Page Number - 5

MODEL NOS. 2710 & 2740

PUMP & HOIST ASS’Y

MODEL NOS. 274680 & 274681

400 LB. DRUM SIZE AIR OPERATED, MANUALLY CONTROLLED

Form 402074

INSTALLATION:

1. Select a location where there is adequate clearance around

the hoist to operate and maneuver around the hoist and

pump assembly when installing and removing drums.

2. The mounting base must be securely fastened to the floor

before use. Mounting dimensions are provided on Base

Mounting Dimensions illustration (See Illustration 3), or the

base may be used as a template for drilling and positioning

anchors.

3. After hoist has been secured to the floor adjust the pump

support, item 56, so that it is parallel to the floor. This will

keep the pump tube parallel with the support tube.

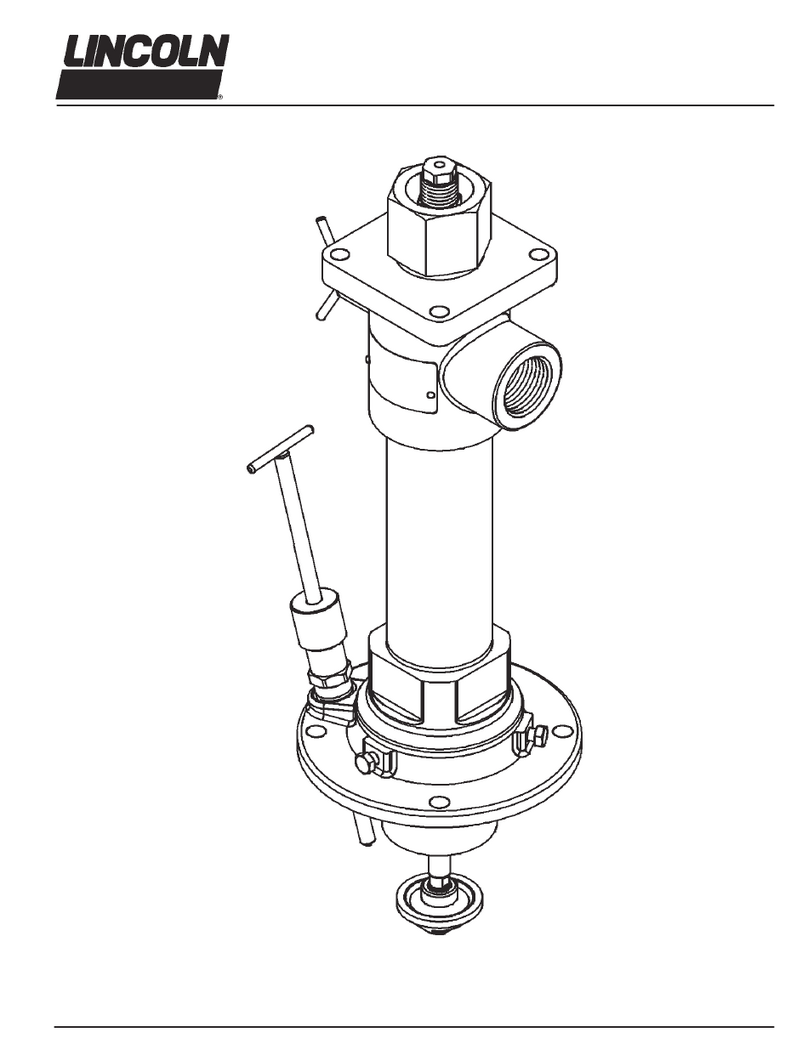

4. Mount pump to pump mount (item 29 or 53) depending on

model.

When attaching the Series 40 pumps to the mount, (item

53), attach pump outlet body to pump mount with four ¼-20

x 9/16 hex screw and washer assemblies, item 54. See

Series 40 Assembly Details.

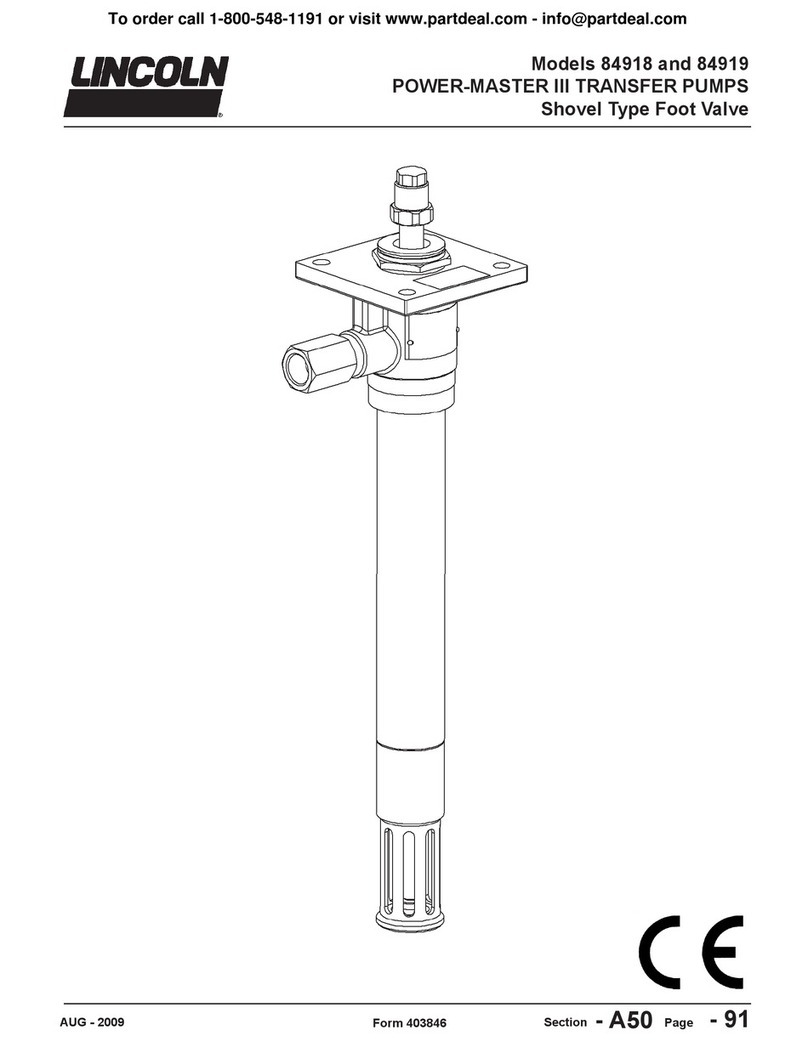

When attaching the Power Master Pump to the mount,

item 29, use four extension adapters, item 40. See Power

Master III Assembly Details. Note that the extension adapt-

ers are threaded onto the pump tie rods against the tie rod

nuts, as shown in the illustration.

5. Place pump and mount into pump support, item 56, and

loosely install hex bolts, lock washers, and flat washers,

items 4, 5, &6, through slots in support. Leave loose until

final adjustment is made.

6. Assemble air inlet fittings as shown in the appropriate as-

sembly detail page for the model that is being assembled.

Assemble the air regulator, item 44, to the air inlet of the

hoist as shown in the illustration. Note that there is a 1/8

pipe plug packaged with each regulator for plugging the

unused gage port in the regulator.

7. After all fittings are assembled and tight measure and cut

a length of ¼ OD black polyurethane tubing, supplied, to

connect the air inlet to the regulator inlet as shown in the il-

lustrations. The tubing will simply push fit into the ¼ fittings

included with the model.

8. Assemble the air hose to the air coupler as required for the

model assembled. (Note that the air coupler for the Power

Master Air Motor is supplied with the air motor.) Make sure

the ball valve, item 35 or 45, is closed and the hoist control

valve, item 10, should be placed in the down position, and

attach air hose to source of filtered, regulated air. The air

pressure should be set initially to about 40 PSI.

9. Adjust the hoist air regulator, item 44, for a pressure of

around 30-40 PSI. Check for air leaks in all connections.

Slowly move the hoist control valve, item 10, to the raised

position and raise pump so the end of the pump tube will

clear the primer assembly.

Failure to securely fasten the base to the floor may result

in severe injury and or property damage. Pump hoist may

topple over if not securely fastened.

10. Attach the primer assembly to the end of the pump tube.

When assembling the Power Master Pump tube to the fol-

lower, apply some grease to the end of the pump tube, and

the O-rings inside the follower assembly. Lower the end

of the pump tube into the follower until the pump tube is

flush with the bottom of the follower. Tighten the three hex

screws, item 24, on the follower until tight.

When assembling the Series 40 pump to the follower, a

reducing adapter is used, item 55. Apply some grease to

the outside of the adapter and the O-rings on the inside

of the adapter and the inside of the follower. Push the

adapter into the follower assembly until it seats against the

shoulder. Tighten the three hex bolts on the follower, item

24, securely. Apply some grease to the end of the pump

tube and slide into the reducing adapter, item 55, until the

pump tube is flush with the bottom of the follower. Tighten

the three set screws, item 32, securely.

11. Raise the follower high enough to clear an open 400# con-

tainer. Place the container under the follower and slide the

drum back on the mounting base, item 8, until it is against

the two gusset plates on the base. Adjust the position of

the pump with respect to the drum by sliding the pump

mount (item 29 or 53) in the pump support, item 56, until

the follower is centered over the open drum. Tighten the

hex bolts, item 4, through the slots in the pump support to

secure the pump mount.

12. Using the remaining polyurethane tubing, attach to the

open fitting on the 2-way air valve, item17, mounted on the

pump support, item56, by pushing one end of the tube into

the fitting until secure. Thread the tubing down along the

pump tube to the fitting, item 1, in the top of the follower as-

sembly. Secure the tubing to the pump tube with two nylon

wire ties, supplied with the assembly.

13. Check for proper air flow by pressing button on 2-way air

valve, item17, making sure that air flows through check

valve, item 30, and out under follower assembly.

14. Connect fluid hoses to pump outlet.

Power Master Pumps are supplied with a 3/8” ID high

pressure hose with ½ NPT female threaded connections.

Thread a ¾ NPT x ½ NPT bushing adapter, item 36, into

the pump outlet and tighten securely. Thread a ½ NPT hex

nipple, item 34, into the bushing and tighten securely. At-

tach the high pressure hose, item 50, to the hex nipple and

tighten for leak free fit.

Series 40 pumps are supplied with a ¼” ID high pressure

hose, item 52, with 33/64 female thread on both ends. Two

male adapters, item 48, are supplied to adapt the hose to

¼ NPT male for the pump outlet, and working end of the

hose. Insert the hose adapters, item 48, into each end of

the high pressure hose and tighten securely for leak proof

seal. Thread one end of the hose into the pump outlet and

tighten securely. Attach the other end as required for the

application.