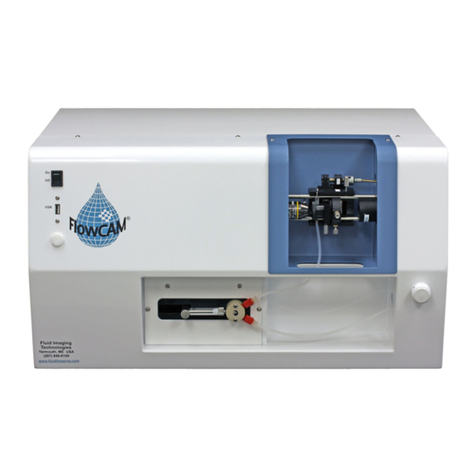

Fluid Imaging Technologies FlowCam 8000 series User manual

FlowCam®8000 Series

Dynamic Imaging Particle Analyzer

User Guide

FlowCam® 8000 Series Dynamic Imaging Particle Analyzer

2 of 39

Proprietary Rights Notice

Information in this document is subject to change without notice. No part of this document may be reproduced or

transmitted in any form or by any means, electronic, mechanical or otherwise, for any purpose, without the

express written permission of Fluid Imaging Technologies. Fluid Imaging Technologies may have patents or pending

patent applications, trademarks, copyrights or other intellectual or industrial property rights covering this

document or subject matter in this document. The furnishing of this document does not give a license to these

property rights except as expressly provided in any written license agreement from Fluid Imaging Technologies.

© 2017 Fluid Imaging Technologies, Inc. All rights reserved. 11072017

FlowCam and VisualSpreadsheet are registered trademarks of Fluid Imaging Technologies, Inc. All other product

and company names and logos are trademarks of their respective holders.

Fluid Imaging Technologies

200 Enterprise Drive

Scarborough, Maine 04074 USA

fluidimaging.com

FlowCam® 8000 Series Dynamic Imaging Particle Analyzer

3 of 39

Contents

Warnings............................................................................................................................... 4

Laser Precautions .............................................................................................................................................4

Cautions............................................................................................................................................................4

Safety Precautions ............................................................................................................................................4

Introduction .......................................................................................................................... 6

Technical Specifications....................................................................................................................................7

Physical Specifications ......................................................................................................................................7

Analyzer Components ......................................................................................................................................8

Overview...........................................................................................................................................................9

Objectives .......................................................................................................................................................10

Fluorescence Detection System (FlowCam 8400) ..........................................................................................10

Welcome............................................................................................................................. 11

Package Contents ...........................................................................................................................................11

Choosing a Location........................................................................................................................................11

Computer Peripherals.....................................................................................................................................11

Setting Up the Analyzer ....................................................................................................... 12

Connecting Peripherals...................................................................................................................................12

Powering on Your Analyzer ............................................................................................................................12

Preparing the Analyzer ........................................................................................................ 13

Checking Internal Connections.......................................................................................................................13

Adding Solutions.............................................................................................................................................13

Installing the Flow Cell....................................................................................................................................14

Installing the Objective Lens...........................................................................................................................15

Autofocusing the Flow Cell .............................................................................................................................17

Focusing the Flow Cell Manually ....................................................................................................................19

Defining the Context Settings.........................................................................................................................22

Performing a Sample Analysis.............................................................................................. 27

Cleaning and Rinsing the Analyzer ....................................................................................... 28

Care and Maintenance......................................................................................................... 30

Appendix A: Changing the Pump Syringe.............................................................................. 31

Appendix B: Frequently Asked Questions............................................................................. 34

Appendix C: Services ........................................................................................................... 35

Standard Factory Limited Warranty ..................................................................................... 37

Fluid Imaging Technologies FOV (Field-of-View) Flow Cell Limited Warranty ...............................................38

Customer Support ............................................................................................................... 38

Declaration of Conformity ................................................................................................... 39

FlowCam® 8000 Series Dynamic Imaging Particle Analyzer

4 of 39

Warnings

Before operating your FlowCam 8100 or 8400 analyzer, read this guide carefully to prevent damage to

humans, animals, integrated devices, and connected devices. Always follow local safety rules. The

instrument should be verified for safe operation following normal use, maintenance, and any factory

service activities. Failure to use this instrument in the manner specified in this guide may impair safety

features and nullify operator protection.

Laser Precautions

•The FlowCam 8400 analyzer contains an

embedded Class 3 laser within its housing. Under

normal operating conditions, the housing and

other protective features prevent the emission of

laser light outside the analyzer. To avoid the

possibility of any laser light exposure, ensure that

you follow all operating instructions and that the

analyzer’s doors and housings remain closed

while it is operating.

•Operating the FlowCam 8400 analyzer with

protective housing or doors that are damaged or

otherwise not in good operating condition may

expose the user and others to laser radiation. If

laser light is observed or detected, discontinue

use of the product immediately and contact Fluid

Imaging Technologies.

Cautions

To reduce the risk of electric shock, do not remove any protective covers.

During operation of the FlowCam analyzer, the syringe pump/barrel can move

unexpectedly and without warning. Keep all body parts clear of this area.

Safety Precautions

•To reduce the risk of serious personal injury or equipment damage, never remove the inner

panels of the FlowCam analyzer.

•Beware of electrical shock hazards. To prevent the risk of electrical shock or fire, do not locate

the instrument in wet or unsafe laboratory conditions. Do not touch any damaged, non-isolated

electrical parts.

FlowCam® 8000 Series Dynamic Imaging Particle Analyzer

5 of 39

•Use appropriate precautions to minimize and prevent the introduction of liquid into the

instrument and contact with any electrical assemblies. The instrument operates on a detachable

power supply that allows for immediate disconnect from power in the event of an emergency.

Use only the power cords provided by the manufacturer to operate the instrument and

peripheral devices.

•Mishandling may harm this instrument. Before lifting or moving the instrument, ensure that all

cords and external equipment have been properly disconnected. When moving the instrument,

always carry it with both hands. Grasp the front corner with one hand and place the other hand

under the opposite side back corner for support. Always use proper lifting techniques.

•Install the instrument in such a way as to ensure that all power cords and ventilation openings

are easily accessible and clear from obstruction with a minimum distance requirement of 10 cm.

Do not operate or store this instrument outside of the following ranges:

oOperation: 4–40° C, humidity 0-90% (noncondensing)

oStorage: -20–60° C, humidity 0-95% (noncondensing)

oMaximum operating altitude: 2000 meters

•Do not attempt any repairs yourself. Doing so will void your Standard Factory Limited Warranty.

If your FlowCam analyzer requires service, contact Fluid Imaging Technologies for additional

instructions.

FlowCam® 8000 Series Dynamic Imaging Particle Analyzer

6 of 39

Introduction

The FlowCam 8000 Series Dynamic Imaging Particle Analyzer combines selective capabilities of flow

cytometry, microscopy, and fluorescence detection to rapidly evaluate particulate matter in a moving

fluid. The FlowCam analyzer’s high-speed digital camera automatically counts, images, and characterizes

the particles or cells in a sample.

The FlowCam analyzer uses dynamic imaging particle analysis to perform these key functions:

•Examine a fluid under an objective lens backlit with a flashing LED light

•With a laser, excite particles through a laser light and detect fluorescence using two different

filters

•Capture images of the magnified particles within that fluid

•Characterize the particles using a variety of measurements

Dynamic imaging particle

analysis uses digital images to

measure the size and shape of

each particle. The sample

containing the particles streams

through the optics of the flow

cell, and the camera captures

thousands of particle images

per second.

FlowCam® 8000 Series Dynamic Imaging Particle Analyzer

7 of 39

Technical Specifications

Optics Options

8100

8400

4X Flow Cell

•Fused quartz

•FOV300, 300 µm depth x 1500 µm width

•

FOV600, 600 µm depth x 1750 µm width

10X Flow Cell

•Fused quartz

•FOV80

•

80 µm depth x 700 µm width

20X Flow Cell

•Fused quartz

•FOV50

•50 µm depth x 350 µm width

Frame Rate

Up to 100 frames per second

Image Output

8-bit grayscale TIFF and 24-bit color TIFF

Objectives

4X, 10X, 20X

Lasers

NA

Excitation wavelengths:

Blue: 488 nm, 40 mW laser output

Green: 532 nm, 40 mW laser output

Red: 633 nm, 40 mW laser output

Laser Detector Bands (PMT Filters)

NA

Emission wavelengths:

Blue: Ch1 650 LP; Ch2 575/30

Green: Ch1 650 LP; Ch2 525/30

Red: Ch1 700/10; Ch2 650/10

Fluorescence Detectors

NA

Two photomultiplier tubes (PMTs) in

standard configuration

Fluidics

4X Minimum/Maximum Particle Size

25 µm–300 µm

10X Minimum/Maximum Particle Size

4 µm–100 µm

20X Minimum/Maximum Particle Size

2 µm–50 µm

Minimum Sample Flow Rate

0.01 mL/min

Maximum Sample Flow Rate

20 mL/min

Physical Specifications

Height: 15 in

Width: 14.125 in

Depth: 17.17 in

FlowCam® 8000 Series Dynamic Imaging Particle Analyzer

8 of 39

Analyzer Components

Fluid

position

sensor

Flow cell

retainer

thumbscrews

Syringe

valve

Syringe

pump

manifold

Upper hatch

with safety

interlock

Tubing

manifold

Sample

inlet port

Lower door

and bins for

fluidics

bottles

Flow cell

and

retainer

Objective

shroud

FlowCam® 8000 Series Dynamic Imaging Particle Analyzer

9 of 39

Overview

The FlowCam 8100 and 8400 analyzers use dynamic imaging particle analysis to perform microscopic

particle measurements rapidly enough to produce statistically significant amounts of particle data. The

FlowCam analyzers gather numerous measurements for each particle, providing the detailed data

needed for a thorough particle analysis.

This diagram represents the general components of the FlowCam system. Your analyzer may not have all of the features shown.

•An ultra-high-precision syringe pump aspirates the fluid sample through the flow cell, which

positions the particles within the optical system.

•A high-intensity LED light source combines synchronously with a very short shutter speed in the

camera to freeze the moving particles in a fluid medium.

•The high-resolution camera, coupled with optical magnification from the objective lens,

captures thousands of particle images per second. Optional electronics capture two channels of

fluorescence data per camera frame.

•As the camera captures each frame, the VisualSpreadsheet software extracts the particle images

from the background in real time and stores them for analysis.

•The software then subjects each image to a series of more than 30 mathematical measurements

to characterize that particular particle.

FlowCam® 8000 Series Dynamic Imaging Particle Analyzer

10 of 39

Objectives

Objective lenses with varying magnification are used depending upon the application. As all optical

systems have a specific focal depth of field (DOF), it is important to select an appropriate objective/flow

cell combination to optimize image collection.

Fluorescence Detection System (FlowCam 8400)

The FlowCam 8400 analyzer offers a fluorescence system to excite and detect particles that process the

property of fluorescence. The fluorescent system consists of a laser, focusing optics, and one or more

photomultiplier tubes (PMT) detectors. In front of each PMT detector is a filter that prevents the

analyzer from measuring unwanted wavelengths. The wavelength and power of the laser is application-

specific and can be configured for a wide range of particle types.

The laser beam focuses on the center of the flow cell and when a particle with fluorescent properties

passes through the beam, the PMTs detect the fluorescent emission of light and trigger the optical

system to capture an image of the entire frame. The laser excites the particle to create a trigger event.

Relative fluorescent emission values are recorded for all particles.

In addition to minimum thresholds, the VisualSpreadsheet program offers upper thresholds that allow

you to reject overly bright or physically large particles. You can configure the program to trigger using

channel 1, channel 2 or both. You can also set the minimum and maximum threshold values of particle

intensity that you want each channel to capture.

These graphs display relative fluorescence compared to diameter (ESD) for channel 1 (left) and channel

2 (right). The main population appears in green and the subpopulation in red. The graph axes autoscale

based upon the data values.

Objective

4X

10X

20X

Flow Cell

300FOV, 600FOV

80FOV

50FOV

Minimum Particle Size to

Obtain Morphological Data

12 µm 4 µm 2 µm

FlowCam® 8000 Series Dynamic Imaging Particle Analyzer

11 of 39

Welcome

This guide explains how to set up, operate and maintain your FlowCam® 8000 Series Dynamic Imaging

Particle Analyzer. It also covers basic features of the VisualSpreadsheet® software application that will

assist you with the initial setup and operation of the analyzer.

Package Contents

Your shipping container includes the following items:

•FlowCam analyzer with power cord

•Monitor with power cord and connectors

•Wireless desktop (keyboard and mouse)

•Accessory case with flow cells, syringe assembly and objectives

•Autofocus beads

•Pipette tips

•Nitex mesh

•Cleaning kit

•Tubing

•Connectors (dependent upon system configuration)

•Funnel (dependent upon system configuration)

Ensure that there is no damage to the packing materials or equipment inside. If anything has been

damaged or is missing, contact Fluid Imaging Technologies or your local distribution representative

immediately. Be sure to save the white shipping container that your FlowCam analyzer came in.

Note: Use two people when lifting the analyzer. Depending upon its configuration, it could weigh in

excess of 50 pounds.

Choosing a Location

•Locate your FlowCam analyzer in a well-ventilated area that is free of vibration and dramatic

shifts in temperature.

•Place the analyzer on a clean, level, sturdy base capable of holding up to 100 pounds. Be sure to

allow space for the monitor, keyboard and mouse.

•For power, you will need two outlets, one for the analyzer and one for the monitor. We

recommend using a stable power supply with surge protection and battery backup.

Computer Peripherals

Unpack the monitor, keyboard, mouse, and their accompanying cables and power cord. These

peripheral components connect to the back of the FlowCam analyzer, which contains the

VisualSpreadsheet software program. Place the monitor, keyboard and mouse next to the FlowCam

analyzer close enough to connect them.

FlowCam® 8000 Series Dynamic Imaging Particle Analyzer

12 of 39

Setting Up the Analyzer

Connecting Peripherals

Connection ports are on the back of the FlowCam analyzer.

1. Connect the keyboard and mouse USB cables to two of the USB ports on the back on the

analyzer.

2. Connect the monitor cable to the monitor’s VGA, DVI or HDMI port (depending upon your

monitor model) and the other end to the corresponding port on the back of the analyzer.

3. Connect the monitor’s power cord to the AC input port on the monitor and plug the other end

into a power outlet.

4. Turn on the monitor’s power switch.

Powering on Your Analyzer

1. Connect the analyzer’s power cord to the AC input port on the back of the analyzer and plug the

other end into a power outlet. You will hear the analyzer’s internal fan turn on.

2. Press the round power button on the top right of the analyzer to initialize its internal pump and

the computer. The power button turns blue and you should see the startup process begin on the

monitor.

3. After a few moments, the Microsoft Windows operating system opens and the icon for the

VisualSpreadsheet software appears on the desktop.

Two USB3

ports

Four USB2 ports

Two RS-232

serial ports

HDM1 port

Two Ethernet

ports

DVI port

VGA port

Audio in

Audio out

Microphone in

FlowCam® 8000 Series Dynamic Imaging Particle Analyzer

13 of 39

Preparing the Analyzer

Checking Internal Connections

Open the upper hatch and lower door on the analyzer and inspect all of the tubing connections to

ensure they are in place and secure.

•Check the inlets from the rinse and cleaner bottles into the system.

•Check the waste tubing connection from the pump to the waste container.

•Check the connection tube from the internal portion of the system to the top of the flow cell

apparatus.

Adding Solutions

The FlowCam analyzer contains three fluid bottles—one each for cleaner, rinse and waste solutions. The

cleaner bottle should be filled with a cleaning solvent to remove remaining particles in the system. The

rinse bottle should be filled with the final solution that will flush the system before you introduce more

sample (e.g., deionized or distilled water, or buffer).

1. The three fluid bottles are located inside the lower door at the front of the analyzer.

2. Fill the cleaner and rinse bottles with the corresponding cleaning and rinse solutions you want

to use with your first sample.

3. Ensure that the caps and tubing are secure.

Cleaner

Waste

Rinse

FlowCam® 8000 Series Dynamic Imaging Particle Analyzer

14 of 39

Installing the Flow Cell

The flow cell is a high-precision optical component. Great care is taken during its manufacture to ensure

conformance to exacting tolerances. The polished optical faces undergo dozens of inspections to ensure

uniformity, from the certification of raw materials to the matching of the finished cells.

•The flow cell is fragile. Handle it carefully to ensure you do not damage it.

•Do not touch the faces of the flow cell with your fingers. Wear gloves when handling it.

•

Use only labgrade water and low-lint lens paper to clean the exterior of the flow cell.

•Remove the flow cell from

its protective case and

inspect it for any damage.

•Clean the outside of the

flow cell with a piece of lens

paper to remove any

particles or fingerprints.

•The front face of the flow

cell has a serial number

etched at the top of it.

•The flow cell has two pieces

of tubing that you need to

connect to it before placing

it into the analyzer.

•Connect the upper tubing to the top of the flow cell. (The etched serial number indicates the

top.) You will hear a click when the connection is secure.

•Connect the lower tubing to the bottom of the flow cell. You will hear a click when the

connection is secure.

Flow cell

Upper (Teflon) tubing

Lower (silicone) tubing

FlowCam® 8000 Series Dynamic Imaging Particle Analyzer

15 of 39

To install the flow cell:

1. Open the upper hatch and lower

door of the FlowCam analyzer.

2. Loosen the flow cell retainer’s two

red thumbscrews and remove it.

3. With the flow cell’s serial number

toward you, connect the upper

tubing attached to the flow cell to

the sample inlet port.

4. Connect the lower tubing attached

to the flow cell to the syringe

pump manifold.

5. Place the flow cell into its

associated opening, and fit the

upper and lower tubing into their

respective slots.

6. Place the flow cell retainer into

the slot so that the flow cell is held

in place and tighten the two

thumbscrews.

7. Close the lower door and upper

hatch.

Installing the Objective Lens

The FlowCam analyzer offers three sizes of objective lenses (4X, 10X and 20X). Depending upon your

particular system configuration, you may have multiple objective lenses.

10X objective lens in

protective container

Sample

inlet port

Flow cell

and retainer

Flow cell

retainer

thumbscrews

Syringe

pump

manifold

Fluid

position

sensor

Lower

tubing

Upper

tubing

FlowCam® 8000 Series Dynamic Imaging Particle Analyzer

16 of 39

Note: When changing the objective lens from one magnification to another, you must also change the

pump syringe. See Appendix A for more information.

To install an objective lens:

1. Open the analyzer’s upper hatch and pull the silver knob to open the objective shroud.

2. In VisualSpreadsheet, select Setup> Change Objective. This causes the stage that holds the

objective lens to move to the left so you can access the objective fitting.

3. Carefully remove the objective lens from its container by unscrewing it from its cap.

4. Gently thread the lens clockwise into the fitting. Do not overtighten.

5. Click OK on the Change Magnification dialog.

6. The Select Magnification dialog appears. Select the applicable magnification and click OK.

7. Click OK on the Objective Lens Setup dialog. The stage moves the objective back into position

and the VisualSpreadsheet status bar displays the new objective lens value.

8. Close the objective shroud and the upper hatch.

Objective

shroud

Objective

lens

Objective

stage

FlowCam® 8000 Series Dynamic Imaging Particle Analyzer

17 of 39

Autofocusing the Flow Cell

The FlowCam analyzer’s autofocus feature focuses the optical system algorithmically without operator

intervention, ensuring repeatable focus position and, therefore, measurements. To focus the flow cell,

you need the Fluid Imaging focusing standard (Autofocus Beads), other bead standards, or the sample

you will be analyzing. Use the following autofocus beads:

•Low Magnification Focus Beads for the 300FOV or 600FOV flow cell (approximately 50 μm in

diameter), 60,000 p/mL

•High Magnification Focus Beads (or 25-µm Focus Beads) for the 80FOV flow cell (approximately

25 μm in diameter)

•10-µm Focus Beads for the 50FOV flow cell (approximately 10 μm in diameter)

To autofocus the flow cell:

1. From the tool bar, click the Setup and Focus tool to open a live view of the camera window on

the flow cell.

Note: When fluid is primed into the flow cell, the intensity mean should be ~150–180.

The acceptable region

lies within the red

indicator lines. The

acceptable region is set

in the Context settings.

FlowCam® 8000 Series Dynamic Imaging Particle Analyzer

18 of 39

2. If necessary, align the flow cell to the correct position using the positioning knob located to the

left of the flow cell assembly in the interior of the analyzer. The flow cell can be moved left and

right.

Note: The red lines need to be positioned within the gray lines, which represent the walls of the

flow cell. Align the red indicator lines as close as possible within the flow cell.

3. Click the Autofocus button. The Autofocus Assistant opens. Click Next and and follow the

onscreen prompts.

4. Confirm that you have the correct objective lens, flow cell and syringe installed, and click Next.

5. Select the desired autofocus algorithm option (Best Bead Count or Best Focus Image) and click

Next.

Note: Select the algorithm depending upon whether you are running uniform materials for

primarily counting, or varied particles for image quality. The stage assembly orients itself

depending upon the selection after the routine is completed.

6. Place a pipette tip into the sample introduction port on the top of the analyzer and add at least

0.5 mL of focusing sample. Click Next. The pump draws the sample into the flow cell and the

analyzer begins the autofocus process.

Important:Apply some pressure to ensure the tip is securely in the port to prevent air from

being drawn into the system.

7. When the autofocus process finishes, a message appears indicating success. Click Start Flush to

flush the solution from the system. The pump continues until you click Stop.

Flow cell positioning knob

FlowCam® 8000 Series Dynamic Imaging Particle Analyzer

19 of 39

8. Close the Setup and Focus Mode window. You are now ready to begin analyzing samples.

Note: You only need to perform the autofocus routine upon initial startup, and after you change

the flow cell or the objective lens. Otherwise, you can use the manual focus process to adjust

the focus of individual samples. The autofocus log files are saved to Documents>

Visualspreadsheet> Autofocus Logs.

Focusing the Flow Cell Manually

To focus the flow cell:

1. From the tool bar, click the Setup and Focus tool to open a live view of the camera window on

the flow cell.

Note: When fluid is primed into the flow cell, the intensity mean should be ~150–180.

The acceptable region

lies within the red

indicator lines. The

acceptable region is set

in the Context settings.

FlowCam® 8000 Series Dynamic Imaging Particle Analyzer

20 of 39

2. If necessary, align the flow cell to the correct position using the positioning knob located to the

left of the flow cell assembly in the interior of the analyzer. The flow cell can be moved left and

right.

Note: The red lines need to be positioned within the gray lines, which represent the walls of the

flow cell. Align the red indicator lines as close as possible within the flow cell.

3. Click the Manual Focus button. A warning appears. Click OK.

4. Using a pipettor with an ejector, pipette at least 0.5 mL of focusing sample, place the pipette tip

into the sample introduction port on the top of the analyzer, eject it and leave it there.

Important:Apply some pressure to ensure the tip is securely in the port to prevent air from

being drawn into the system.

5. In the VisualSpreadsheet Setup and Focus window, click the Pump Control button to open the

Pump Control dialog.

Flow cell positioning knob

This manual suits for next models

2

Table of contents

Other Fluid Imaging Technologies Measuring Instrument manuals