Fluid Concepts Rear Bimini User manual

Axis Rear Bimini

2015-2019 (all models)

Instruction Manual

Congratulations on your purchase of one of the premier tow boat products in the industry! This

bimini top is designed to provide you years of service and satisfaction with the proper care and instal-

lation. Please read these instructions carefully. If at any time you have a question about the bimini

or installation, please call (480) 609-1182 and ask for technical assistance.

*****Important Safety Precautions*****

Please Read

This Bimini is designed to used at tow boat speeds only. Do not trailer boat while deployed.•

Do not allow passengers to hang on or pull on rear frame extension wihile deployed.•

Ensure all bolts and hardware are tightened before each use.•

Do not use bimini if hardware is missing or broken or if the bimini shows any type of stress (cracks, broken welds, etc).•

When operating or towing boat with bimini installed, be aware of low bridges, waterways, powerlines, trees, or other low objects•

that may come into contact with bimini top.

Do not store surf boards or other objects on top of bimini.•

Failure to adhere to these safety warnings and guidelines will void warranty and may cause personal injury.•

Fluid Concepts

134 E. Broadway Rd. #101

Mesa, AZ 85210

(480) 609-1182

www.fluidconcepts.net

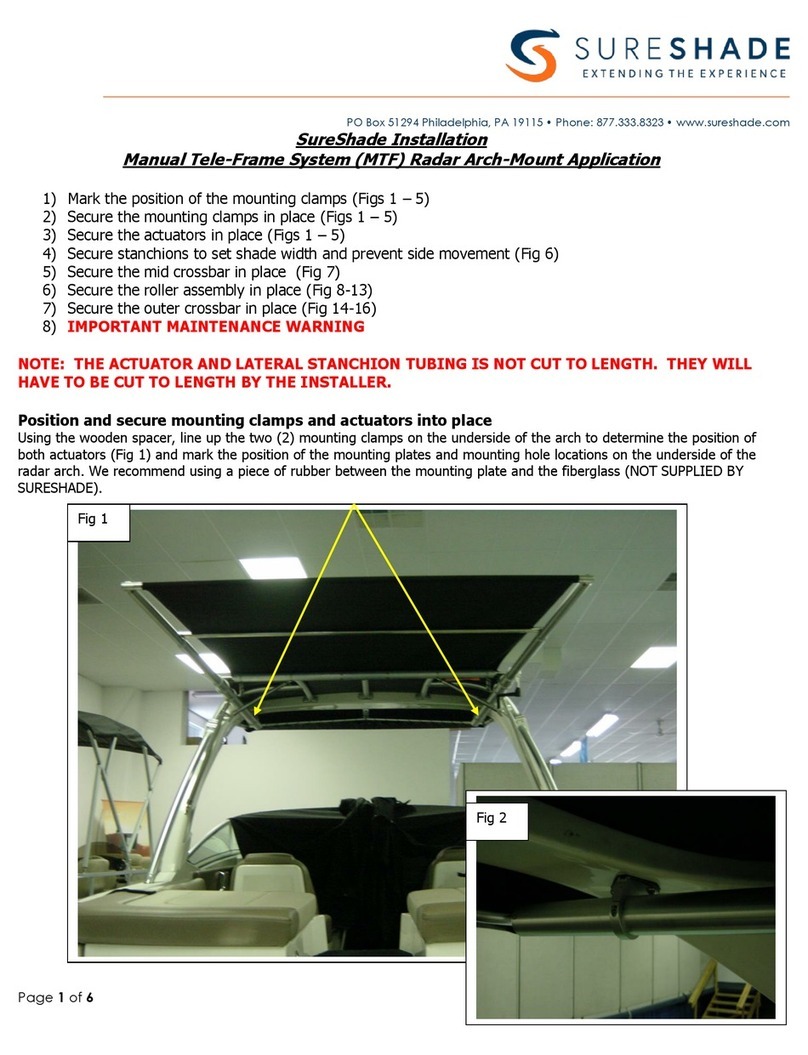

Unpack Contents:

Carefully unpack contents of boxes. Find a suitable area to lay the parts out and assemble (wood shop

table or other soft work area). Please identify parts using the list below. Now is a good time to inspect

parts for damage from shipping.

Fluid Concepts Page 2

Rear Frame

Front Frame Assembly

Canvas and Boot

Folding Arm Assembly

Hinges

Front Shorts w/Snaps

Ball End Fittings

Stanchions

Fig 1

Fig 2

Tools:

1. Hex keys x 3: 1/8” (or 3mm*), 5/32”, 1/4”

2. 9/16” wrench

2. Thread Lock (Loctite Blue) ---optional

*depending on components used in assembly

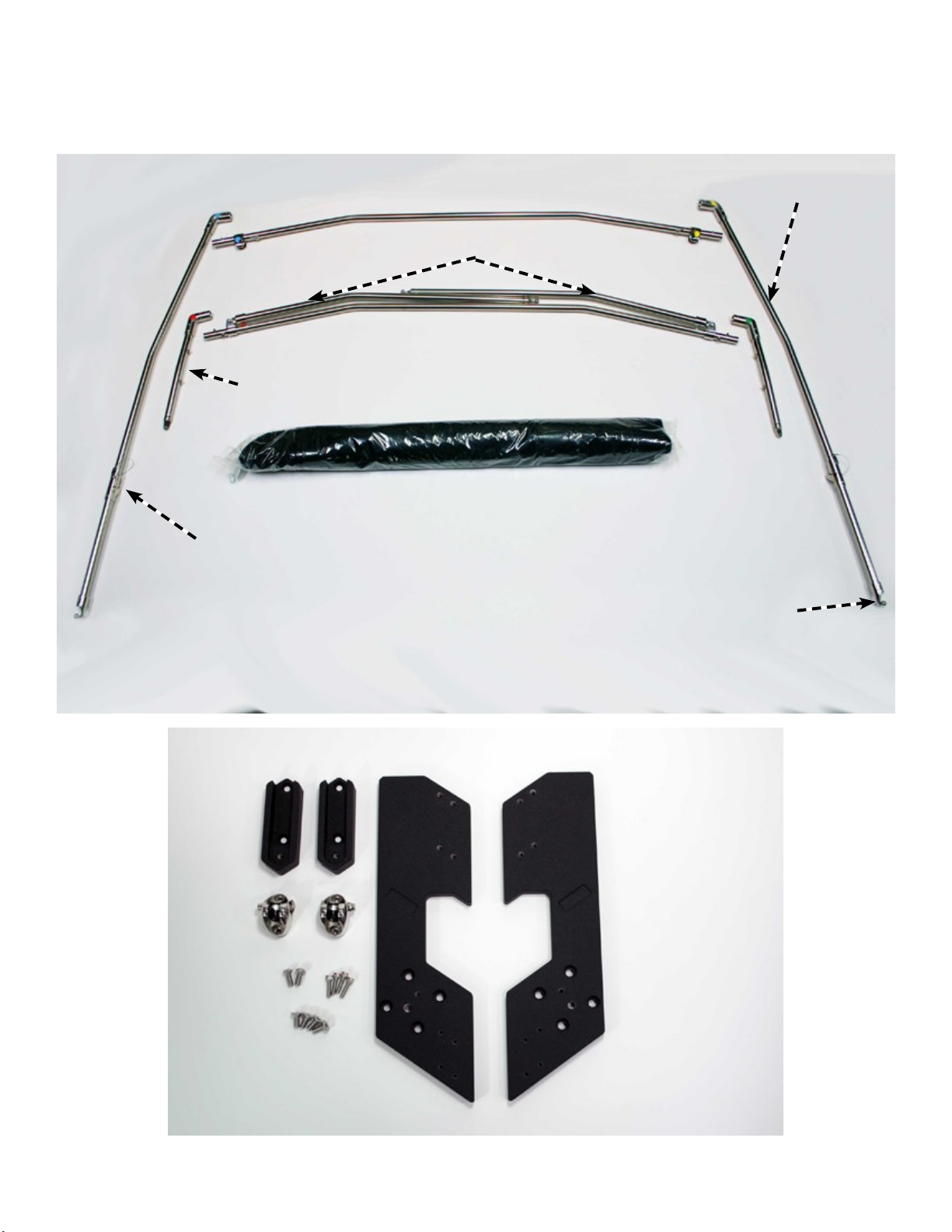

Bimini Frame Pre-Assembly:

Step 1: Identify each frame piece according to Fig-1.

CornerFittingsareidentiedbyacolors(4total)Fig-3.

Find corresponding tube piece with same color and insert

into Corner Fitting Fig-4A. Push until Snap Button clicks

into locating hole on Corner Fitting. Make sure pin is fully

engaged in hole as shown in Fig-4B. Repeat for the 3

remaining corners. Note: Colors may not be the same as

shown in picures.

Step 2: Tighten all set screws adjacent to Snap Button tube

locks. Fig-5A At this point you should have two separate

frames assembled (front frame and rear frame) as shown in

Fig-5B.

Fluid Concepts Page 3

Fig 3

Fig 4A Fig 4B

Fig 5A Fig 5B

Snap Button Snap Button

fully engaged

Set Screw

Rear Frame

Front Frame

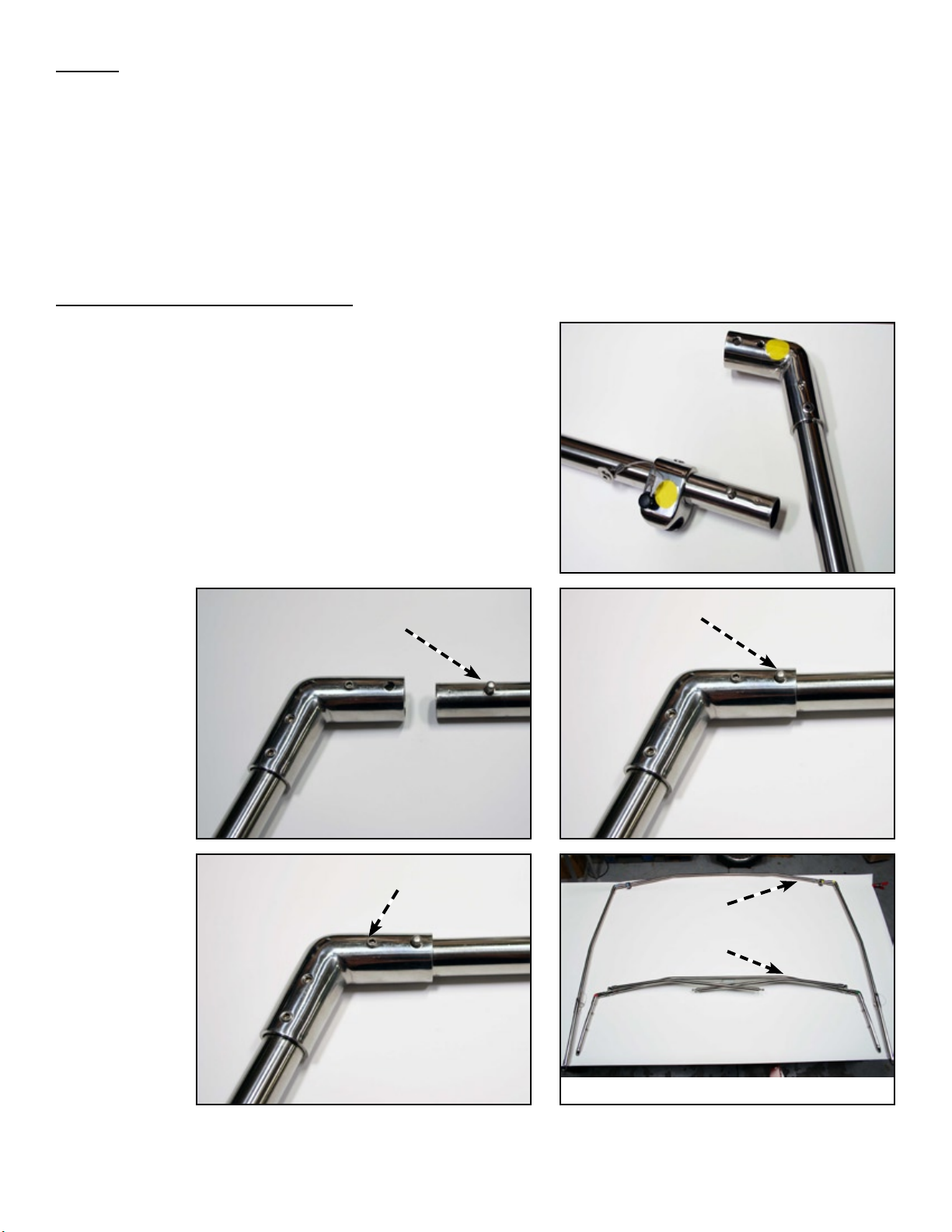

Bracket Pre-Assembly:

Step 1: Mount Tube-Stops to top of Mounting Brackets.

Position the Tube-Stops with groove opening pointing towards

top of bracket as seen in Fig-6 and Fig-7. Secure with (4)

1/4-20atheadscrews.

NOTE: Some brackets may have auxilary sets of threaded

holes located in close proximity to desired mounting holes.

Do not use these holes! Please use holes closest to

the edge of Mounting Brackets.

Step 2: Mount Quick-Release Ball End Fittings to

Mounting Brackets.Positionttingsexactlyasshown

in Fig-6 and Fig-8. Thettingsshouldmirroreachother

withthetwistpinslocatedontheupperhalfofthetting.

Use mounting holes located closest to the edge of the part.

Secure with the 10-24 x 3/4” socket head cap screws. Do not

overtighten! D-Ring on each part should be located toward

edge of part. Fig-8

NOTE:Thequick-releasettingsaremirroredparts.There

is a left and right. There is also a top and bottom. The larger

opening (and D-Ring Twist Pin) are located toward the top of

thetting.Thisallowsthebiminiballendtoslidedownward

to lock into place. Fluid Concepts Page 4

Fig 4

Fig 8

NOTICE:

Pay special attention to position

of each component in relation

to brackets and mounting holes.

Brackets and components mirror

each other.

10-24 x 3/4” (x 4)

1/4-20 x 5/8” (x 4)

Fig 6

Mounting Bracket

Starboard/left

Mounting Bracket

Port/right

Tube-Stop

Quick-Release Ball End

Fitting

Fig 7

Tube-Stop

Groove Opening

Quick-Release

D-Ring Twist Pin

Installing Brackets and Bimini Frame to Tower:

Step 1: Determine Mounting Bolt Kit. Depending on the

board rack options on your boat, you will need one of the 3

available bolt kits:

Step 2:Inourexamplewehavexedracks,sowe’llbe

usingthexedrackmountingkit.We’llalsobeusingablack

mounting bracket on a white tower for picture contrast.

Fig-9 Remove both boardracks and replace existing mounting

hardware with new hardware supplied with your bimini kit.

Set brackets on tower using new hardware, then carefully

slide rack spacer over the screws. Fig-10 Next, carefully hold

rack into position while tightening screws. Fig-11

HINT: it may be easier to do two screws rst, then

come back and insert remaining screws. Depending on

agility, have a second person hold boardrack in place

while the other tightens screws. Notice pin on back of

mounting bracket sits in corner of machined window of tower.

Fig-12 Once everything is in place, tighten all screws using

1/4” hex key/wrench.

Fluid Concepts Page 5

Swivel Rack Mounting Kit

OBSOLETE (standard kit)

Fixed Rack Mounting Kit

Standard Mount Kit

Standard Mounting Kit:

Use when mounting bimini brackets to tower with

no boardracks.

***Replaces obselete kit as seen below***

PART: AXS-EB-STD

Description: (8) 5/16-18 x 1-3/8” SHCS SS, (8)

5/16 SS Washers, (8) 5/16-18 Acorn Nuts

Fixed Rack Mounting Kit:

Use when mounting bimini brackets to tower and

OEM fixed boardracks are mounted in top position.

This kit replaces stock screws.

PART: AXS-EB-FMK

Description: (8) 5/16-18 x 1-3/4” SHCS SS

Swivel Rack Mounting Kit:

Use when attaching bimini brackets to tower and

OEM Swivel boardracks are mounted in top posi-

tion. This kit replaces stock screws.

NOTE: The use of the swivel rack feature will be lost when

bimini is deployed. We suggest moving swivel racks into the

lower position to maintain full functionality.

PART: AXS-EB-SMK

Description: (8) 5/16-18 x 3-1/4” SHCS SS

OBSOLETE Standard Mounting Kit:

Please call (480) 609-1182 for free upgrade to the

updated kit above. New part: AXS-EB-STD

Fig 9

Fig 10

Fig 11

Fig 12

Step 3: Install Front Frame Assembly. Set frame ends

into grooves of the tube-stops. Fig-13 Make sure Stanchions

and Stanchion Hinges are facing towards the rear of the

boat.Theframemayneedtobeexedslightlytogetinto

the grooves. This is normal. Aligned Eye Ends with mounting

threaded hole and use supplied 1/4” button-head socket

screw to fasten. Fig-14A Tighten both fasteners. The front

frame should look like Fig-14B

Step 4: Install Rear Frame Assembly: Make sure Quick-

Release Ball End Fittings are ready to accept frame Ball Ends.

Turn the D-Ring Twist Pin until groove is open. Fig-13 With

Bimini Hinge Pins pointing upward on Rear Frame, insert one

endofRearFrameballttingintotheQuick-Releasetting

and slide downward to set in place. Do the same for the

opposite side. Lock in place by turning D-Ring Twist Pin until

groove is closed. Fig-16 The rear bimini frame should look

like this. Fig-17

Fluid Concepts Page 6

Fig 13

Fig 14A Fig 14B

Fig 16

Fig 15

Fig 17

D-Ring Groove

Open

D-Ring Groove-

Closed

Installing Bimini Canvas on Frame:

Step 1: Locate Underside of Canvas. To locate underside

ofcanvas,layonatsurfaceandlocatesidewithcorner

pockets visible (stainless snaps will also be facing in same

direction). Fig-18

Step 2: Wrap canvas corner around Front Frame Corners as

shown in picture. Snap canvas to frame using the 3 snaps.

Repeat for opposite side. Underside of Canvas should be

facingoorofboat.MakesuretheStancionsarepointed

towards the center of the boat. Canvas can then drape over

the frame at this point. Fig-19

Step 3: Place zipper pocket around Front Frame and close

zipper. Fig-20

Step 4: Lift frame up and position corners of Canvas over

the rear corners of the Bimini Frame. The frame should be

hanging in air at this point, with the Stanchions still pointing

towards the center/rear of the boat. Fig-21

Step 5: Again, using rear zipper pocket, secure canvas

around rear frame and zip. See instructions below to setup

bimini for use. Fig-22

Fluid Concepts Page 7

Fig 18

Fig 19

Fig 20

Fig 22Fig 21

Instructions for Use:

Stowing Bimini:

NOTE: At this point your bimini should be loosely hanging

fromrearoftower.Inthenextsteps,we’llshowyouhowto

stow bimini, then deploy.

Step 1: Stow bimini. Fold Stanchions toward center of

boat, then secure to underside of Front Frame using velcro

strap. Fig-23

Step 2: Pull Pins out of Hinges on Rear Frame to allow the

frame to collapse. Fig-24 HINT: Occaisonally there may

be tension on the bimini frame which makes the pins

dicult to pull out. If so, try slightly pulling the bimini

frame upwards and towards the center of the boat (at

the hinge) while pulling pins. This should alleviate and

tension in hinge pins. Allow frame to fold, then manuever

Rear Frame to sit just behind the Front Frame. Place loose

canvas over the top and wrap around both frames. Fig-25

Step 3: Using frame clips, clip folded frame together. Fig-

26 The canvas and the frame clips should hold the frame in

place long enough to get the Bimini Boot over the canvas.

HINT: Depending on boat and speaker package, it may

be easier to use a small strap or have someone help

hold frame for next step.

Step 4: Install Bimini Boot. Pull boot over top of frame

and canvas. Zip to secure. Fig-27 The bimini should be

secure and stowed at this point.

NOTE: While towing boat when bimini is in the stow position,

it is a good idea to push dangling hinge pins into hole. Be

sure to remember to remove them before deploying bimini!

Fig 23

Fig 24

Fig 25

Fig 26 Fig 27

Fluid Concepts Page 8

White Nylon Frame

Clips

Deploying Bimini:

Step 1: Remove Bimini Boot and remove Bimini Frame Clips.

Allow frame to rest below tower. Fig-28

Step 2: Straighten rear frame. Install Hinge Pins. Make

sure Hinge Pins are fully inserted. Fig-29

Step 3: Bimini frame should be loosely hanging from rear

of tower (same position as the last step on page 7). Check

bimini canvas and make sure it is in postion before moving on

to next step. The pockets should be around the rear frame,

with the canvas in a loose setup postion. Fig-30

Step 4: Remove Stanchions from velcro strap. Swing one

Stanchion towards rear of boat and secure into the Ball End

Fitting on Rear Frame. Secure with Pin. Fig-31 Repeat for

other side. HINT: sometimes the bimini canvas may

be tight and prevent the stanchion end from sliding

into position on the rear ttings. It may help to pull

down on the frame to pre-tension the canvas so the

stanchions can be locked into place.

Step 5: Tighten the side skirts by wrapping strap around

frame and snapping. Fig-32 That’sit.Checkbiminitoproper

tandmakesureframefeelssecure.Centerzipperpocket

is for easier access to tow rope spool in center of tower.

Reverse Process to Stow.

Do not hang from bimini frame. This will

cause premature wear and may damage

canvas or frame.

Fig 28

Fig 29

Fig 30

Fig 32

Fluid Concepts Page 9

Fig 31

Care and Maintenance

Periodic maintenance: Wipe down surfaces with damp cloth. Soap and water may used to clean.

Avoid harsh chemicals as they will damage the painted/polished surfaces. Canvas may be washed with

water and vacuumed.

5 Year Limited Warranty

Weoera5YearWarrantyonourproductsalongwitha30daymoney-backguarantee.Ifyouarenotsatisedwithourproducts

in any way, return the item and we will refund your money!

Warranty Information

Fluid Concepts L.L.C. (Fluid) warrants to the original purchaser that this product will be free from defects in material and

workmanshipundernormaluseforaperiodofve(5)yearsfromdateoforiginalpurchasefromanauthorizedFluiddealer.See

exclusionsforspecicitemsnotcoveredorwithlimitedwarranty.Shouldrepairbenecessaryunderthiswarrantyforanyreason

due to a manufacturing defect or malfunction during the warranty period, Fluid will repair or replace (at its discretion) the defective

product with equivalent product at no charge. Discontinued products may be replaced with equivalent products. Any applicable

implied warranties are limited in duration to a period of the express warranty as provided herein beginning with the date of the

original purchase at retail, and no warranties, whether express or implied, shall apply to this product thereafter. This warranty is

limited to defects in material and workmanship, and it does not apply to loss of damage due to accident, misuse or negligence, or

any cause occurring after delivery to the original purchaser.

Warranty Claims

Defective merchandise must be returned to your local authorized Fluid Dealer for warranty issues. To locate an Authorized Dealer

please email or call Fluid Concepts direct. If the return of defective merchandise is necessary, call Fluid at (800) 284-6615 to

obtain a Return Authorization (RA) number. Package all defective items in the original container or in a suitable package that will

prevent shipping damage, and return to:

Fluid Concepts

134 E. Broadway Rd. #101

Mesa, AZ 85210

Include a dated proof-of-purchase from an Authorized Dealer. Warranty expiration on items returned without proof-of-purchase

will be determined from the manufacturing date code. Freight must be prepaid; items received freight collect will be refused.

Failure to follow these steps may void your warranty. Non-defective items received will be returned freight collect. Any warranty

questions can be directed to the Fluid Concepts at (480) 609-1182.

Warranty Exclusions:

The following items have a limited warranty:

1.Rubber components (1 year)

2.Stretch cord (1 year)

3.Chromenish(1year)

4.Anodizednish(3years)

5.Powdercoatednish(2years)

This warranty is valid only if the product is used for the purpose for which it was designed.

Fluid Warranty does not cover:

•Damageresultingfromnegligence,misuse,oraccident

•Itemsphysicallydamagedduetoabuse

•Freightdamageormishandling

•Itemspreviouslyrepairedbyanyunauthorizedrepairfacility

•Speakerswithsiliconcaulkingortapeusedforgasket/sealingmaterial

•Itemsreturnedbyunauthorizedindividualsordealers

•Returnshippingofnon-defectiveitems

•Speakersdamagedduetoamplierclippingordistortionorincorrectsignals

•ThecostofshippingproducttoFluidConcepts

•Installationslipsincludingscrewdriverholesinspeakersurroundsandscratchedsurfaces

•Normalwear-and-tearfromuse,storage,andtransportation

•Damagecausedbyexposuretowaterand/orexcessiveheat

•Itemsdamagedfromcross-threadingfastenersorimproperinstallationtoolsandtechniques.

•Damageresultingfromitemscomingintocontactwithobjectssuchasbridges,otherboats,etc.

Fluid Concepts Page 10

Table of contents

Popular Boating Equipment manuals by other brands

Old Town

Old Town Saranac Seat Kit instructions

SLEIPNER MOTOR AS

SLEIPNER MOTOR AS Side-Power Series installation manual

MAX PROP

MAX PROP Easy installation instructions

Vetus

Vetus BOW1254DE Operation manual and installation instructions

MINN KOTA

MINN KOTA RIPTIDE ST user manual

SPORT MARINE TECHNOLOGIES

SPORT MARINE TECHNOLOGIES SE Sport 400 manual

Classic Accessories

Classic Accessories Silver Max 87504 instructions

Quick

Quick GP Series Installation and user manual

Classic Accessories

Classic Accessories StormPro Instructions & Care

Nucraft

Nucraft CraftLander MH-V25108 Assembly & instruction manual

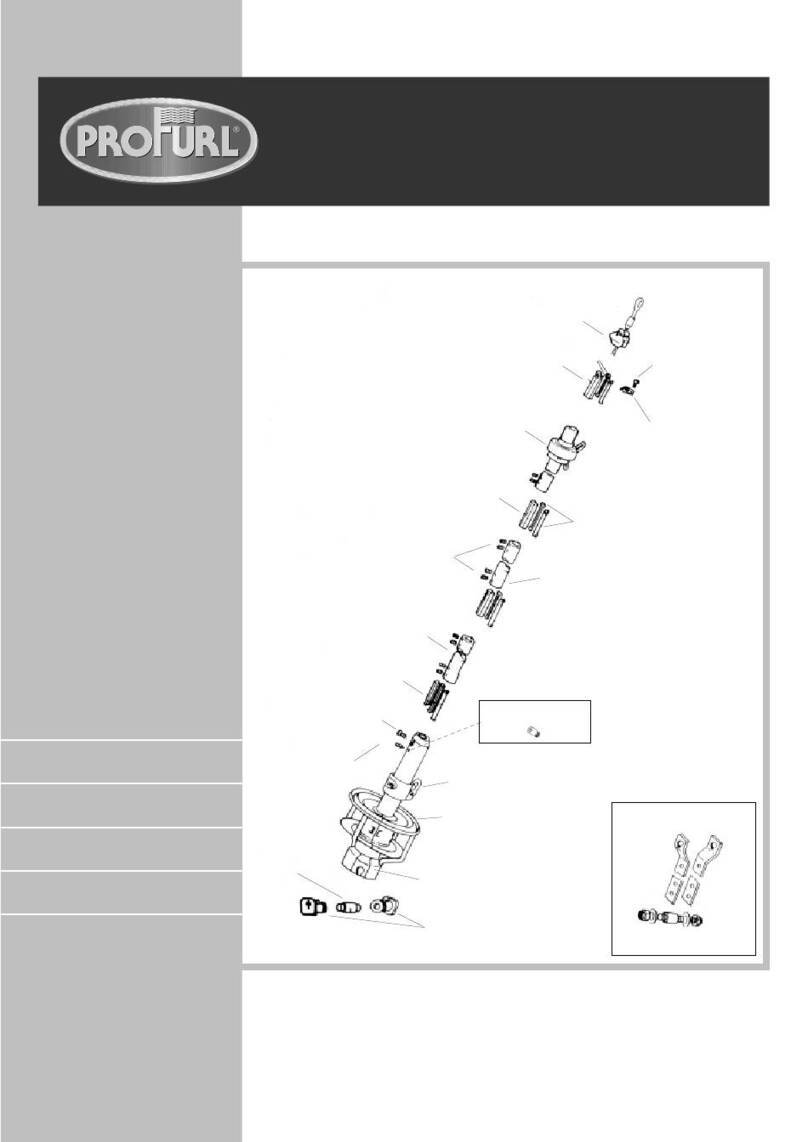

ProFurl

ProFurl B29S installation manual

Uflex

Uflex ULTRAFLEX T71FC Installation and maintenance manual