FOCALSPEC LCI1220 User manual

FOCALSPEC LINE CONFOCAL SENSORS

LCI1220 & LCI1620

USER GUIDE

Version 1.0

2019-09-30 FOCALSPEC User quide LCI1220-1620 v1.0 1/31

FocalSpec Oy • Elektroniikkatie 13, FI-90590 Oulu • www.focalspec.com

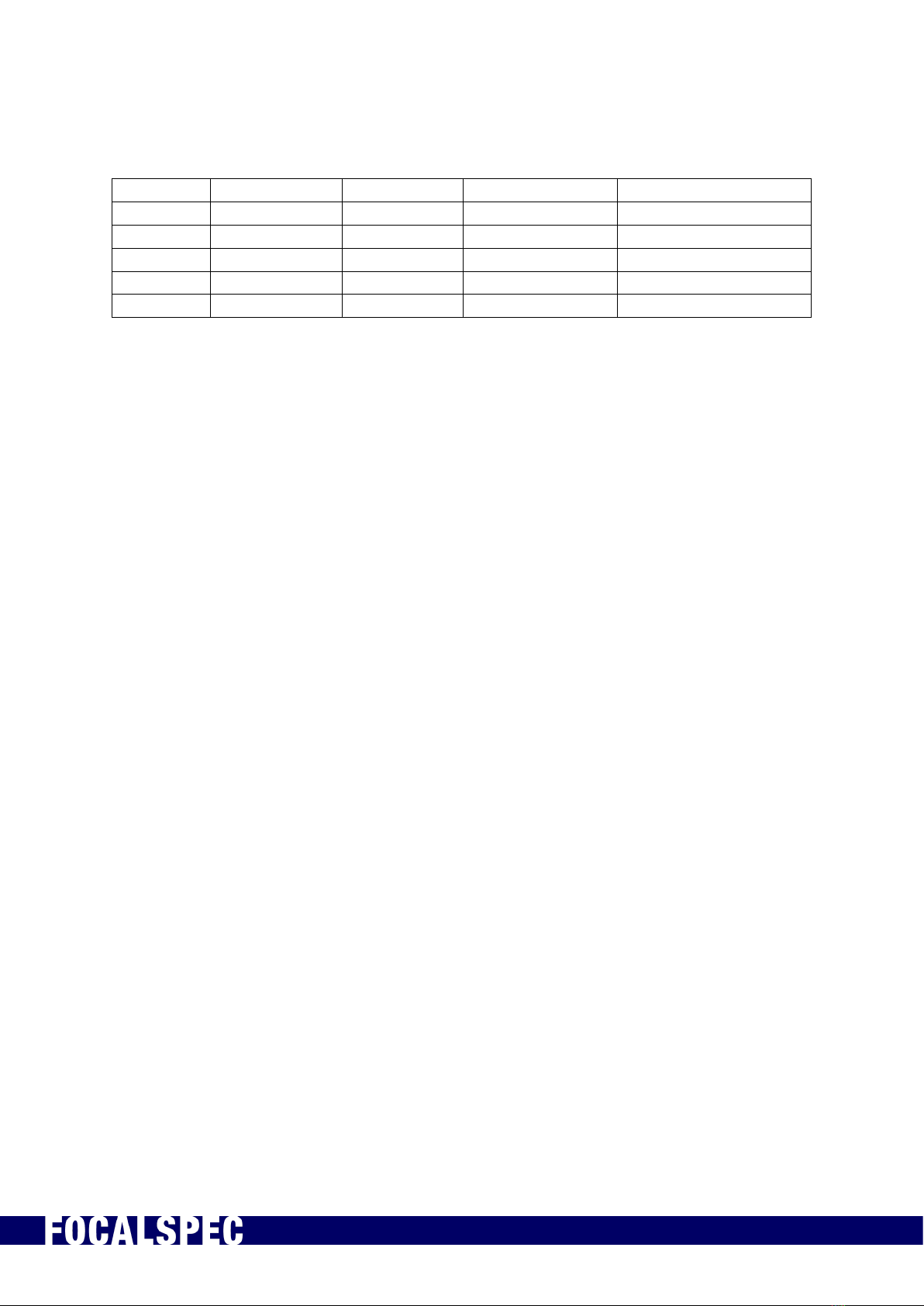

Version history

Version

Status

Date

Author

Comments

1.0

Approved

30.9.2019

Esa Kalistaja

First version

2019-09-30 FOCALSPEC User quide LCI1220-1620 v1.0 2/31

FocalSpec Oy • Elektroniikkatie 13, FI-90590 Oulu • www.focalspec.com

CONTENTS

0

FOCALSPEC LINE CONFOCAL SENSORS LCI1220 & LCI1620 0

0

1 About this Document..........................................................................................3

2 Safety Information ............................................................................................3

2.1 Safety Notes 3

2.2 Warnings 3

2.3 Proper Use 4

2.4 CE Marking 4

3 Technical Data...................................................................................................5

4 Delivery Contents ..............................................................................................5

5 Connecting to PC...............................................................................................6

6 Installation and Mounting...................................................................................6

7 Handling Optical Cable and SFP+ Modules ..........................................................9

7.1 General Instructions 9

7.2 Installing SFP+ Module and Optical Cable 10

7.3 Detaching SFP+ Module from Optical Cable 11

8 Electrical Connections..................................................................................... 12

9 Input and Output Description ........................................................................... 15

10 External Trigger Configurations......................................................................20

11 Sensor Warming Up ........................................................................................ 21

12 Preparing Measurement Setup ....................................................................... 21

13 Getting Started ..............................................................................................23

14 Troubleshooting.............................................................................................29

15 Support..........................................................................................................30

16 Abbreviations.................................................................................................30

2019-09-30 FOCALSPEC User quide LCI1220-1620 v1.0 3/31

FocalSpec Oy • Elektroniikkatie 13, FI-90590 Oulu • www.focalspec.com

1About this Document

This document is user guide of sensors LCI1220 and LCI1620. Sensors LCI401, LCI1200,

LCI1201 and LCI1600 are covered by separate guide. FocalSpec Software Development

Kit (FSSDK) and the API documentation can be found after FSSDK installation from

folder: C:\Focalspec\FocalSpec Software Development Kit\Manual.

2Safety Information

This chapter contains important safety information for installing and using the LCI

sensors.

•Note! Read this document carefully before use.

•Note! Keep this document for future reference.

•Note! Original instructions. The original language is English.

2.1 Safety Notes

This document uses safety notes as follows:

•Note! Notes are tips, shortcuts or alternative approaches to the task at hand.

Ignoring a note should have no negative consequences.

•Caution! A Caution statement alerts you to situations that can be potentially

hazardous to you or cause damage to hardware, firmware, software, or data.

•Warning! A Warning statement indicates conditions or situations that can be

potentially lethal or extremely hazardous to you. Safety labels are also attached

directly to products to warn of these conditions or situations.

2.2 Warnings

•Caution! Do not remove any safety devices or open the cover. Risk of injuries

and insecure operation. The warranty is void if the cover is opened.

•Caution! Do not look directly into the light source. Light radiation may damage

your eyes.

•Caution! This is a high-precision optical instrument. Protect the device from

dust and moisture and avoid subjecting it to shocks and strong forces.

•Caution! Before using the sensor for the first time, check the sensor for

transport damage. If the sensor is damaged, contact support. See

Support

.

•Warning! Use only qualified personnel for the installation of all electrical

supplies and fixtures, and make sure that all installations adhere to local

regulations and safety standards.

2019-09-30 FOCALSPEC User quide LCI1220-1620 v1.0 4/31

FocalSpec Oy • Elektroniikkatie 13, FI-90590 Oulu • www.focalspec.com

2.3 Proper Use

The LCI sensor is designed for the use in industrial areas. The sensor is used for optical

measurements, such as 3D topography, dimensions and distances measurements,

measuring the tomography of transparent materials, surface micro profile

measurements, and film thickness measurements.

Only use the sensor in such a way that, in the case of malfunction or failure, personnel

or machinery are not endangered.

Ambient temperature range: +15 ºC … +35 ºC.

2.4 CE Marking

FocalSpec Oy has confirmed that these products comply with the essential

requirements of the applicable EC Directive, based on the following specifications.

2019-09-30 FOCALSPEC User quide LCI1220-1620 v1.0 5/31

FocalSpec Oy • Elektroniikkatie 13, FI-90590 Oulu • www.focalspec.com

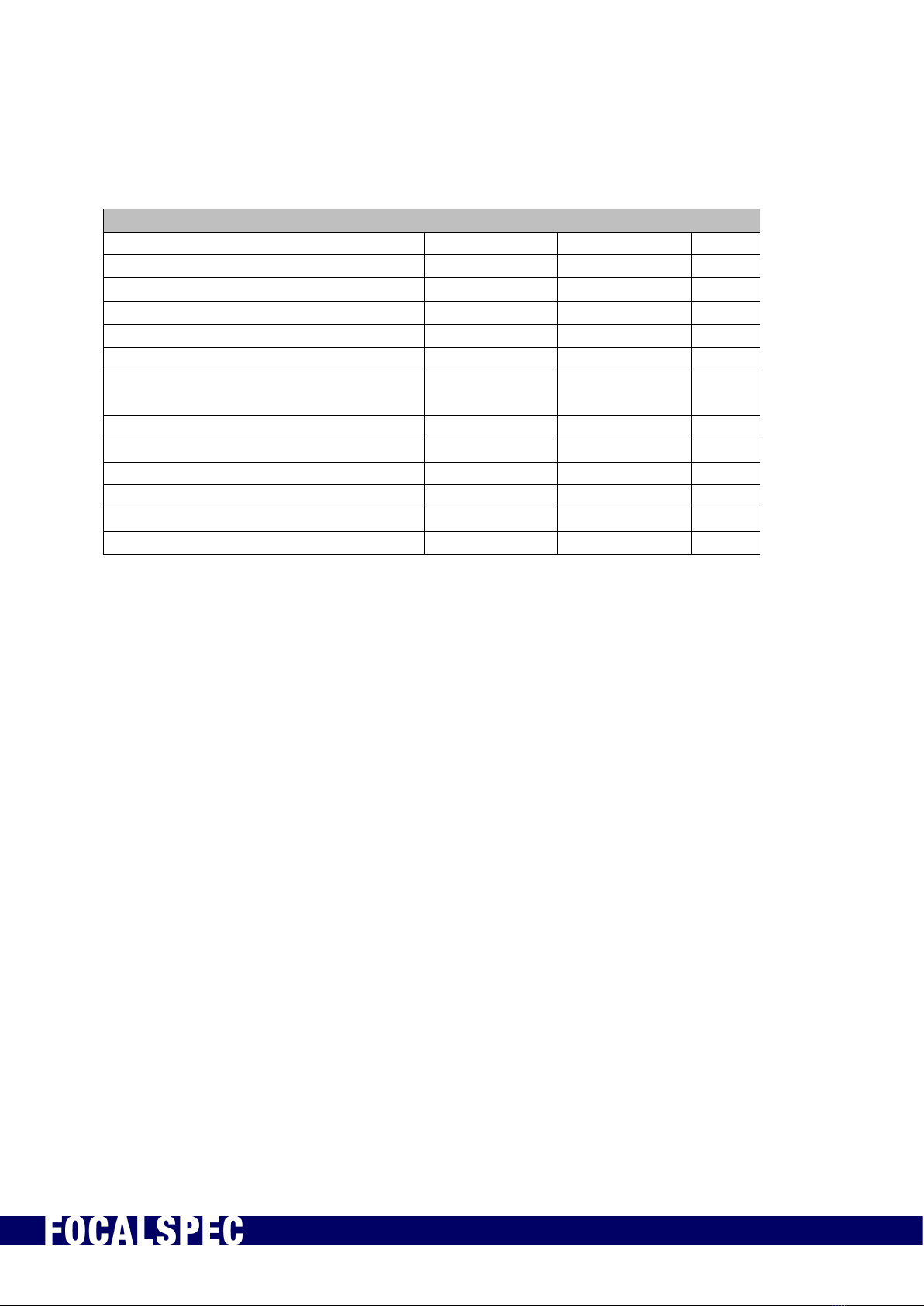

3Technical Data

Table 1. Technical data for the sensors

LCI 1220

LCI 1620

Optical profile length

11.6

17.0

mm

Pixel size X

6.7

9.85

µm

Pixel size Y

10

36

µm

Z repeatability*

0.19

0.25

µm

Stand-off distance

20.58

64.00

mm

Depth of field

3.00

5.50

mm

Measurement speed at full depth of

field

3000

3000

Hz

Max measurement speed**

16000

11000

Hz

Number of points / profiles

1728

1728

Max slope of objects +/-

20.0

13.5

deg

Dimensions

419x354x91

432x358x113

mm

Weight

19

21

kg

Level of protection (EN 80529)

IP55

IP30

* Z repeatability is the standard deviation of Z measurements using the FocalSpec target at the specified

reference distance

** Maximum speed is maximum frequency to measure region of interest (ROI) with the depth 0.4 mm on full

optical profile length

4Delivery Contents

Sensor delivery content includes:

✓FocalSpec LCI sensor

✓PushPull type 4-pin power cable (5 m)

✓PushPull type 10-pin signal cable (5 m)

✓Push Pull type optical cable (5 m) with two SFP+ modules

✓USB drive:

oSoftware Development Kit (FSSDK) installer

oLCI1220 and 1620 user guide

oSensor 3D CAD STEP files

oSensor mounting drawings

Reference measurement sample is an optional sales item, and not included in the

standard delivery content.

2019-09-30 FOCALSPEC User quide LCI1220-1620 v1.0 6/31

FocalSpec Oy • Elektroniikkatie 13, FI-90590 Oulu • www.focalspec.com

5Connecting to PC

10 Gbit connection with SFP+ interface is needed to enable the high-speed data

transmission.

The recommended network adapter is Intel Ethernet Converged Network Adapter X520

either two port DA2 or four port DA4 model.

Figure 1. Example of two port Intel Ethernet Converged Network Adapter X520 DA2

Windows 10 64-bit is the recommended operating systems, but sensors work also with

Windows 7.

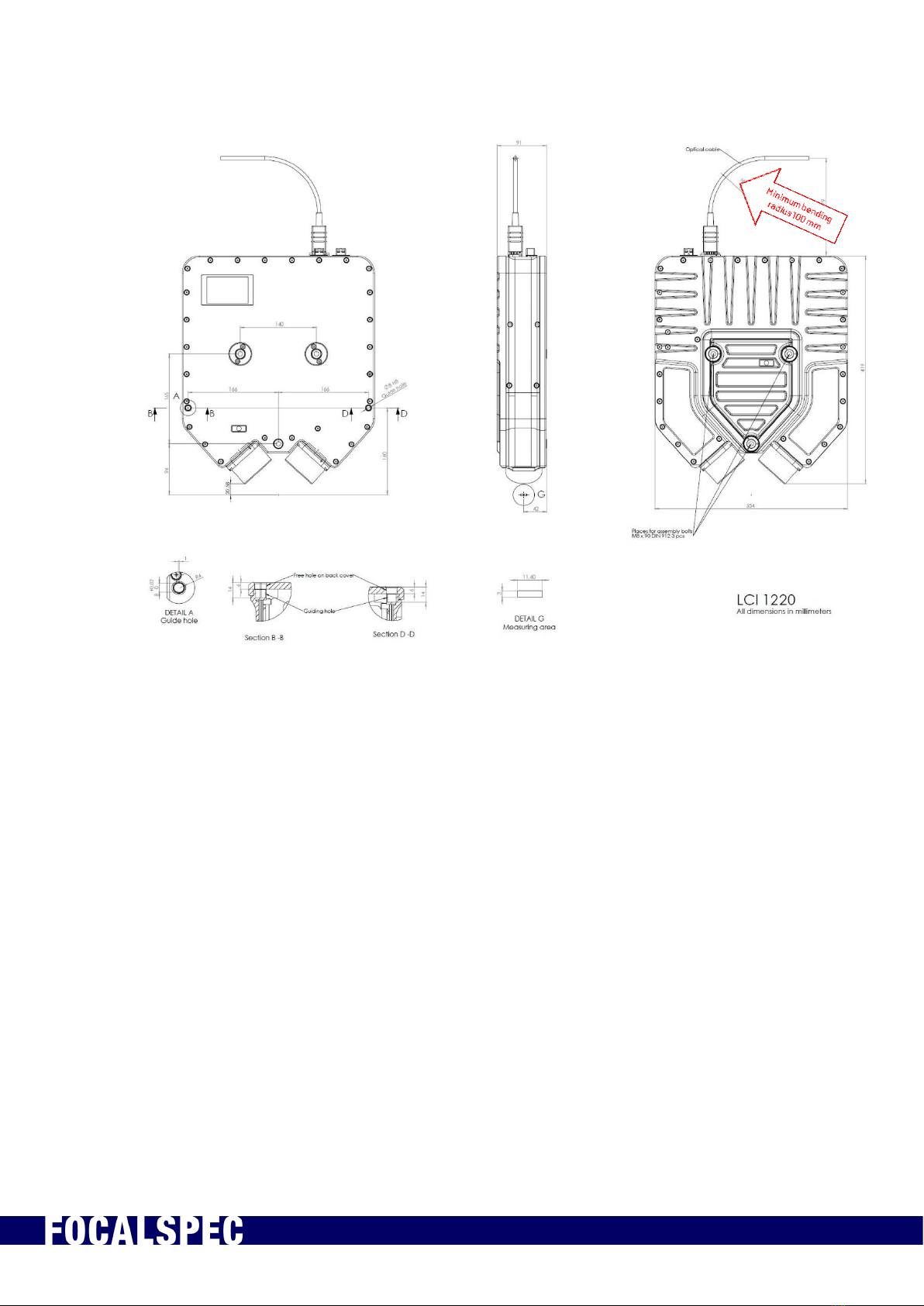

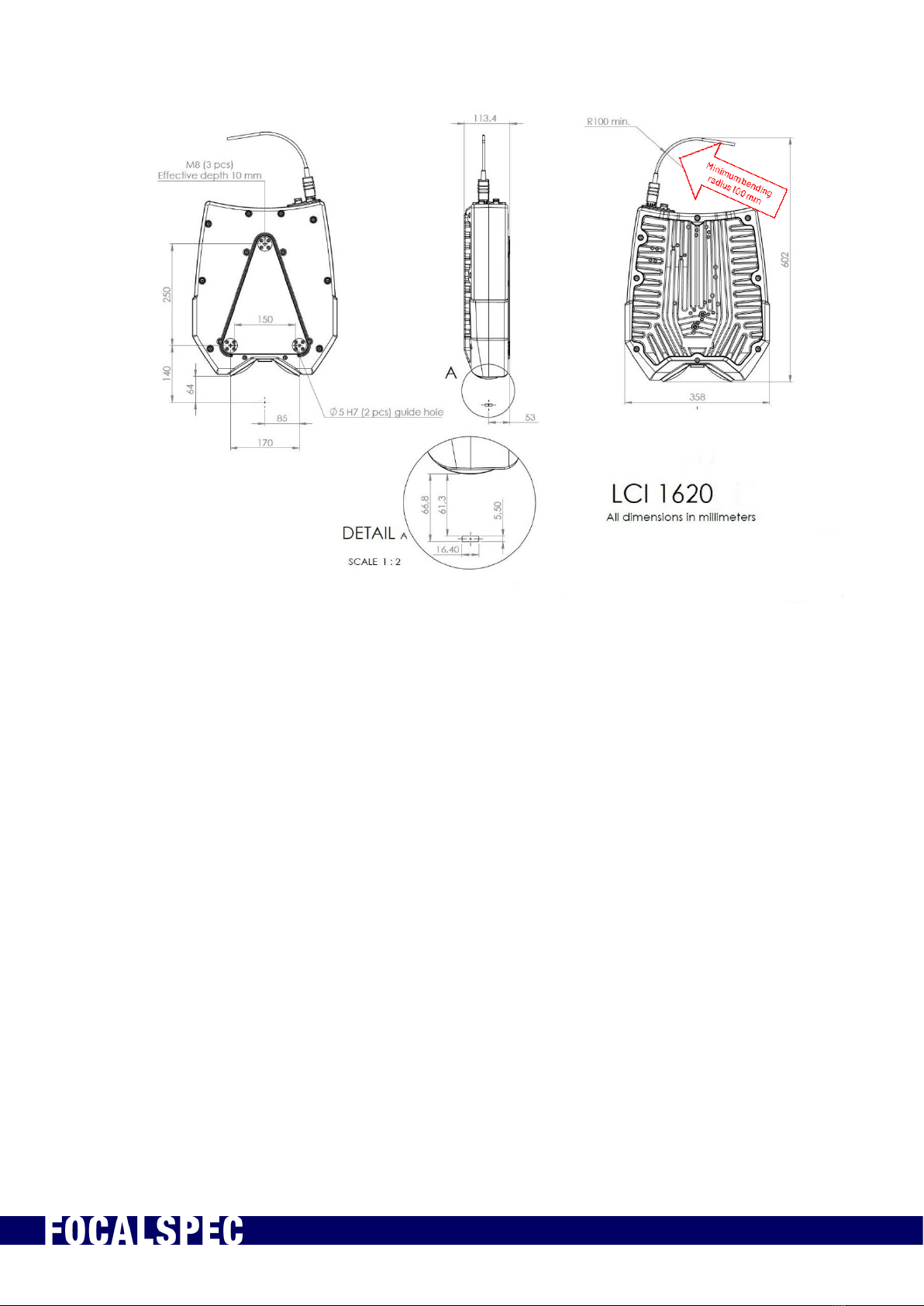

6Installation and Mounting

3D CAD STEP as well as high-resolution versions of the drawings below are included in

the USB drive folder “hardware”. The position and orientation of the optical profile is

shown in an enlarged detail image for each model. The X, Y, Z origin in each STEP file is

placed into the middle of the optical profile.

2019-09-30 FOCALSPEC User quide LCI1220-1620 v1.0 7/31

FocalSpec Oy • Elektroniikkatie 13, FI-90590 Oulu • www.focalspec.com

Figure 2. Installation and mounting of LCI1220.

2019-09-30 FOCALSPEC User quide LCI1220-1620 v1.0 8/31

FocalSpec Oy • Elektroniikkatie 13, FI-90590 Oulu • www.focalspec.com

Figure 3. Installation and mounting of LCI1620.

2019-09-30 FOCALSPEC User quide LCI1220-1620 v1.0 9/31

FocalSpec Oy • Elektroniikkatie 13, FI-90590 Oulu • www.focalspec.com

7Handling Optical Cable and SFP+ Modules

IMPORTANT – FRAGILE

Minimum bending radius of optical cable is 100 mm. Don’t bend

cable more than this. This applies to the whole length of the

cable and it is especially important to pay attention to computer

end of the cable as it is more flexible.

Never touch optical cable fiber ends with bare hands or let the

fiber ends touch anything else but cleaning equipment.

Never put anything inside the optical fiber slots of the SFP+

module.

7.1 General Instructions

1. When storing optical cables and SFP+ modules, make sure the protective caps are

attached.

2. When the cables and SFP+ modules are in use, store the protective caps in an

airtight plastic bag.

3. Never touch the cable ends with anything other than the cleaning cloth.

4. If a cleanroom is available, it’s recommended to install SFP+ modules to cable in

there.

5. Preferably wear cloth gloves when handling cable connectors.

6. Make sure the minimum bending radius of cable bend is about 100 mm (Figure 3).

Don’t let the cable bend more than this. This applies to the whole length of the cable

and it is especially important to pay attention to computer end of the cable as it is

more flexible.

2019-09-30 FOCALSPEC User quide LCI1220-1620 v1.0 10/31

FocalSpec Oy • Elektroniikkatie 13, FI-90590 Oulu • www.focalspec.com

Figure 4: Minimum bending radius of the optical cable is 100 mm

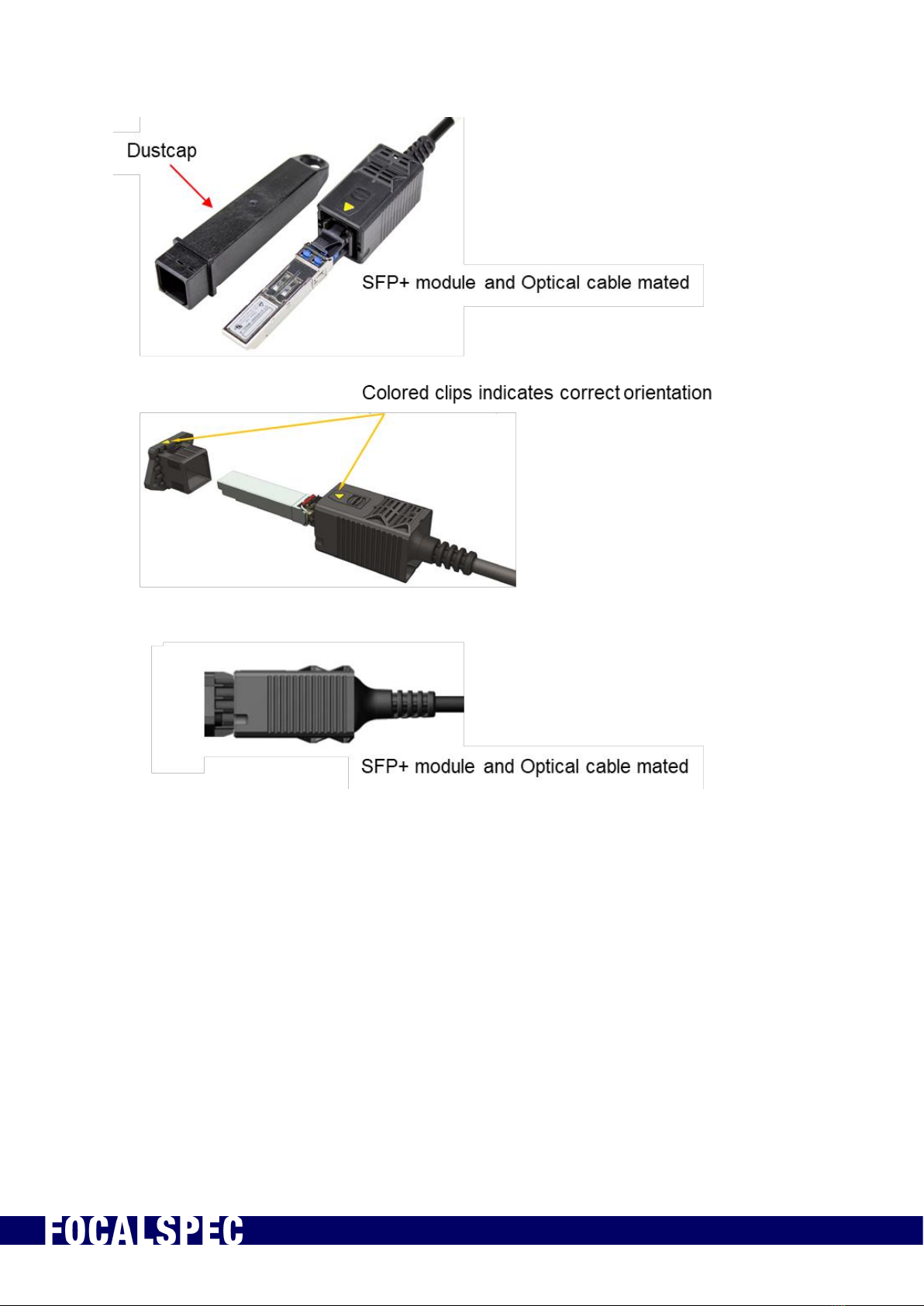

7.2 Installing SFP+ Module and Optical Cable

Steps to install the optical cable and SFP+ module:

1. Remove protective plug from SFP+ module.

2. Remove protective caps from the other end of the optical cable. Be sure not to touch

the optical fiber ends with anything.

3. Push the lock handle down on the SFP+ module (step 1). This is the open position.

This is done because the SFP+ module might be used with some SFP+ slots which

.

2019-09-30 FOCALSPEC User quide LCI1220-1620 v1.0 11/31

FocalSpec Oy • Elektroniikkatie 13, FI-90590 Oulu • www.focalspec.com

have a lock. Having the lock readily in the open position enables quick and easy

attaching of the SFP+ module.

4. Carefully insert the cable connector to SFP+ module. Push the connector gently until

it locks in place (step 2). Usually there is an audible “click” when the connector locks

in place. Make sure the lock handle has remained in the open position.

5. Verify that connector is locked to the SFP+ module by pulling very gently on the

cable: it must not be loose (step 3). If it is loose and detaches from the SFP+ module,

repeat by pushing the connector to the SFP+ module until it locks into place.

6. Insert SFP+ module to the SFP+ card at PC (step 4). Make sure the SFP+ module is

positioned in the correct way.

◦CORRECT: There should be a slight resistance when pushing the SFP+ module

the correct way, as the connector in the SFP+ module slides into the connector at

SFP+ slot side. The SFP+ module should not come out very easily.

◦INCORRECT: If the SFP+ module is inserted in incorrect way, there is no

resistance. The SFP+ module slides out very easily.

7. Insert the quick connector of the optical cable to the sensor.

7.3 Detaching SFP+ Module from Optical Cable

Steps to detach SFP+ module from optical cable:

1. Press the lock tab down in optical cable connector (step 1).

2. Pull the cable out of SFP+ module (step 2).

3. Place protective caps on the optical cable connector and SFP+ module.

2019-09-30 FOCALSPEC User quide LCI1220-1620 v1.0 12/31

FocalSpec Oy • Elektroniikkatie 13, FI-90590 Oulu • www.focalspec.com

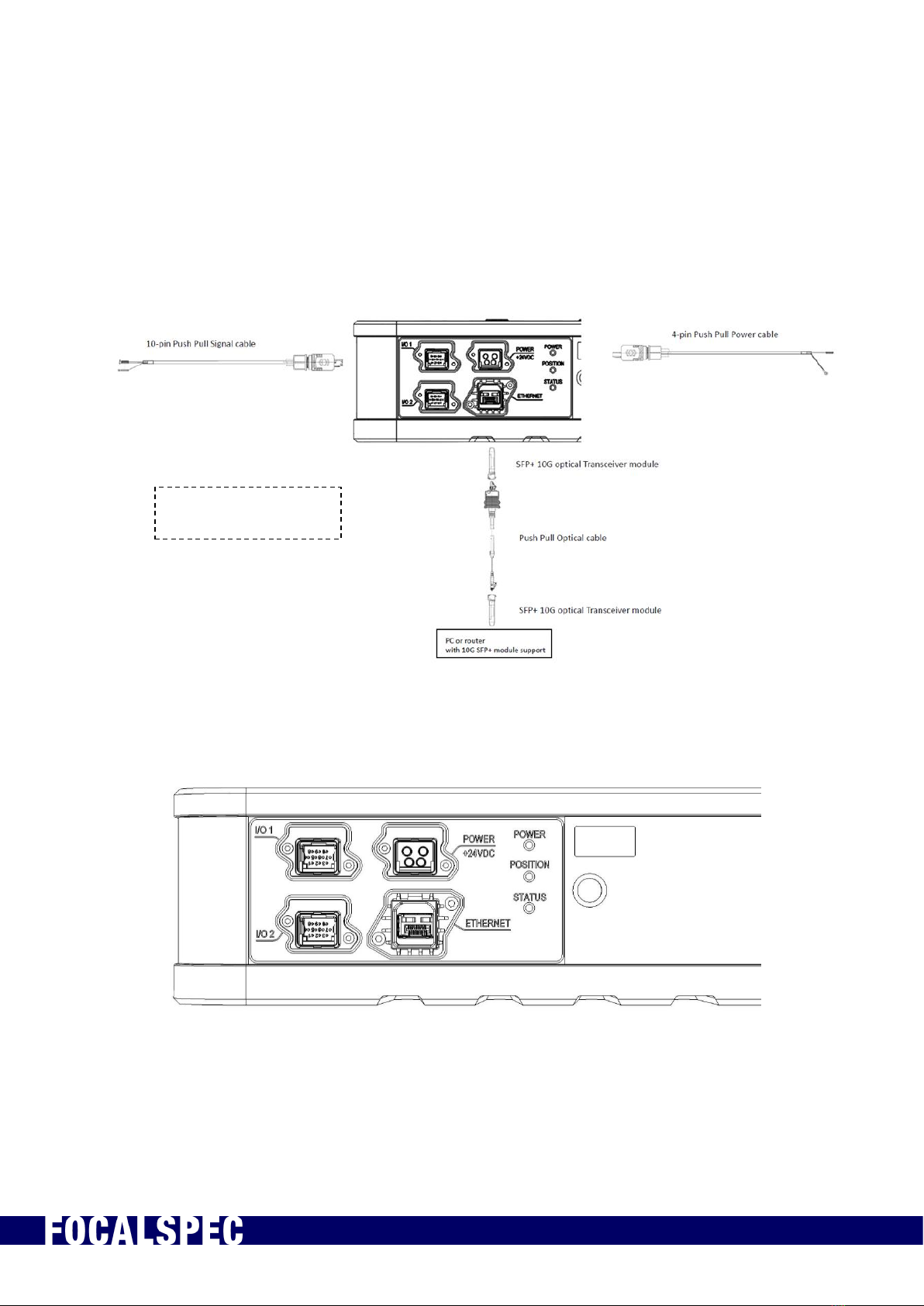

8Electrical Connections

LCI1220 and LCI1620 sensors are powered by using a PushPull type 4-pin cable with

Harting Power connector. For input signals which can be used for synchronization

purposes 10-pin PushPull type cables with Harting Signal Connectors is used. The

sensor communicates with PC via Optical cable with SFP+ 10G transceiver modules.

Figure 5. Electrical connections

Figure 6. Electrical connections for LCI1220 (I/O 2 connector is not in-use at the

moment)

I/O 2 connector is not

in-use at the moment

2019-09-30 FOCALSPEC User quide LCI1220-1620 v1.0 13/31

FocalSpec Oy • Elektroniikkatie 13, FI-90590 Oulu • www.focalspec.com

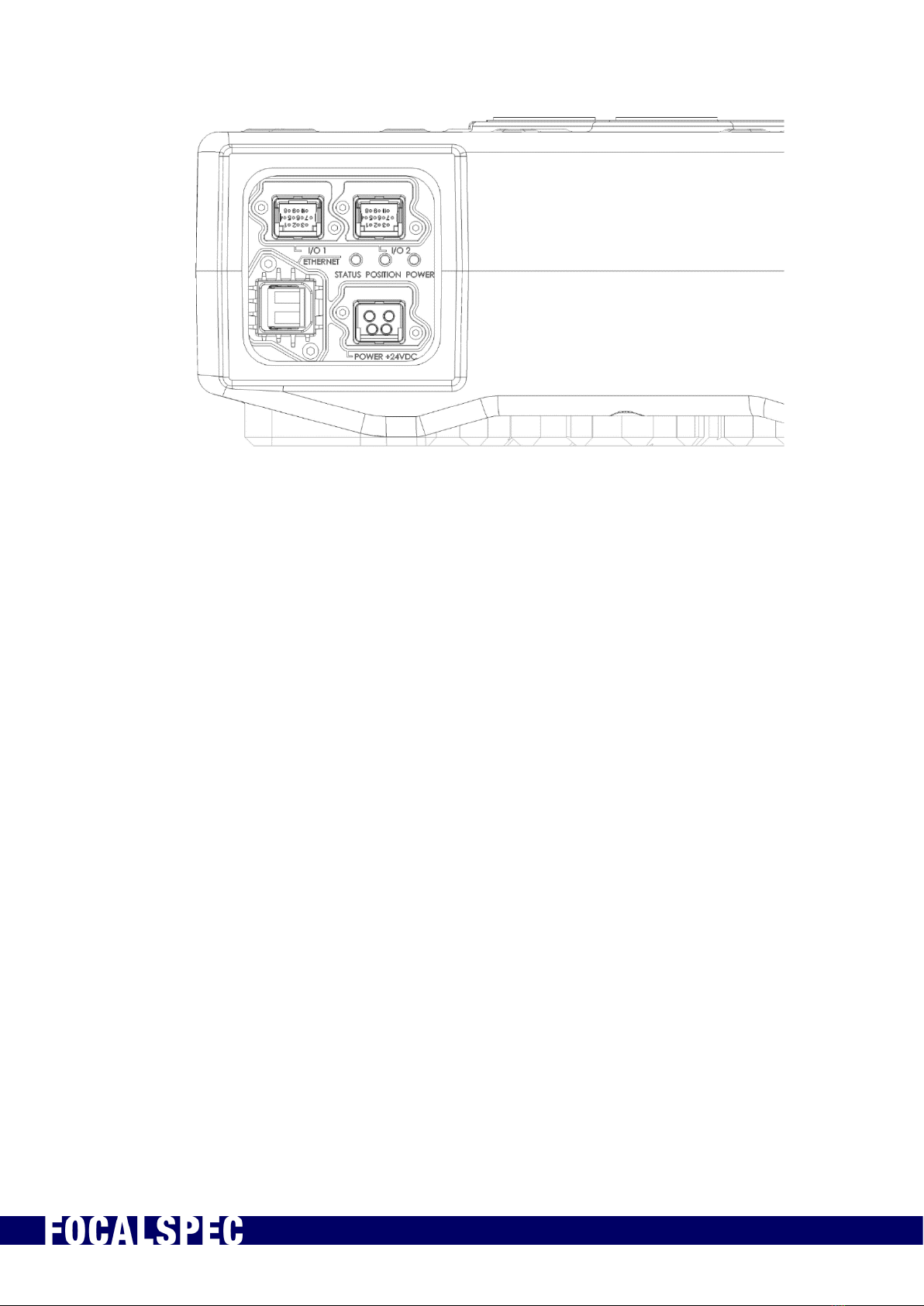

Figure 7. Electrical connections for LCI1620 (I/O 2 connector is not in-use at the

moment)

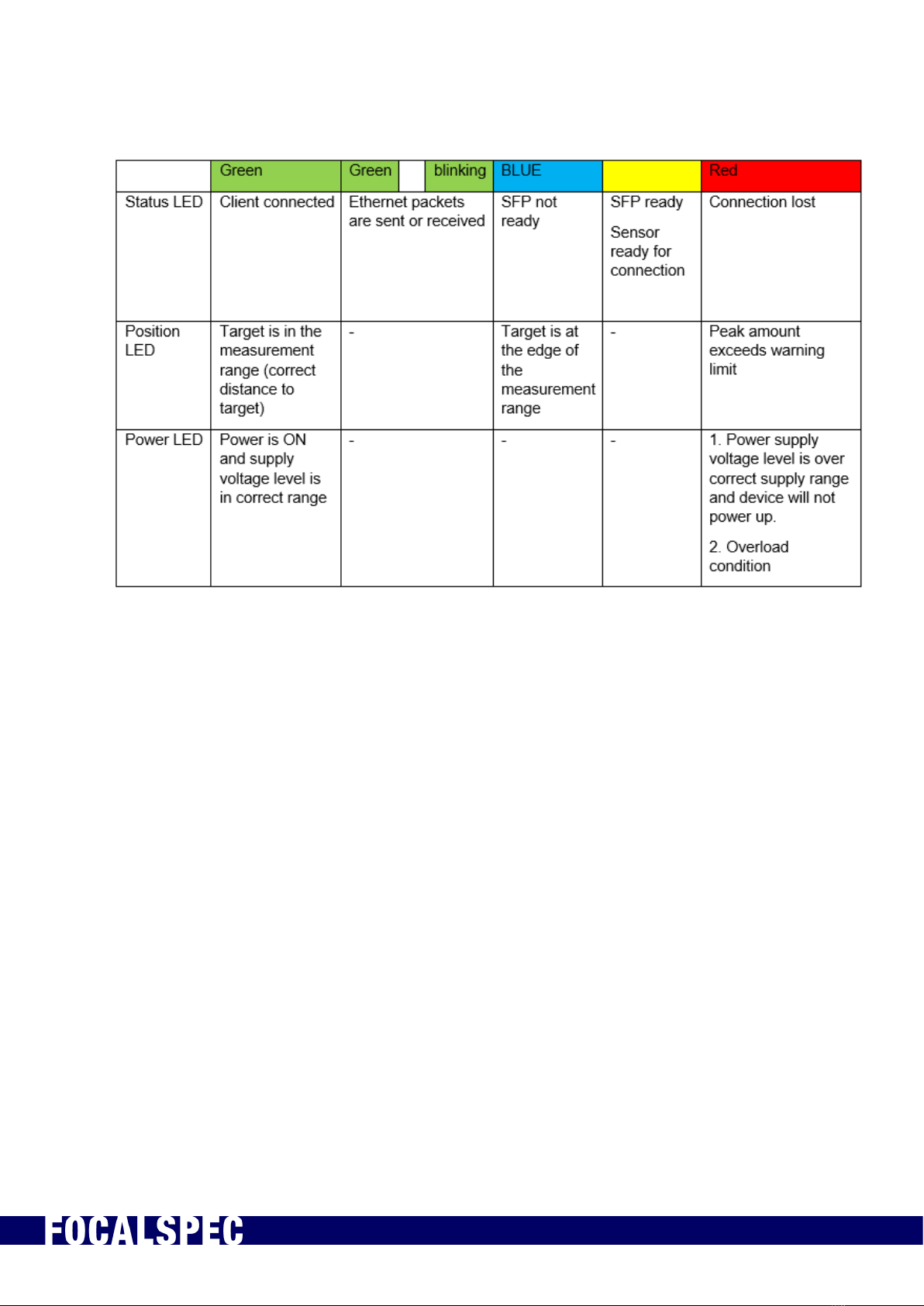

There are three indicator LEDs next to the connectors on the connector panel.

The status LED turns red if the sensor is not connected to a PC or a router. Blue means

SW is booting up, whereas a green light indicates that the connection is established. The

status LED blinks green when Ethernet packets are sent or received.

The position LED helps the user to find the correct distance to the target to measure. A

green light is shown when target is in the measurement range. A blue light is shown when

target is at the edge of the measurement range. A red light is shown when the sensor

detects ambient light. This can be caused by incorrect illumination settings.

Power LED indicates with green light that power is ON and supply voltage level is in

correct range. Red indicates that supply power is over the correct supply range and then

the device will not power up.

2019-09-30 FOCALSPEC User quide LCI1220-1620 v1.0 14/31

FocalSpec Oy • Elektroniikkatie 13, FI-90590 Oulu • www.focalspec.com

Table 2. Indicator LEDs

2019-09-30 FOCALSPEC User quide LCI1220-1620 v1.0 15/31

FocalSpec Oy • Elektroniikkatie 13, FI-90590 Oulu • www.focalspec.com

9Input and Output Description

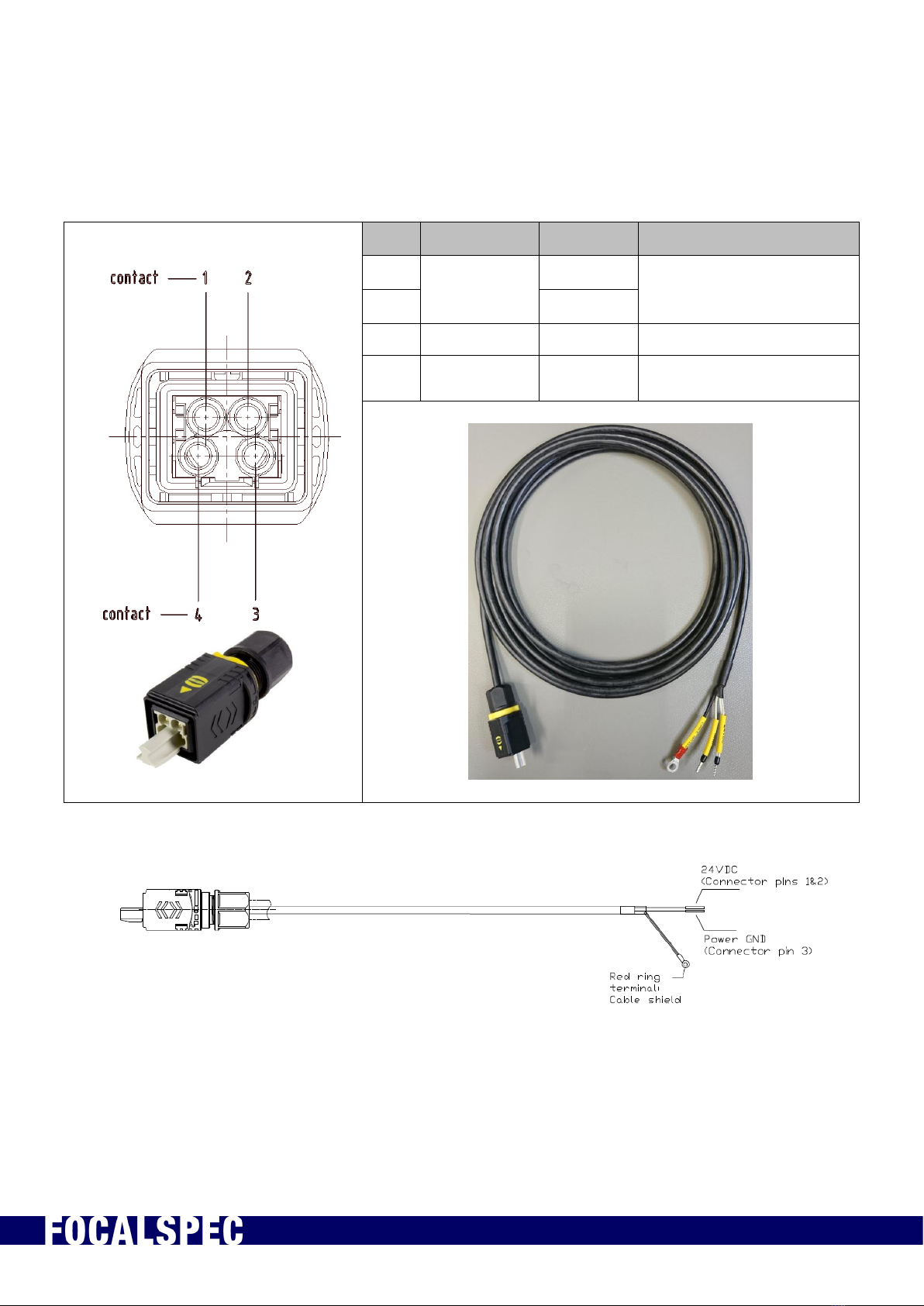

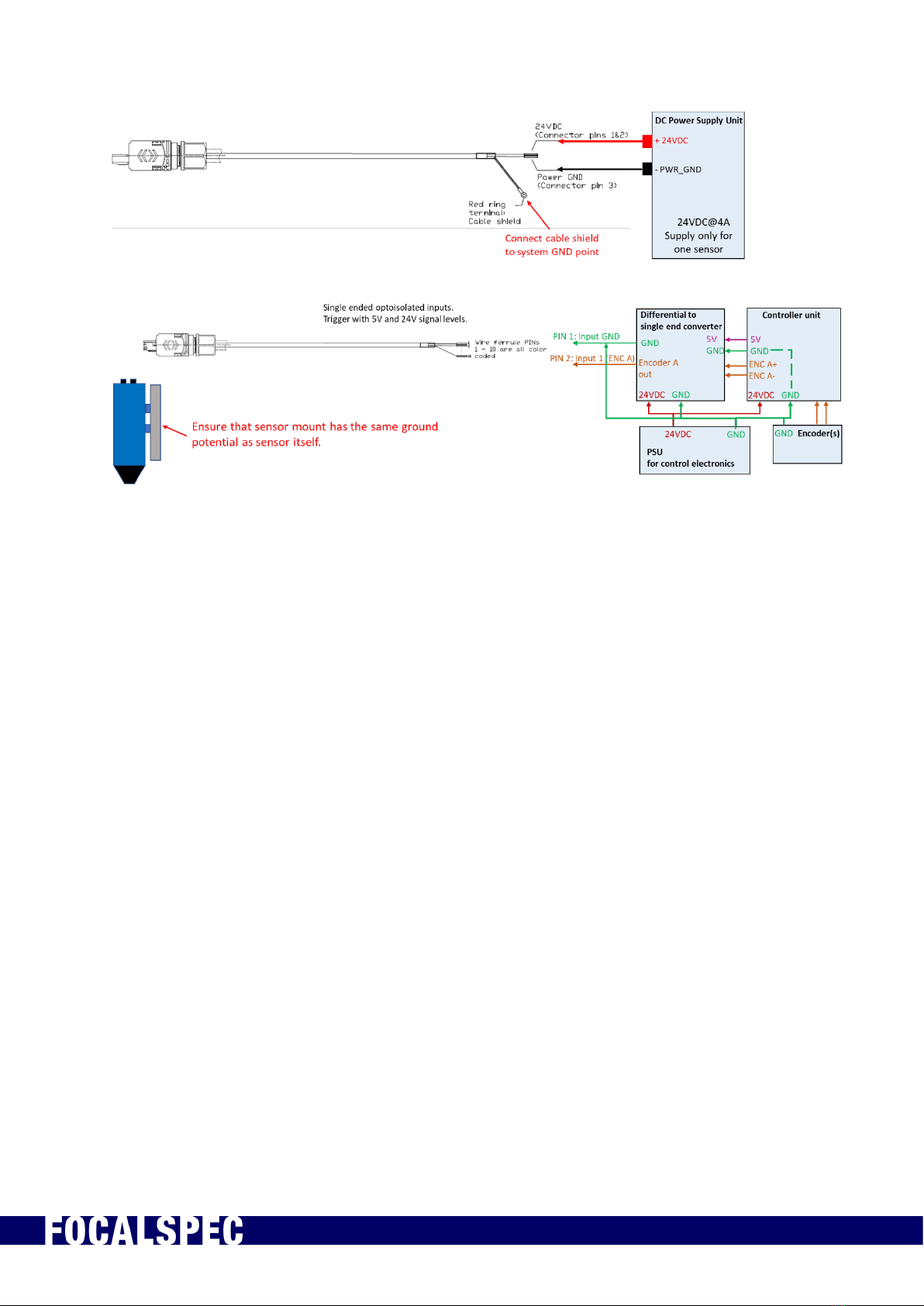

Table 3. Power cable pinout

Pin

Color

Name

Description

1

24VDC

24 V (21 V –28 V) / 2.3 A

2

24VDC

3

GND

Power Ground

4

Red ring

Terminal

Cable

Shield

Cable shield (connect to

system GND)

Figure 8. Power cable

NOTE 1: Connect the power cable ring terminal to system GND

2019-09-30 FOCALSPEC User quide LCI1220-1620 v1.0 16/31

FocalSpec Oy • Elektroniikkatie 13, FI-90590 Oulu • www.focalspec.com

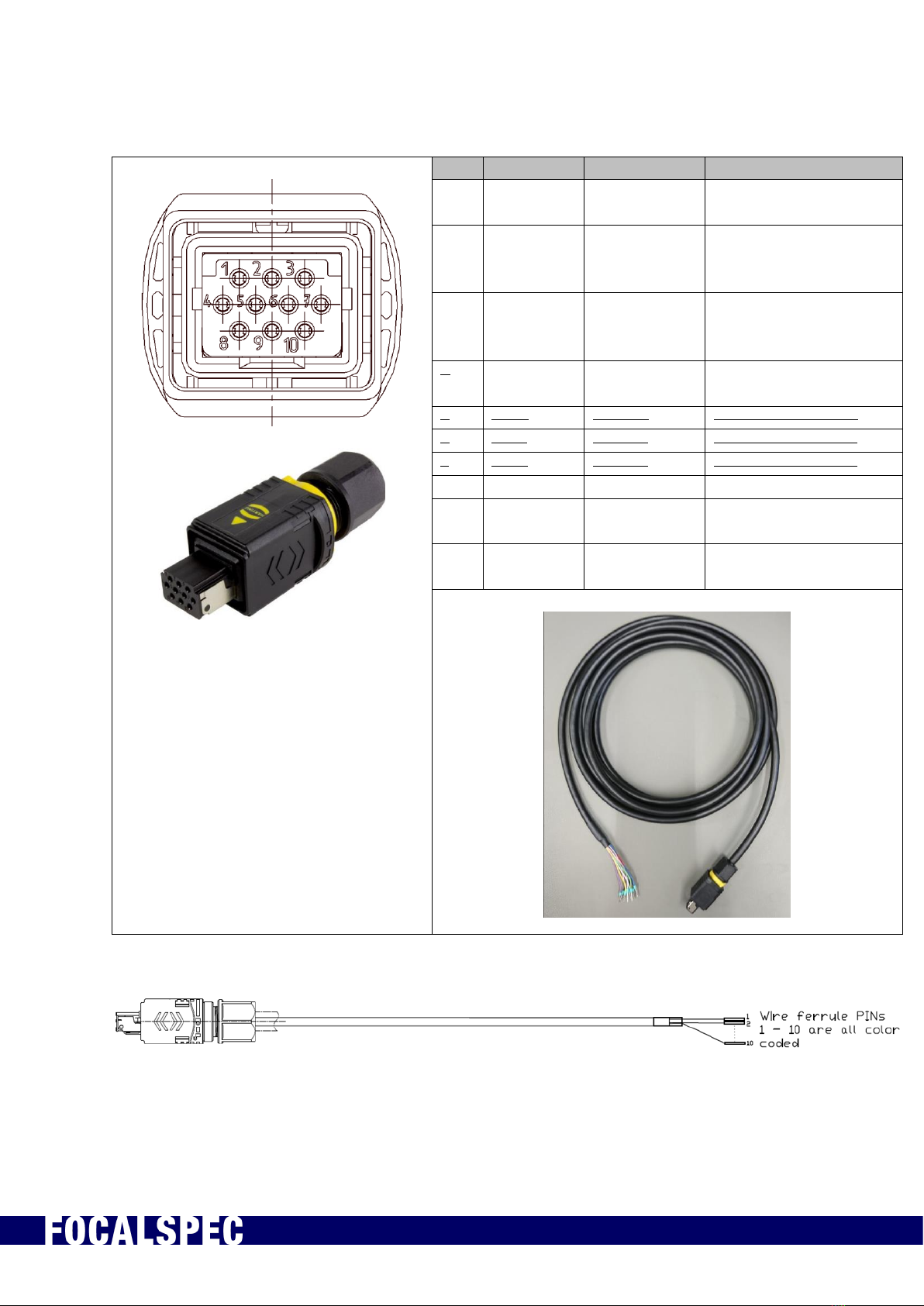

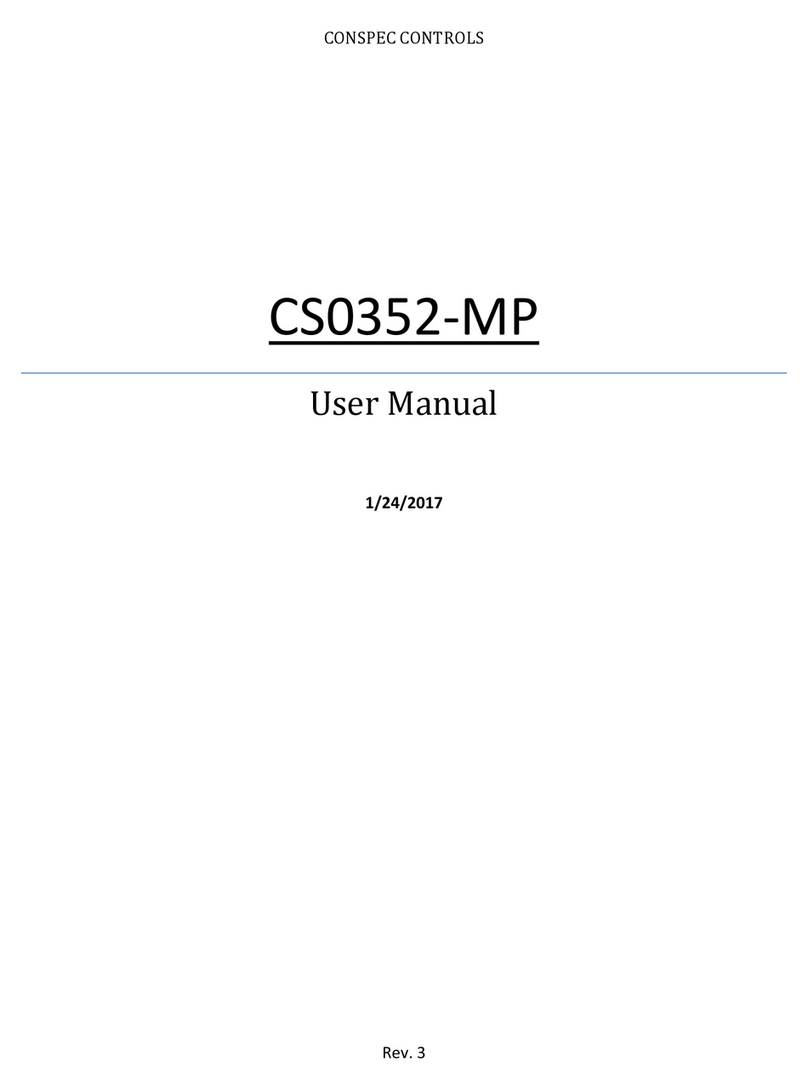

Table 4. Signal cable pinout (pins 5 to 7 not in use till later SW update)

I/O 1 PINOUT

Pin

Color

Name

Description

1

White

Input GND

Common ground for

inputs

2

Brown

Input 1

Input 1 (5V & 24 V,

default encoder A

input)

3

Green

Input 2

Input 2 (5V & 24 V,

default encoder

disable-input)

4

Yellow

Input 3

Input 3 (5V & 24 V,

default zero input)

5

Grey

Input 4

Input 4 (5V & 24 V)

6

Pink

Input 5

Input 5 (5V & 24 V)

7

Blue

Input 6

Input 6 (5V & 24 V)

8

Red

Output 1

24 V Output 1 (250 mA)

9

Black

Output 2

24 V Output 2 (250

mA)

10

Violet

GND

Digital GND (for

Output use)

Figure 9. Signal cable

2019-09-30 FOCALSPEC User quide LCI1220-1620 v1.0 17/31

FocalSpec Oy • Elektroniikkatie 13, FI-90590 Oulu • www.focalspec.com

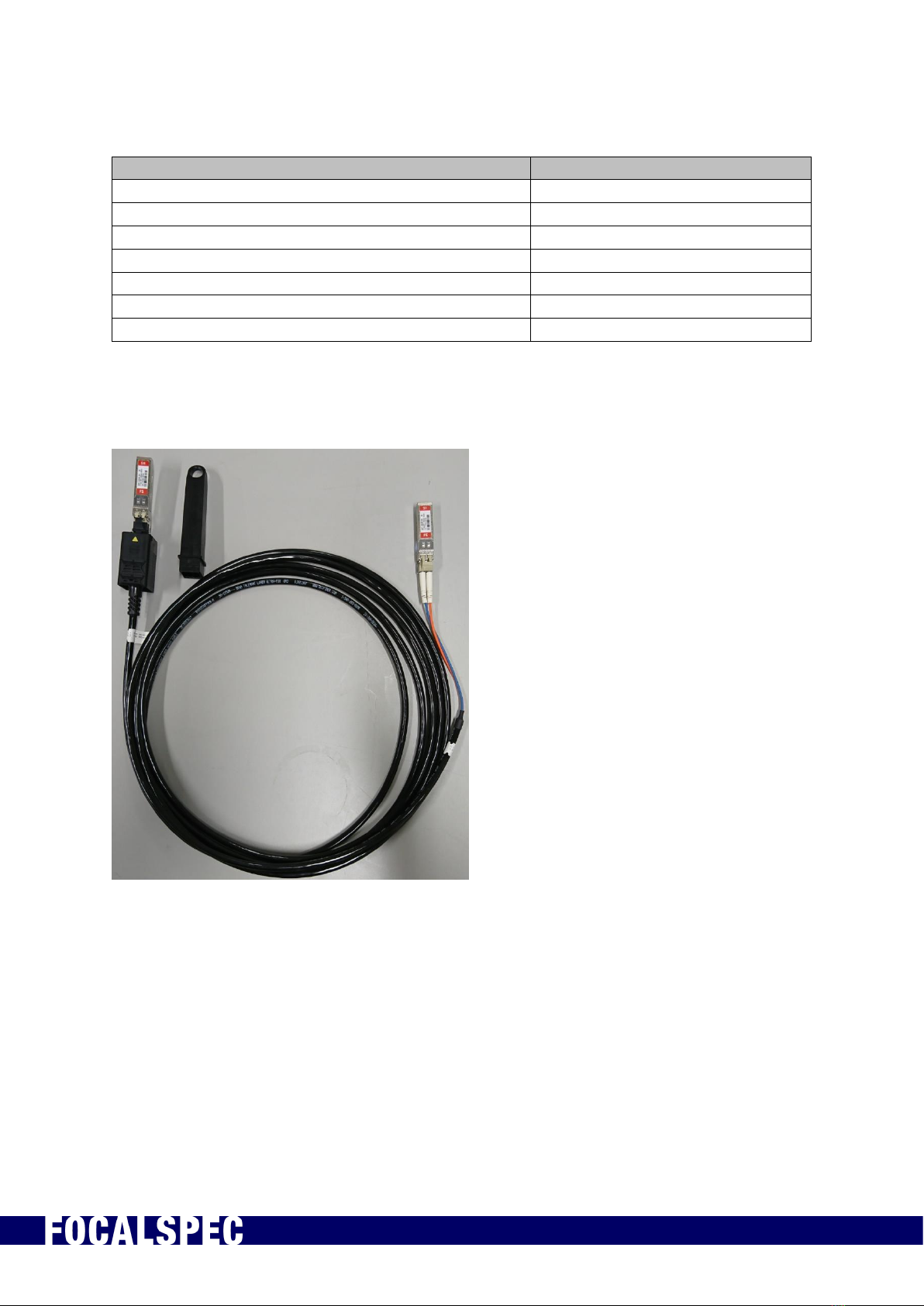

Table 5. Input / Output parameter values.

Input / Output Parameter

Value

Sensor Power supply voltage (recommended)

24VDC

Power supply unit requirements (PSU):

24VDC@4A

Input signal voltage (operating range)

3.5V - 26V

Input signal Maximum pulse rate

150 kHz

Input signal current Min

2.7 mA

Input signal current Max

15 mA

Output signal current Max (2 output pins)

250 mA

Figure 10. Optical cable with SFP+ modules in both ends

2019-09-30 FOCALSPEC User quide LCI1220-1620 v1.0 18/31

FocalSpec Oy • Elektroniikkatie 13, FI-90590 Oulu • www.focalspec.com

Figure 11. Optical cable SFP+ module

2019-09-30 FOCALSPEC User quide LCI1220-1620 v1.0 19/31

FocalSpec Oy • Elektroniikkatie 13, FI-90590 Oulu • www.focalspec.com

Figure 12. Example wiring for sensor connection

NOTE 1: Connect the power cable ring terminal to system GND

NOTE 2: Ensure that the sensor mount has the same ground potential as the sensor

itself.

This manual suits for next models

1

Table of contents

Popular Accessories manuals by other brands

Conspec Controls

Conspec Controls CS0352-MP user manual

Kathrein

Kathrein ESD 44 quick start guide

Maclean Energy

Maclean Energy MCE359 manual

Campbell

Campbell 253 product manual

Hubbell

Hubbell BTSMP-HMO Installation and operation instructions

Lucky Reptile

Lucky Reptile Herp Nursery II operating instructions