XENIT PLUS USER’S MANUAL ____ ___ VER. 1.1

___________________________________________________________________________

© Copyright

FLY

Products s.r.l. Page

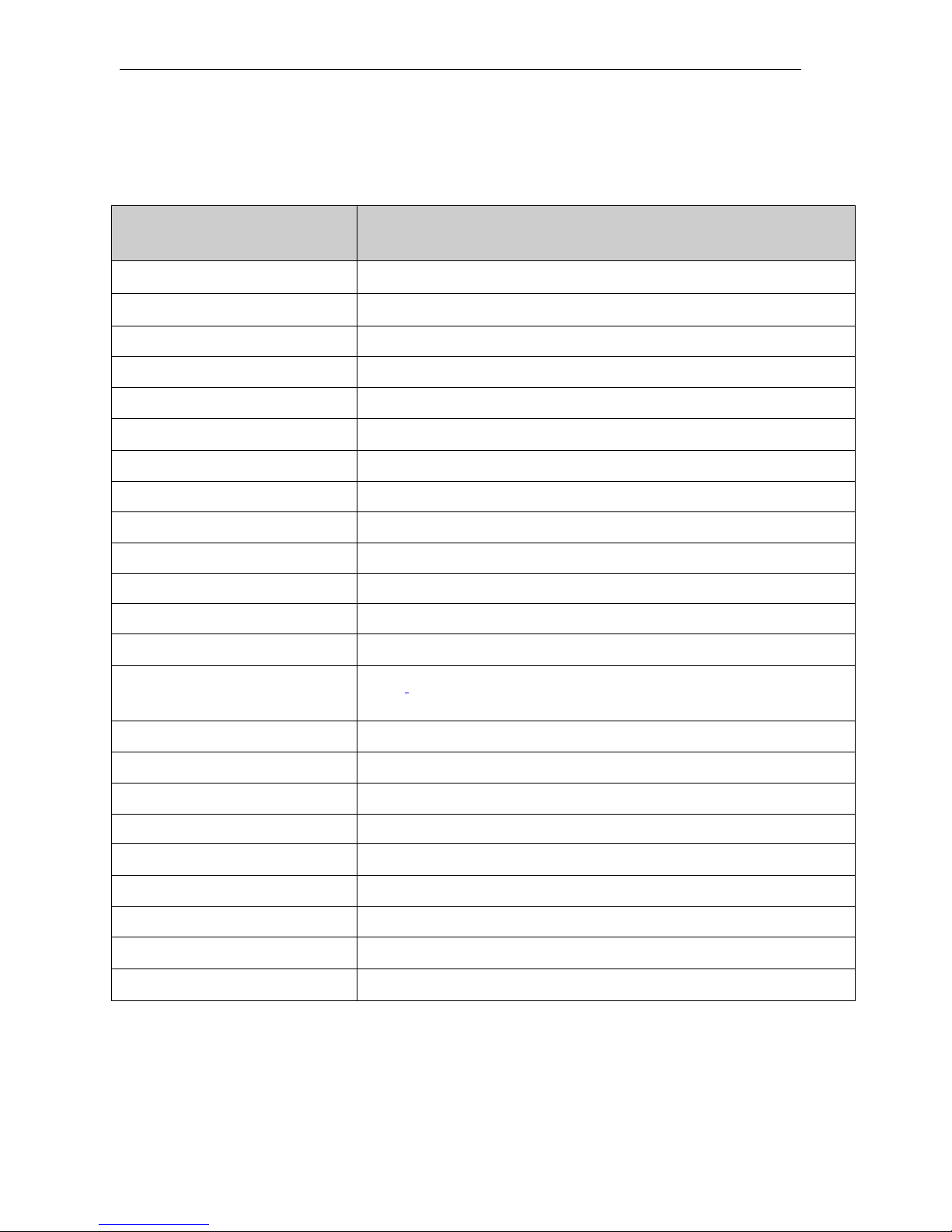

Section 1. XENIT PLUS

The XENIT PLUS Trike is for all those pilots who want to fly alone or with a passenger in a light but solid vehicle which is

also cost-efficient, low-maintenance and easy to transport.

The cage is made in powder-coated aluminum and the carriage bar, the harnesses attach to, in stainless steel 304.

This guarantees safety, flexibility and support for the pilot and the passenger. The choice of aluminum and steel is aimed at

reducing weight whilst maintaining solidity in the most important points.

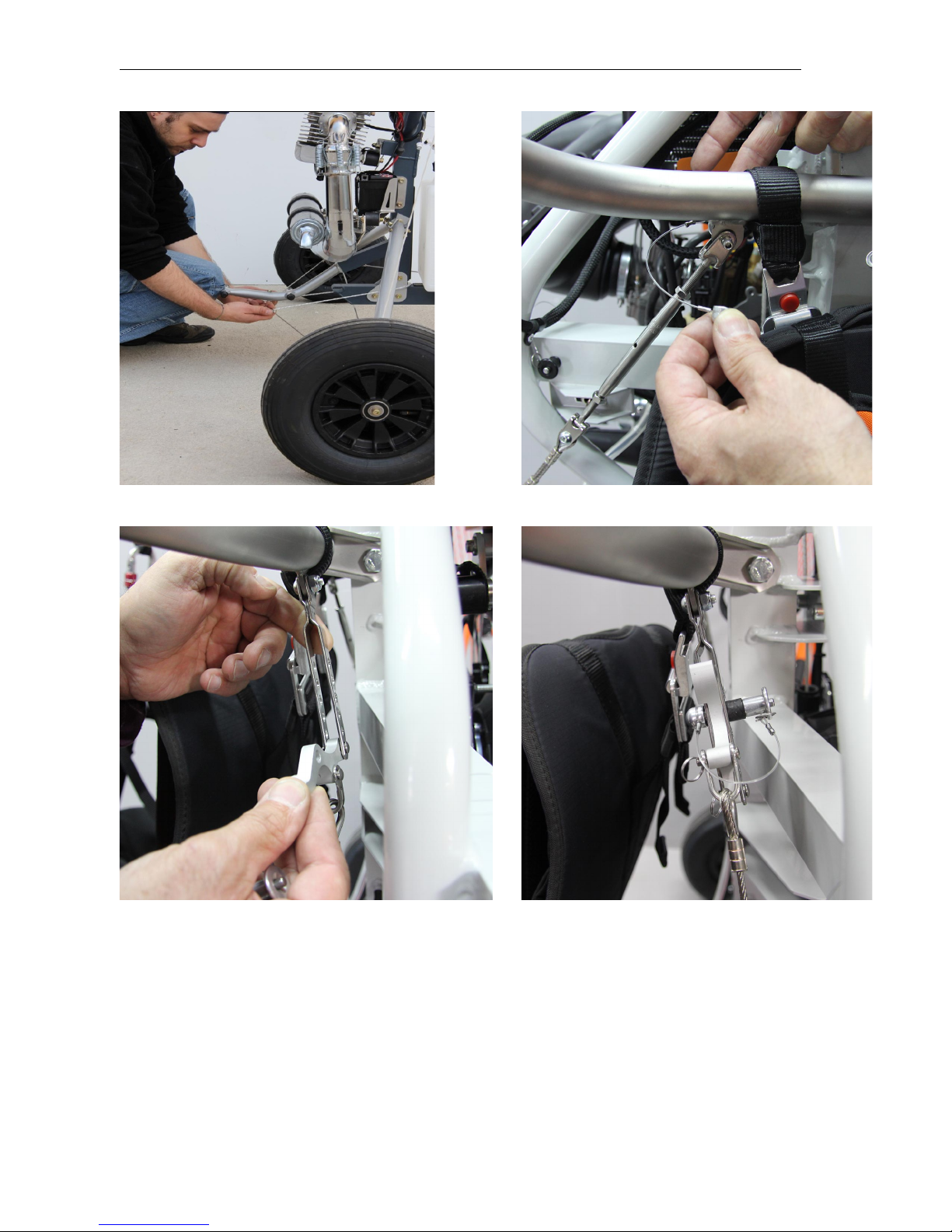

Another important factor is the use of steel cables which keep the entire Trike structure in shape and assure optimum

performance.