FLYGT FPC100 User manual

Single pump controller

Installation and user

manual for FPC100

Table of Contents

QUICK SET-UP OF FPC100...................................................................................................................2

Quick set-up of FPC100......................................................................................................................2

SAFETY.................................................................................................................................................... 3

Safety.....................................................................................................................................................3

UNPACKING, INSPECTION AND RECYCLING...................................................................................4

Unpacking, inspection and recycling................................................................................................4

INSTALLATION.......................................................................................................................................5

............................................................................................................................................................... 5

Connection terminals..........................................................................................................................5

Choice and adaptation of current transformer................................................................................6

Current transformer connection........................................................................................................7

Supply voltage connection................................................................................................................ 7

Alarm relay connection.......................................................................................................................7

Pump relay connection.......................................................................................................................7

Digital input connection (DIG IN)......................................................................................................8

Terminal 5 connection (e.g. temperature supervision).................................................................. 8

FRONT PANEL LAYOUT AND FUNCTION KEYS............................................................................... 9

Front panel layout and function keys................................................................................................9

DISPLAY, SYMBOLS AND UNITS....................................................................................................... 10

Display, symbols and units...............................................................................................................10

DETAILED SETTINGS...........................................................................................................................11

General...............................................................................................................................................11

Lock and unlock menu settings.......................................................................................................11

Returning to default settings........................................................................................................... 11

Complete set-up............................................................................................................................... 11

Adjustment of the stop level............................................................................................................14

Start conditions and pause time adjustment.................................................................................14

Window parameters......................................................................................................................... 15

PROTECTION AND ALARM................................................................................................................19

Protection and alarm........................................................................................................................ 19

TROUBLESHOOTING..........................................................................................................................21

Troubleshooting................................................................................................................................21

TECHNICAL SPECIFICATIONS...........................................................................................................22

Electronics..........................................................................................................................................22

EU specifications............................................................................................................................... 22

USA specifications.............................................................................................................................22

Canadian specifications................................................................................................................... 23

Part numbers......................................................................................................................................23

Table of Contents

Single pump controller Installation and user manual for FPC100 1

QUICK SET-UP OF FPC100

Quick set-up of FPC100

The purpose with the quick set-up is to initiate the stop function. FPC100 stops the pump

when the water level has dropped to such a low level that the pump begins to draw air

(snore). At air intake the pump motor power drops and below a manually set power-level

FPC100 stops the pump.

Pump power

Manually set power level

Full load power

Stop level

“Snore power”

Time

Stop at underpower

If FPC100 has been used previously, some parameters could have been changed and

locked. Then go to Complete set-up (page 11) that describes a complete set-up.

The prerequisite for quick set-up is that the pump is installed to a control panel including

FPC100. The control panel should preferably also include a Hand-0-Auto switch for the

pump.

In event of an alarm during the set-up, see PROTECTION AND ALARM (page 19).

Auto-set at normal pumping (pumping water without drawing air)

1. Check that the amount of water is enough for pumping about 30 seconds without

drawing air.

2. Turn on the supply voltage to FPC100 and set the Hand-0-Auto switch in the Auto-

position. The pump shall now be pumping water without drawing air. If the pump

doesn’t start, press START/RESET.

3. When the pump is working steadily, press AUTOSET until “SEt” is shown on the

display. The power level for stop is now set.

The stop function is now initiated and FPC100 controls the pump. Adjustments can be

made according to DETAILED SETTINGS (page 11).

Auto-set at snoring (pumping a mix of air and water)

1. Set the Hand-0-Auto switch in the 0-position and turn on the supply voltage to

FPC100.

2. Step with NEXT to window 13 and press “–“ so that the line is shown at the bottom of

the display ( _ ). Press ENTER to verify. FPC100 is now prepared for Auto-set at

snoring.

3. Set the Hand-0-Auto switch in the Auto-position to start the pump. If necessary, press

START/RESET.

4. Run the pump until it starts to snore.

5. Press AUTOSET until “SEt” is shown on the display. The power level for stop is now

set, hence stopping the pump due to the snoring.

The stop function is now initiated and FPC100 controls the pump. Adjustments can be

made according to DETAILED SETTINGS (page 11).

QUICK SET-UP OF FPC100

2 Single pump controller Installation and user manual for FPC100

SAFETY

Safety

WARNING:

Before doing any work, check that the automatic control cubicle is disconnected from the

power supply and cannot become live.

Always isolate the power supply before attempting to trace a fault. Otherwise the pump

can start without warning.

• Read

TECHNICAL SPECIFICATIONS

(page 22) before starting the installation.

• Authorised electrician shall perform the installation.

• The installation shall comply with general and local regulations.

• Disconnect all supply circuits before installation. Also disconnect all supply circuits

before connecting and disconnecting cables to FPC100.

FPC 100 conforms to international standards and is UL/ CSA and CE-marked.

WARNING:

Antes de empezar cualquier trabajo, comprobar que el armario de sistemas automáticos

esté desconectado de la red eléctrica, y que no pueda recibir tensión.

Prima di iniziare qualsiasi lavoro, controllare che la centralina degli automatismi sia

staccata dalla rete di alimentazione elettrica e che non sia sotto tensione.

Controleer, voordat u begint te werken, of de schakelkast gescheiden is van de elektrische

voeding en niet omder spanning kan komen te staan.

Antes de iniciar qualquer trabalho, verifique se o compartimento do sistema automático se

encontra desligado da rede eléctrica e assegure-se de que a corrente não poderá ser

activada.

Inden nogen form for arbejde påbegyndes, skal det kontrolleres, at automatikskabet er

koblet fra elnettet, og at det ikke kan blive spændingsførende.

Før arbeide påbegynnes, påse at automatikkskapet er frakoplet strømnettet og at det ikke

kan bli spenningsførende.

Ennen kuin mitään työtä aloitetaan, on varmistettava, että automatiikkakaappi on kytketty

irti sähköverkosta eikä voi tulla jännitteiseksi.

Áður en starfræksla hefst, gangið úr skugga um að sjálfvirkur gangsetningarbúnaður sé

óvirkur, þ.e.a.s. ekki tengdur við rafmagn.

Ðñéí áðü êÜèå åñãáóßá, åëÝãîôå áí ôï êéâþôéï ôïõ áõôüìáôïõ åëÝã÷ïõ Ý÷åé áðïóõíäåèåß

áðü ôï ñåýìá êáé äåí ìðïñåß íá ôåèåß õðü ôÜóç.

SAFETY

Single pump controller Installation and user manual for FPC100 3

UNPACKING, INSPECTION AND

RECYCLING

Unpacking, inspection and recycling

The delivery comprises:

• FPC100 control unit

• Current transformer

• Installation and user manual for FPC100

If anything is missing or damaged in the delivery, contact your local Xylem sales office.

Keep the packing. It can be needed for return of the delivery or in case of inspection at

damage.

The housing of the FPC100 is made of recyclable plastic, type PC/ABS. The circuit boards

contain minimal amounts of tin and lead.

When scrapping the FPC100, all parts must be handled and recycled according to local

regulations.

UNPACKING, INSPECTION AND RECYCLING

4 Single pump controller Installation and user manual for FPC100

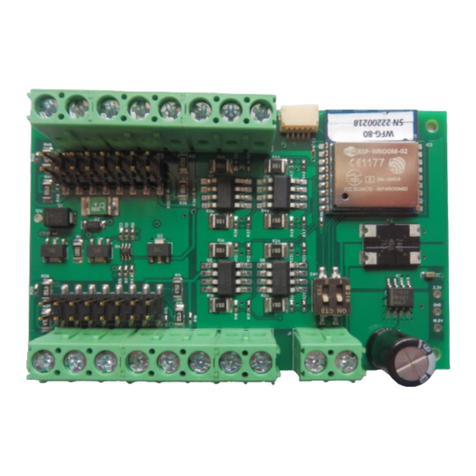

INSTALLATION

The installation shall be performed by an authorised electrician according to local safety

regulations.

WARNING:

Before installing, make sure that no voltage is applied to the equipment.

Check that the rated voltage of FPC100 corresponds with the supplying line voltage. The

rated voltage can be found on the rating plate on the side of the control unit.

FPC 100 is mounted on a standard DIN-rail, 35 mm. Dimensions, temperature range and

other necessary data for the installation can be found in

TECHNICAL SPECIFICATIONS

(page 22).

PE

L1

L2

L3

N

M

3

Max

240VAC

Hand

IDig

in

Temp Alarm Pump

1 3 45 7 8

6

9

L1

11

L2 L3

13

2

Supply

Auto 0

Alarm

Auto-set

Reset

High level

Thermistor (PTC)

or

Thermal contact

Alternative connection

K

FPC100

R

Connection terminals

No Label Function

1 I Current transformer input

2 I Current transformer input

3 DIG IN Digital input for closing contact

4 DIG IN/TEMP Signal ground for terminals 3 and 5

5 TEMP Input for thermistor (PTC), thermal

contact and/or any voltage-free

opening contact

6 ALARM Alarm relay output

7 ALARM/PUMP Common input for alarm- and pump

relay

INSTALLATION

Single pump controller Installation and user manual for FPC100 5

No Label Function

8 PUMP Pump relay output

9 L1 Supply voltage

10 (not used)

11 L2 Supply voltage

12 (not used)

13 L3 Supply voltage

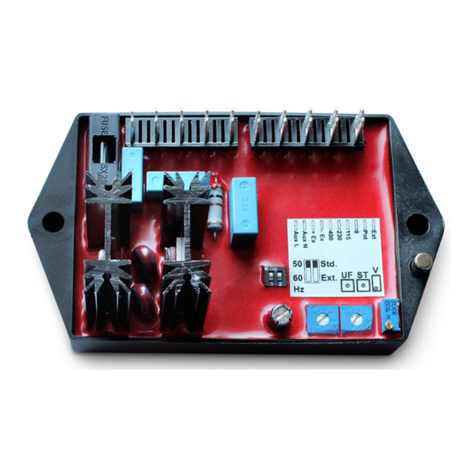

Choice and adaptation of current transformer

The pump motor size decides whether one or two current transformers shall be used. For

motor currents up to 100 A, one current transformer shall be used. From 100 to 1000 A

two transformers are needed.

0-100A

The current through the transformer should be close to its primary current rating, but

should not exceed it.

Current transformers with a choice of four ratings are available, i.e. 10A, 25A, 50A and

100A.

The phase conductor of the motor can be run through the current transformer core an

additional number of turns to put the available transformer capacity to full use.

The formula below can be used to determine how many turns the phase conductor of the

motor should be run through the transformer core.

Number =rated primary current of current transformer

of turns rated motor current

(Round down to next lowest integer value).

Example 1:

Rated current of motor = 12 A

Primary current of current transformer = 25 A

Number of turns = 25 A/12 A

Answer = 2

Example 2:

Rated current of motor = 7.8 A

Primary current of current transformer = 10 A

Number of turns = 10 A/7.8 A

Answer = 1

100-1000A

If the rated motor current is in excess of the highest rated primary current of the available

transformers (100A), proceed as follows:

INSTALLATION

6 Single pump controller Installation and user manual for FPC100

1. Use a standard current transformer which has a primary current rating just in excess

of the rated motor current and which has a rated secondary current of 5 A.

2. Pass the lead, connecting to the secondary side of the standard current transformer,

twice through the 10 A current transformer (CT10).

Example:

Rated current of motor = 210 A

A standard current transformer with a current rating 250:5 A is chosen. The secondary side

of the standard transformer should be run twice through the 10 A current transformer core.

Note: The choice and adaptation of current transformer(s) should at pumping with full load

power result in a secondary current as close to 55 mA as possible, but should not exceed

it. This in order to put the available capacity of the current input range in FPC100 to full

use, hence resulting in a better functionality. The secondary current can be checked in

window 61 or with an external multimeter.

Current transformer connection

Choose appropriate current transformer (CT) according to

Choice and adaptation of

current transformer

(page 6).

Connect the CT secondary winding to terminals 1 and 2.

Note: The CT must be linked to the phase connected to terminal 9 (L1).

Supply voltage connection

Connect FPC100 directly to the pump motor supply cable via terminals 9 (L1), 11 (L2), and

13 (L3). Make this connection before the contactor to the pump motor in order to supply

FPC100 also when the contactor is open. See circuit diagram.

When motor fuses larger than 10 A are used, FPC100 must be fused separately.

Alarm relay connection

Terminals 6 and 7 are the alarm relay connections. Terminal 6 is the alarm relay output.

Terminal 7 is the common input for the alarm- and pump relays.

When FPC100 is powered off, the alarm relay is “nc” (normally closed). When powered on,

“nc” or “no” (normally open) can be selected in window 51. Default setting is “no”.

Pump relay connection

Terminals 7 and 8 are the pump relay connections. Terminal 8 is the pump relay output.

Terminal 7 is the common input for the pump- and alarm relays.

When FPC100 is powered off, the pump relay is “nc”. When powered on, “nc” or “no” can

be selected in window 52. Default setting is “nc”.

INSTALLATION

Single pump controller Installation and user manual for FPC100 7

Digital input connection (DIG IN)

Terminals 3 and 4 are intended for an external closing contact. The input is galvanically

isolated.

Terminal 4 is the common signal ground for terminal 3 and terminal 5.

The functions for the digital input that can be selected in window 53 are:

1. High level switch (to enable immediate start of the pump)

2. External Reset

3. External Auto-set

Terminal 5 connection (e.g. temperature supervision)

Terminals 4 and 5 can be used for temperature supervision: a thermal contact or a PTC

thermistor. As an alternative the terminals can be used with any device using a voltage-free

opening contact such as a motor protection unit.

Terminal 4 is the common signal ground for terminal 5 and terminal 3.

INSTALLATION

8 Single pump controller Installation and user manual for FPC100

FRONT PANEL LAYOUT AND

FUNCTION KEYS

Front panel layout and function keys

The operator’s panel comprises a display and a set of six keys.

The keys are described below and the display is described in

DISPLAY, SYMBOLS AND

UNITS

(page 10).

Key Function

RESET/START Resets a latched alarm / Starts pump motor

AUTO SET Sets the stop level when pressed for 3 s

NEXT Proceeds to the next window

–Decreases the displayed value

For fast decrement, depress button 6 sec

+Increases the displayed value

For fast increment, depress button 6 sec

ENTER Confirms the adjustments made

FRONT PANEL LAYOUT AND FUNCTION KEYS

Single pump controller Installation and user manual for FPC100 9

DISPLAY, SYMBOLS AND UNITS

Display, symbols and units

The display contains three symbols, five units, three bigand two small digits.

The small digits show the window number in the menu structure. The big digits show a

value. If the value is greater than three digits the two small digits alternate between the

window number and the first two digits in the value.

Example: The total pumping time (window 07) is 13467 hours. Window number 07 is

displayed for 2 sec and then 13467 is displayed for 2 sec.

Symbol Meaning

Alarm

Time value

Parameter lock

Unit Meaning

V Volt

mA Milli-ampere

m Minutes

S Seconds

% Percent

Note 1: When FPC100 is turned on, a self test is performed during 3 seconds and all

characters and symbols on the display are shown.

Note 2: During alarm the entire display is flashing.

Note 3: If “oor” (out of range) is shown on the display, it means that the value is too big to

be shown on the display.

DISPLAY, SYMBOLS AND UNITS

10 Single pump controller Installation and user manual for FPC100

DETAILED SETTINGS

General

Adjustments and settings are done in a single-level menu structure, windows 00-99.

When FPC100 is turned on, press NEXT to proceed to the next window, press + or – to

increase or decrease the value and press ENTER to confirm the new value in each window.

One minute after any key has been pressed, FPC100 returns to:

• window 00 if there is an alarm

• window 01 if the pump is pausing

• window 02 if the pump is pumping

• window 03 if the pump is pumping due to start on high level switch

See

Window parameters

(page 15) for a summary of all the menu windows.

Lock and unlock menu settings

It is possible to avoid unintentional change of parameters. Set window 09 to 369 and

confirm with ENTER. A padlock is shown, indicating access only to windows 00-09. Re-

entering value 369 and confirming with ENTER gives access to all windows.

Returning to default settings

If any value differs from the default settings, “Usr” (set by the user) is displayed in window

99. Press + to return to the default settings. “dEF” (default setting) is then shown in the

window. Confirm by pressing ENTER. All user settings are erased and replaced by default

settings according to

Window parameters

(page 15). New user settings must be

reentered.

Complete set-up

FPC100 stops the pump when the power drops due to snoring. The stop level has to be

set manually by the AUTOSET-key. A correct level is in the range between the full load

power at normal pumping and the power level at snoring.

DETAILED SETTINGS

Single pump controller Installation and user manual for FPC100 11

The stop level can be set in two ways:

1. Pressing AUTOSET at pumping without snoring sets the stop level as a percentage

below the full load power, see

Complete set-up at pumping (without snoring)

(page

12).

2. Pressing AUTOSET at snoring sets the stop level as a percentage above the snore

power, see

Complete set-up at snoring

(page 13).

In event of an alarm during the set-up, see PROTECTION AND ALARM (page 19).

Pump power

Manually set power level

Full load power

Stop level

“Snore power”

Time

Stop at underpower

Complete set-up at pumping (without snoring)

1. Install FPC100 according to

INSTALLATION

(page 5).

2. Set the Hand-0-Auto switch in the 0-position and turn on the supply voltage to

FPC100.

3. If a padlock ( ) is shown on the display, viewing and changing of parameters are

locked. Set window 09 to 369 and confirm with ENTER to remove the padlock and

get access to parameter settings (windows 11- 99).

4. Clear the present stop level by pressing AUTOSET until “SEt” is shown on the display.

The stop level is hence set to 0 % since the pump is off.

5. Set window 13 to ( – ) and confirm with ENTER. FPC100 is now prepared for Auto-set

at pumping without snoring.

6. Set the Hand-0-Auto switch in the Auto-position to start the pump. If necessary, press

START/RESET.

7. Make sure that the pump is working steadily. Press AUTOSET until “SEt” is shown on

the display.

The stop level (window 11) is now set in relation to the measured power (window 04) and

the snore margin (window 12).

Further adjustments can be done according to

Adjustment of the stop level

(page 14)—

Window parameters

(page 15).

Example:

Stop level (window 11) = Measured full load power (window 04) - Snore margin (window

12)

The pump is pumping water at the measured full load power 68 %. The snore margin is set

to 10 %. Pressing AUTOSET will then give the stop level 58 %.

DETAILED SETTINGS

12 Single pump controller Installation and user manual for FPC100

When the pump starts to snore the measured power will decrease from 68 %. When the

power has decreased below 58 % FPC100 will stop the pump.

Pump power

Full load power (window 04)

Snore margin (window 12)

“Snore” power

Stop level (window 11)

AUTOSET is pressed

Time

Complete set-up at snoring

1. Install FPC100 according to

INSTALLATION

(page 5).

2. Set the Hand-0-Auto switch in the 0-position and turn on the supply voltage to

FPC100.

3. If a padlock ( ) is shown on the display, viewing and changing of parameters are

locked. Set window 09 to 369 and confirm with ENTER to remove the padlock and

get access to parameter settings (windows 11-99).

4. Clear the present stop level by pressing AUTOSET until “SEt” is shown on the display.

The stop level is hence set to 0 % since the pump is off.

5. Set window 13 to ( _ ) and confirm with ENTER. FPC100 is now prepared for Auto-set

at snoring.

6. Set the Hand-0-Auto switch in the Auto-position to start the pump. If necessary, press

START/RESET.

7. Run the pump until it starts to snore.

8. Press AUTOSET until “SEt” is shown on the display. The power-level for stop is now

set, hence stopping the pump due to the snoring.

The stop level (window 11) is now set in relation to the measured power (window 04) and

the snore margin (window 12).

Further adjustments can be done according to

Adjustment of the stop level

(page 14)—

Window parameters

(page 15).

Example:

Stop level (window 11) = Measured “snore” power (window 04) + Snore margin (window

12)

The pump is pumping a mix of air and water at the measured “snore” power 28 %. The

snore margin is set to 20 %. Pressing AUTOSET will then give the stop level 48 %, hence

stopping the pump.

From now on FPC100 will stop the pump each pump cycle when the power drops below

48 %.

Pump power

Full load power

AUTOSET is pressed

Time

Snore margin (window 12)

“Snore” power (window 04)

Stop level (window 11)

DETAILED SETTINGS

Single pump controller Installation and user manual for FPC100 13

Adjustment of the stop level

The stop level can always be adjusted in the following two ways:

• Change the snore margin (window 12) and perform a new AUTOSET. The new stop

level will be set in relation to the new snore margin. See examples in

Complete set-up

(page 11).

• Change the stop level directly in window 11.

Start conditions and pause time adjustment

In normal operation there are three starting options:

1. Pump start after calculated pause time (window 25 = “on”)

2. Pump start after calculated pause time, or at high level (window 25 = “on”, window

53 = “1”)

3. Pump start at high level only (window 25 = “OFF”, window 53 = “1”)

Note: Option 2 and 3 require connection of a high level switch according to

Digital input

connection (DIG IN)

(page 8).

The pump will also start if a non-latched alarm disappears or if the START-button is

pressed during pause.

Calculation of pause time is based on previous pumping- and pause times and is

controlled by the two parameters level setting (window 21) and maximum pause time

(window 22). The parameters can be adjusted to achieve the desired sizes of pause times,

start level and number of starts per hour.

The level setting in window 21 is set for shorter or longer pumping and pause cycles.

Higher value increases the calculated pause time and the amount of accumulated water.

The level setting can preferable be adjusted after some pumping cycles in order to adjust

the pause times, and hence the start level in the pit. See schematic pump cycle example

below.

Maximum pause time for the pump is set in window 22. The calculated pause time will be

limited to this value. In some applications the inflow may increase rapidly during a pause.

To prevent overflow in these situations the maximum pause time can be set in accordance

with the circumstances.

DETAILED SETTINGS

14 Single pump controller Installation and user manual for FPC100

Window parameters

The following table is a summary of all the windows in the single level menu structure.

Window number, function and value ranges are listed as well as the default settings that

are programmed in FPC100 before delivery.

Window Function Value/Range Default setting Own settings and

comments

00

Alarm indication.

Flashes when an

alarm is present.

Symbol

is flashing

See

PROTECTION

AND ALARM

(page

19)

01

Remaining time to

next calculated pump

start.

Standard window

during pause.

Symbol

is flashing together

with m or S.

720–15 min

900–0 s

02

Pumping time since

the latest pump start.

Standard window

when pumping.

Symbol

is flashing together

with m or S.

0–90 s

15–720 min

12–999 h

03

Pumping time since

the latest pump start

due to start on high

level

. Standard

window when

pumping after high

level.

Symbol

is flashing together

with m or S.

0–900 s

15–720 min

12–999 h

04

Measured power

in %

of the measuring

range

0–125 %

05

Measured line

voltage

0–999 V

06

Measured peak

power

in % of the

measuring range

0–125 % 0 %

DETAILED SETTINGS

Single pump controller Installation and user manual for FPC100 15

Window Function Value/Range Default setting Own settings and

comments

07

Total pumping time

in hours. Symbol

is displayed.

Press + and –

simultaneously for 3

sec to set the value to

0.

0–99999 0

08

Total number of

pump starts.

Press +

and – simultaneously

for 3 sec to set the

value to 0.

0–99999 0

09

Parameter lock.

Symbol

is displayed when

parameters are

locked. Enter 369 to

lock/unlock window

11-99.

0–999 0

11

Stop level (power)

in

%0–125 % 0 %

12

Snore margin

in % 0–125 % 10 %

13

Type of Auto Set.

AUTOSET is pressed at

normal pumping

when pump doesn’t

snore ( ¯ ).

AUTOSET is pressed at

snoring or dry

running ( _ )

¯ or _ ( ¯ )

21

Level setting

(used

for pause time

calculation).

Higher value

increases the

calculated pause

time. Example: the

value 3.2 gives 3.2

times longer pause

time than 1.0.

The level setting can

preferable be

adjusted after some

pump cycles in order

to adjust the pause

times, and hence the

level in the pit.

1.0–10.0 1.0

DETAILED SETTINGS

16 Single pump controller Installation and user manual for FPC100

Window Function Value/Range Default setting Own settings and

comments

22

Maximum pause

time.

Symbol

is displayed.

If the calculated

pause time is longer

than the Maximum

pause time, the

pump will start after

the Maximum pause

time.

0–900 s

15–720 min

600 s

23

Start-up delay.

Symbol

is displayed.

This is the time from

pump start until

snore detection is

activated.

1–170 s 5 s

24

Stop delay.

Symbol

is displayed.

This is the time from

snore detection until

the pump is stopped.

1–90 s 2 s

25

Pump starts when

pause time is

finished

.

“OFF” means start

only on high level

(set window 53 to 1)

on / OFF on

31

Terminal 5

supervision, e.g.

temperature

supervision.

on / OFF OFF

32 Terminal 5 alarm

latched “on” or not

latched “OFF”.

Can only be used

when window 31 is

“on”.

on / OFF OFF

41 Permitted

phase

voltage asymmetry

level.

Pressing “–” when the

window shows 5 %

turns off the

supervision (OFF).

OFF/5–50 % 10 %

42 Phase voltage

asymmetry alarm

latched. Can only be

used when window

41 is set between

5-50%.

on / OFF OFF

DETAILED SETTINGS

Single pump controller Installation and user manual for FPC100 17

Window Function Value/Range Default setting Own settings and

comments

51

Alarm relay

(terminal

6)

nc = normally closed.

no = normally open

nc / no no

52

Pump relay

(terminal

8)

nc = normally closed.

no = normally open

nc / no nc

53

Digital input

for

closing contact.

1 = High level switch

(gives immediate

start of the pump)

2 = External Reset

3 = External Auto-set

1, 2, 3 1

61

Measured current

on

terminals 1 and 2. 0–70 mA

99

Default settings

(dEF) / User settings

(Usr)

Setting (dEF) returns

to default settings.

dEF / USr dEF

DETAILED SETTINGS

18 Single pump controller Installation and user manual for FPC100

Table of contents

Other FLYGT Controllers manuals

Popular Controllers manuals by other brands

National Instruments

National Instruments CompactRIO cRIO-9035 Getting started guide

MICRO STORM

MICRO STORM MS-001 manual

Rodix

Rodix 121-000-0881 quick start guide

Power Electronics

Power Electronics TAIYO EXU-61A user manual

FunkTronic

FunkTronic Major BOS V Series manual

Pinnacle

Pinnacle microGUARD DIN-rail Controller Module installation manual