Foerster CORCOGRAPH Ro 20 P User manual

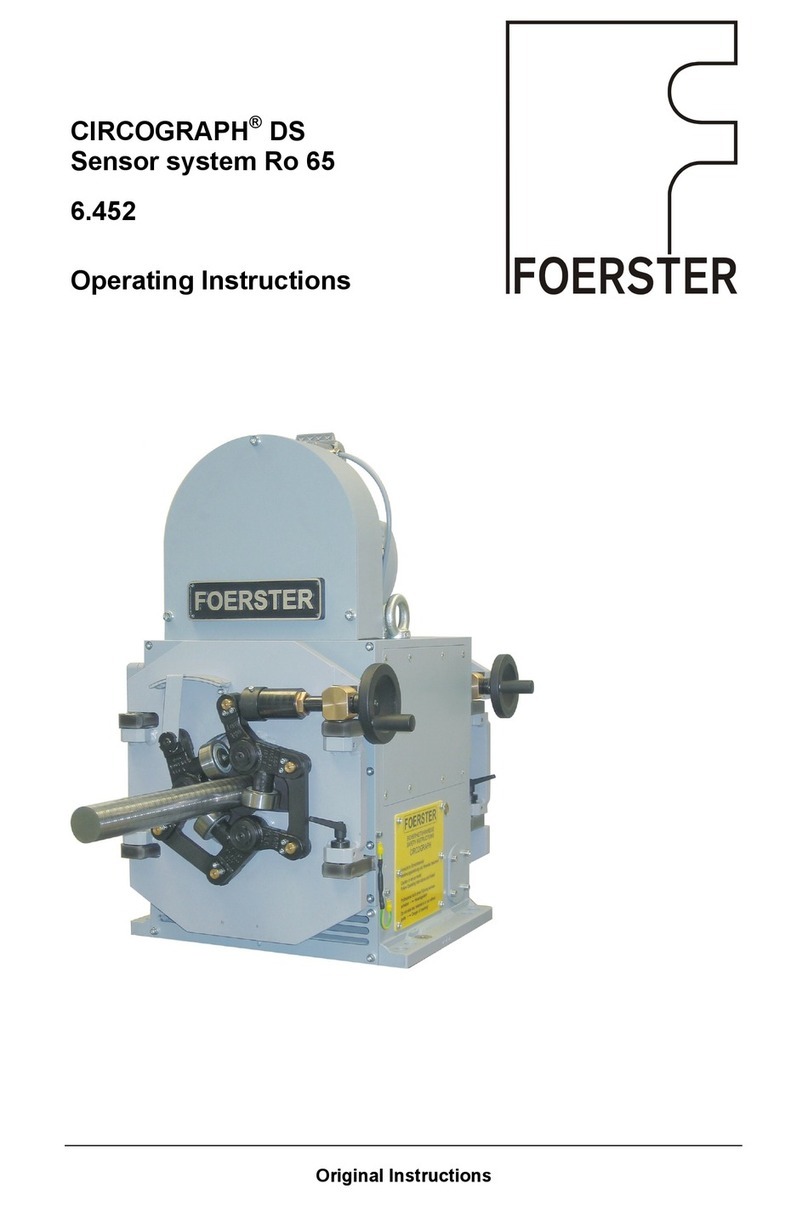

CIRCOGRAPH®

Sensor system Ro 20 P 6.460

Operating Instructions

FOREWORD

FOREWORD

These operating instructions were written to be read, understood

and complied with in full by those persons responsible for operat-

ing the machine.

The complete operating instructions consist of the following sec-

tions:

1 Safety

2 Description

3 Installation

4 Operation

5 Maintenance

Machine faults can only be avoided and fault-free operation of the

machine can only be guaranteed through knowledge of the oper-

ating instructions.

It is therefore particularly important that all responsible persons

are familiar with and understand the full operating instructions.

Our service department or one of our representatives would be

pleased to receive suggestions about how to further improve

these operating instructions. Any questions not covered by these

instructions will also be dealt with quickly and comprehensively.

6.460 - 10/2002 I

Copyright

These operating instructions contain copyrighted information.

All rights reserved, INSTITUT DR. FOERSTER GmbH & Co. KG.

These operating instructions are intended for assembly, operating

and monitoring personnel.

Copying, reproduction or translation of these operating instructions

into other languages in whole or in part requires the express written

approval of INSTITUT DR. FOERSTER GmbH & Co. KG.

© 2002 INSTITUT DR. FOERSTER GmbH & Co. KG.

In Laisen 70, D-72766 Reutlingen

II 6.460 -08/2004

Table of Content1 SAFETY 1/1

1.1 Dangers posed by this machine 1/1

1.2 Safety information and tips 1/1

1.3 Use as intended 1/2

1.4 Dangers posed by accessories 1/2

1.5 Emissions 1/2

1.6 Danger sources 1/3

1.7 Workstations 1/3

1.8 Authorised operators 1/3

1.9 Personal safety equipment 1/3

1.10 Safety measures at the installation location 1/4

1.11 Protective safety devices 1/4

1.12 Behaviour in the event of an emergency 1/4

2 Description 2/1

2.1 Application 2/1

Testing capacity 2/1

2.2 Mode of operation 2/2

2.3 Construction 2/4

2.3.1 Test Heads 2/6

2.3.2 Rotating Head Ro 20 P 2/7

Rotor 2/7

Sensor 2/8

Rotating head electronics 2/8

Drive 2/9

Diameter adjustment 2/10

Protective nozzles standard 2/10

Precision guide 2/12

Roller guide 2/13

2.4 Technical data 2/14

2.5 Operating, storage and transport conditions 2/15

Operation 2/15

Storage and transport 2/15

Storage conditions 2/15

2.6 Dimension sheet 2/16

2.7 Standard Components 2/18

3. INSTALLATION 3/1

3.1 Setup and Connection 3/1

Electrical connections 3/2

SENSOR SYSTEM Ro 20 P

Table of Content page

6.460 - 10/2002 1

i

4. OPERATION 4/1

4.1 Dimension change 4/1

Preparation 4/1

Dimension change procedure 4/1

4.2 Selection and installation of the protective nozzles 4/2

4.2.1 Selection of the protective nozzles 4/2

Function of the protective nozzles 4/2

Standard Nozzle 4/3

Precision Nozzle 4/4

4.2.2 Required tools 4/5

4.3 Changing nominal diameter 4/6

4.3.1 Preparation 4/6

4.3.2 Removing nozzle holder 4/7

Adjustment side 4/7

Drive side 4/8

4.3.3 Changing nozzles 4/9

4.3.4 Adjusting probe clearance 4/10

4.3.5 Adjusting roller guide 4/13

4.4 Rotational speed preselection 4/13

4.5 Switching on motor 4/14

5. Maintenance 5/1

5.1 Maintenance schedule 5/1

5.2 Cleaning 5/2

5.3 Removing test heads 5/3

5.3.1 Installing test heads 5/7

5.4 List of parts subject to wear 5/8

SENSOR SYSTEM Ro 20 P

Table of Content page

26.460 - 10/2002

1SAFETY

1.1 Dangers posed by this machine

The CIRCOGRAPH sensor system Ro 20 P features protective

safety devices. It has been subjected to a safety test and safety

acceptance test. In the event of operating errors or misuse, the

machine may pose dangers and risks to

§the life and limb of the operator,

§the machine and other operator’s valuables and

§efficient operation of the machine

All persons involved in installation, commissioning, operation,

servicing and maintenance of the machine must

§be appropriately qualified and

§must strictly follow the information provided in these operating

instructions.

Your safety is at stake!

1.2 Safety information and tips

The following symbols are used in these operating instructions:

DANGER!

This warns against dangers to persons. These sections

provide you with information on what to do and what not

to do in order to prevent personal injury.

WARNING!

These sections indicate possible damage to the test sys-

tem. They provide information on what to do and what

not to do in order to prevent damage to property.

+NOTE!

These sections provide tips for the user on how to use

the system better and also provide other useful informa-

tion.

SENSOR SYSTEM Ro 20 P

SAFETY 1.1 Dangers posed by this machine

6.460 - 10/2002 1/1

1.3 Use as intended

The CIRCOGRAPH sensor system Ro 20 P is suitable only for

non-destructive testing of round material.

Diameter range 2 mm to 20 mm, continuously adjustable!

Larger diameters may not be admitted into the sensor system un-

der any circumstances.

Material with a cross-section which is anything other than round

may not be admitted into the sensor system under any circum-

stances.

The sensor system may be operated only in conjunction with a

suitable conveying mechanism and a lifting table.

On no account may you convert or modify the sensor system arbi-

trarily, for reasons relating to safety.

DANGER!

Masses rotating at high speed pose a serious danger to

your life if the machine is operated incorrectly.

Never touch the rotating sensor components.

+NOTE!

The information on operation, servicing and mainte-

nance prescribed in these operating instructions must

be followed strictly.

1.4 Dangers posed by accessories

Transport mechanisms, lifting table and external control equip-

ment must not render the protective safety devices of the

CIRCOGRAPH sensor system Ro 20 P inoperable.

1.5 Emissions

The maximum A-weighted equivalent sound pressure level lies at

82 dB(A) in a distance of 1 m from the machine’s surface and at

1.6 m above basement, measured in axial direction of the ventila-

tor. The values at the workstations of the personell are resp.

lower, also when using rotating speeds less than 18.000 rpm.

SENSOR SYSTEM Ro 20 P

1.3 Use as intended SAFETY

1/2 6.460 - 10/2002

1.6 Danger sources

The CIRCOGRAPH sensor system Ro 20 Poperates with a

rotating test system and an attached roller guide system

during operation. A person coming into contact with the roller

guide or the rotating test system may suffer very serious injuries.

Switch offthe drives before you put your hands into or touch the

sensor system. Wait for all motions to cease.

Before carrying out servicing and cleaning work, switch off the

drive for the sensor system and conveying mechanisms and dis-

connect the power supply (secure the master switch in position

OFF).

Never remove protective safety devices or render them inopera-

ble by making modifications to the system.

1.7 Workstations

The workstation is located on the electronic equipment cabinet or

on the operating panel of the CIRCOGRAPH sensor system Ro

20 P.

Do not carry out any work or tamper in any other way with the

sensor system when it is rotating.

1.8 Authorized operators

Only authorized personnel may work on the CIRCOGRAPH sen-

sor system Ro 20 P. Please comply with the minimum legal age!

The operator is responsible for the safety of third parties in the

work area.

The scopes of authority for the various activities on the sensor

system must be clearly defined and complied with.

Untrained personnel pose asafety risk!

The operator must make

- the operating instructions available to the machine operator and

- sure that the machine operator has read and understood them

1.9 Personal safety equipment

No personal safety equipment is required.

SENSOR SYSTEM Ro 20 P

SAFETY 1.6 Danger sources

6.460 -08/2004 1/3

1.10 Safety measures at the installation location

The CIRCOGRAPH sensor system Ro 20 P must be installed

stably on a machine foundation provided for it and must be firmly

anchored to the foundation. If this is not done, this will pose a po-

tentially lethal risk.

+NOTE!

Ensure that the area surrounding the workstation is al-

ways clean and unobstructed by issuing appropriate

in-company instructions and conducting inspections.

1.11 Protective safety devices

The CIRCOGRAPH sensor system is shut down

§when opening the housing (safety switch on the rotor cover)

§with the switch on the operating panel or on the electronic

equipment cabinet

§with the EMERGENCY-STOP switch on the operating panel

(EMERGENCY-STOP has to be linked with motor control)

The protective safety devices

§are installed to ensure the safety of the operating staff

§may not be modified, removed or bypassed by making modifi-

cations to the sensor system under any circumstances.

1.12 Behavior in the event of an emergency

In an emergency, please immediately press the red

EMERGENCY-STOP switch. Have authorized personnel remedy

the cause of the fault immediately.

SENSOR SYSTEM Ro 20 P

1.10 Safety measures at the installation location SAFETY

1/4 6.460 - 10/2002

DECLARATION of CONFORMITY

Manufacturer: INSTITUT DR. FOERSTER GmbH & Co. KG Phone. +49 7121 140-0

In Laisen 70 Fax +49 7121 140-488

GERMANY www.foerstergroup.de

Responsibility for

documentation: Dr. Juergen Schroeder

Product: CIRCOGRAPH DS Ro20

Type: 6.460.01-1001

Serial No.: 00309 and higher

We declare, that this product complies with the requirements of following European Directives

and corresponding Standards:

European Directive 2006/42/EC: Safety of machinery

European Standards EN 12100-1, -2, EN 14121-1, EN 60204-1

European Directive 2006/95/EC: Safety of electrical apparatus

European Standard EN 61010-1

European Directive 2004/108/EC: Electromagnetic Compatibility

European Standard EN 61326-1

This declaration relates exclusively to the machinery in the state in which it was placed on the market, and excludes

components which are added and/or operations carried out subsequently by the final user.

Reutlingen, December 29, 2009

Dr. Juergen Schroeder

General Manager - Division Test Systems

Notes:

SENSOR SYSTEM Ro 20 P

1/6 6.460 - 10/2002

BESCHREIBUNG

2Description

2.1 Application

Nondestructive testing of ferromagnetic, austenitic and

nonferromagnetic round materials (wires, bars and tubes) for sur-

face flaws in conjunction with the CIRCOGRAPH®DS 6.430 (two

channel with Clearance Compensation) or CIRCOGRAPH®CP6.412

(one-channel without Clearance Compensation) testing and eval-

uation electronic equipment and a suitable mechanical handling

system

§Diameter range of testing material 2 to 20 mm

§Preferably continuous testing, also separate piece testing

§Surface free of scale, wherever possible bright

§Testing mode without physical contact at rotational speeds

upto 18.000 rpm

§End condition free of projecting burrs

§Max. test material temperature +80 °C

§Testheads with tracking width 1,5 / 2,5 und 5 mm [BS]

Typ N as standard,

Typ DF for encreased clearance (prefered for FE material)

§Quickcange nozzeles inside and outside

§Blower facilitiy for cooling and maintaining cleanliness

§Precision guiding unit

Testing capacity

§surface flaw testing, preferably longitudinal flaws

§flaw detectability for bright material surface from flaw depth of

approx. 30 µm

§testing speed of up to 3 m/s for gapless testing (rotational

speed = 18,000 rpm, two test heads with 5 mm track width)

SENSOR SYSTEM Ro 20 P

Description 2.1 Application

6.460- 10/2002 2/1

i

2.2 Mode of operation

The sensor system Ro 20 operates on the basis of the eddy-cur-

rent principle in accordance with EN 12. 084. Rotating systems

are used to detect longitudinal surface defects. Probes rotate at

high speed and without physical contact around the test piece. By

feeding the material the probes scan the surface in helical paths.

Due to the locally high resolution of the probes and the transverse

movement across the crack by each revolution, this is the most

sensitive method for detecting longitudinal defects.

Any time a probe crosses a crack, it generates a signal. Thus,

the rotating system generates a high number of consecutive

signals that reliably indicate a flaw of a some length.

The testing speed result in the number of rotating pin probes,

integrated in the Ro 20 (2 or 1 pin probes), the track width of all

pin probes and the rotating speed (rpm). The helical path of

all probes must be side by side to guarantee a fully gapless scan.

The signals recorded by the probes are transferred from the sen-

sor system to the test electronics for evaluation.

The primary power supply and the secondary signal of the probes are

transmitted by rotating inductive transmitters without physical contact.

Two types of motor controls are available:

MOC E (economy version) with one constant rational speed

at 9000 rpm and manual brake system.

MOC EV with variable rotational speeds up to 18000 rpm

and electrical brake system.

SENSOR SYSTEM Ro 20 P

2.2 Mode of operation Description

2/26.460 -08/2004

i

Sondenrotation

Probe rotation

Rotiersonde

Rotating probe

Riß Crack

Sondenwirkbereich

Effective probe area

Signal generation during

rotary testing

Rotiersonde

otating probe

Gesamtfehlersignal

Overall flaw signal

Abtastspuren Scanning tracks

Test tracks and flaw signals of

a rotating probe

Abtastspuren Scanning tracks

2

122

1

2

1

Test tracks of two rotating

probes offset by 180º

SENSOR SYSTEM Ro 20 P

Description 2.2 Mode of operation

6.460 - 10/2002 2/3

i

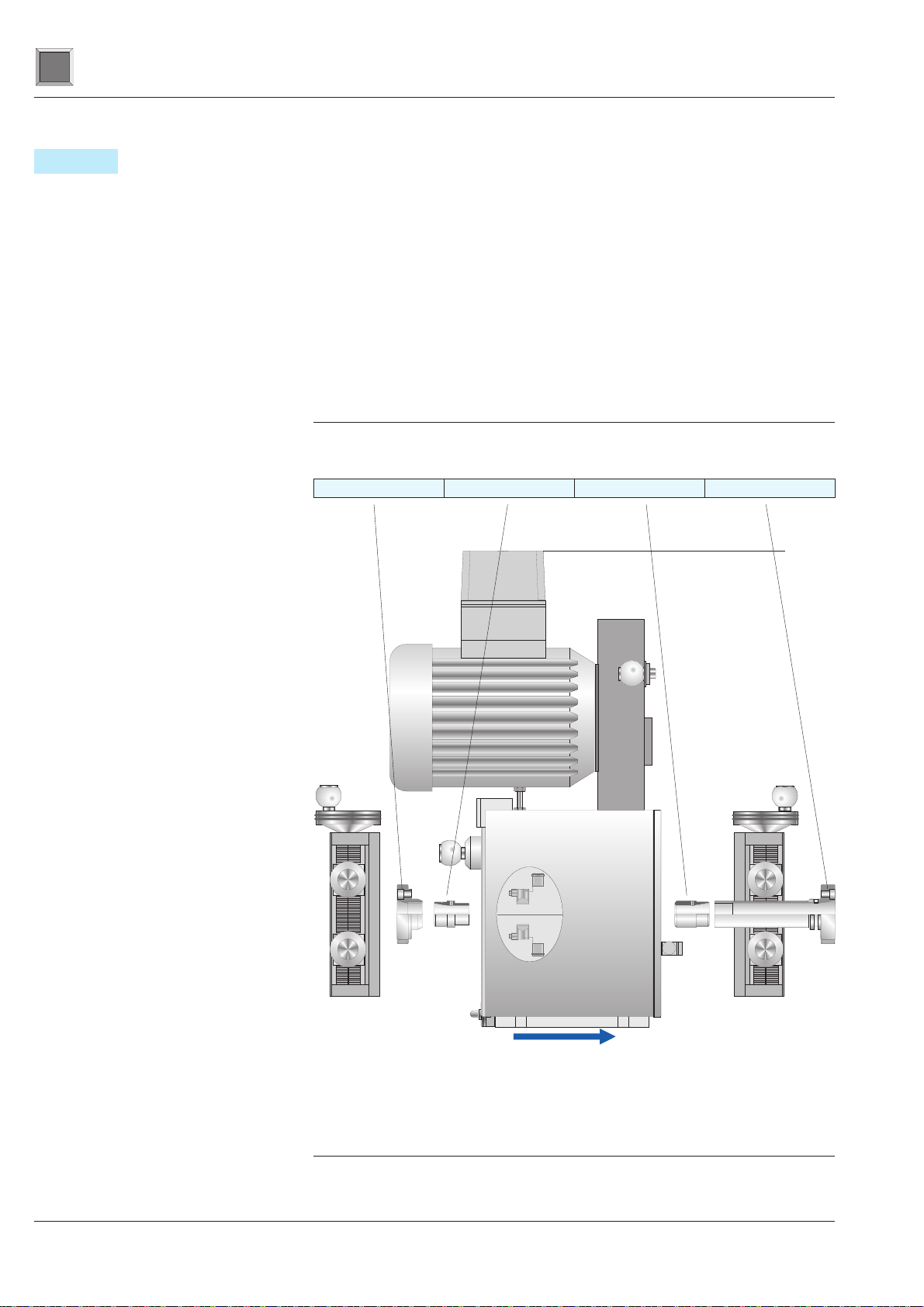

Fig. 2/4Test equipment configuration, CIRCOGRAPH CP (top), CIRCOGRAPH DS (bottom)

2.3 Construction

CIRCOGRAPH DS or DEFECTOMAT CP test electronics and the

connection cables are required for a complete test system, be-

sides the sensor system which scans the test material and gener-

ates the eddy-current signal.

Separate Leaflets:

“CIRCOGRAPH DS System 6.430", Order-No. 163 852 1 and

”CIRCOGRAPH CP 6.412", Order-No. 152 266 3 will inform You

about the according test electronics.

SENSOR SYSTEM Ro 20 P

2.3 Construction Description

2/4 6.460 - 10/2002

i

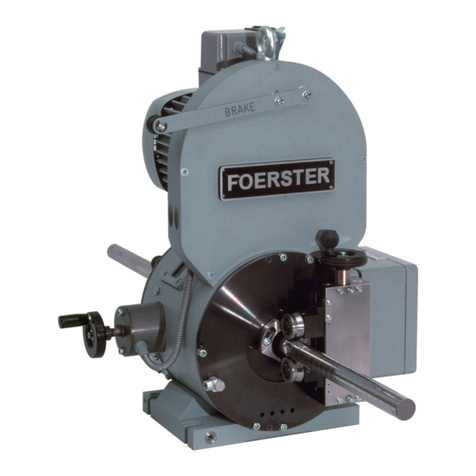

Fig.2/5 CIRCOGRAPH sensor system Ro 20 P

Throughput

preferred direction

Roller guide Ro 20 P left

Ø 4,5 - 20 6.460.01-5001

Ø 1 - 8 6.460.01-5002

Roller guide Ro 20 P right

Ø 4,5 - 20 6.460.01-5011

Ø 1 - 8 6.460.01-5012

Nozzle Holder Outside Nozzle Outside Nozzle Inside Nozzle Holder Inside

The compact CIRCOGRAPH CP test electronics is recommended

in the following cases

§no clearance compensation is required

§a reasonably priced solution is needed

In order to withstand the rough conditions of use, the Ro 20 P has

been designed to be dust-protected, robust and reliable by means

of complex constructional measures such as labyrinth seals and

dirt deflectors.

The chamber surrounding the test zone serves the purpose of

contact and burst protection as well as dust collection. This

chamber is provided with a connection facility for a suction con-

nector for an external extraction system (to be provided by cus-

tomer).

The Ro 20 P sensor system consists of the following compulsory

components:

§rotating head Ro 20 P

§test heads, track width 1.5 – 2.5–5mm

§protective nozzles

The following options are available for adaptation to particular

material conditions:

§roller guides, right, left or on both sides

§precision guide, can be used for 2 to 20 mm

SENSOR SYSTEM Ro 20 P

Description 2.3 Construction

6.460 - 10/2002 2/5

i

2.3.1 Test Heads

The test heads are both the heart of the sensor system and its

most critical components.

They consist of an eddy-current probe with field, measuring and

clearance windings which are installed in a precise mechanical

holder and are connected by means of a highly flexible special

cable with a connection plug.

Due to the high centrifugal forces (acceleration up to 10,000 g!)

and the rough environmental conditions at the testing location,

the test heads are completely cast and can be replaced as a

complete part only.

As already mentioned in the ‘Mode of operation’ section, there is

a mathematical relationship between the number and track width

of the test heads, the rotational speed and the testing speed.

The following table shows these relationships and gives typical

examples for a practical selection:

Maximum testing speed

[m/s] Decreasing

sensitivity to short

flaws Track width BS

[mm] Test head type

0,45 0,9 1,5 N 6.460.01-2015

DF 6.460.03-2015

0,75 1,5 2,5 N 6.460.01-2025

DF 6.460.03-2025

1,5 3,0 5,0 N 6.460.01-2050

DF 6.460.03-2050

n = 9.000 U/min

n = 18.000 U/min

SENSOR SYSTEM Ro 20 P

2.3 Construction Description

2/66.460 -08/2004

i

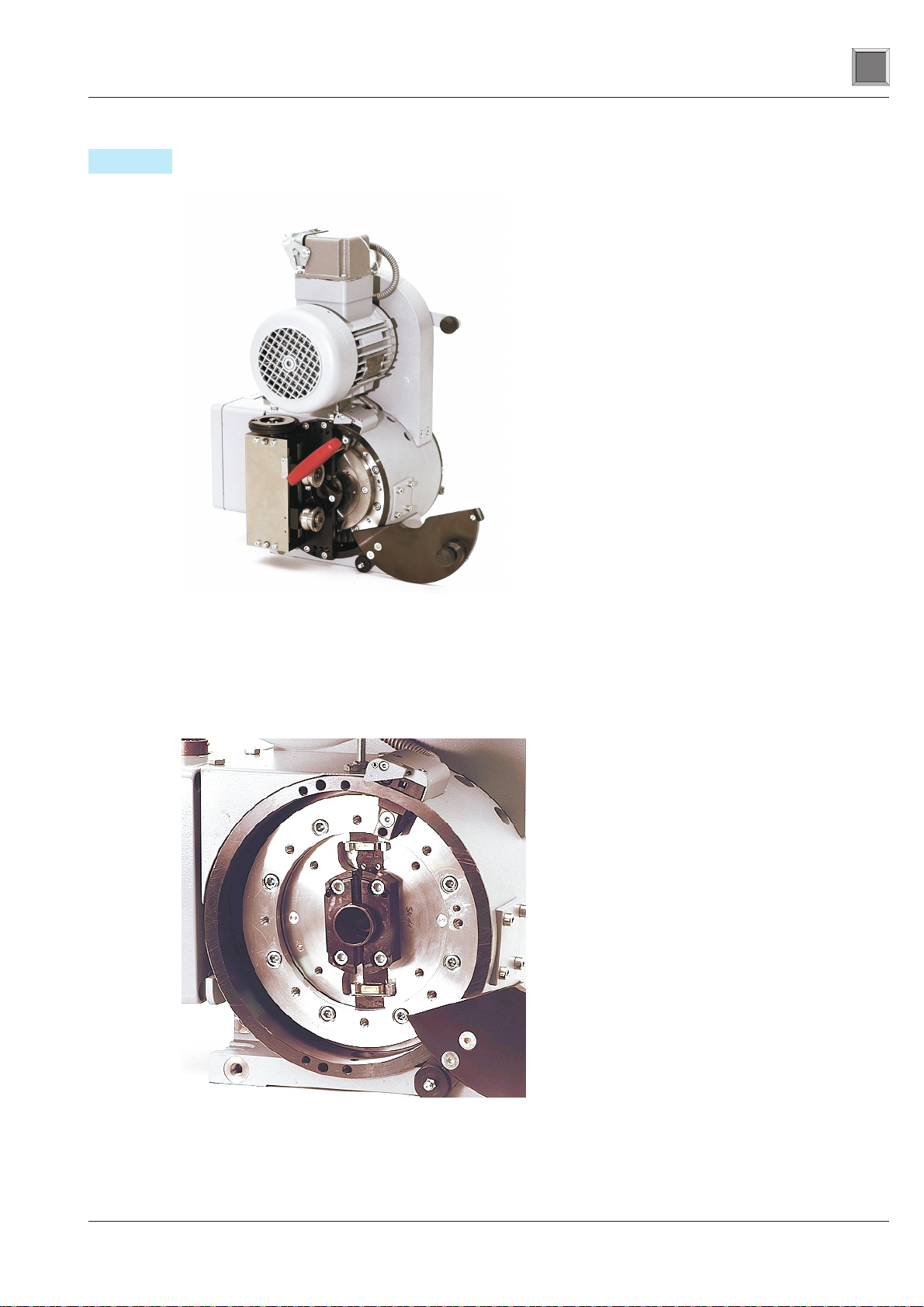

Test heads

Rotating disc with test heads

2.3.2 Rotating Head Ro 20 P

The rotating head is the main component

of the sensor system. It consists of:

§rotor

§transmitter

§drive

§housing

§rotating head electronics

The test direction can be selected as right

or left (viewed in the throughput direction).

In order to withstand the rough conditions

of use, the Ro 20 P has been designed to

be dust-protected, robust and reliable by

means of complex constructional measures

such as labyrinth seals and dirt deflectors.

Rotor

The rotor consists of a hollow shaft, a rotor

disc and the movable part of the sensor.

The rotor is driven by the motor by means

of a high-power profile flat belt. It is sup-

ported in the housing by two high-speed

bearings.

The high-precision rotating disc for holding

the test heads is fitted on the front side.

A pivot-mounted spiral disc with an actuat-

ing gear and automatic blocking facility is

fitted in the rotating disc for precise and si-

multaneous test head diameter adjustment.

SENSOR SYSTEM Ro 20 P

Description 2.3 Construction

6.460 - 10/2002 2/7

i

Fig. 2/6Rotiating head Ro 20 P

Fig. 2/7Rotating disc with test heads

View though the opened adjustment side, housing

flange and cover of rotating disc removed

Sensor

Wear-resistant rotating sensor in disc-type construction with a

field sensor, two measuring channels and a clearance channel.

Consisting of a rotor and stator, it transmits the field current for

the rotating probes from the stator to the rotor and, in the oppo-

site direction, transmits the test signal to the test electronics for

evaluation.

Rotating head electronics

The rotating head electronics amplifies the probe signals and the

field current. It is installed in a robust box on the connection side

of the bearing housing to permit ease of maintenance. The cable

to the test electronics is connected using MIL plug connectors.

The drive motor is connected directly using a Harting plug con-

nector.

Drive

SENSOR SYSTEM Ro 20 P

2.3 Construction Description

2/8 6.460 - 10/2002

i

Field 1,2

Channel 2

Channel 1

Clearance

Channel

Rotating

transmitter

Rotier-

übertrager

Preamplifier

Booster

Vorverstärker

Booster

F

M1

M2

A

F

M1

M2

A

FOERSTER CIRCOGRAPH DS 6.430

Fig.2/8Signal path

Table of contents

Other Foerster Accessories manuals