FMT DIESELFI Series User manual

84 882 A801 GB

DIESELFIxx / DIESELMAxx

with NUMERIxx3 oval gear meter, mechanical

60 l/min · 100 l/min

230 V-1~AC

2

GOperating instructions for DIESELFIxx/ DIESELMAxx

Contents

General Information1. __________________________________________________________________2

Usage Stipulations1.1. ___________________________________________________________________2

Construction and Functional Description1.2. _________________________________________________2

Application Range1.3. ___________________________________________________________________3

Operational Area Requirements1.4. ________________________________________________________3

General Safety Advice2. ________________________________________________________________3

Information on safety at work2.1. __________________________________________________________3

Signs and symbols used in the safety instructions2.2. __________________________________________3

Risks when Working with the Diesel Pump2.3. ________________________________________________4

Installation3. _________________________________________________________________________4

Wall mounting3.1. ______________________________________________________________________4

Mounting the hose support3.2. ____________________________________________________________6

Installing the Siphon Protection3.3. ________________________________________________________6

Operation4. __________________________________________________________________________6

Safety4.1. _____________________________________________________________________________7

Servicing5. ___________________________________________________________________________8

Replacing worn blades5.1. ________________________________________________________________8

Repairs/Service6. ______________________________________________________________________9

Spare parts and accessories7. ____________________________________________________________9

EC Declaration of Conformity8. __________________________________________________________9

Exploded view9. _____________________________________________________________________10

1. General Information

1.1 Usage Stipulations

The diesel pump is to be used only for the delivery of diesel fuel.

Danger!

Never use it to deliver explosive uids like petrol, or other uids with similar ashpoints!

The diesel pump must be connected to a 230 V electrical supply.

To ensure that usage stipulations are met, read through the operating instructions completely before

using the pump and observe all stipulations.

Any departure from the usage stipulations (other uid media, use of force) or user modications

(changes, use of non-original parts) can be dangerous and are considered as non-stipulated usage.

The user is liable for any damage resulting from non-stipulated use.

For any repairs to electrical components, the appropriate safety and test requirements are to be

observed.

Only original replacement parts are to be used for any repairs, otherwise the warranty will be

invalidated.

1.2 Construction and Functional Description

The diesel pump can be tted with a variety of FMT accessories.

To prevent environmental damage the diesel pump is tted with a siphon protection system. This

means that if the discharge hose is damaged while the pump is stopped, siphon action will not empty

the tank.

The fuelling station provides automatic shut down of the pump when the automatic nozzle valve is

replaced in the holder.

3

Operating instructions for DIESELFIxx/ DIESELMAxx G

1.3 Application Range

The diesel pump is suitable for the delivery of diesel and heating oil only when they are not heated

above their ash points.

The temperature of the delivery uids must be between –10 °C and +40 °C. The temperature limits

must not be exceeded.

Because the motor and switch are not explosion-protected, the pump must not

be operated in an explosion risk area.

be used to deliver fuels of danger classication A I, A II and B.

1.4 Operational Area Requirements

Heating oil and diesel are water polluting substances. Therefore the country specic rules and

regulations regarding the delivery and storage of such uids must be obeyed.

According to § 19g WHG (Germany) the lling installation must be so constructed and built,

maintained and operated, such that water pollution and/or any other environmental damage is

prevented.

The operator of such an installation is, according to § 19i WHG (Germany) responsible for continuous

monitoring to ensure compliance with the above stated requirements at the installation.

2. General Safety Advice

2.1 Information on safety at work

The diesel pump has been designed and manufactured according to the health and safety

requirements of the relevant EC guidelines.

Nevertheless, there can still be risks if the product is not set up or operated as stipulated.

Therefore, before using the diesel pump, read these operation instructions and pass them on to other

users.

When operating the diesel pump, the local safety and accident prevention rules and regulations always

apply, as well as the safety advice in the operating instructions.

2.2 Signs and symbols used in the safety instructions

The safety advice provided in these operating instructions is categorised according to

dierent danger levels. The dierent danger levels are identied within the instructions by the fol-

lowing symbols and identifying words:

Pictogram Keyword Consequences of failure to comply with the

safety instructions

Danger Death or very serious injury

Caution Possible slight or not serious injury or material damage

In addition, another symbol is used to indicate general tips about using the product.

Pictogram Keyword Meaning

Tip Background information or tips about how to use the product

4

GOperating instructions for DIESELFIxx/ DIESELMAxx

2.3 Risks when Working with the Diesel Pump

Danger!

Never work on a pump that is running!

Mount or remove attachments and accessories only when the pump is switched o.

For your own safety, disconnect the pump from the power supply.

Danger!

Do not pump contaminated uids!

Take special care to ensure that there is no contaminant in the uid to be pumped.

Install a strainer on the suction pipe.

Danger!

Damaged attachments and accessories can lead to personal injury and material damage!

Suction and pressure pipes must not be kinked, twisted or stretched.

Attachments and accessories must be checked for wear, splits or other damage at all times.

Damaged attachments and accessories must be replaced immediately.

With reference to the period of use, please note the details in ZH 1/A45.4.2 or DIN 20066

Part 5.3.2.

Caution!

Spilled fuel can result in environmental damage!

Local and country rules and regulations relating to domestic water supplies and fuel

storage must be obeyed.

Caution!

If the diesel pump is incorrectly installed, or used for a purpose other than that originally

intended for, it can result in personal injury or damage to equipment!

Before starting to use the diesel pump, read through these operating instructions carefully and

completely.

3. Installation

3.1 Wall mounting

When installing the pump, ensure that it is mounted on a stable surface. Select a secure location

(protected from water spray, damage and theft).

Loosen screw (Item 36) and remove reset wheel (Item 34, 35).

Remove the adaptor (Item 42) on the pressure side.

Loosen the screws on both side walls. The cover can now be removed (see Fig. 3-1).

5

Operating instructions for DIESELFIxx/ DIESELMAxx G

Figure 3-1: Removal of cover

4 screws (not supplied) with diameter less than 9 mm are required to attach the fuelling station unit. Select

suitable screws according to the surface on which the unit is to be mounted..

Screw in the screws so far, that between screw head and wall approx. 5 mm of space remains.

Hang the housing onto the screws, then tighten screws through the openings in the rear panel.

Remove the plastic plugs from the suction and discharge junctions.

Connect hose to the suction connector. Attach a strainer to the end of the suction hose.

Connect the nozzle valve and swivel joint to the pressure hose and hang them in the pistol holder on the

front panel.

Caution!

Nozzle valve must be hung up, in order to prevent inadvertent starting of the pump when

connecting to the power supply.

Connect the pump to a 230 V supply through the power connector.

Lift the nozzle valve briey from the holder to check if the pump starts up. Actuate the rocker switch on

the pump if the pump does not start. Return the fuel nozzle to the holder.

Screw the main assembly and cover together.

Ret the adaptor on the pressure side.

Connect lter and delivery hose to the delivery connector.

Mount the reset wheel for the meter.

Connect the drum adapter to the suction side.

The pump is now ready for operation.

Tip

Pay attention to cleanliness and the acurate connection of the accessories when assembling.

Use suitable sealing and adhesives (for example Teon tape).

6

GOperating instructions for DIESELFIxx/ DIESELMAxx

3.2 Mounting the hose support

The hose support is pre-assembled.

Loosen the two screws and pull out the hose support, appr. 100 mm.

Tighten the screws.

Figure 3-2: Mounting the hose support

3.3 Installing the Siphon Protection

Remove cover as in chapter 3.1.

Install the siphon protection according to the manual of the Diesel pump 60 l/min resp. 100 l/min.

Re-assemble the cover in reverse sequence.

Tip

Ensure when installing the siphon protection system that the end of the hose is not immersed

in the uid. If it is, the siphon protection system will not work!

4. Operation

Check the diesel pump and installed accessories for completeness and damage. Replace any damaged

components immediately. Never use a pump if damaged.

Check the suction lter for damage each time the tank is lled/emptied and replace it if damaged.

Never operate the pump without the suction lter, because the pump will not be protected against

contamination by foreign bodies.

Tip

To ensure that the tank can be completely emptied, the suction hose must reach to the bottom

of the tank.

Position the nozzle valve in the container to be lled.

100 mm

7

Operating instructions for DIESELFIxx/ DIESELMAxx G

Caution!

Never operate the pump without delivery uid. There is a danger of your diesel pump being

damaged if operated dry.

Squeeze the nozzle valve control lever according to the delivery ow required, or lock it in„automatic“ for

maximum delivery rate.

Caution!

Tank pump does not switch o automatically, therefore when lling, never leave the pump

running without supervision.

To nish a pumping session, release the nozzle valve control lever.

The pump then operates in the bypass mode. Ensure that under no circumstance the pump runs in this

mode longer than 2 minutes. Switch the pump o after re-fuelling as soon as possible. This is done by

hanging up the nozzle valve into the pistol holder.

Caution!

Danger of product damage

The power source must be the correct voltage for the pump type.

For operation of the oval gear meter NUMERIxx3 please refer to the operating manual for the

NUMERIxx3.

4.1 Safety

To prevent unauthorized usage of the fuelling station, the nozzle valve can be secured with a commercial

padlock (see Fig. 4-1).

The pin diameter of the lock may be 9 mm max., the distance inbetween the pins minimum 30 mm.

Figure 4-1: protection with padlock

8

GOperating instructions for DIESELFIxx/ DIESELMAxx

5. Servicing

5.1 Replacing worn blades

Danger!

Never work on a pump that is running!

Assemble or disassemble accessories only with switched o pump.

For your own safety additionally isolate the pump unit from the power supply.

Remove cover as in chapter 3.1.

Place a suitable collecting bowl into the housing. During the disassembly small quantities of Diesel can

leak out.

Open swage tting between pump and meter and remove meter.

Loosen pump nuts and remove the pump.

Caution!

Spilled fuel can result in environmental damage

Local and country rules and regulations relating to domestic water supplies and fuel

storage must be obeyed.

Figure 5-1: Pump unit rear view (illustration shows no. 23 420)

Remove worn blades as in the operation manual of the Diesel pump 60 l/min resp. 100 l/min.

Replace in reverse order.

9

Operating instructions for DIESELFIxx/ DIESELMAxx G

6. Repairs/Service

The diesel pump was developed and produced according to the highest quality standards.

Should a problem develop, despite all quality controls, please contact our customer service:

FMT Swiss AG

Tel +49 9462 17-216

Fax +49 9462 1063

7. Spare parts and accessories

Diesel pump 60 l/min, No. 23 100

Diesel pump 100 l/min, No. 23 102

NUMERIxx3 oval gear meter, three-digit, No. 23 192 889

Automatic nozzle valve for Diesel, 60 l/min resp. 100 l/min, with German design approval, No. 23 168

resp. 23 160

Automatic nozzle valve for Diesel, 60 l/min resp. 100 l/min, No. 23 176 resp. 23 178

8. EC Declaration of Conformity

We hereby declare that the product described here, its concept and construction, including this particular

model, complies with the EC requirements. Any change to the product, not approved by us, will invalidate

the declaration.

Product Description DIESELFIxx

Product Type Pump unit for diesel

Year of Manufacture see nameplate

Applicable EC-Directives EC-Low Voltage Directives (73/23/EWG)

EC-Directives Electro-magnetic Compatibility (89/336/EEC) -

93/31/EEC

Corresponds to the international

standards

(and to their changestandards)

EN ISO 12100-1

EN ISO 12100-2

EN 294

EN 61000-6-1

EN 61000-6-3

EN 60204-1

EN 60335-1

EN 60335-2-41/A1

EN 60335-2-75

Applicable National Standards DIN VDE 0843 T1

VDE 0110

VDE 0113

VDE 0630

12.06.2013 FMT Swiss AG

Dipl.-Ing. Rudolf Schlenker

10

GOperating instructions for DIESELFIxx/ DIESELMAxx

9. Exploded view

No. Quantity Description DIESELFIxx DIESELMAxx

1 1 Sheet metal assembly for DIESELFIxx NUM 83 791

1 1 Sheet metal assembly for DIESELMAxx NUM 83 792

2 4 Washer DIN1256,4x12x1,6 - Steel zn 04 516 04 516

3 10 Screw DIN 933 M6x20 - 8.8 zn 02 886 02 886

4 2 Countersunk screw DIN 7991 M3x22 83 966 83 966

5 2 Screw DIN 912 M3x16 - zn 83 969 83 969

6 2 Washer DIN 433 6x3,2x0,55 - zn for M3 83 974 83 974

7 1 Arm 85 040 85 040

8 1 Switch housing 83 810 83 810

9 1 Switch cover 83 576 83 576

10 1 Microswitch MZX1 072 308 85 042 85 042

11 1 Pressure spring 1x8,5x30 00 668 00 668

12 1 Grommet NBR 43x3 Gufero Code 241092 83 898 83 898

13 7 Nut DIN 985 M6 - A2K 00 044 00 044

14 1 Foot for DIESELFlxx plastic 83 177 83 177

15 0,15 Threaded rod M10 galvanized, length = 1000 mm 83 176 83 176

16 1 Nut DIN 985 M10 - A2K 87 763 87 763

17 1 Drum-Adapter G 2“ a-G 1“ a - Alu 19 524 19 524

18 4 Shim DIN 9021 galvanized steel 6.4x18x1.6 87 126 87 126

19 4 Spacer SW13 L22 83 811 83 811

20 1 Diesel pump 60 l/min 230 V-1~AC-50 Hz-EUS-blank 23 100 091

20 1 Diesel pump 100 l/min 230 V-1~AC-50 Hz-EUS-blank 23 102 091

21 4 Washer DIN 433 15x8,4x1,6 - zn 88 315 88 315

22 1 Manual for NUMERIxx oval gear meter, mechanical 82 550 82 550

23 1 Threaded adaptor G 1“ i - G 1“ a 89 071

23 1 Threaded adaptor G 1“ a - G 1“ i Suction 100 L 83 813

24 4 O-Ring-NBR 70-29x2,5 89 111 89 111

25 1 Ground strap 170x4 mm M6-M6 85 063 85 063

26 1 Lock nut M12x1.5 mm for cable gland 85 079 85 079

27 1 Cable gland M12x1.5 mm, polyamide 85 078 85 078

28 1 Cable for DIESELFIxx 84 239 84 239

29 1 Threaded nipple G 1“ BAL 85 358 85 358

30 1 Flat connector DIN 46245 Klauke 85 069 85 069

31 4 Spade connector DIN 46245 Klauke 730 V 85 062 85 062

32 3 Swaged coupling - Al-G 1“ a - G 1“ i NW 25 23 218 23 218

33 1 NUMERIxx- turned 90° - without hood - for

DIESELFIxx/-maxx

23 192 889 23 192 889

34 1 Adapter for NUMERIxx 84 287 84 287

35 1 Adjusting wheel 88 243 88 243

11

Operating instructions for DIESELFIxx/ DIESELMAxx G

No. Quantity Description DIESELFIxx DIESELMAxx

36 1 Cheese head screw M3x25 DIN 912 A2K 8.8 83 401 83 401

37 1 Nozzle support for Dieselxx 85 036 85 036

38 1 FMT display foil for DIESELFIxx-DIESELMAxx 84 285 84 285

39 1 Diesel-exchange lter 30 µm - 100 l/min - G 1½“ i 23 209 23 209

40 2 Elbow 90°-Al-DN 19 G 1“ a - G 1“ a - DK 60° BES 85 370 777 85 370 777

41 8 Countersunk screw DIN 7991 M4x10 - 8.8 zn 84 012 84 012

42 1 Threaded adaptor G 1“ a - G 1“ i output 83 812 83 812

43 1 Filter adaptor 23 207 23 207

44 1 Screw cap G 1“ 89 483 89 483

45 1 Nozzle valve G 1" i - 60 l/min Alu 23 176

45 1 Nozzle valve G 1“ i - 100 l/min Alu 23 178

46 1 Instructions Diesel pump 60 l/min on CD 89 349

46 1 Instructions Diesel pump 100 l/min on CD 89 351

47 1 Manual for DIESELFIxx/DIESELMAxx with NUMERIxx,

mechanical

84 882 84 882

48 1 Threaded nozzle, M5 x 4 GTS 54 MSV 89 278 89 278

49 1 Seal 7,76x5,4x1 - PVC 89 279 89 279

50 3 LDPE- hose 6x1 mm, black 80 327 80 327

51 2 Thermal label H 90 - B 165 mm, neutral unprinted 87 998 87 998

52 1 Check valve G 1“ i - G 1“ i 19 892 19 892

53 1 Strainer G 1“ a 23 180 23 180

54 1 Disposal information FMT D-GB-F-I-E-P-GR-NL-S-PL-

RUS

00 511 801 00 511 801

55 1 Cable ties HELLERMA T3OR - N66 NA-3,5 x L

141-transparent

87 561 87 561

56 1 Warning„For Diesel + Heating oil“ label 38x92,

11-languages

89 297 89 297

57 1 Low friction-swivel joint DN 25 G 1“ i-G 1“ a 19 625 19 625

Tab. 9-1: Legend to Fig. 9-1

12

GOperating instructions for DIESELFIxx/ DIESELMAxx

Figure 9-1: Exploded view of the pump unit DIESELFIxx/DIESELMAxx

H

25

13

Operating instructions for DIESELFIxx/ DIESELMAxx G

FMT Swiss AG

Fluid Management Technologies Swiss AG

Gewerbestraße 6

6330 Cham / Schweiz

Tel. +41 41 712 05 37

Fax +41 41 720 26 21

info@fmtag.com

www.fmtag.com

This manual suits for next models

1

Table of contents

Other FMT Water Pump manuals

Popular Water Pump manuals by other brands

KSB

KSB Emporia MB Installation & operating manual

LEAD FLUID

LEAD FLUID YZ Series operating manual

ABS

ABS Piranha S10/4W-50 Installation, Operating and Maintenance Instruction

Agora-Tec

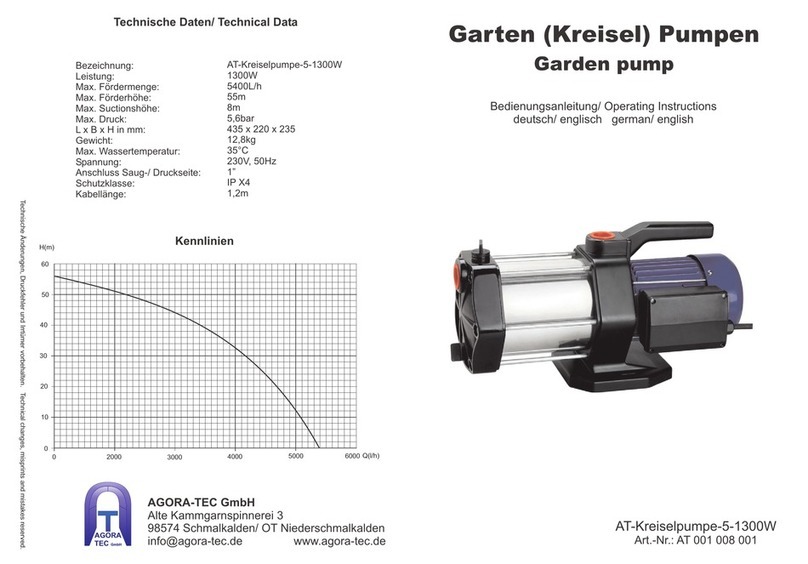

Agora-Tec AT 001 008 001 operating instructions

Ruris

Ruris MP100 manual

Zhejiang

Zhejiang JYM1.6 Series operating instructions

Xylem

Xylem Flowtronex SILENT STORM instruction manual

Becker

Becker O 5.10 operating instructions

Aqua

Aqua DGTEC CD Instruction and maintenance manual

Stübbe

Stübbe NM Series Original operating manual

Grindex

Grindex MINEX Installation, Care and Maintenance

Pontec

Pontec PondoAir Set 3600 operating instructions