FMA Direct G100 User manual

•USING REMOTE GAIN: Remote gain is an extremely useful feature of the G100. When

using the remote gain input to the G100, the gyro's gain can be controlled from the transmitter

via an auxiliary channel on the receiver. Unlike most gyros on the market, the G100 remote

gain is fully proportional.

Setting Up For Remote Gain: To set the system up for remote gain, perform the following:

a) Position the POT/RMT program dip switch to the RMT setting to defeat the gain

control trim pot and enable the AUX input on the gyro.

b) Plug the AUX lead into a proportional auxiliary channel. A switch channel such as

landing gear can be used as long as the end-points are adjustable in the transmitter.

Note: the simplest way to use the G100 with remote gain is to utilize an auxiliary

channel that has variable gain. This way, gain can easily be controlled during flight by

moving the transmitter knob. If the transmitter being used does not have a variable

auxiliary channel, gyro operation can still be set up for remote gain operation using a

switched type auxiliary channel such as landing gear. This setup will provide for two

gain settings; the end-point adjustments in the transmitter can be used to set high and

low gain values.

c) With the radio system ON, move the model about the control axis while moving the

gain channel knob or switch on the transmitter. You should notice the sensitivity of the

gyro change as the auxiliary channel control is moved.

With a computer, programmable transmitter, the versatility of the G100 can be realized

to an even greater extent. For instance, the gain channel can be mixed with the flight mode

switch so that two gain options are available, one setup for hover, and a different setup for

forward flight. This setup is ideal because the gain required for hover will usually be greater

than the gain required for forward flight as the forward motion of the helicopter tends to

restrict tail rotation.

FLYING:

•PRECAUTIONS:

1. It is extremely important that the model be at ambient temperature before the system

is powered up for flight. Never take the aircraft out of a warm car on a cold day and

power up the system right away. You must allow the model to sit for 10 to 15 minutes

on the ground. In order to perform properly, the gyro must be at the same temperature

as the air.

2. After powering up the system, the aircraft must remain absolutely still for 5 seconds. If

these precaution are not taken, trim changes could occur throughout the flight.

•FIRST FLIGHT: The gain should be set to 25% on the initial flight. Hover the helicopter for a

short moment, then increase the gain. Repeat this procedure until a smooth hover is

achieved. If the gain is turned up too high, the helicopter may start to oscillate back and forth

rapidly. This condition is termed "hunting".

Good luck and enjoy the high performance operation of your new G100!

IN CASE OF PROBLEMS:

1. The G100 gyro is designed and manufactured by Arcamax, Inc.

2. You may call Arcamax ((618) 453-4428) with technical questions or for issues of

repair.

OWNER'S MANUAL

NOTE: PLEASE READ MANUAL

COMPLETELY BEFORE OPERATION

INTRODUCTION:

CONGRATULATIONS!!! Your decision to purchase the FMA Direct G100 piezo gyro assures

you of the highest standards of design available to the R/C industry at an affordable price. The

G100, designed by Arcamax, Inc., and distributed exclusively by FMA Direct, is designed for use in

high performance helicopters and aircraft. Due to its solid state piezo sensor, unique temperature

compensation circuitry, and precision switching voltage regulator, it offers performance unsurpassed

by gyros from other manufacturers. The G100 operates as a standard "rate" gyro, or, if used in

conjunction with a programmable transmitter, proper mixing setups will allow the G100 to be

configured as a "stick priority" gyro.

Although intended primarily for helicopter use, the small size, low weight, low current

consumption and high sensitivity make the G100 ideal for scale aircraft, ducted fan models, and

experimental aircraft such as VTOL.

Piezo gyros are a significant technological advance over the old motor gyros. The absence of

moving parts greatly decreases current consumption, extending both run time and the life of the

gyro. Furthermore, their low mass increases responsiveness. It is important to understand that a

piezo crystal is fragile. Special precautions should be taken when installing and using your

new gyro. Please read the manual completely before attempting to install and fly your new G100.

SPECIFICATIONS:

SIZE: 1.53" X 1.45" X .81"

WEIGHT: 1.0 OZ.

OPERATING VOLTAGE: +4.0V TO +6.5V

CURRENT DRAW: 20 mA (max)

OPERATING TEMP: 23°F - 155°F (-5°C - 70°C)

SERVO PULSE WIDTH: .75 - 2.25 mS

SENSITIVITY: 1/10°per second

FMA, Inc.

5716A Industry Lane

Frederick, MD 21704

Sales: (800) 343-2934 -Technical: (301) 831-8980

PACKAGE CONTENTS:

1. FMA Direct G100 Piezo Gyro. (See TABLE 1 below for system compatibility)

2. Owner's Manual.

TABLE 1 RECEIVER COMPATIBILITY SERVO COMPATIBILITY

G100 Model #: ACE AIR FUT HITEC JR ACE AIR FUT HITEC JR

G100A 9NO! YES NO! NO! NO!

G100F 99YES NO! YES YES YES

G100J 99NO! NO! NO! YES YES

G100FJ 9999YES NO! YES YES YES

PREPARATION:

•INSTALLATION, RECEIVER AND SERVO CONNECTION

1. The G100 is several times more sensitive than standard motor gyros in terms of

responsiveness. To realize this improved sensitivity in your model, FMA Direct

recommends the use of a high quality, ball bearing servo with fast response. A good

candidate is the FMA Direct model S700 servo. In addition, linkages between the

servo and the control surfaces must have absolutely zero slop. Replace any ball links

or horns that show indications of slop or fatigue. Care must be taken when installing

the gyro to isolate the electronics from vibration as much as possible. The G100

should be installed with servo tape that is a minimum of 1/16" thick, 1/8" is preferred.

The gyro mounting surfaces should be extremely rigid - mounting the gyro to a floppy

object will cause reduced sensitivity or could cause failure of the product due to

excess vibration. Never mount the gyro near any sources of heat such as the engine

or the exhaust. An excellent location for mounting the gyro would be under the

canopy next to the radio gear.

2. IMPORTANT: The top of the G100 is labeled "INSTALL THIS SIDE UP!". Care must

be taken to install the gyro in accordance with this label. Failure to do so will prevent

the gyro from operating. The sensitive axis of the gyro runs parallel to the face of the

gyro (the side containing the color portion of the case label). The gyro will detect

rotation on any axis parallel to the sensitive axis. When mounting the gyro in a

helicopter to stabilize the yaw axis, the sensitive axis must be seen as cutting straight

through the main rotor blades of the helicopter.

3. When hooking up the gyro to your servo and to your receiver, use TABLE 1 to check

equipment compatibility. Note that it is possible to interface JR or Hitec servos with

Futaba style channel leads. Be sure that the Brown or Black leads of each of the

connectors are aligned to one another. Model G100FJ will allow for the maximum

possibilities of interfacing the gyro to different equipment types. You may mix and

match Futaba and JR servos, but neither may be used in combination with Airtronics

servos as the voltage polarity is incompatible and a short circuit will be produced

should the two be interfaced.

4. Connect the OUT lead to the servo, the IN lead to the desired channel on the receiver

and, if desired, the AUX lead to an auxiliary channel on the receiver.

•BENCH TESTING THE GYRO

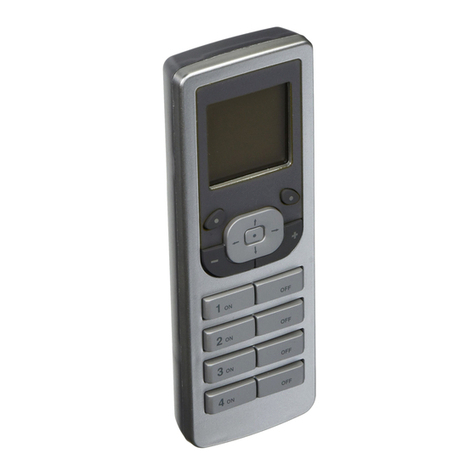

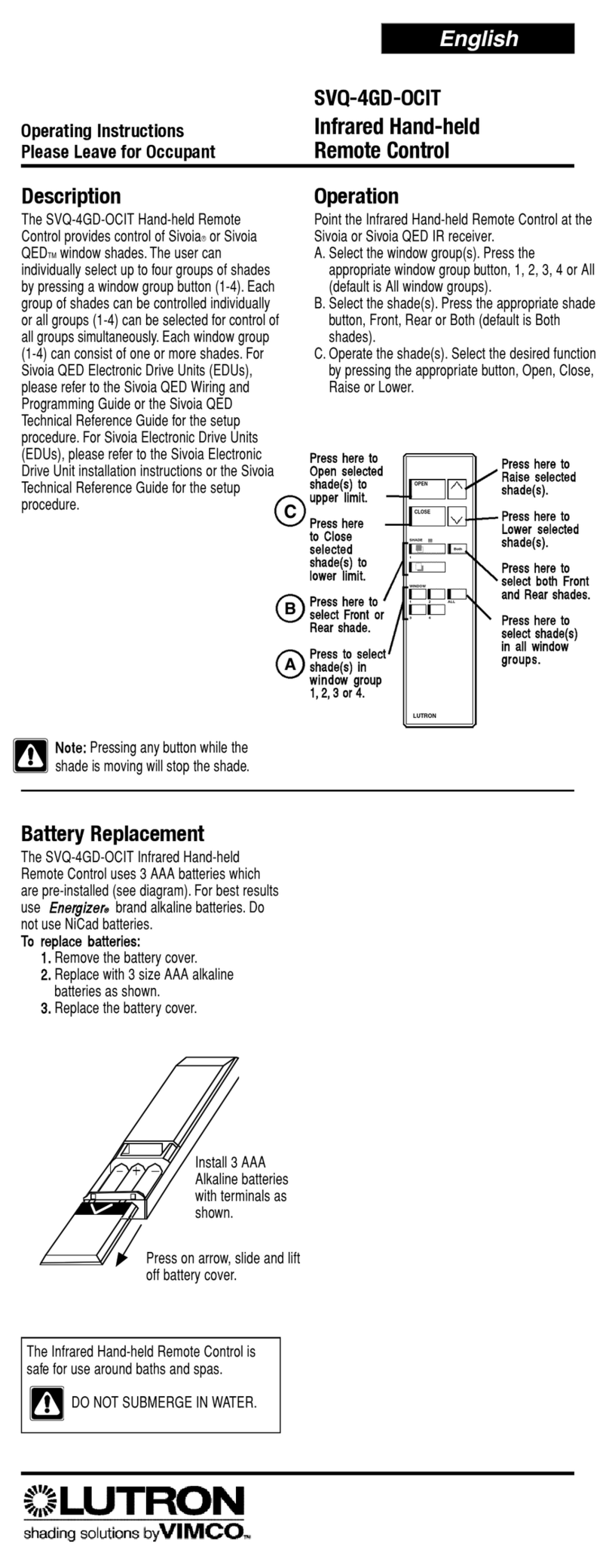

Referring to FIGURE 1, set the program mode dip switches as shown. The POT/RMT switch

should be closer to POT and the REV/NRM

switch should be closer to NRM. Use a

small screw driver to change the settings on

the dip switches if necessary. Bench test

the gyro by turning on the transmitter and the

receiver at this time. After 15 seconds, the

servo connected to the gyro will center. In

normal operation, the model must be

absolutely stationary for 5 seconds every

time the receiver is powered up. If this

procedure is not followed, trim changes will

result from flight to flight. Move the model

about the sensitive axis (or control axis).

The servo should move as the model is

rotated.

If no movement is obtained:

a) re-verify that the gyro is in "trim pot gain" mode (explained in detail later) by adjusting

the dip switches as shown in FIGURE 1.

b) turn the gain control trim pot to maximum sensitivity (fully clockwise).

If still no movement occurs, check wiring and battery voltage. If still no movement occurs,

contact FMA Direct customer service.

If movement occurs, move the model about the other axis. You may notice some movement

in the servo but it should be substantially less than when moved about the sensitive axis.

•SETTING THE DIRECTION

Once you are satisfied that the gyro is operational, the correction direction must be set. With

the radio on, move the model sharply about the control axis. Notice the movement in the

control surface or tail rotor. The direction of the control surface should counteract the

direction of rotation. If it does not, change the setting of the program dip switch marked

REV/NRM. This setting is extremely important as failure to set the direction switch will

result in loss of control of your aircraft. If you are unsure about how to determine this

setting, please talk to someone who can help you.

MODES OF OPERATION:

•TRIM POT GAIN MODE: Trim pot gain is useful if several gyros are on a model or an

auxiliary channel is not available. When using trim pot gain, the gain select dip switch must

be in the POT position. The gyro's gain can now be controlled by adjusting the gain control

trim pot. Turning the pot clockwise causes the gyro to be more sensitive. The AUX input has

no effect when in this mode of operation and may be disconnected.

•REMOTE GAIN MODE: Remote gain mode is used whenever gain control is to be applied

remotely from the transmitter. When using remote gain, the gain select dip switch must be in

the RMT position. The gain control trim pot will be defeated in remote gain mode.

•STICK PRIORITY: Stick priority operation is easily established using a computer radio. A

standard rate gyro at hover keeps the tail from swinging by applying negative feedback. The

problem is when the pilot desires to spin the tail, the gyro senses this and tries to compensate

by applying opposite tail rotor, thus canceling the pilot's command. The result is a slow rate

of rotation about the axis. With a stick priority gyro, the gyro's effect is reduced when the pilot

commands a turn, hence, forcing "stick priority". With a stick priority gyro, a helicopter can be

set up to spin as fast as the pilot wants while still retaining 100% stability at hover. It is

important to note at this time, that stick priority is not recommended for the beginning

helicopter pilot because it makes the aircraft overly sensitive to stick motion.

Setting Up Stick Priority: To set up your transmitter for stick priority, perform the following:

a) Make sure that the G100 is programmed for Remote Gain operation by setting the

POT/RMT dip switch to RMT setting.

b) Set up a mix so that as the stick is moved off center, the gain is reduced.

c) Make the rudder channel the master and the gain channel the slave.

d) Mix +100% for right rudder and -100% for left rudder.

e) Power up the radio and move the model about the control axis and notice the gyro

sensitivity.

f) Continue moving the model about the control axis while at the same time adding

rudder inputs via the transmitter stick. You should notice a reduction in gyro sensitivity

as the stick approaches the limits in either direction.

g) If an opposite condition occurs (an increase in gyro sensitivity at stick limits), reverse

the mixing percentages. That is, mix -100% for right rudder and +100% for left rudder.

h) You may wish to adjust the mix percentages to tailor performance to your specific

requirements. The mixing percentages determine how "fast" the gain is reduced while

the gain control knob or switch on the transmitter determines the total amount of gain.

GAIN

AUX

IN

OUT

RMTNRM

POT

REV

LEADS

MADE IN

U.S.A. BY

ARCAMAX

GAIN CONTROL TRIM POT

PROGRAM MODE DIP SWITCHES

1. POT/REMOTE

2. REVERSE/NORMAL

3 LEADS

FUNCTION

MARKED ON

CASE LABEL

FIGURE 1

This manual suits for next models

4

Other FMA Direct Remote Control manuals