Owner & Safety Manual

En-3 D.403.000.V4

OUTLAND LIVING™FIRE TABLE OWNER & SAFETY MANUAL

LP CYLINDER:

All LP cylinders to be used with this appliance must be:

a. Constructed and marked in accordance with the

specifications for LP-gas cylinders Standard, CAN/CSA

B339, Cylinders, Spheres and Tubes for the Transportation of

Dangerous Goods.

b. Provided with a listed overfilling prevention device.

c. Provided with a cylinder connection device compatible with the

connection for outdoor cooking appliances.

d. Only a 20 lb. (9 kg) LP gas cylinder is to be used for this

appliance, approximately 18” (46 cm) high & 12” (30 cm)

diameter.

e. The use of an approved LP gas cylinder stabilizer, such as the

one included, must be used when using this appliance in order

to prevent the LP gas cylinder from tipping over.

ENCLOSURES FOR SELF-CONTAINED

LP GAS SYSTEMS:

An enclosure for an LP-gas cylinder shall be ventilated by openings

at both the upper and lower levels of the enclosure. This shall be

accompanied by one of the following:

a. One side of the enclosure shall be completely open; or

b. For an enclosure having four sides, a top, and a bottom:

At least two ventilation openings (see Part IV, Definitions) shall be

provided in the sidewalls of the enclosure, located within

5 in (217 mm) of the top of the enclosure, equally sized, spaced

at a minimum of 90 degrees (1.57 rad), and unobstructed. The

opening(s) shall have a total free area of not less than 1 in2per lb

(14.2 cm2per kg) of stored fuel capacity.

Ventilation opening(s) shall be provided at floor level of the

enclosure and shall have total free area of not less than 1/2 in2per

lb (7.1 cm2per kg) of stored fuel capacity. If ventilation openings

at floor level area are in the side wall, there shall be at least two

openings. The bottom of the openings shall be 1 in (25.4 mm) or

less from the floor level and the upper edge no more than 5 in

(127 mm) above the floor level. The openings shall be equally sized,

spaced at a minimum of 90 degrees (1.57 rad), and unobstructed.

Every opening shall have minimum dimensions so as to permit the

entrance of a 1/8 in (3.2 mm) diameter rod. Ventilation openings in

sidewalls shall not communicate directly with other enclosures of

the appliance.

CONNECTION:

1. Be sure the cylinder valve and appliance valves are “off”.

2. Place full LP gas cylinder on tank stabilizer ring. Secure the base

of the LP gas cylinder by hand tightening the wing-nut collar.

3. Center the nipple in the cylinder valve and hold in place.

4. Using the other hand, turn the hand wheel clockwise until there

is a positive stop. Do not use tools.

5. Hand tighten only. When making the connection, hold the

regulator in a straight line with the cylinder valve, so as not to

cross thread the connection.

6. Leak test the connection.

LEAK TEST:

1. DO NOT USE OR PERMIT SOURCES OF IGNITION IN THE

AREA WHILE DOING THE LEAK TEST.

THIS INCLUDES SMOKING.

2. Leak testing should be done once per year or whenever the

LP gas cylinder or any other gas system part is taken apart,

serviced or replaced, whichever is more frequent.

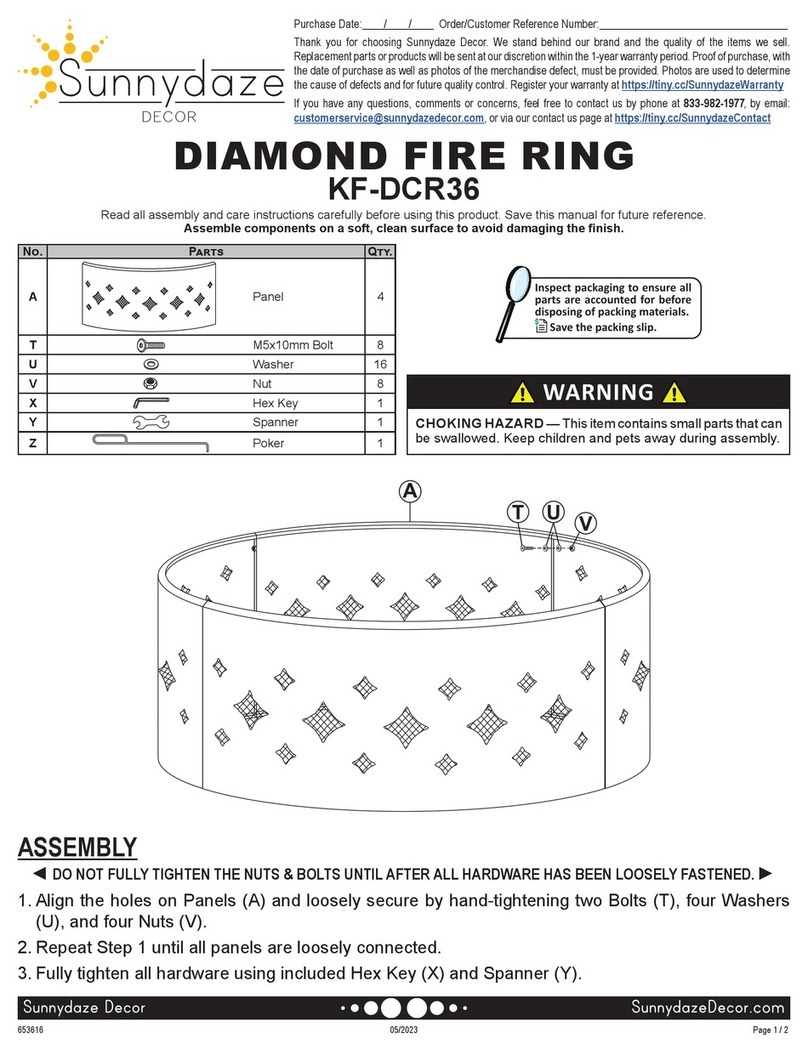

3. Ensure all gas system coupling joints are tight and properly

attached.

4. Prepare a leak testing solution of half liquid detergent and half

water.

5. Apply the solution to the LP gas delivery system at points as

shown in illustration indicated on page 4.

6. The leak(s) must be stopped by tightening the loose joints,

if possible, or by replacing the faulty parts(s) with the part(s)

recommended by the appliance manufacturer.

Should you have any questions or comments regarding this

appliance, please do not hesitate to contact FMI Brands Inc. at

(888) 514-1663 or E-Mail to info@outlandliving.com

THE APPLIANCE IS NOT TO BE USED UNTIL ANY LEAK IS

CORRECTED.