FNW HP Series Manual

FNW.COM

©2021 Ferguson Enterprises, LLC 0721 2945816

We reserve the right to modify or improve the designs or

specifications of our products at any time without notice.

HIGH PERFORMANCE BUTTERFLY VALVE

FIGURE HPA

1

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

TABLE OF CONTENTS

1. Safety instructions ............................................. 2

2. Delivery................................................................. 2

3. Valve handling and storage ............................ 3

4. Valve installation ................................................ 4

5. Valve operation .................................................. 6

6. Troubleshooting...................................................7

7. Exploded view .................................................... 8

8. Periodic maintenance ......................................10

9. Recommended spare parts............................14

10. Disposal action ..................................................14

11. CE instructions...................................................14

Appendix A ...............................................................15

YOUR PIPING PRODUCTS SOURCE

Since FNW was established in 1979, we have been dedicated to providing quality products for industrial and

commercial applications. With a basic philosophy to provide a product suited to the needs of the end user, FNW

has built a product oering with an innovative approach to the market and has continued to grow its product

range to meet those needs. If you do not see the type or size of item needed for your project, please contact us

at 757-969-4974.

We continue to add products that may not be reflected in this publication. Therefore, please visit our web site at

fnw.com for updates and the latest additions to our product oering.

SCOPE

The purpose of this manual is to ensure that the valves

supplied are properly installed, handled, operated and

maintained to give trouble free performance.

This manual covers FNW high performance butterfly

valves from 2"–24" wafer and lug designs.

NOTES:

• Read the manual carefully before removal,

installation, maintenance or operation of

the valve.

• Refer to general arrangement drawings to

identify the design as valves may vary in

features and parts.

• Pay attention to cautions and

illustrationscarefully.

FNW.COM

©2021 Ferguson Enterprises, LLC 0721 2945816

We reserve the right to modify or improve the designs or

specifications of our products at any time without notice.

HIGH PERFORMANCE BUTTERFLY VALVE

FIGURE HPA

2

Fig. Sample nameplate

PROD. CODE:-

REF NO:-

SIZE (NPS):-

ASME BODY PR. CLASS:-

PR. AT 38°C (100°F):-

Pmax (Tallow):-

BODY/DISC:-

STEM/SEAT:-

SR. NO:-

TAG NO:-

MFG DATE:-

CHECK:

• Tag numbers and details of valves upon receipt.

• Valves thoroughly for any damages that may have occurred during transit.

• Condition of end protectors.

In case of any discrepancies in the above-mentioned details or discovery of any kind of damage to the valve

upon delivery, please contact a FNW or manufacturerrepresentative.

2. DELIVERY

2.1 HPA Butterfly Valves are shipped with the disc in

fully closed position for the protection of the disc.

2.2 The valve specification details are marked on the

nameplate and valve body. A typical nameplate is

shown in Fig. 1.

2.3 The valves are delivered with end protecting caps

to avoid damage of internals and flange facing.

2.4 Handwheels for gear operated valves are

packed separately in the same packing box. The

pin is attached to the gear box shaft using an

adhesive tape.

2.5 For lever operated valves, the hand lever is

either assembled with the valve or shipped loose

depending on size.

1. SAFETY INSTRUCTIONS

Do not exceed the valve pressure-temperature

ratinglimitations. Exceeding the pressure-temperature

rating limitations marked on the valve may result in

significant damage to the valve and personal injury. Users

of these valves should ensure that the process design

pressure-temperature is less than or equal to the rated

pressure-temperature of the valves. If required, user

should incorporate appropriate limiting and monitoring

devices in the system for safe operation of the valve.

Use the valve for specified application only. User to

ensure that the valve is used only for the specified

application as agreed between the manufacturer and

the purchaser.

Follow the safety rules and regulations. User must be

aware of all the safety rules and regulations related to the

environment in which the valve is to be used.

Do not disassemble the valve or remove it from the

pipeline while the valve is pressurized. Disassembling

or removing a pressurized valve will result in uncontrolled

pressure release. Always isolate the relevant part of the

pipeline, release the pressure from the valve and remove

the media before moving the valve. Be aware of the type

of media involved. Protect people and the environment

from any harmful or poisonous substances. Make

sure that no dust or dirt can enter the pipeline during

valve maintenance.

Beware of disc movement and keep hands, tools and

other foreign objects out of the valve opening while

valve is actuated. Disconnect supply sources and

make sure valve actuation is in “fail safe” state before

performing any work. Failure to do this may cause

damage and/or personal injury.

FNW.COM

©2021 Ferguson Enterprises, LLC 0721 2945816

We reserve the right to modify or improve the designs or

specifications of our products at any time without notice.

HIGH PERFORMANCE BUTTERFLY VALVE

FIGURE HPA

3

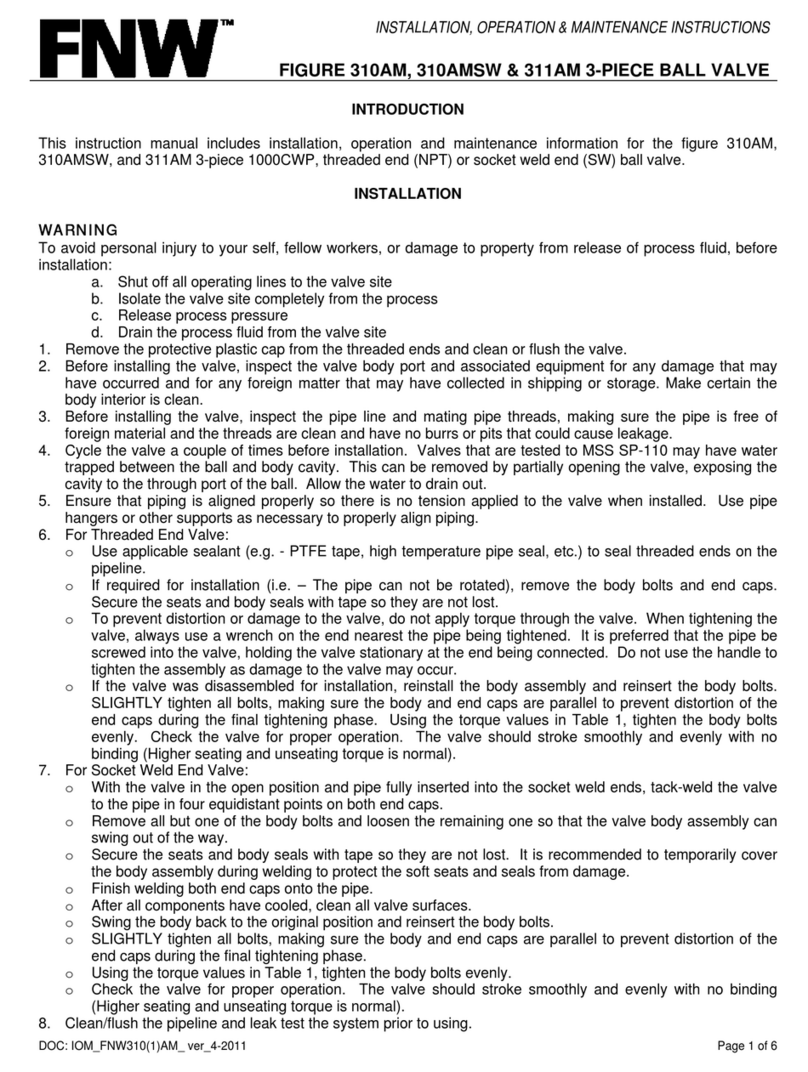

3. VALVE HANDLING AND STORAGE

3.1 HANDLING

3.1.1 Valve shall be properly supported and secured

before moving to prevent possible damage to

valve and property or harm to personnel.

3.1.2 Do not drag the valve on the ground during

transportation. A minimum of one-foot height

from the ground is recommended while moving

the valve.

3.1.3 When handling the valve or the valve package,

bear in mind its weight. Never lift the valve or

valve package near the actuator or operator.

Do not sling crane straps or wires around any

automation components such as lever, gear,

actuator, accessories and tubing to avoid any

load acting on it. Place the lifting device securely

around the valve body while handling the valve.

Refer to Fig. 2.

3.1.4 Valve shall not be handled with the handwheel

fixed to the gear unit. The handwheel shall be

dismantled before handling and transporting of

the valve.

3.1.5 Extreme care shall be taken to check that the

stem and automation components (such as lever,

gear, actuator, accessories, and tubing) are not

bent, pinched or damaged during handling.

3.2 STORAGE

3.2.1 Clean the valves and ensure that end protectors

are in place before the valves are stored, as dry

contaminants like dust, sand, grit, etc. can scratch

the metal seating surfaces and the soft inserts,

leading to leakages on full pressure operation.

3.2.2 Valves shall be stored in an indoor/covered area

which is dust free, dry and well ventilated to

protect from rain and storm. Refer to Fig. 3.

3.2.3 The valve shall always be maintained in an

ambience with temperature higher than the dew

point with a preferred range from 40°C to 29°C at

the storage location to avoid collection of water

droplets on the valve surface.

3.2.4 Do not keep the valve directly on the floor. Valve

shall be placed on a wooden pallet with at least 6"

from the floor.

3.2.5 Care should be exercised not to damage the

extended portions of the stem housing and

automation components during storage.

3.2.6 Do not apply tar, grease or any other foreign

materials inside the valve aside from proper

lubrication, as it could impair valve performance.

CORRECT WRONG

Fig. Lifting the valve

CAUTION:

• Improper storage and/or handling may cause valve assembly damage or deformation, which will aect

performance of the valve. Disc/seat damage can impair sealing capabilities and increase operation torque.

• Valve must not be stored for more than 2years.

• When valves are stored for a long time, open and close the valve once every 3months.

DO NOT:

• Store the valve outdoors.

• Store valve without end protectors.

• Place or drag the valve on the floor.

• Place and/or handle valve in positions that may

damage the valve or its accessories.

Fig. Properly covered storage

FNW.COM

©2021 Ferguson Enterprises, LLC 0721 2945816

We reserve the right to modify or improve the designs or

specifications of our products at any time without notice.

HIGH PERFORMANCE BUTTERFLY VALVE

FIGURE HPA

4

4.2 FLANGED ENDS

Refer Appendix section A1 for applicable standards.

4.2.1 The valve shall be in the closed position during

installation process, except in case of fail OPEN

valves; in such case additional care shall be taken

not to damage the disc surface by any debris.

4.2.2 The pipes must be properly aligned, and

provisions made to minimize stresses from

thermal expansion. Always review pipe

manufacturer's recommendations.

4.2.3 In cases of pipes with long overhangs, adequate

support shall be provided at the flange ends of

the pipe to avoid bending of pipes due to weight

of the valve. Refer to Fig. 5.

4.2.4 Align the bolt holes of the valve end flange and

pipe flange.

4.2.5 Insert gasket and tighten the bolts. Flange bolts

shall be tightened evenly, using a torque wrench,

in cross rotation to prevent damage to flanges.

4.2.6 For sequence of tightening of bolts. Refer to

Appendix, section A2.

Fig. Support to the valve (picture for reference).

4. VALVE INSTALLATION

4.1 GENERAL

4.1.1 Carefully unpack the valve and check for tags or

identification plates, etc. If the nameplates and/

or tags are lost or destroyed during shipment or

storage, or if it is not legible, contact an FNW or

manufacturer representative for assistance before

installing the valve.

4.1.2 Check valve for any damage and check condition

of end protectors. Upon discovery of any damage,

contact an FNW or manufacturer representative

prior installation.

4.1.3 Look for any special warning tags or plates

attached to the valve; if there are any, take

appropriate action.

4.1.4 HPA Series butterfly valves are recommended to

mount the valve in the preferred flow.

4.1.5 Never install the valve with the actuator on the

underneath side of the pipeline. Refer to Fig. 4.

4.1.6 It is recommended to remove all foreign particles

from the pipeline by flushing it with a suitable

fluid. Corrosion inhibitors shall be added to the

flushing medium to prevent any corrosion from

trapped fluids.

4.1.7 Remove the valve end protectors and protective

sheath within the flow bore of the valve.

4.1.8 After removal of end protectors, thoroughly clean

valve ports and cavities and ensure the flange

gasket faces are free from dust or debris.

4.1.9 Gasket contact faces of the valve and pipe flanges

shall be inspected thoroughly for scratches or

any defects.

4.1.10 After cleaning, operate the valve for at least two

complete cycles before installing.

Fig. Incorrect mounting position (picture for reference).

CAUTION:

• If valve is not cleaned or if cleaning is done

only after valve installation, valve cavities

may form a natural trap in the piping

system and any impurities not dissolved or

washed out by the flushing fluid/line fluid

may settle in such cavities and adversely

aect valve performance.

• Only properly qualified personnel must do

the installation.

FNW.COM

©2021 Ferguson Enterprises, LLC 0721 2945816

We reserve the right to modify or improve the designs or

specifications of our products at any time without notice.

HIGH PERFORMANCE BUTTERFLY VALVE

FIGURE HPA

5

4.3 CLEANING AND TESTING

4.3.1 Clean the pipeline by flushing the system with a

compatible liquid to remove any contaminants

that may be present in order to avoid scratches

being formed on the sealing surfaces by

these contaminants.

4.3.2 While testing the pipeline, ensure that the media

is clean and free from sand, dirt, pebbles, etc. Add

corrosion inhibitors to the testing media to avoid

any internal corrosion of the valve.

4.3.3 Operate the valve once to check for

smooth operation.

4.3.4 If no obvious problems are observed, test

pressure according to applicable standard may

be applied and leak tightness and operability may

be checked.

CAUTION:

The improper alignment of the pipe and

the valve during installation can lead to

unbalanced tightening of the flanges which

may cause excessive stress on the bolts and

lead to leakage. Ensure all nuts, flanges and

cables are properly fastened.

CAUTION:

• Faulty installation may lead to valve and/or

pipeline damage.

• Avoid contact with the valve closure

element during cycling.

• During shell test, the valve shall be in

the partially open position to prevent the

seat from being subjected to the shell

testpressure.

CHECK:

• Installation of the valve as per the piping drawing.

• End protectors are not removed during storage and only to be removed before valve installation.

• General pipe and valve cleanliness.

• Face to face and/or end to end dimensions.

• Conformance of piping connectors with relevant standards or norms.

• Parallelism of piping flanges or piping connectors.

• Alignment of the bolt holes of the pipe and valve flanges.

• For availability of enough space for the valve and its accessories and for easy operation.

• The suitability and eciency of valve and accessories support.

FNW.COM

©2021 Ferguson Enterprises, LLC 0721 2945816

We reserve the right to modify or improve the designs or

specifications of our products at any time without notice.

HIGH PERFORMANCE BUTTERFLY VALVE

FIGURE HPA

6

5. VALVE OPERATION

5.1 GENERAL

5.1.1 Operational life of the valve can be maximized

if the valve is used within the rated range, in

accordance with pressure, temperature and

corrosion data.

5.1.2 For arrangement of the internal construction, refer

to the Exploded View of the valve.

5.2 ACTUATION

General instructions given below, refer to separate

operator IOMs for further details.

5.2.1 Mechanism: The stem of the valve is rotated

by using a wrench/handle/lever for small sized

valves and by a gear unit in case of larger valves.

Electric/hydraulic/pneumatic actuators can also be

used for actuation.

5.2.2 Wrench/handle/lever operated valves shall be

opened or closed by turning the operator by a

quarter turn (90°).

• Valve in open position – the operator is in

parallel (in-line) with the valve or pipeline.

• Valve in closed position – the operator

is perpendicular (crossed) with the valve

or pipeline.

5.2.3 Gear units are provided on valves for easier

operation. Usually, clockwise operation is for

closing and anti-clockwise is for opening of the

valve. The position of the valve can be noted by

the position indicator provided on top of the gear

unit. The number of turns will depend on the gear

unit used. Gear units are of the self-locking type

(i.e., the line fluid will not make the valve rotate)

and the gear units have factory-set mechanical

stopper screws for setting the exact opening and

closing positions.

Refer to section 8.4 for how to adjust the

mechanical stoppers, if required.

• Worm gear operators are packed with grease.

Normally the grease is suitable for -20°C (-4°F) to

80°C (176°F). For other applications, consult the

nearest FNW or manufacturer representative.

CAUTION:

• HPA series butterfly valves are quarter-turn valves (i.e., 90° rotation of the disc makes the valve either fully

opened or fully closed).

• Butterfly valves employed for throttling duties shall be limited to a max pressure drop of 20% of the inlet.

Pressure at max open position.

• Recommended controls angles are between 25°-70°. Preferred angles for control valve sizing is 60°-65° open.

• Valve is to be operated for maximum 5 m/s velocity for liquids and 100 m/s for gaseousfluids.

CAUTION:

• Keep hands, tools and other foreign objects out of the internals of valves. A remotely actuated valve might

close without warning causing physical damage and personal injury. Disconnect valve from supply sources

and make sure valve automation is in fail safe state before performing any maintenance work.

• In cases when valves are supplied as bare stem as per customer requirements, please ensure that the

connecting devices for operator do not exert any axial or radial loads on the valve stem as it may lead

to bending of the stem and excessive loading on the ball. Ensure the end cover of actuator position is

interchanging to valve position when installing/mounting actuator to valve. Brackets, mounting hardware of

product, are designed to support the weight of the automation assembly. Do not apply additional weight as

this may result in leakage and performance failure of the valve assembly, causing possible seat damage and

increase operation torque.

• Bare stem position indicator: When valve is closed, the position of the stem double-D or keyway is

perpendicular to pipeline; when valve is open, the position of the stem double-D or keyway is parallel

topipeline.

FNW.COM

©2021 Ferguson Enterprises, LLC 0721 2945816

We reserve the right to modify or improve the designs or

specifications of our products at any time without notice.

HIGH PERFORMANCE BUTTERFLY VALVE

FIGURE HPA

7

• Grease should be changed as follows: If

operated frequently, after approximately 3 years.

If operated rarely, after approximately 5 years.

• Recommended Greases: Servo gem EP2

(Extreme Pressure), Mobilux EP2, Oline EP2,

Chevron EP2.

5.2.4 Electric actuator, which gives a multi-turn output,

is fitted on the gear unit. The actuator drives the

gear unit which in turn rotates the stem. Electrically

actuated valves are provided with declutching

mechanism for manual operation of the valve.

For electric actuators, FNW or manufacturer

recommends to strictly adhere to the instructions

as per actuator manufacturer’s manual.

5.2.5 Pneumatic or hydraulic actuator is fitted directly

on the valve, without a separate gear unit, unless

a separate manual override is requested as these

actuators have built-in quarter turn mechanisms.

For these actuators, FNW or manufacturer

recommends to strictly adhere to the instructions

as per actuator manufacturer’s manual.

5.3 FIRE SAFETY FIRE SAFE DESIGN

In the event of fire, the soft seals may burn out. In this

condition, the line pressure pushes the metal seat ring

against the disc. The disc makes contact with the metal

seat ring to provide a fire safe metal sealing. Valves are

tested to meet the fire safety requirements of international

standards according to either API 607.

CAUTION:

• Apply gradual force on the handwheel

of the gear operator and do not apply

sudden impacts.

• Do not apply extra leverage (using

pipe/bar) when the end stops of the gear

operator reach its extremeposition.

CAUTION:

• Use the valve only for applications for

which it is designed and recommended for

to avoid unexpected failure of the valve.

• Suspended particles in the line fluid may

damage the soft components in valve.

DO:

• Ensure that the valves in the pipeline

aected by a fire are replaced as soon as

possible for satisfactory performance.

Symptom Possible Cause Corrective Action

Stem packaging leaks

from top

1. Gland bolts loose

2. Packaging damaged or missing

3. Seal misaligned

1. Tighten the bolts

2. Replace packaging (shut down first)

3. Replace and aligned it correctly

Body gasket leaking 1. Body bolts loose

2. Body gasket damaged

1. Tighten the body bolts

2. Remove gasket

Valve leaks at

closedposition

1. Seat is worn or damaged

2. Disc edge is worn or damaged

1. Replace seat as described in disassembly and assembly

2. Replace the disc. (Consult factory for potential

applicationproblem.)

6. TROUBLESHOOTING

The table below lists some common problems that may be encountered with double eccentric butterfly valves, the probable

causes and recommended remedy to the problems. However, judgment and experience must be applied when working on

the valves in actual field, based on site conditions.

Table Troubleshooting check list

FNW.COM

©2021 Ferguson Enterprises, LLC 0721 2945816

We reserve the right to modify or improve the designs or

specifications of our products at any time without notice.

HIGH PERFORMANCE BUTTERFLY VALVE

FIGURE HPA

8

Item Description

Body

Disc

Seat (Soft)

Seat (Fire Safe)

Stem (Soft Seat)

Stem (Fire Seat)

Seat Retaining Ring

Disc Spacer

Bearing (Soft Seat)

Bearing (Fire Safe)

Wedge Pin

Retainer Screw

Packing Spacer

Item Description

Gland Packing (Soft Seat)

Gland Packing (Fire Safe)

Stem Retainer

Gland Flange

Stud

Belleville Spring

Hex Nut

Cover Gasket (Soft Seat)

Cover Gasket (Fire Safe)

Bottom Cover

Punch Washer

Hex Hd Screw

Seat Gasket (Fire Safe)

7. EXPLODED VIEW

A: 2"–12" (Lug/Wafer)

FNW.COM

©2021 Ferguson Enterprises, LLC 0721 2945816

We reserve the right to modify or improve the designs or

specifications of our products at any time without notice.

HIGH PERFORMANCE BUTTERFLY VALVE

FIGURE HPA

9

Item Description

Body

Disc

Seat (Soft)

Seat (Fire Safe)

Stem (Soft Seat)

Stem (Fire Seat)

Seat Retaining Ring

Disc Spacer

Bearing (Soft Seat)

Wedge Pin

Retainer Screw

Packing Spacer

Gland Packing (Soft Seat)

Gland Packing (Fire Safe)

Item Description

Stem Retainer

Gland Flange

Stud

Belleville Spring

Hex Nut

Cover Gasket (Soft Seat)

Cover Gasket (Fire Seat)

Bottom Cover

Punch Washer

Hex Hd Screw

Seat Gasket (Fire Safe)

Mounting Plate

Counter Sunk Screw

B: 14"–24" (Lug/Wafer)

FNW.COM

©2021 Ferguson Enterprises, LLC 0721 2945816

We reserve the right to modify or improve the designs or

specifications of our products at any time without notice.

HIGH PERFORMANCE BUTTERFLY VALVE

FIGURE HPA

10

8. PERIODIC MAINTENANCE

8.1 GENERAL

8.1.1 For extended valve life and better operability,

FNW or manufacturer recommends periodic

inspection and maintenance of the valves as per

the procedure explained below. To avoid valve

failure during operation, all valves in a process

plant should be periodically inspected thoroughly

to detect the wear of disc, seats, seals and even

body. It is recommended that on such occasions

seats, seals and bushings should be replaced.

8.1.2 The type of process, fluids involved, working

conditions and location of the valves in the

process plants will determine the frequency of

periodic inspection/maintenance to be made at

the time of partial or total shutdown of the plant.

Preventive maintenance is essential as failure

to do so may cause an emergency shutdown of

the plant.

8.1.3 Use genuine FNW spare parts only for

maintenance and replacements. Refer to

Section 9.

8.1.4 Studs and nuts fixing pipeline flanges and valves

to be properly tightened and in position, if

found loose.

8.1.5 Gland nuts and bolts to be inspected and ensured

that they are intact and not loosened during

service. Properly tighten the nuts by means of

spanner or wrench if found loose. Over tightening

of gland nut may damage the gland seal packing

and stem.

8.1.6 Once the valve is repaired, it should undergo a

complete set of tests to make sure that the valve is

adequate for required working conditions. Hydro/

Pneumatic tests should be carried out as per the

specifications relevant to the valve (Refer to GAD

or specifications related to order).

8.2 OPERABILITY AND TORQUE

8.2.1 Check for ease of operation of the valve.

8.3 STEM LEAKAGE

8.3.1 Any major leakage at the stem region can easily

be detected by observing for unexpected

pressure drops in the pipeline.

8.3.2 Minor leakage at the stem region may be

detected by using soap bubbles, after removing

the operator (actuator/gear/lever) unit.

CAUTION:

• For your safety, it is important that these precautions be taken before removal of the valve from the line or

before disassembly.

• De-pressurize the line before removing the bolting.

• Wear protective clothing and equipment appropriate for the line fluid.

• Ensure cavity pressure is relieved.

• Cycle the valve several times before disassembly to relieve pressure completely.

• Disconnect valve from supply sources and make sure valve actuation is in fail safe state before performing

any maintenance work.

FNW.COM

©2021 Ferguson Enterprises, LLC 0721 2945816

We reserve the right to modify or improve the designs or

specifications of our products at any time without notice.

HIGH PERFORMANCE BUTTERFLY VALVE

FIGURE HPA

11

CAUTION:

• If complete disassembly becomes necessary, replacement of seats and all seals is recommended.

• Once the valve is dismantled, the soft seals and gasket shall be changed. Make sure these parts are available

before dismantling of valve.

8.5 DISMANTLING PROCEDURE

8.5.1 Depressurize the line and open the valve to drain

the line.

8.5.2 Before removal from the line, cycle (open and

close) the valve to relieve residual pressure in the

body cavity.

8.5.3 Always fully close valve before removing from line

to avoid damage to disc.

8.5.4 Valves shall be slung and supported properly

before loosening flange bolts.

8.5.5 Place the valve on a platform or base and

transport to repair shop.

8.5.6 Before disassembly, cycle (open and close) the

valve several times to clear it of fluid; then flush

with water.

8.5.7 Valve shall be positioned vertically by resting

body side flange on clean ground surface

(preferably covered with rubber sheet).

STOPPER BOLT ARRANGEMENT

Open position Close position

Adjust right bolt for open position

Adjust left bolt for close position

Lock nut/check nut

Lock washer intact with nut

8.4 GEAR STOPPER ADJUSTMENT PROCEDURE

8.4.1 Before changing the setting, ensure that the nut

locking washer is intact. If not intact, then only

proceed for resetting.

8.4.2 Loosen the lock nut by unlocking the nut washer.

Loosen left side bolt for one rotation. Rotate the

handwheel in the clockwise direction to close the

valve till it is stopped by the left side bolt.

8.4.3 The adjustment of valve should be within ±5º of

mean position indicated by the indication plate.

8.4.4 Check valve leakage after adjustment. If valve is

found leaking again repeat the procedure. If no

leakage is detected, then tighten the lock nut and

lock washer.

Fig. Gear unit

FNW.COM

©2021 Ferguson Enterprises, LLC 0721 2945816

We reserve the right to modify or improve the designs or

specifications of our products at any time without notice.

HIGH PERFORMANCE BUTTERFLY VALVE

FIGURE HPA

12

8.5.8 Close the valve completely and remove operator

unit. Unscrew the lever lock bolt. Lift the lever by

pressing the latch of the lever out of the stem in

case of hand lever operated valve.

8.5.9 Disconnect supply source and remove the

pneumatic/electric/hydraulic actuator unit. Do

not remove a spring return actuator unless a

stop-screw is carrying spring force. Lift the gear

operator out of the stem by removing the bolts in

case of gear operated valve.

8.5.10 Secure body in a suitable clamping device without

damaging it.

8.5.11 Remove all retainer screws (9) and remove the

seat retainer (5).

8.5.12 Remove the seat (04) and replace it.

8.5.13 Remove counter sunk screws (24) and mounting

plate (23) on wafer and lug valve sizes above

12" (see 9 B). For double flange type (see 9 C),

remove hex bolts (23), spring washers (25) and

bracket (23).

8.5.14 Remove the hex nuts (17) and Belleville washer

(16) from gland flange (17) and remove the

gland flange(14). The studs (15) do not have to

be removed.

8.5.15 Remove the wedge pin welds by grinding or

machining o the welds and remove the wedge

pin (8).

8.5.16 Remove the stem retainer (snap ring) (13) and pull

the stem (3) out and remove the disc spacers (6),

gland (12) gland packing (11).

8.5.17 Gently pull the disc (2) from the body (1).

8.5.18 Remove the bottom flange bolt (21), spring

washers (20) and remove the bottom cover (19).

8.5.19 Remove the bottom gasket (18).

8.5.20 Remove top bearings (7) either from top of the

valve or the waterway.

8.5.21 Remove the bottom bearings (7).

8.6 REPAIR OF COMPONENTS

8.6.1 The metallic parts should be cleaned.

8.6.2 After cleaning components, examine for damaged

parts. Ensure that there are no scoring marks on

the metallic sealing surfaces. Check the seals for

scratches/wear.

8.6.3 Replace the damaged parts. The parts such

as seats and stem packing bearings are

recommended to be replaced with new ones

whenever the valve is disassembled.

8.7 ASSEMBLY PROCEDURE

8.7.1 Inspect and clean all parts to make sure they

are free of dust, grit or other material. A new

set of gasket and seals shall be used once

the valve is disassembled. Refer to Section 9

for recommended spare parts. Replace any

damaged parts.

8.7.2 Before assembly, visually inspect all the valve

components for damage. Look for damage to the

seating areas on the disc and check parts as per

bill of material.

8.7. 3 Apply rust preventative oil to parts, wherever

applicable (i.e., body and disc stem bore in case of

CS material).

8.7.4 Place the body (1) on a clean work surface. Install

the bearings (7) with the help of mandrill into

the upper stem bore and lower stem bore of the

body. Refer to 9A, 9B, 9C for quantity of bearings

required for each construction.

8.7.5 Place the cover gasket (18) from bottom side.

8.7.6 Assemble bottom cover (19) and fasten the bolts

(21) with spring washers (20) of bottom cover.

8.7.7 For smooth assembly of the stem (3) into the disc

(2), it may be necessary to coat the stem (3) and

disc bore lightly with a lubricant compatible with

the media to be handled by the valve.

CAUTION:

• Before removal of the valve, ensure that the line is fully depressurized.

• Improper handling may cause disc damage or deformation of stem or seat, which will aect sealing and

operational torque of the valve.

• Ensure that the disassembled components are kept in a clean place so that there will be no damage to

thecomponents.

FNW.COM

©2021 Ferguson Enterprises, LLC 0721 2945816

We reserve the right to modify or improve the designs or

specifications of our products at any time without notice.

HIGH PERFORMANCE BUTTERFLY VALVE

FIGURE HPA

13

8.7.8 Slide the stem (3) through the top bearing (08) and

engage the top disc spacer (6) toward the bonnet

when applicable, place the disc (2) and slide the

stem (3) through disc stem bore. Place the lower

disc spacer (6) and push the stem through lower

bearing (7) into the body (1).

8.7.9 Insert the wedge pins (8) into disc holes for wedge

pin. Take care that pin flat surface matches to stem

flat surface and drive them into place. When pins

are correctly installed, the drive shaft will be as

shown in Fig. 7. Cycle the disc 4 to 5 times.

8.7.10 Place the packing spacer (10) into stung box

region and insert the set of gland packing (11) into

stung box above the packing spacer.

8.7.11 Place the gland (12) above the gland packing.

8.7.12 Install the stem retainer (snap ring) (13) on

the stem.

8.7.13 Fix the gland flange assembly (14) through stem,

insert the Belleville washers (16) and install nut (17),

tighten the nut (17) slowly till to the ISO top flange.

8.7.14 Install the Seat (3) into the Seat Retainer Ring (5).

8.7.15 Insert the seat and seat retainer assembly into the

body with disc in closed position. Apply anti-seize

grease for threading area. Insert the retainer bolts

in alternating sequence.

8.7.16 Cycle the disc and set disc in closed position.

8.7.17 Disc pins to be Tig spot welded after

leakage testing.

8.7.18 When the gear operator or hand lever or actuator

is reassembled on the valve, it may be necessary

to adjust gear operator or hand lever, or actuator

travel stops to ensure proper setting of the

butterfly in the open and closed position).

8.7.19 In case of gear operated valves, install bracket

and coupling and fix the gear unit. Ensure smooth

operation of valve during opening and closing.

8.7.20 In case of actuated valves, install the actuators

per manufacturer’s IOM. Ensure the indicator of

actuator position is matching to valve position

when installing and mounting actuator to valve.

8.7.21 After assembly, the valve shall be tested for

leakage across the seats and through the

stem seals.

8.8 PROCEDURE FOR GLAND

PACKINGREPLACEMENT

If further adjustment of the gland packing is inappropriate,

adopt the following procedure for its removal

and replacement.

8.8.1 Remove the operator (lever, gear box or actuator)

in accordance with section 8.5.

• Remove key from shaft (if applicable).

• Remove gland nuts.

• Remove gland, gland flange.

• Remove gland packings using a

pointed instrument.

8.8.2 Fit new gland packing rings.

8.8.3 Refit gland and gland flange.

8.8.4 Refit gland nuts, tighten evenly until heavy

resistance is felt. During this operation, turn

the stem to ensure that the packing is not

over tightened.

8.8.5 Refit the operator.

SPOT WELD HAS TO BE DONE

AFTER VALVE TESTING

(FIRST WELD IS MADE ON THIS

SIDE)

STEM

WEDGE PIN

Wedge pin

Stem

Spot weld has to be done after valve testing.

(First weld is made on this side)

Fig.

FNW.COM

©2021 Ferguson Enterprises, LLC 0721 2945816

We reserve the right to modify or improve the designs or

specifications of our products at any time without notice.

HIGH PERFORMANCE BUTTERFLY VALVE

FIGURE HPA

14

8.9 PROCEDURE FOR SEAT REPLACEMENT

8.9.1 Remove the retainer ring as per procedure

described in section 8.5.

8.9.2 Remove retainer ring gasket in fire safe seat

design. This is not applicable for soft seat.

8.9.3 Remove fire safe seat/soft seat.

8.9.4 Remove body gasket (applicable for fire

safe design).

8.9.5 If the seat is tight, move the disc to open position

and if still tight, gently drive the seat out of the

body using smooth blunt instrument.

8.9.6 Ensure that all components are clean. Position the

disc in closed position.

8.9.7 Refit components by using steps in section 8.7.

CAUTION:

• Improper handling may cause disc and seat damage or deformation of stem, which will aect sealing and

operational torque of the valve.

• Faulty installation may lead to valve and/or pipeline damage.

• Ensure that the soft parts are changed once they are removed from the valve.

• Avoid contact with the valve closure element during cycling.

CAUTION:

All equipment must be fitted only with

manufacturer’s original spare parts. When

ordering for spare parts, always convey the

following information: size of valve, sr. no. and

mfg. date which is available in the nameplate tag.

9. RECOMMENDED SPARE PARTS

9.1 Before the start of repair operations, we recommend that

one set of spares as given in Table 2 should be available.

9.2 For normal operation (2 years), we recommend one

set of spares to be available at site.

Item No. Part Description

Seat ()

Bearing ()

Gland packing ()

Stem Retainer ()

Bottom Gasket ()

6 Wedge Pin (8)

7Belleville Spring (16)

Seat Gasket ()

Table 2: Recommended spare parts list

10. DISPOSAL ACTION

10.1 DISPOSAL INSTRUCTIONS

10.1.1 Metallic components of product are to be

cleaned and recycled.

10.1.2 Foam, Rubber, Elastomer, Polymers and

Plastics components, along with packing

materials are to be scrapped according to

regional regulations in which they are to

be disposed.

10.1.3 Wooden boxes may be reused based on

the condition of the boxes, or they may

be recycled.

11. CE INSTRUCTIONS

11.1 Each valve has a stainless-steel name plate

fixed to the body.

11.2 The nameplate is marked with details of figure

number, along with various other details

such as the materials of construction, limiting

temperatures and pressure rating.

FNW.COM

©2021 Ferguson Enterprises, LLC 0721 2945816

We reserve the right to modify or improve the designs or

specifications of our products at any time without notice.

HIGH PERFORMANCE BUTTERFLY VALVE

FIGURE HPA

15

Thread size

(inch)

Torque

(Nm)

/ –

/ –

/ –

/ –

/ –

/ –

–

-/ –

-/ –

-/ –

-/ –

-/ –

-/ –

-/ –

–

Table 3 Tightening torque values

APPENDIX A

TECHNICAL INFORMATION

A1. References

Design/pressure-temperature ratings

API 609 Butterfly Valves: Lug- and wafer-type

ASME B 16.34 Valves: flanged, threaded and welding ends

Face-to-face dimensions

API 609 Face-to-face and end-to-end dimensions of valves

End connections

ASME B16.5 Pipe flanges and flanged fittings (NPS 1/2 through NPS 24)

ASME B16.47 Large diameter steel flanges (NPS 26 through NPS 60)

Fire test

API 607 Fire test for soft seated quarter-turn valves

A2. Tightening sequence and torque

Tighten bolts evenly and diagonally opposite to each other or in a crisscross pattern.

Use the torque figures as shown in Table 3.

Fig. 8 Tightening sequence for 12 bolts

FNW.COM

©2021 Ferguson Enterprises, LLC 0721 2945816

We reserve the right to modify or improve the designs or

specifications of our products at any time without notice.

HIGH PERFORMANCE BUTTERFLY VALVE

FIGURE HPA

16

A3. Technical data

Seat

material

Max operating

temperature Properties Application

PTFE -58°F (-50°C) –

400°F (204°C)

1. Outstanding chemical resistance.

2. Good Mechanical properties.

Resistance to most of the

chemicals and solvents.

RPTFE -58°F (-50°C) –

428°F (220°C)

1. Excellent mechanical properties.

2. Excellent chemical resistance.

3. Good temperature and pressurecapabilities.

4. Excellent abrasion resistant.

Resistance to most of the

chemicals and solvents.

ULTR A -58°F (-50°C) –

500°F (260°C)

1. Excellent mechanical properties.

2. Excellent chemical resistance.

3. Good temperature and pressurecapabilities.

4. Excellent abrasion resistant.

Resistance to most of the

chemicals and solvents.

Table 4 Seat temperature range and general chemical resistance

CAUTION:

FNW does not assume responsibility for any liabilities/damages arriving out of erroneous application of its

valves or imprudent operations carried out by inexperienced operators that do not comply with this manual or

instructions provided by FNW. The valves shall be appropriately used for the purpose they are built for and their

intended applications. Use of standard valves for special applications is not recommended unless it has been

communicated and agreed to by FNW. Valves shall be operated and maintained strictly in accordance with the

procedures. Operation or maintenance outside of these procedures constitutes abuse of the product and voids

all warranty and claims.

This manual suits for next models

20

Table of contents

Other FNW Control Unit manuals

Popular Control Unit manuals by other brands

Siemens

Siemens PM-E F pm DC24V PROFIsafe Installation and operating manual

Avaya

Avaya J100 Series Using instructions

ThinkPad

ThinkPad EM120R-GL Regulatory notice

Erie

Erie 541N Series Technical manual

Rittal

Rittal CMC III DK 7030.501 Assembly and operating instructions

HEIDENHAIN

HEIDENHAIN ITNC 530 - CONVERSATIONAL PROGRAMMING user manual