dGdoser Model INSTRUCTION AND MAINTENANCE MANUAL

Programmable digital peristaltic pump ENGLISH

ADSP7000634 rev. 1.3 23/09/2020 3/36

CONTENTS

1.0 INTRODUCTION ……………………………………….…………………………………………………………………………..…………… 4

1.1 Warnings …………………………………………………………………...………………………….……………….......………………. 4

1.2 Standards of reference …………………………………………………………………………………………………………………….. 4

1.3 Technical features ….. ……………………………………………………………………………………….….......…………………….. 5

1.3.1 Electrical features……………………….………………………………………………………………….…………………….. 5

1.3.2 Performance …………….……………………….……………………………………………………………………………… 5

2.0 INSTALLATION ………………………………………………………………………………………………….……………………………… 5

2.1 General rules………. …………………………………….………………………….…………………………………..….……………….. 5

2.2 Installation kit…..……………………………………………………….……………………..……………………………….……………… 5

2.3 Assembly…………….………………………………………………………………………….……………………….…………..………… 7

2.3.1 Conductivity probe connection ……………………………………………………………………….…………………………... 7

2.4 Electrical connections …………………….………..………………………………………………………..……………….……………… 8

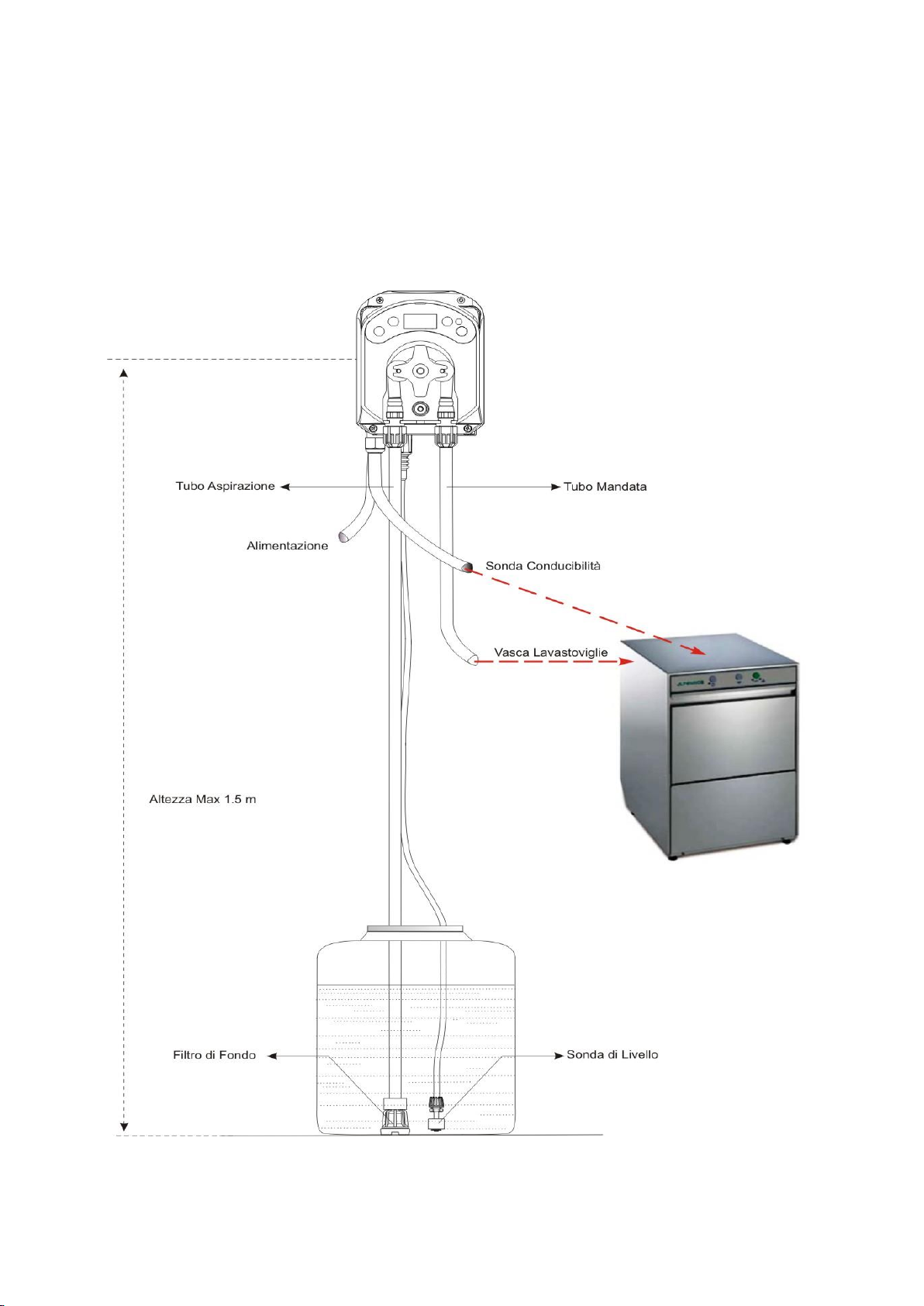

2.5 Hydraulic connections. ………..…………………………………………………………………………………………………………….. 9

2.5.1 Installation for dosing liquid detergent ……………………………….………………………………………………………….. 9

2.5.1 Installation for dosing solid detergent ……………………………….…………………………………………………………… 10

3.0 PROGRAMMING ………..………..……..……………………….……………….………………………………………................................ 11

3.1 Main Features ……………..….…………………………………………..…………...………………………….…………………………..11

3.2 Quick Start-Up ………….………………………………………………….……………………………………..…………….……………..14

3.3 Advanced Programming……………………………..………………………………………………………………………………………. 15

3.3.1 Setting the Language……………………………..………………………………………………………………………………… 15

3.3.2 Setting the Set-point ……………………………………………………………………………………………………………….. 15

3.3.3 Displaying and Resetting Statistics ………………………………………………………………………………………………. 16

3.3.4 Setting the Temperature ………………………………….………………………………………………………………………. 17

3.3.5 Pump Calibration ………… ……………………………………………………………………………………………………….. 17

3.3.6 Resetting Default Parameters………………………………………………………………………………………………………18

3.3.7 Settings Menu………………………………………………………………………………………………..…..………………….. 18

4.0 ALARMS …………………………..…………………....…………………………………………………………………………..………..…… 19

4 1 Motor Alarm……………………………..…………………………………………………………………..………………………………… 19

4.2 Maintenance Alarm……………………………..………………………………………………………………….…………………………. 20

4.3 Level Alarm ……………………………..……………………………………………………………….…………………..……………….. 20

4.4 OFF Status Alarm……………………………..…………………………………………………………………..…………………………. 20

4.5 OFA Alarm……………………………..…………………………………………………………………..……………..…………............... 21

4.6 Temperature Alarm…………………………………………………………………………………………………………………………… 21

5.0 MAINTENANCE …………………………………..…………………….………..…………………………………………..………………….. 21

5.1 General Rules …….…………………………………………..…………………………………………………………………………….. 21

5.2 Periodic Maintenance………….…………….………………………………………………….…………………………………………... 21

5.3 Troubleshooting ………………….….…………………………………..…………………………………………………………………… 23

6.0 RETURNING MATERIAL TO THE AFTER-SALES

SERVICE………………………..……………………..…………………………………………………………………………………………………… 24

7..0 WARRANTY CERTIFICATE ………..………..………………………………………….……………….……………………………..……… 24

8.0 ATTACHMENTS ………………………..………………………………………………………………………………………………………. 25

ATTACHMENT A –OVERALL DIMENSIONS………………………………………………………………………………………………… 25

ATTACHMENT B –REFERENCE FIGURES………………………………………………………………………………………………….. 26

ATTACHMENT C –EXPLODED VIEWS………………………………..……………………………………………………………………… 27

ATTACHMENT D –CHEMICAL COMPATIBILITY TABLE……..…………………….……………………………………….………………29

ATTACHMENT E –DEFAULT PARAMETERS ………..…..………………………………………………………………………………….. 31

ATTACHMENT F –ACRONYM TABLE …….………..…..…………………………………………………………………………………….. 32

ATTACHMENT G –MENU LAYOUTS…. …….………..…..…………………………………………………………………………………… 33