Flowmeter EASYVAC User manual

SERVICE

MANUAL

SERVICE MANUAL

EASYVAC

®

VACUUM REGULATOR

PUBLICATION CODE: MS003

EDITION: no. 6

DATE: February 2010

SERVICE

MANUAL

2 EASYVAC VACUUM REGULATOR MS003 February 2010

Contents

Warning .............................................................. 2

Your local dealer and service center.................. 3

Table of illustrations............................................ 4

Drawings ............................................................ 5

List of spare parts............................................... 8

Maintenance operations..................................... 9

Warning WARNING: DANGER INDICATION

Attention: Important indication

General information

•Read this manual carefully before using the

EASYVAC vacuum regulator.

•THIS DOCUMENT MUST BE USED TOGETHER

WITH AND IN ACCORDANCE WITH THE

OPERATOR MANUAL SUPPLIED WITH THE

PRODUCT.

•AFTER UNPACKING AND CONNECTION,

PERFORM THE FUNCTIONAL TEST DESCRIBED

IN THE CHAPTER "PERIODIC CHECKS" OF

OPERATING MANUAL MO002 ON THE DEVICE.

•USE OF INSTALLATION PROCEDURES NOT

DESCRIBED IN THE OPERATOR MANUAL

MAY REDUCE THE DEVICE’S SAFETY LEVEL.

•BEFORE EACH USE, ENSURE THAT THE

EASYVAC VACUUM REGULATOR IS

DIRECTLY OR INDIRECTLY CONNECTED TO A

COLLECTION SYSTEM FITTED WITH AN

OVERFLOW VALVE AND ANTIBACTERIAL

FILTER AND THAT THE CONNECTOR HOSES

USED CONFORM WITH THE STANDARD EN

ISO 10079-3.

•The company accepts no responsibility for the

non-observance of these service instructions,

the use of non-original spare parts and/or

repairs by unauthorised persons.

Connections

•DO NOT ALLOW OIL AND GREASE TO COME

INTO CONTACT WITH THE DEVICE.

•The vacuum supply connector is positioned on

the rear of the device and can be identified by

referring to the drawing on page 5 of

Instructions Manual MO002 (pos. 7).

Operation

•THE EASYVAC VACUUM REGULATOR MUST

ALWAYS BE USED WITH CARE AND ONLY BY

PERSONNEL WHO ARE AWARE OF THE

CONSEQUENCES OF THE ONGOING

THERAPY.

•Disconnect the vacuum supply when the unit

is not in use.

Cleaning and disinfection

DO NOT USE SOLVENTS OR ABRASIVE PRODUCTS

FOR CLEANING: THESE CAN SERIOUSLY DAMAGE

THE SURFACES OF THE EQUIPMENT AND THE

PLASTIC PARTS.

•DO NOT IMMERSE THE UNIT IN DISINFECTANT;

•DO NOT PLACE THE UNIT IN AN AUTOCLAVE;

•DO NOT USE INFLAMMABLE PRODUCTS.

IF THE EQUIPMENT IS ACCIDENTALLY CONTAMINATED

BY SUCTIONED LIQUIDS, IT MUST BE ISOLATED AND

THE NECESSARY CLEANING AND DISINFECTION

OPERATIONS CARRIED OUT BY QUALIFIED

PERSONNEL.

IF NECESSARY, STERILISE THE EASYVAC VACUUM

REGULATOR WITH A VALIDATE ETHYLENE OXIDE

STERILIZATION CYCLE (E.G. 14% EO 12 H. / 50 KPA /

37 °C).

Service

•

A

ll the modifications and repairs must only be

performed by personnel authorized by

FLOW METER S.p.A., or by hospital

technicians approved by the same company.

•Original spare parts must always be used for

the maintenance operations.

•Check the EASYVAC vacuum regulator every

three years in accordance with the chapter

“Periodic checks” of Instructions Manual

MO002.

•Due to periodic updates, the construction of

the appliance may vary. On this point,

FLOW METER guarantees the availability of

spare parts for a minimum period of 5 years

from the date of manufacture.

•Any modification to the device should only be

performed if approved by the manufacturer

and in accordance with the procedures

provided.

The device has been designed and

manufactured to meet the safety requirements

of the following standards:

•EN ISO 10079-3

SERVICE

MANUAL

3 EASYVAC VACUUM REGULATOR MS003 February 2010

Your local dealer and service center

Your local dealer and service center for FLOW METER S.p.A. products is:

TO BE FILLED IN BY THE LOCAL DEALER OR AGENT

COPYRIGHT©FLOW METER S.p.A. 1998-2010

All rights reserved. None of the information contained in this publication must be used for purposes other than the

original ones.

No part of this publication may be reproduced without the written permission of FLOW METER S.p.A.

FLOW METER S.p.A. appliances are subjected to periodic revisions to maintain and improve the production

standards, functioning and increase their reliability. For this reason, the contents of this publication may be

modified at any time without prior warning. It is possible to obtain the updated version of the present document,

when obsolete, by applying to the local dealer or agent, indicating the edition in your possession.

The equipment described in this publication is designed and manufactured by FLOW METER S.p.A. - Via del

Lino, 6 - 24040 LEVATE (Bg) – Italy – Tel. +39-035-594047 – Fax +39-035-594821 – e-mail: [email protected] -

http://www.flowmeter.it

SERVICE

MANUAL

4 EASYVAC VACUUM REGULATOR MS003 February 2010

Table of illustrations

Drawing no. TITLE PAGE

1.1 Spares for EASYVAC vacuum regulator ........................................... 5

SERVICE

MANUAL

5 EASYVAC VACUUM REGULATOR MS003 February 2010

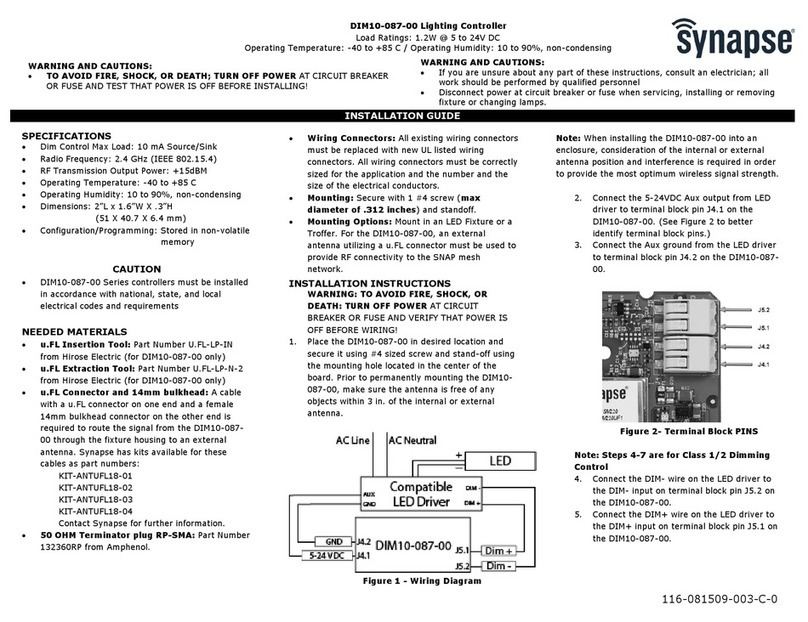

Drawing no. 1.1

SERVICE

MANUAL

6 EASYVAC VACUUM REGULATOR MS003 February 2010

List of spare parts

Position Code Description

1 000010199 Lid for EASYVAC regulator with membrane and adjusting knob

2 000010200 I-O button switch complete with gaskets

3a 000010192 Vacuum gauge -1000 mbar for EASYVAC regulator complete with fixing support,

gaskets and protection cover

3b 000010193 Vacuum gauge -600 mbar for EASYVAC regulator complete with fixing support,

gaskets and protection cover

3c 000010194 Vacuum gauge -250 mbar for EASYVAC regulator complete with fixing support,

gaskets and protection cover

SERVICE

MANUAL

7 EASYVAC VACUUM REGULATOR MS003 February 2010

Maintenance operations

2. MAINTENANCE

2.1 INTRODUCTION

This section provides instructions for proper maintenance of the device, in order to guarantee correct functioning

and appropriate conditions of safety.

2.2 FREQUENCY OF MAINTENANCE

It is recommended that the operations specified in chapter 2.3 MAINTENANCE OPERATIONS be performed with

the following frequency:

2.3.1 REPLACEMENT OF THE I-0 BUTTON

in the case of breakage or loss of seal

2.3.2 CLEANING OF THE MEMBRANE AND BODY

every 6 months

2.3.3 REPLACEMENT OF THE LID WITH A MEMBRANE

every 24 months

2.3.4 REPLACEMENT OF THE VACUUM GAUGE

in the case of accuracy outside the tolerance levels or breakage

2.3 MAINTENANCE OPERATIONS

2.3.1 REPLACEMENT OF THE I-0 BUTTON

If the I-0 closing tap shows signs of leakage or is damaged, the entire kit (2), shown in the drawing specified in the

Table of illustrations on page 4, must be replaced.

The replacement methods are provided with the assistance of the following illustrations:

Holding the EASYVAC vacuum regulator firmly,

pull out the red button, until it is completely free of

its quick coupling, and remove it completely.

Using a screwdriver, push the green button

outwards, until it is completely removed from the

vacuum regulator.

SERVICE

MANUAL

8 EASYVAC VACUUM REGULATOR MS003 February 2010

Maintenance operations

Replace the I-0 buttons group, complete with the

relative sealing gaskets with caps. Spread a light

layer of lubricant over all sealing elements of a

new I-0 tap, using oxygen-compatible products

(e.g. FOMBLIN YNX).

Insert the green button on the left-hand side of the

EASYVAC vacuum regulator, ensuring it is turned

with the indication “I” towards the front. The rear

slot of the button must fit into the relative coupling

inside the body of the vacuum regulator itself.

Insert the red button on the right-hand side of the

EASYVAC vacuum regulator, ensuring it is turned

with the indication “0” towards the front. The rear

slot of the button must fit into the relative coupling

inside the body of the vacuum regulator itself.

Keeping the green button pressed down, push

down until the red button clicks fully into place.

Move several times in both directions in order to

lubricate the gasket housing completely and check

that the I-0 switch moves correctly. Perform the

functional checks required and indicated in the

operating manual Mo_002 of the EASYVAC

device before use.

WARNING: DO NOT USE OIL TO LUBRICATE THE PARTS.

2.3.2 CLEANING OF THE MEMBRANE AND THE BODY

The vacuum pressure membrane and the one inside the body of the EASYVAC vacuum regulator should be

cleaned periodically, to ensure the device keeps working properly.

The cleaning methods are shown with the assistance of the following illustrations:

SERVICE

MANUAL

9 EASYVAC VACUUM REGULATOR MS003 February 2010

Maintenance operations

Unscrew the lid, complete with the regulating knob

and the membrane, remove from the vacuum

regulator body and check that the inside surfaces

have not been accidentally contaminated by the

aspired liquids. If this is the case, perform the

operations indicated in the chapter “Warning” on

page 2 before continuing with the subsequent

phases.

Thoroughly clean the entire surface of the

membrane, using a soft cotton cloth dampened

with ethyl alcohol diluted to 60% in water.

Thoroughly clean the entire internal surface of the

body of the vacuum regulator, using a soft cotton

cloth dampened with ethyl alcohol diluted to 60%

in water.

Reattach the lid, complete with the regulating knob

and the membrane, onto the body of the vacuum

regulator, tightening it manually for as long as

resistance between the two parts can be felt.

Perform the functional checks required and

indicated in the operating manual Mo_002 of the

EASYVAC device before use.

2.3.3 REPLACEMENT OF THE LID WITH MEMBRANE

In order to ensure correct functioning of the EASYVAC vacuum regulator, the lid (1), complete with the silicone

membrane as shown in the drawing specified in the Table of illustrations on page 4, should be periodically

replaced. This is due to deterioration of elasticity of the membrane, which could interfere with stable and safe

regulation of the suction value set on the device.

The replacement operations are the same as those described in paragraph 2.3.2 above.

SERVICE

MANUAL

10 EASYVAC VACUUM REGULATOR MS003 February 2010

Maintenance operations

2.3.4 REPLACEMENT OF THE VACUUM GAUGE

If the periodic checks on the accuracy value of the vacuum gauge indicated in the operating manual of the

EASYVAC device shows this value falls outside the tolerance levels or in the case of accidental damage to the

vacuum gauges, they must be replaced, as specified in the Table of illustrations on page 4.

WARNING: REPLACE THE VACUUM GAUGES USING ONLY ORIGINAL SPARE PARTS WITH THE

SAME FULL-SCALE VALUE AS THE ONES BEING REPLACED.

The replacement methods are shown with the assistance of the following illustrations:

Use a TORX screwdriver of suitable dimensions to

unscrew the two screws on the rear lid. After removing the lid, take the vacuum gauge out

of the body of the regulator, pulling it outwards,

ensuring it is moved at a right angle to the body.

SERVICE

MANUAL

11 EASYVAC VACUUM REGULATOR MS003 February 2010

Maintenance operations

Screw the block back onto the vacuum gauge,

complete with the relative sealing gaskets, for as

long as slight resistance between the two parts

can be felt. Tighten for another ¼ turn, positioning

the surfaces in alignment with the metal coupling

of the vacuum gauge.

Carefully insert the vacuum gauge unit back into the

body, aligning the vacuum gauge holder block guides

with those on the body of the EASYVAC vacuum

regulator, pushing it right in. Be careful to ensure the

sealing gasket remains inserted in the block, to avoid

damage to it and a consequent loss of vacuum.

Reposition the lid and fix it in place with the two

screws by using a TORX screwdriver of suitable

dimensions. Perform the functional checks

required and indicated in the operating manual

Mo_002 of the EASYVAC device before use.

Table of contents