DUCTILE IRON FLANGED GATE VALVE

FIGURE 751

FNW.COM We reserve the right to modify or improve the designs or

specifications of our products at any time without notice.

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

©2022 Ferguson Enterprises, LLC 0522 4108704

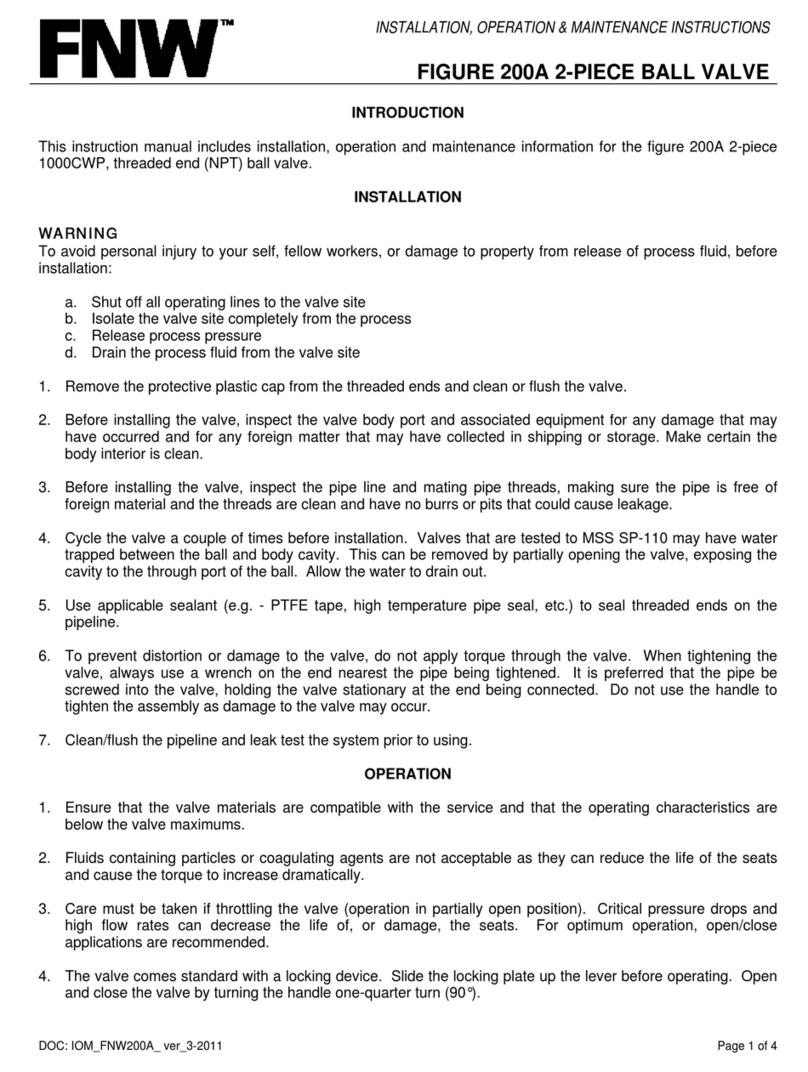

DISASSEMBLY AND ASSEMBLY

GATE VALVES

See Figure for the following disassembly and assembly

instructions. NOTE: All gate valves may not have the same

components listed below. Refer to the corresponding valve

drawing for a parts list. These steps are after the valve has been

removed from the pipeline.

DISASSEMBLY

• Turn the handwheel () to open the valve.

• Remove the bonnet screws ().

• Mark the body () and bonnet () flanges to hold them in place

during assembly.

• Lift the bonnet (), stem () and disc () assembly out of the

body (), taking care not to scratch the disc surface.

• Remove the bonnet gasket () from the valve.

• Remove the valve plate () from the lifting nut () of the valve stem

().

• Loosen the locking screw () on the handwheel lock nut ().

Remove the handwheel lock nut () from the valve stem nut

(), and then remove the handwheel () from the valve stem

nut ().

• Loosen the nut () on the gland bolt () to release the gland

(). Turn the valve stem counterclockwise from the bottom of

the valve cover () to remove the valve stem nut (), pull out

the valve stem (), and remove the valve stem nut () from the

valve cover ().

• Remove packing () using a suitable tool.

ASSEMBLY

• Thoroughly clean the inside of the valve and all parts. Remove

any limescale, oil, grease or other foreign matter. Wipe disc ()

with a cloth. Clean body () and bonnet () inside and outside

surfaces and all nuts and bolts.

• Put packing () into the packing groove of bonnet (), align and

center the packing gland () into the packing groove, put on

the gland bolts (), tighten the nuts () by hand, and carefully

pass the valve stem () through the valve Packing hole in cap

(), gland (), until the stem thread engages with stem nut ().

Slowly rotate the valve stem female () counterclockwise until

the valve stem () protrudes from the valve stem female ()

and passes through the top of the valve cover ().

• Put the handwheel () on the valve stem nut () and fix it with the

handwheel lock nut (), then lock it with the locking screw ().

• Put a new gasket () in the groove of the top flange face of the

valve body (), the gasket can be greased with butter.

Do not reuse the gasket.

Figure 5 Disassemby and assembly

• Install the valve plate () on the lifting nut () on the valve stem

() to complete the assembly of the valve cover (), valve stem

() and valve plate () and other components.

• Slowly place the bonnet (), stem () and disc () assembly into

the body (). Pay attention to prevent the surface of the valve seat

from being scratched, align the flange of the valve cover () with

the top flange of the valve body () according to the mark made

in advance, make sure that the gasket () does not extend out of

the groove of the top flange of the valve body, and then fasten

it with screws () , when tightening the screws, do so diagonally

until tight. See recommended torque values in Table .

• Tighten the gland nuts () alternately by hand.

• Use handwheel () to open and close the valve. The action

should be smooth throughout the stroke