User Manual LR-1BS35

OMEN-1BS35-202202

目录

1. About this documen ...........................................................................................................1

2. Safety information..............................................................................................................1

3. Product introduction...........................................................................................................1

4. Installation and operation ...................................................................................................1

4.1. Mechanical interface.................................................................................................1

4.2. Pin and wire color assignments ................................................................................ 2

4.3. Communication interface..........................................................................................4

5. Measurement principle.......................................................................................................5

6. Data packet format .............................................................................................................5

6.1. Overview...................................................................................................................6

6.2. Definition of Header ................................................................................................. 6

6.3. Definition of data block ............................................................................................ 6

6.4. Data conversion ........................................................................................................7

7. Parameter configuration .....................................................................................................8

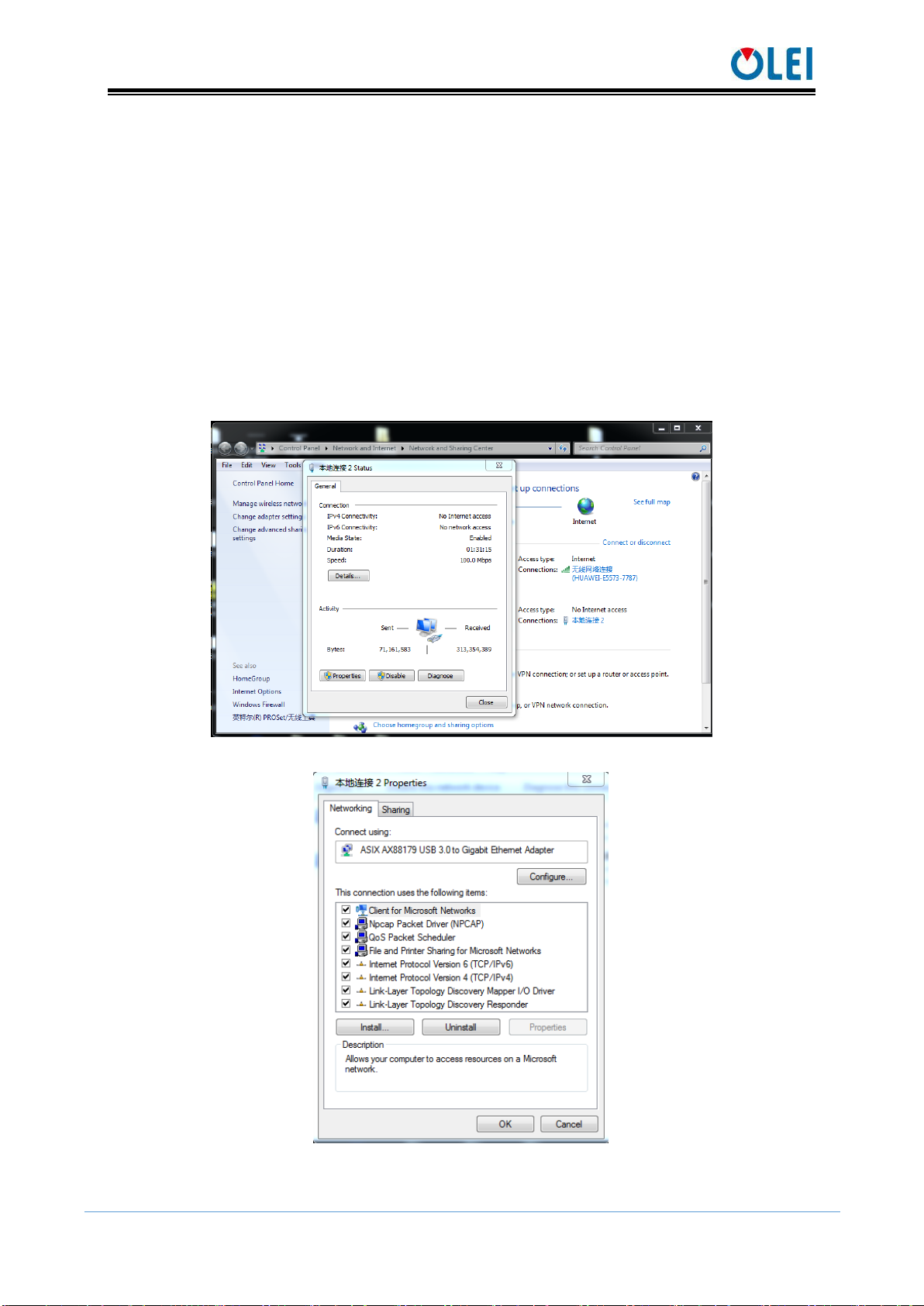

7.1. Parameter configuration of web page ....................................................................... 8

7.2. Configuration of OlamViewer ................................................................................10

8. Troubleshooting................................................................................................................10

Appendix A Data packet ........................................................................................................ 11

Appendix B Mechanical Dimensions .................................................................................... 11

Appendix C Example of Electrical Connection.....................................................................12

Appendix D Firmware Upgrade............................................................................................. 12

Appendix E Suggestions on Mechanical Installation ............................................................13

Appendix F Cleaning of sensor..............................................................................................16

F.1 Notice ......................................................................................................................16

F.2 Materials required ...................................................................................................16

F.3 Cleaning method ...................................................................................................... 16