Stand November 2007 Seite 1 ©Krick Modelltechnik Knittlingen

Building Instructions Lisa M.

Order-No. 20320

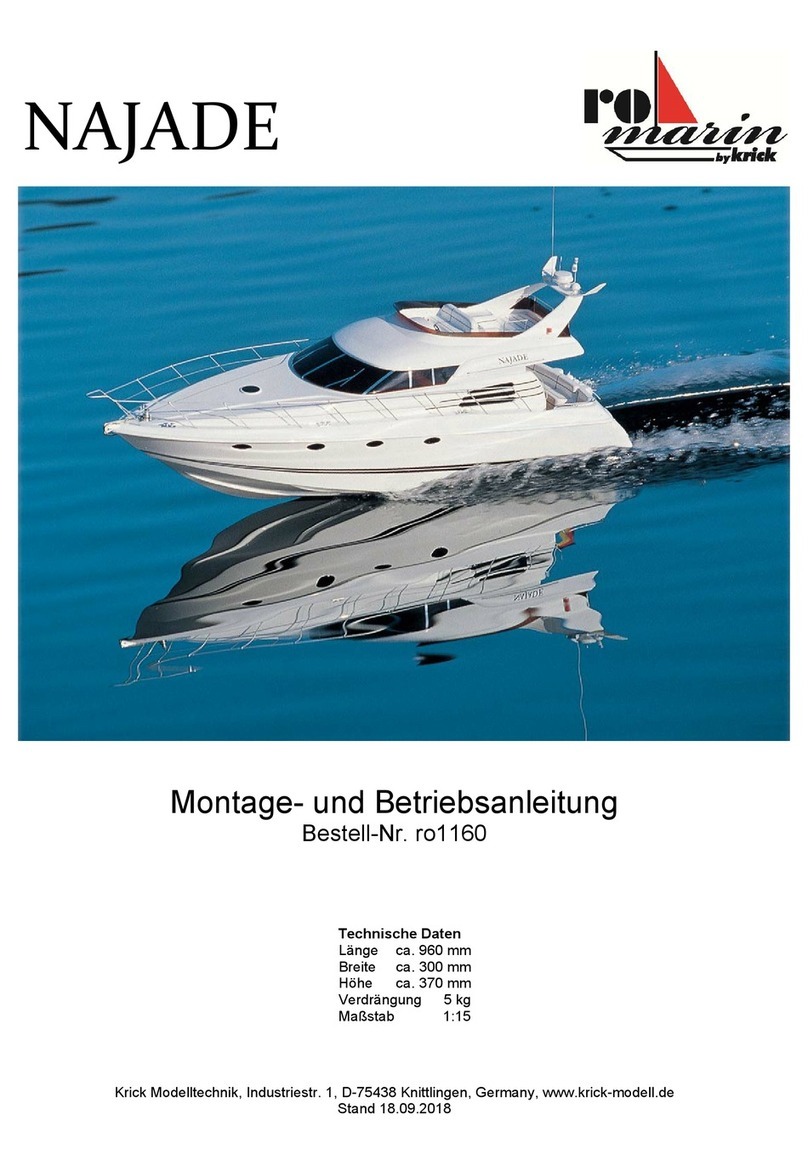

Congratulations for buying this model kit of the

motor yacht „Lisa M.”. This model is mainly

designed for the beginner, but is also a very

interesting kit for more experienced modellers

as a basis for own ideas.

For building this model you should have follow-

ing glues, fillers and paints:

- Superglue Krick ruck-zuck 20g thin (80491)

- Superglue Krick ruck-zuck 20g medium

(80495)

- 5min-Epoxy glue 100g (80479)

- wood glue UHU Holz waterresistant 75g

(48515)

- 2-component glue UHU-Plus acrylit 30g

(48315)

- Filler Micro-Fill white 295 ml (80480)

- Primer (Lord Nelson 80110)

- Clear Varnish for stairs, doors, (80112)

- paint spray blue (320053), light grey (Primer

and for deck), and white (320010)

-lacquer red, grey, silver and black for fittings

Following tools are recommended for building

“Lisa M.”:

- modelling knife (416002)

- hand drill (473841)

- sandpaper files (491016)

- sanding block (490080)

- sand paper of grane 180, 320, 400 and 600

(Set 490190)

- round file ca. Ø 6 mm

- drills Ø 1 mm, 1,5 mm, 2 mm, 3 mm, 4 mm,

6,5 mm

- wet sand paper 400 und 600 for filler, primer

and paints

When painting you should have masking tape

for areas, which should not be painted. A 3 mm

wide tape should be used for the water line.

For running and radio control you should have

following parts:

- 2 channel radio control including one Servo

- electronic speed control 20 A, forward/back

including BEC

- battery pack 7,2V NiCd, NiMH or lead battery

6V/1,1 Ah

- charger 220V AC or 12V DC

Many pictures in the following instruction

should make the building of the model as easy

as possible.

For identifying the laser cut parts in the

wooden sheets, there is a drawing at the end