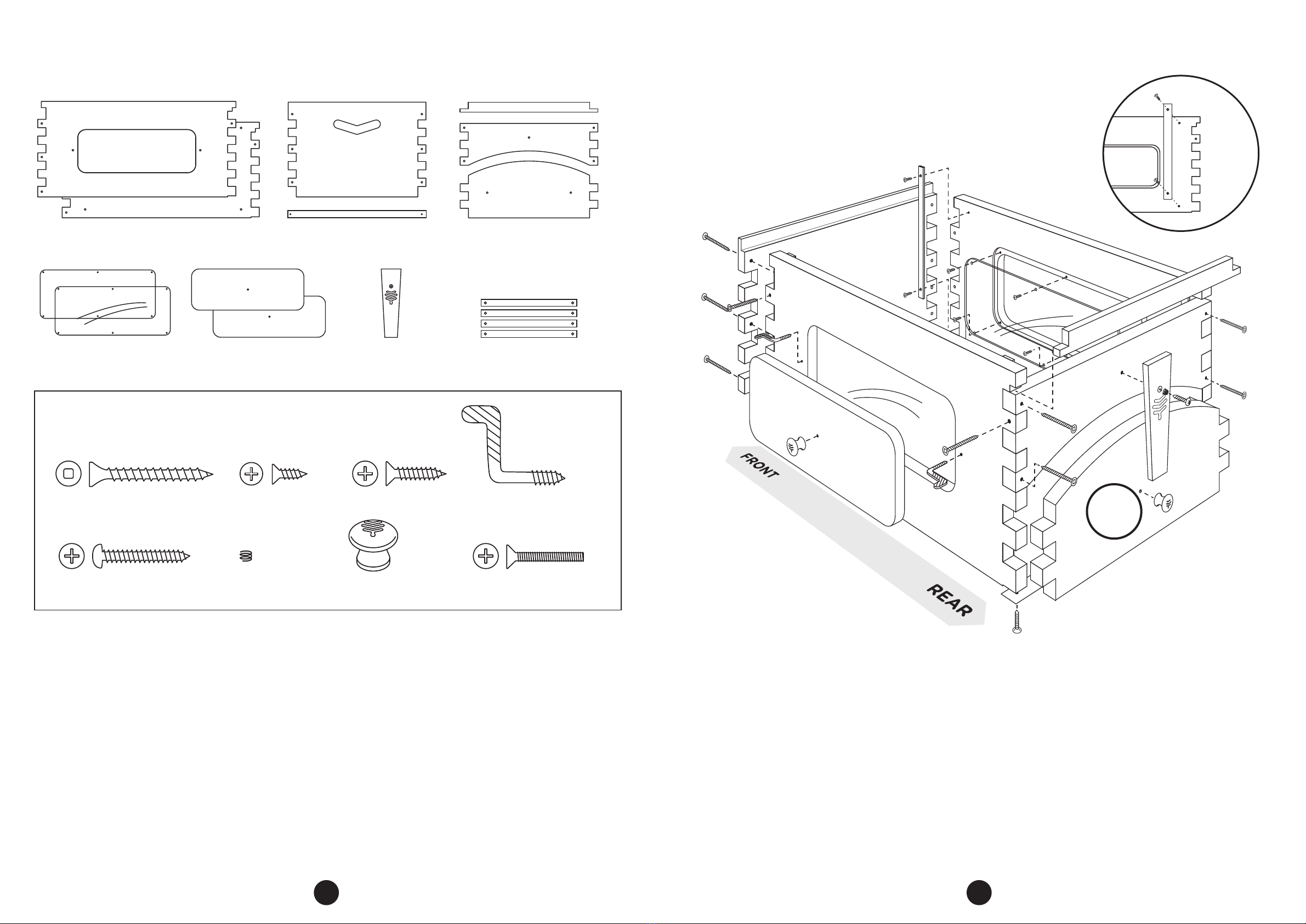

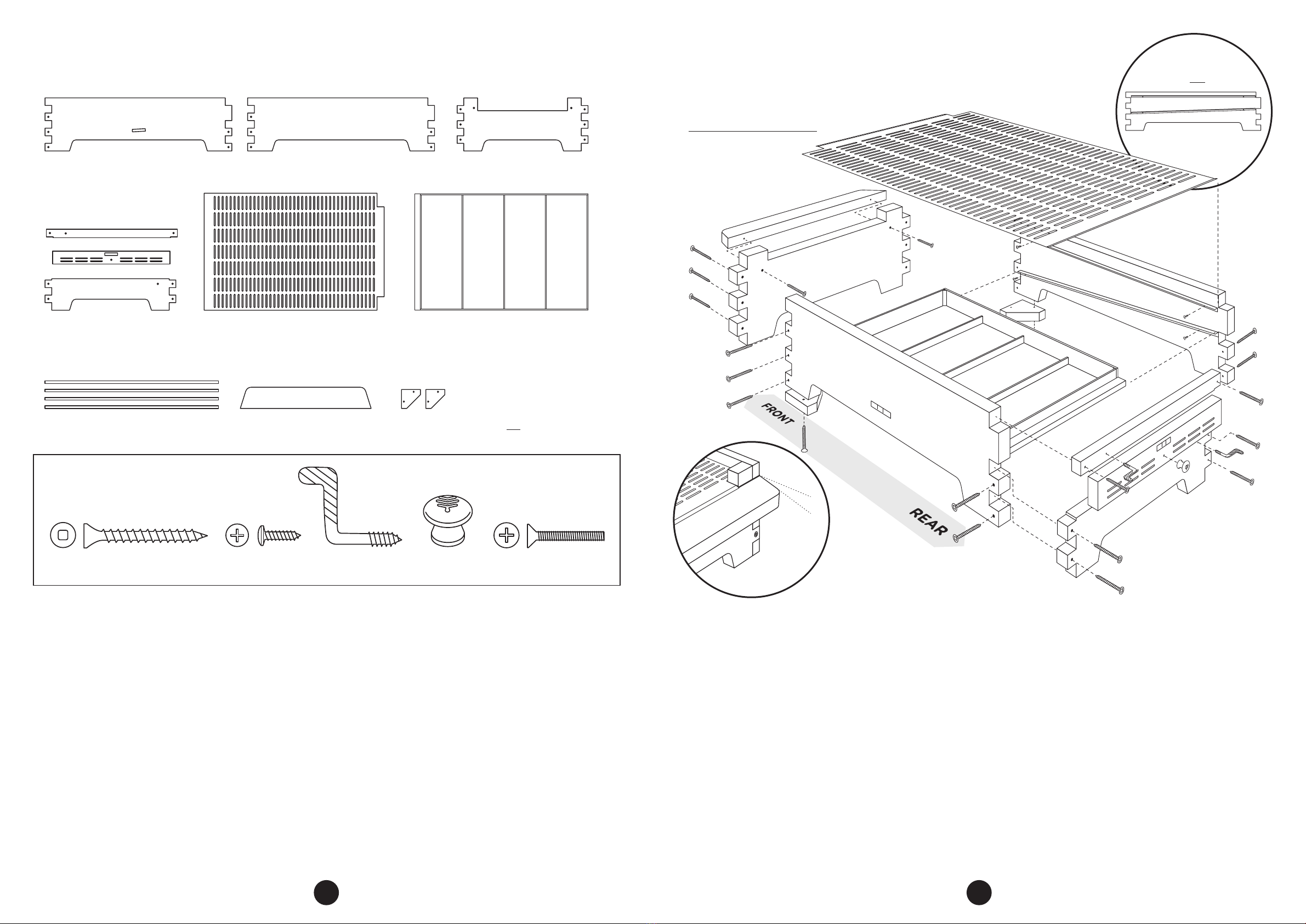

BASE ASSEMBLY

• These L screws sit asymmetrically (see diagram).

Screw in until they almost scrape on the external

box side.

8. To attach the brass knob onto the rear vented cover

(with spirit level), insert the knob screw through the

pilot hole and tighten by hand until the head of the

screw is flush with the wood. You can now put the

base rear vented cover in place using the brass L

screws to secure it.

• The base rear vented cover can be used in two

positions. Place vents on the top side to assist with

ventilation, or turn upside down with vents at the

bottom to block ventilation.

• The vented cover should touch the acrylic tray to

create a sealed surface on the inner edge.

9. Remove plastic protective layer from the metal screen

and place onto the top side of metal rails so that the

entrance lip slopes down to touch the landing board.

10. To create an optimal harvesting slope on the base for

customers who do not have the optional leg kit, you

will need to attach the 2 footblocks to the front of

the base (the front is the side with the landing board

attached). Line up each footblock so that the corners

match and using the square drive bit, screw 2 square

drive screws into the pilot holes.

• Your base includes a side panel spirit level, which

indicates when the base is sloped to the optimal

harvesting angle (3°). Once you have attached your

2 footblocks, check the spirit level to ensure that

your base is sloped for optimal harvesting.

• Please also note; there are 6 pilot holes in the

bottom corners of the base for the optional leg

kit. Disregard these pilot holes if you have not

purchased this.

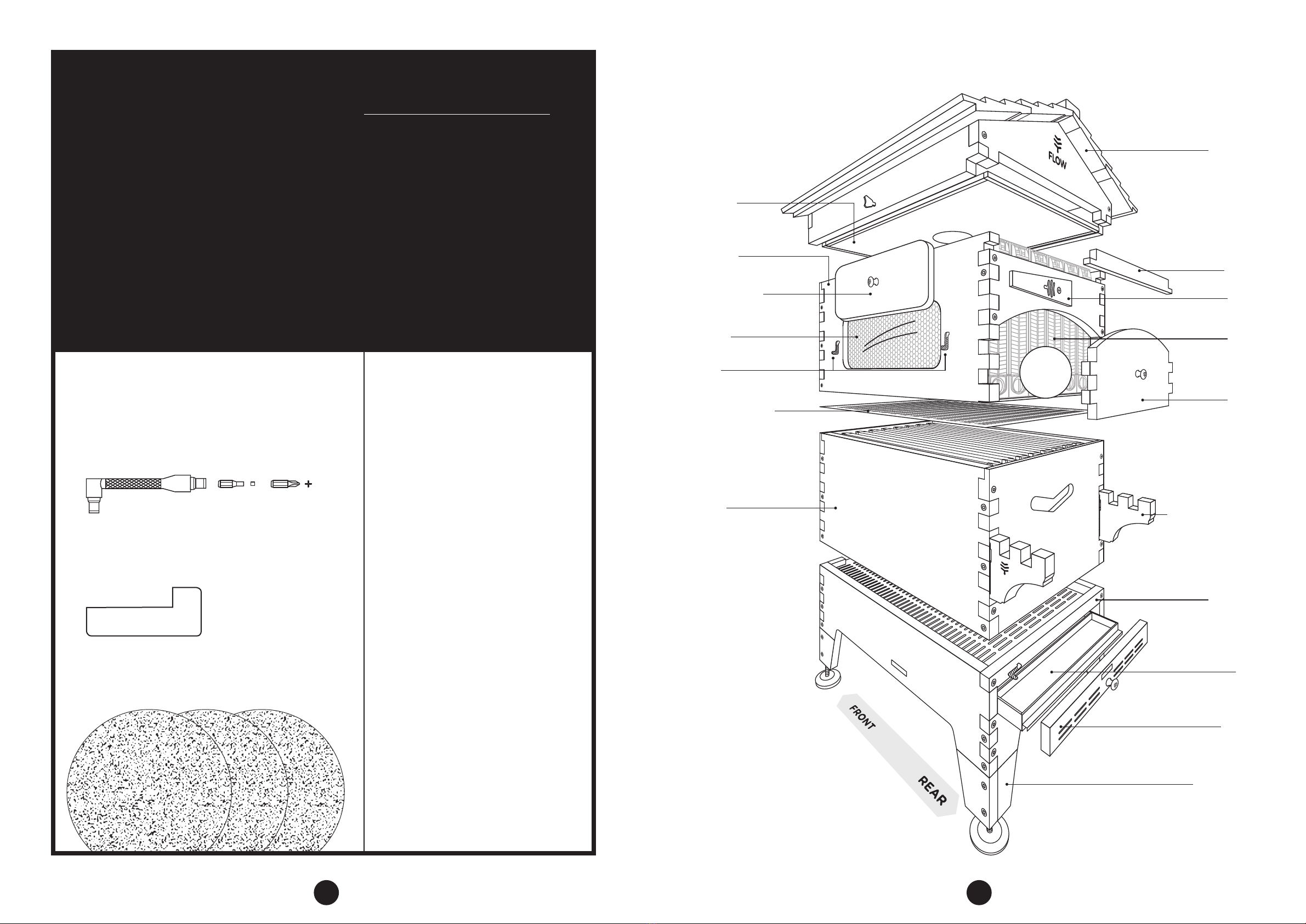

1. Dry fit the base sides, rear and front panels together.

• The 4 small pilot holes on each side panel (for

supporting the metal rails, acrylic tray and metal

base screen) face the inside.

2. Hold the finger joints tightly together (clamp optional)

and use the assembly tool and square drive bit to

secure your base (square drive screws). Take care to

stop when the head is almost flush with the wood

surface. If using a drill, be careful not to overtighten

or the wood may split.

3. Attach the rear support beam (square drive screws) to

the top rear of the side panels with a gap between the

support beam and the base rear panel (this is where

the rear vented cover will sit, but do not attach this).

4. Centre the landing board at the front of the base and

attach to the front panel using the pilot hole locators

(square drive screws), as shown, with a downward

angle to deter rain from entering the hive.

5. Now ax the 4 metal rails to the inside face of the

side panels (Phillips head driver bit). These rails will

house the acrylic tray and metal screen. Line up the

screw holes in each metal rail with the internal side

panel pilot holes.

• The right angle rails mount with the holes on the

underside (and forms a shelf on the top edge).

• Repeat on each side panel to create two small

horizontal bracket shelves on each side as shown.

• The rails are not parallel. The bottom rail slopes

toward the front.

6. Slide the acrylic tray into place through the gap

between the rear panel and the rear support beam.

• When the tray is in place, a gap remains for

ventilation.

7. Locate the 2 brass L screws and screw them into the

pilot holes by hand on the rear panel and the rear

support beam.

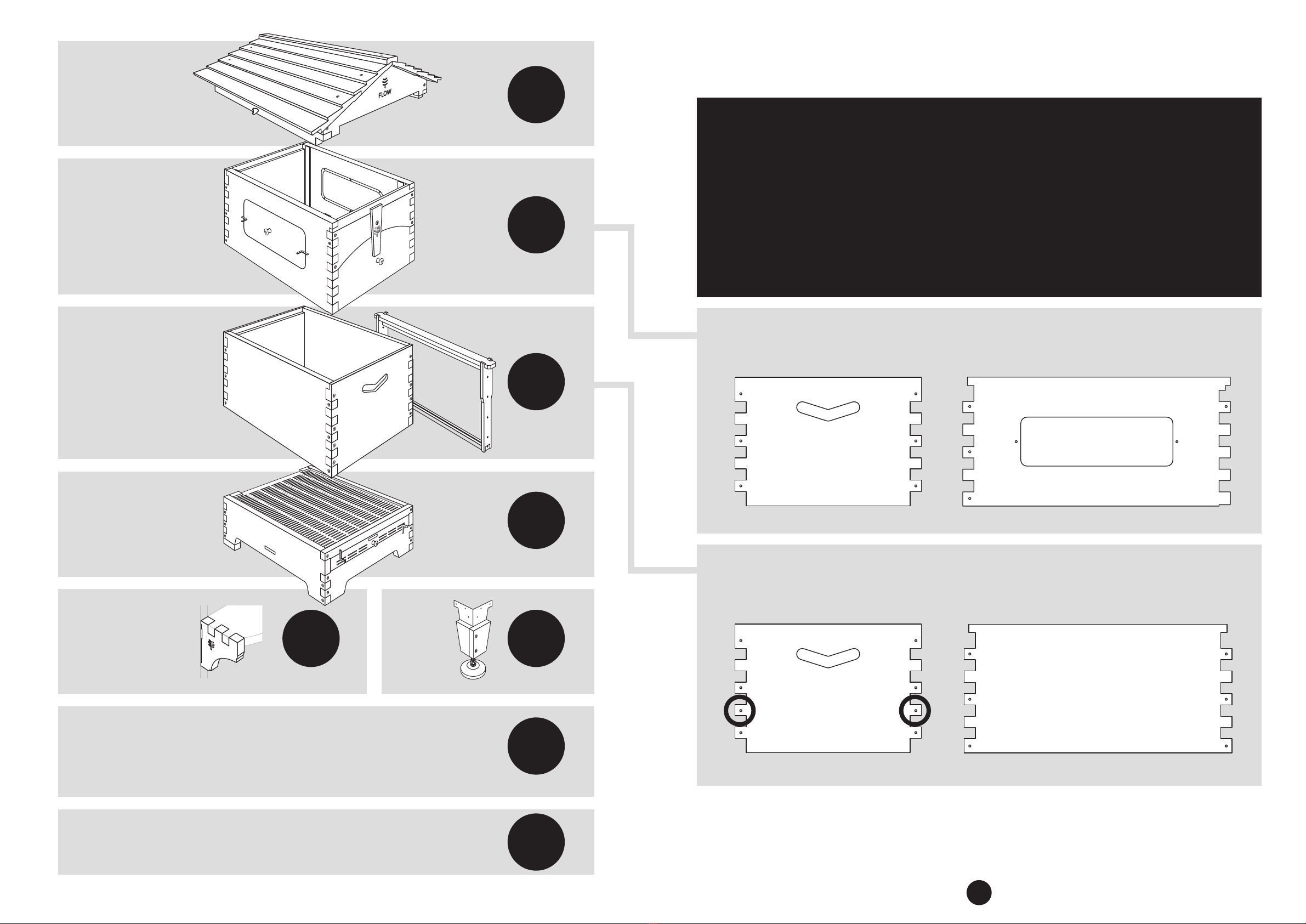

1 x side panel left (with spirit level) 1 x side panel right 1 x front panel

1 x metal screen

1 x landing

board

2 x footblocks –for use if not

installing the optional leg kit

PARTS ASSEMBLY

1 x rear support beam

1 x rear vented cover

(with spirit level)

1 x rear panel

4 x metal rails

1 x tray

BASE SCREW PACK – ACTUAL SIZE

30 x square drive screws 8 x rail screws 2 x brass L screws 1 x brass knob screw1 x brass knob

For extra tips, check out our

assembly video at:

www.honeyflow.com/assembly

The landing

board has a

downward

slope when

fitted

The bottom rail will

slope toward the

front

The rails form a shelf

on their top edges