Foerster CIRCOGRAPH DS User manual

CIRCOGRAPH®DS

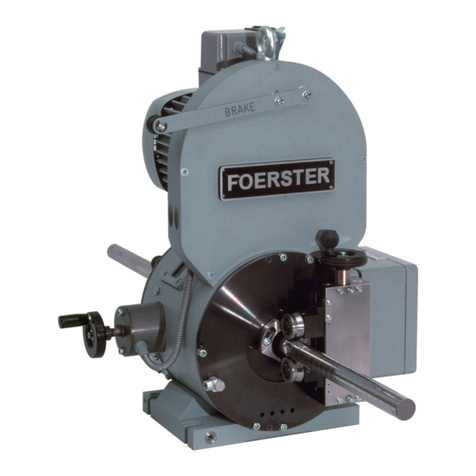

Sensor system Ro 130

6.453

Operating Instructions

SENSORSYSTEM Ro 130

6.453 – 01/2006 I

FOREWORD

These operating instructions were written to be read, understood and

complied with in full by those persons responsible for operating the ma-

chine.

The complete operating instructions consist of the following sections:

1 Safety

2 Description

3 Installation

4 Operation

5 Maintenance

Machine faults can only be avoided and fault-free operation of the ma-

chine can only be guaranteed through knowledge of the operating instruc-

tions.

It is therefore particularly important that all responsible persons are famil-

iar with and understand the full operating instructions.

Our service department or one of our representatives would be pleased to

receive suggestions about how to further improve these operating instruc-

tions. Any questions not covered by these instructions will also be dealt

with quickly and comprehensively.

SENSORSYSTEM Ro 130

II 6.453 – 01/2006

Copyright

© 2006 INSTITUT DR. FOERSTER GmbH & Co. KG.

In Laisen 70, D-72766 Reutlingen

Copyright 2006 Institut Dr. Foerster for Software:

So far software is supplied or installed on the system, it is subject to copy-

right laws. It may be used only for operating the related system in the

manner described in the sales documentation or in the User Manual. Any

use over and above this is expressively prohibited. Violations of this

clause shall entail liability to pay compensation for damages and may

also result in prosecution under criminal law

Copyright 2006 Institut Dr. Foerster for Documentation:

INSTITUT DR. FOERSTER GMBH & CO KG retains ownership of all

property rights to all information provided in this document. The docu-

ments shall support only operation and service of the delivered units. All

(direct and indirect) duplication and disclosure to unauthorized third par-

ties is strictly prohibited.

SENSORSYSTEM Ro 130

CONTENTS

6.453 – 01/2006 1

1SAFETY ................................................................................................................... 1-1

1.1 Dangers posed by this machine...................................................................................1-1

1.2 Safety information and tips...........................................................................................1-1

1.3 Use as intended ...........................................................................................................1-2

1.4 Dangers posed by accessories ....................................................................................1-2

1.5 Emissions.....................................................................................................................1-2

1.6 Danger sources............................................................................................................1-3

1.7 Workstations.................................................................................................................1-3

1.8 Authorised operators ....................................................................................................1-3

1.9 Personal safety equipment...........................................................................................1-4

1.10 Safety measures at the installation location.................................................................1-4

1.11 Protective safety devices .............................................................................................1-4

1.12 Behaviour in the event of an emergency......................................................................1-4

1.13 Declaration of conformity .............................................................................................1-5

2DESCRIPTION ......................................................................................................... 2-1

2.1 Application....................................................................................................................2-1

2.2 Mode of operation ........................................................................................................2-2

2.3 Construction .................................................................................................................2-3

2.3.1 Test Heads........................................................................................................2-6

2.3.2 Rotating Head Ro 130......................................................................................2-7

2.4 Technical Data............................................................................................................2-13

2.5 Dimension sheet ........................................................................................................2-14

2.6 Operating, storage and transport conditions ..............................................................2-16

2.7 Standard Components................................................................................................2-17

SENSORSYSTEM Ro 130

CONTENTS

26.453 – 01/2006

3INSTALLATION........................................................................................................ 3-1

3.1 Setup and Connection..................................................................................................3-1

4OPERATION............................................................................................................. 4-1

4.1 Dimension change .......................................................................................................4-1

4.2 Selection and installation of the protective nozzles......................................................4-2

4.2.1 Selection of the protective nozzles...................................................................4-2

4.2.2 Required tools ..................................................................................................4-3

4.3 Changing nominal diameter .........................................................................................4-4

4.3.1 Preparation .......................................................................................................4-4

4.3.2 Remove Entry Nozzle.......................................................................................4-5

4.3.3 Adjusting nominal diameter ..............................................................................4-7

4.3.4 Remove exit nozzles ......................................................................................4-10

4.3.5 Fitting protective nozzles................................................................................4-12

4.3.6 Setting the roller guides .................................................................................4-15

4.3.7 Positioning the transmitter system in the testing line......................................4-15

4.4 Rotational speed preselection....................................................................................4-16

4.5 Switching on motor.....................................................................................................4-17

SENSORSYSTEM Ro 130

CONTENTS

6.453 – 01/2006 3

5 MAINTENANCE ....................................................................................................... 5-1

5.1 Maintenance schedule .................................................................................................5-1

5.2 Cleaning .......................................................................................................................5-2

5.3 Removing and fitting the test heads.............................................................................5-2

5.4 Replacing parts subject to wear ..................................................................................5-5

5.5 Maintenance of the roller guides ..................................................................................5-6

5.5.1 Lubrication........................................................................................................5-6

5.5.2 Replacing the track rollers................................................................................5-7

5.5.3 Removing the roller guide levers ......................................................................5-8

5.6 Checking and changing the cone belt ..........................................................................5-9

5.7 List of parts subject to wear........................................................................................5-13

SENSORSYSTEM Ro 130

CONTENTS

46.453 – 01/2006

Notes:

SENSORSYSTEM Ro 130

SAFETY 1.1 Dangers posed by this machine

6.453 – 01/2006 1-1

1 SAFETY

1.1 Dangers posed by this machine

The sensor system features protective safety devices. It has been sub-

jected to a safety test and safety acceptance test. In the event of operat-

ing errors or misuse, the machine may pose dangers and risks to

the life and limb of the operator,

the machine and other operator’s valuables and

efficient operation of the machine

All persons involved in installation, commissioning, operation, servicing

and maintenance of the machine must

be appropriately qualified and

must strictly follow the information provided in these operating instruc-

tions.

Your safety is at stake!

1.2 Safety information and tips

The following symbols are used in these operating instructions:

DANGER!

This warns against dangers to persons. These sections provide you

with information on what to do and what not to do in order to prevent

personal injury.

WARNING!

These sections indicate possible damage to the test system. They pro-

vide information on what to do and what not to do in order to prevent

damage to property.

NOTE!

These sections provide tips for the user on how to use the system bet-

ter and also provide other useful information.

SENSORSYSTEM Ro 130

1.3 Use as intended SAFETY

1-2 6.453 – 01/2006

1.3 Use as intended

The sensor system is suitable only for non-destructive testing of round

material.

Diameter range: refer to Technical Data

Smaller diameters and larger diameters may not be admitted into the

sensor system under any circumstances.

Material with a cross-section which is anything other than round may not

be admitted into the sensor system under any circumstances.

The sensor system may be operated only in conjunction with a suitable

conveying mechanism and a lifting table.

On no account may you convert or modify the sensor system arbitrarily,

for reasons relating to safety.

DANGER!

Masses rotating at high speed pose a serious danger to your life if the

machine is operated incorrectly. Never touch the rotating sensor com-

ponents.

NOTE!

The information on operation, servicing and maintenance prescribed in

these operating instructions must be followed strictly.

1.4 Dangers posed by accessories

Transport mechanisms, lifting table and external control equipment must

not render the protective safety devices of the sensor system inoperable.

1.5 Emissions

Refer to 2.4 Technical Data

SENSORSYSTEM Ro 130

SAFETY 1.6 Danger sources

6.453 – 01/2006 1-3

1.6 Danger sources

The sensor system operates with a rotating test system and an attached

roller guide system during operation. A person coming into contact with

the roller guide or the rotating test system may suffer very serious injuries.

Switch off the drives before you put your hands into or touch the sensor

system. Wait for all motions to cease!

Before carrying out servicing and cleaning work, switch off the drive for

the sensor system and conveying mechanisms and disconnect the power

supply (secure the master switch in position OFF).

Never remove protective safety devices or render them inoperable by

making modifications to the system.

1.7 Workstations

The workstation is located on the electronic equipment cabinet or on the

operating panel of the sensor system

Do not carry out any work or tamper in any other way with the sensor sys-

tem when it is rotating.

1.8 Authorised operators

Only authorised personnel may work on the sensor system.

Please comply with the minimum legal age!

The operator is responsible for the safety of third parties in the work area.

The scopes of authority for the various activities on the sensor system

must be clearly defined and complied with.

Untrained personnel pose a safety risk!

The operator must

make the operating instructions available to the machine operator and

make sure that the machine operator has read and understood them.

SENSORSYSTEM Ro 130

1.9 Personal safety equipment SAFETY

1-4 6.453 – 01/2006

1.9 Personal safety equipment

You are to wear ear plugs, if the A-weighted equivalent sound pressure

level at the workstations of the sensor system is greater than 85 dB(A).

Sound pressure level for this equipment: refer to 2.4 Technical Data

1.10 Safety measures at the installation location

The sensor system must be installed stably on a machine foundation pro-

vided for it and must be firmly anchored to the foundation. If this is not

done, this will pose a potentially lethal risk.

NOTE!

Ensure that the area surrounding the workstation is always clean and

unobstructed by issuing appropriate in-company instructions and con-

ducting inspections.

1.11 Protective safety devices

The CIRCOGRAPH sensor system is shut down

when opening the housing (safety switch on the rotor cover)

with the switch on the operating panel or on the electronic equipment

cabinet

with the EMERGENCY-STOP switch on the operating panel

(EMERGENCY-STOP has to be linked with motor control)

The protective safety devices

are installed to ensure the safety of the operating staff

may not be modified, removed or bypassed by making modifications to

the sensor system under any circumstances.

1.12 Behaviour in the event of an emergency

In an emergency, please immediately press the red EMERGENCY-STOP

switch. Have authorised personnel remedy the cause of the fault immedi-

ately.

SENSORSYSTEM Ro 130

6.453 – 01/2006 1-5

1.13 Declaration of conformity

We declare, that this product complies with the requirements of following

European Directives and corresponding standards:

European Directive 89/392/EEC: Safety of machines

European Standards EN 12100, EN 60204

European Directive 73/23/EEC: Safety of electrical apparatus

European Standard EN 61010

European Directive 89/336/EEC: Electromagnetic Compatibility

European Standard EN 61326-1

February 23, 2005

INSTITUT DR. FOERSTER

Division TS - Test Systems

Dr. Jürgen Schröder

SENSORSYSTEM Ro 130

1-6 6.453 – 01/2006

Notes:

SENSORSYSTEM Ro 130

DESCRIPTION 2.1 Application

6.453 – 01/2006 2-1

2 DESCRIPTION

2.1 Application

Non-destructive testing of ferromagnetic, austenitic and non-

ferromagnetic round materials (wires, bars, and tubes) for surface flaws in

conjunction with the CIRCOGRAPH®DS testing and evaluation electronic

equipment and a suitable mechanical handling system.

Diameter range of testing material 10 to 130 mm

Preferably piece testing

Surface free of scale, wherever possible bright

Testing without physical contact at rotational speeds up to 3,000 rpm

End condition free of projecting burrs

Max. test material temperature +80 °C

Test heads with tracking width 2x2.5 – 2x5 – 2x10 mm [BS]

Testing capacity

surface flaw testing, preferably longitudinal flaws

flaw detectability for bright material surface from flaw depth of approx.

50 µm

testing speed of up to 2 m/s for gapless testing (rotational speed =

3,000 rpm and two test heads with 2x10 mm track width)

SENSORSYSTEM Ro 130

2.2 Mode of operation DESCRIPTION

2-2 6.453 – 01/2006

2.2 Mode of operation

The sensor system operates on the basis of the eddy current principle in

accordance with EN 12084. Rotating systems are used to detect longitu-

dinal surface defects. Probes rotate at high speed and without physical

contact around the test piece. By feeding the material the probes scan the

surface in helical paths.

Due to the locally high resolution of the probes and the transverse move-

ment across the crack by each revolution, this is the most sensitive

method for detecting longitudinal defects.

Any time a probe crosses a crack , it generates a signal. Thus, the rotat-

ing system generates a high number of consecutive signals that reliably

indicate a flaw of a certain length.

The testing speed is a result of the number of rotating probes, integrated

in the Ro 130, the track width of all probes, and the rotating speed (rpm).

The helical path of all probes must be side by side to guarantee a fully

gapless scan.

The signals recorded by the probes are transferred from the sensor sys-

tem to the test electronics for evaluation.

The primary power supply and the secondary signal of the probes are

transmitted by rotating inductive transmitters without physical contact.

Signal generation during

rotary testing

Test tracks and flaw signals

of a rotating probe

Test tracks of two test heads

with 2 probes each

offset by 180º

SENSORSYSTEM Ro 130

DESCRIPTION 2.3 Construction

6.453 – 01/2006 2-3

2.3 Construction

CIRCOGRAPH DS test electronics and the connection cables are re-

quired for a complete test system, besides the sensor system which

scans the test material and generates the eddy-current signal.

A separate leaflet:

“CIRCOGRAPH DS System 6.430”, Order-No. 163 852 1

will inform you about the according test electronics.

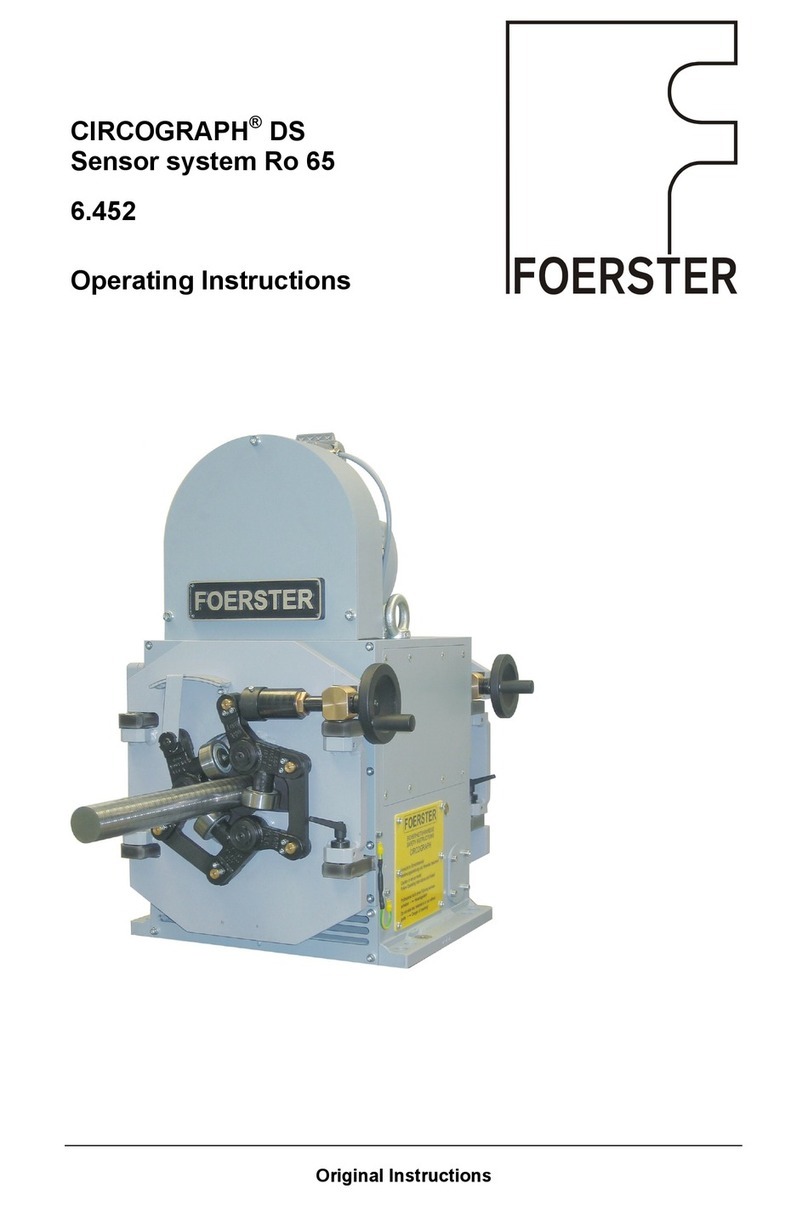

Fig. 2.1 Test equipment configuration,

top: CIRCOGRAPH DS / MOC SB, bottom: Rotating head Ro 130 entry and exit side

SENSORSYSTEM Ro 130

2.3 Construction DESCRIPTION

2-4 6.453 – 01/2006

Roller guide Clamping ring - Nozzle - Adapter - Flange Nozzle - Nozzle holder - Inner and Outer sleeve Roller guide

Fig. 2.2 CIRCOGRAPH Sensor system Ro 130, main view, legend see Chap. 2.7

Flaw direction

Fig. 2.3 CIRCOGRAPH Sensor system Ro 130, basic components

SENSORSYSTEM Ro 130

DESCRIPTION 2.3 Construction

6.453 – 01/2006 2-5

In order to withstand the rough conditions of use, the Ro 130 has been

designed to be dust-protected, robust and reliable by means of complex

constructional measures such as labyrinth seals and dirt deflectors.

The chamber surrounding the test zone serves the purpose of contact

and burst protection as well as dust collection. This chamber is provided

to connect an external extraction system (to be provided by customer).

The Ro 130 sensor system consists of the following compulsory compo-

nents:

rotating head Ro 130

test heads

protective nozzles

The following options are available for adaptation to particular material

conditions:

Centric triple roller guides

Nozzle holder and Protective Nozzles with connector for compressed

air (to keep the testing zone free of dust)

SENSORSYSTEM Ro 130

2.3 Construction DESCRIPTION

2-6 6.453 – 01/2006

2.3.1 Test Heads

The test heads are both the heart of the sensor system and its most criti-

cal components.

They consist of an eddy-current probe with field, measuring and clear-

ance windings which are installed in a precise mechanical holder and are

connected by means of a highly flexible special cable with a connection

plug.

As already mentioned in the ‘Mode of operation’ section, there is a

mathematical relationship between the number and track width of the test

heads, the rotational speed and the testing speed.

The following table shows these relationships and gives typical examples

for a practical selection:

Maximum testing speed Test head type

n = 1,500 rpm

n = 3,000 rpm

Number / Track

width TH / BS

Bright material

Fe - Nfe - Aust

rough rolled

Fe

Decreasing

sensitivity to short

flaws

0.25 m/s

0.5 m/s 2 TH / 2 x 2.5 mm 6.453.01-2311 6.453.03-2311

0.5 m/s

1.0 m/s 2 TH / 2 x 5.0 mm 6.453.01-2321 6.453.03-2321

1.0 m/s

2.0 m/s 2 TH / 2 x 10 mm 6.453.01-2331 6.453.03-2331

Tab. 2.1 Test head selection

Rotating disc with test heads

p

robe

Test head

Other manuals for CIRCOGRAPH DS

1

This manual suits for next models

1

Table of contents

Other Foerster Accessories manuals