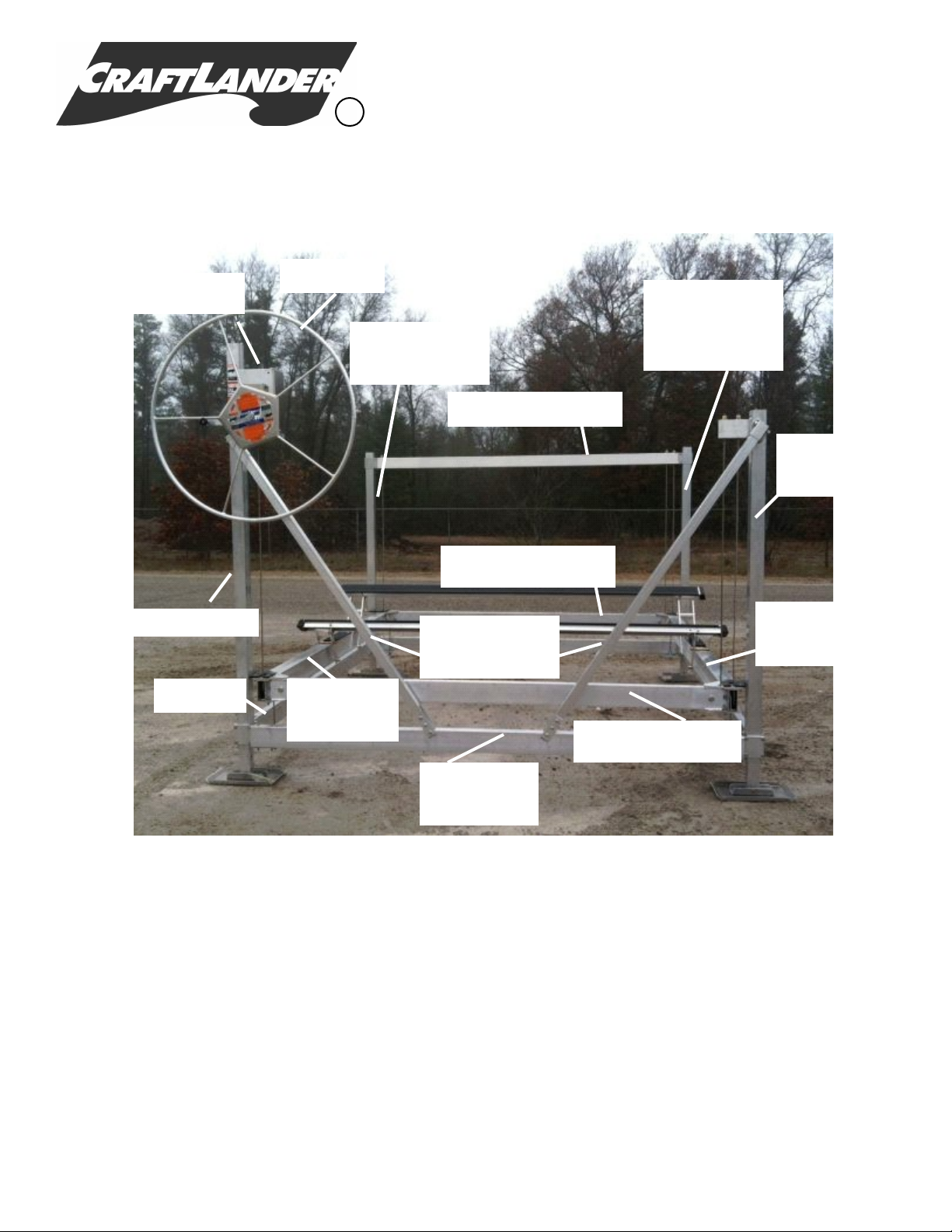

(16) The Cradle Tube Left and Right will have one

cable coming out of it. Each end will have a welded

connection plate. The larger plate will be on top of the

tube. Place the Cradle Tubes so the angle portion of the

connection plate is facing the inside of the hoist. Match

the top larger hole with the holes on the twin beam on

all four corners.

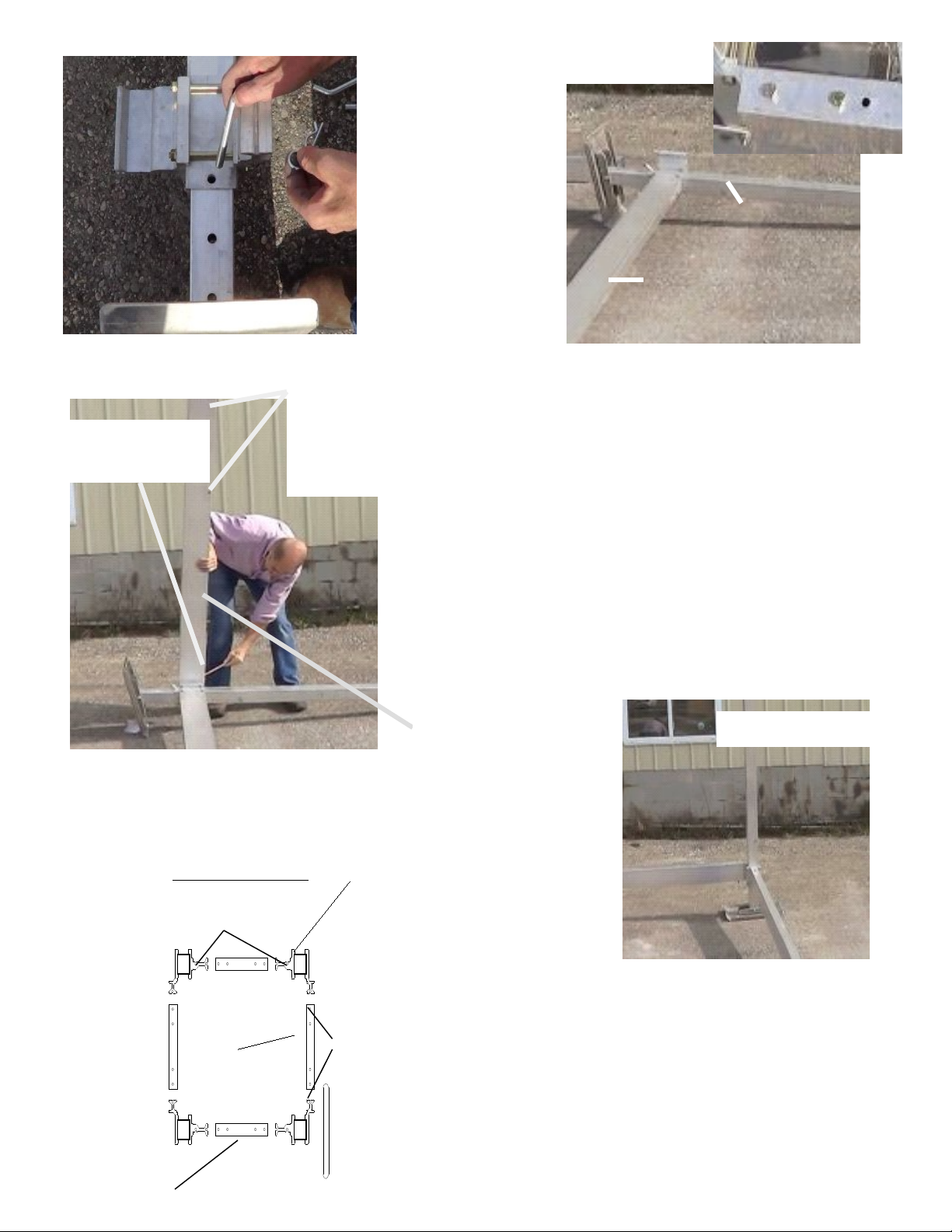

(17) Next, starting with the Non-Winch front corner you will

need to pull the cable coming from the Twin Beams through the

corresponding hole in the Right Cradle Tube. The cable with a

long threaded end coming out of the front Twin Beam will be

pulled through to attach to the Upper Cable Tube. The cable

coming out of the Cradle Tube Right with the short threaded

end will go down to the /4” galvanized plate

fastened to the lower frame.

View of

on-

Winch

Column

front

corner.

Pull up

Cradle Tube

Left

Cradle Tube

Right

Rear

Front

(15) The front Twin Beam will be

the one with one cable coming out

of it. This will be placed in the

front of the hoist. The end of the

beam that has the cable without a

fitting will go on the Winch

corner. The rear Twin Beam will

have two cables coming out of it

and this will be placed at the rear

of the hoist.

Front

Rear

Two Cables

Twin Beam:

4”x4 3/8”x 3 /4” long on V25 08

4”x5 /2”x 3 /4” long on V35 08 or V45 08

4”x5 /2”x 9 /4” long on V45 4

4”x5 /2”x 25 /4” long on V35 20 or V45 20

(16) The Cradle Tube Left and Right will have one

cable coming out of it. Each end will have a welded

connection plate. The larger plate will be on top of the

tube. Place the Cradle Tubes so the angle portion of the

connection plate is facing the inside of the hoist. Match

the top larger hole with the holes on the twin beam on

all four corners.

Cradle Tube (both sides):

3/4”x4”x 00” long on V25

2”x5”x 2” long on V35 & V45

(17) Next, starting with the Non-Winch front corner you will

need to pull the cable coming from the Twin Beams through the

corresponding hole in the Right Cradle Tube. The cable with a

long threaded end coming out of the front Twin Beam will be

pulled through to attach to the Upper Cable Tube. The cable

coming out of the Cradle Tube Right with the short threaded

end will go down to the /4” galvanized plate

fastened to the lower frame.

View of

on-

Winch

Column

front

corner.

Pull up

(18) Continue on to the

Winch corner. The Cable

coming out of the end of

the front Twin Beam will

not have a threaded end.

This end will be connected

to the Winch Box in a later

step. The cable coming out

of the Left Cradle Tube

will go down to be attached

to the lower frame.

Cradle Tube

Left

Cradle Tube

Right

Rear

Front

(15) The front Twin Beam will be

the one with one cable coming out

of it. This will be placed in the

front of the hoist. The end of the

beam that has the cable without a

fitting will go on the Winch

corner. The rear Twin Beam will

have two cables coming out of it

and this will be placed at the rear

of the hoist.

Twin Beam:

4”x4 3/8”x 3 /4” long on V25 08

4”x5 /2”x 3 /4” long on V35 08 or V45 08

4”x5 /2”x 9 /4” long on V45 4

4”x5 /2”x 25 /4” long on V35 20 or V45 20

Note that the beams should

be placed with the holes on

the bottom facing the inside

of the hoist as shown above.

Page#7