fluenta FGM 160 Manual

Document number:

64.120.001

Document title:

FGM 160 Maintenance Procedure

Scope:

ISO 9001:2008 §7.2.3

Additional Information (when applicable)

C

2014.03.25

Procedure updated

KP

AP

CT

MW

MW

B

2013.01.25

Removed from User Manual, updated:

changes in text formatting

MKJ

KH

-

MW

MW

A

2008.04.15

Issued for Fluenta release; moved to

User Manual

MS

TM

AAJ

N/A

DIÅ

Rev.

index

Issue date

Reason for issue

Author

Review

Review

Review

by QA

Approved

Replacement for:

Total pages:

4

Fluenta source doc.

(for translations):

FGM 160 Maintenance Procedure

64.120.001

Page 2 of 4

TABLE OF CONTENTS

1. Purpose ............................................................................................. 3

2. Abbreviations..................................................................................... 3

3. General .............................................................................................. 3

4. Field Computer Unit ........................................................................... 3

4.1 Connectors .................................................................................. 3

4.2 Field Computer Preventive Maintenance ........................................... 3

4.2.1 Inspection for Damages ...................................................... 3

4.3 Functional Check .......................................................................... 3

5. Transducers and Ball Valves .............................................................. 4

5.1 Applicable for Transducer Full Size (TFS).......................................... 4

6. Cables ................................................................................................ 4

FGM 160 Maintenance Procedure

64.120.001

Page 3 of 4

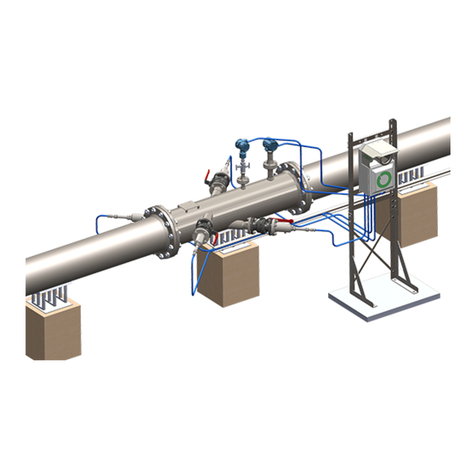

1. PURPOSE

The purpose of this procedure is to describe the necessary maintenance and

preventive maintenance for the Fluenta Flare Gas Meter, FGM 160.

2. ABBREVIATIONS

FGM Flare Gas Meter

TFS Transducer Full Size

O&SC Operator & Service Console

3. GENERAL

The FGM 160 requires only minimum maintenance. Maintenance is carried out if

an error is detected or suspected to have occurred. In addition, Fluenta strongly

recommends a periodical maintenance routine to secure the operational uptime

of the meter. The checks below are a standard procedure. To get more

information or book maintenance service, contact Fluenta Service and Support.

The instructions are given for each major component in the flare gas metering

system and the time periods between each activity are also specified.

4. FIELD COMPUTER UNIT

The following should be checked every six months:

4.1 Connectors

Check that all connectors in the EEx-e housing are properly connected and that

there is no corrosion or contamination on the terminals.

4.2 Field Computer Preventive Maintenance

The following should be carried out every twelve months:

4.2.1 Inspection for Damages

Inspect the FGM 160 housing for damages. Make sure that the EEx-e housing

drain is operating correctly and that there is no contamination on the inside.

4.3 Functional Check

Every twelve months or after shutdown, the following should be carried

out:

Check all meter functions and if there are any indications of malfunction, go

through the Factory Acceptance Test Procedure for FGM 160, Fluenta doc. no.

62.120.018. This shall only be performed after installation, preferably by Fluenta

personnel, generally in collaboration with personnel responsible for daily

operation of the system.

Note:

Subjecting the computer to voltages without a Fluenta certified

personnel present causes loss of warranty.

FGM 160 Maintenance Procedure

64.120.001

Page 4 of 4

In addition to the procedure already mentioned above, a reliable zero point check

and, if required, adjustment for the different transmitted ultrasonic signals

should be carried out. For this purpose, Fluenta service personnel use a portable,

specially designed piece of equipment.

Different signals will also be analyzed by Fluenta personnel, using the Operator &

Service Console (O&SC) program. The O&SC displays important information of

how the system operates, and how to troubleshoot potential errors, as the

signals can be interpreted, compared and optimized if necessary.

Use is recommended of experienced and qualified Fluenta personnel once a year

to run a total system functionality check as this will decrease the possibility of

system malfunction and increase the system’s reliability.

5. TRANSDUCERS AND BALL VALVES

5.1 Applicable for Transducer Full Size (TFS)

The following should be checked every six months or after shutdown:

Make sure that all nuts and bolts between the transducer holder and the

ball valve and between the ball valve and the transducer unit are properly

tightened.

All flanges must be parallel.

Check that the ball valves are open (not in contact with the transducers).

Check that the nut (on fitting) at the end of the packing box is tight.

6. CABLES

Inspect transducer cables and the FGM 160 cables for damages. Make sure that

the cables do not have any sharp bends (minimum internal radius of bend is

8 x D) and ensure that there is no contact between the cables and sharp edges

that can cause damages. Interfering equipment in the surroundings must be kept

in a safe distance from the cables and the rest of the FGM 160 equipment.

Table of contents

Other fluenta Measuring Instrument manuals