FOG Enforcer GREASE ENFORCER Manual

GREASE ENFORCER

Copyright ©2017 FOG Enforcer

Toll Free: 1-844-235-0369

E-mail: [email protected]

Online: www.fogenforcer.com

Operation & Maintenance Manual

Mohegan Sun Casino • Uncasville, CT • 8/17

FOG

ENFORCER

88888

88888

88888

88888

88888

88888

88888

88888

88888

8888

8888 8888

8888

©2017 FOG Enforcer All rights reserved • Patented/Patents Pending • Specications subject to change without notice

FOG Enforcer • 2014 Beeler Road • Wilson, NC 27893 • Phone (844) 235-0369 MNLGE 2

System Overview

DESCRIPTION

The Grease Enforcer was designed for those facilities that want to take charge of their pretreatment system to

meet wastewater discharge limits, solid waste disposal requirements and reduce their risk of exposure to es-

calating disposal costs. You can think of it as having a pumping truck permanently stationed on site providing

daily disposal service, but with an environmentally “friendly” separation operation output of recyclable fats

and oils utilizing the FOG Enforcer component of the Grease Enforcer system, and removal and collection of

landllable “dry” coarse solids utilizing the dual liquids/solids separators.

Incidental solids from kitchen ows are trapped and transferred by the Automatic Solids Transfer System. In

addition to incidental solids, heavy loadings of coarse solids are removed by the dual automatic liquids/

solids separator in the Grease Enforcer system.

The heart of the Grease Enforcer system is the automatic grease and oils separator. This unit removes grease

and oils from wastewater streams. The efcient separation process removes 98% of free-oating grease and

oils, and automatically places them in a container. The oil/grease recovered is virtually water free, and

therefore ready to be sold to a rendering company.

The Grease Enforcer utilizes low shear design diaphragm pumps to transport the grease, oils, and solids from

the remote separator quickly and without emulsification of the grease and oils. The pumps also allow the

specifying engineer to site the Grease Enforcer in the optimum location for convenience, trafc and site

aesthetics, regardless of where the separation tank (or existing grease trap) is located.

The Grease Enforcer has a brain, too, that ensures the operating cycle will perform without a hitch each

time the system operates. The Grease Enforcer system is both environmentally friendly and operation

friendly.

BENEFITS

• Automatically removes coarse solids

• Automatically removes free-oating fats and oils

• Helps reduce BOD levels and associated surcharges and nes

• Reduces operation costs versus paying for pumping service

• Removed dewatered coarse solids are landll ready

• Removed greases/oils are recycle ready for rendering

• Removes up to 900 pounds of fats/oils and 2000 pounds of solids per day

FEATURES

• Rugged corrosion resistant construction

• Easy-access solids removal units

• Reliable automatic operation

• Easy to service modular design

APPLICATIONS

• Restaurants • Casinos • Schools • Bakeries • Cafeterias • Hotels • Nursing Homes

• Universities • Food Processing Plants • Shopping Centers/Malls • Manufacturing Plants

• Commissaries • Airports • Resorts • Hospitals • Institutions • Correctional Facilities

FOG

ENFORCER

GREASE ENFORCER

MNLGE 3

System Specications

Electrical Requirements. . . . . . 230VAC, 3 Phase, 30 Amp.

Eductor Pump Water Supply Requirements**. . 3/4” supply line, 12 GPM

Maximum Grease Removal. . . . . 1744 Pounds/Day

Skimming Rate. . . . . . . . . . 136 Pounds/Hour

Solids Removal Capacity. . . . . . > 2000 pounds/day

Suggested Containment Space. . . 8’ W x 10’ L x 8’ H

Diaphragm Pump Maximum Lift Capability. . . .12 feet from static water level of

separator tank to highest point of diaphragm pump inlet piping. Please contact factory

for higher lift situations.

Services existing sump pit or grease trap daily. Automatically

separates grease and oils into a collection container. Solids are

placed in a separate container.

System Includes:

•FOG Enforcer 75 GPM Automatic Grease Removal Unit

•Two (2) Automatic Solids Separators

•System Control Panel*

•Back-wash Assembly

•Two 1/2 HP (2) diaphragm lift pumps

•Powder Coated Cold-Rolled Steel Support Frame

Grease Enforcer

*Wiring Diagrams & Timing Charts are attached

to Grease Enforcer system.

** Facility is responsible for providing a minimum 3/4”, 12 GPM water supply for

eductor pump operation. FOG Enforcer supplies a 3/4” female connector to

connect to this supply.

©2017 FOG Enforcer All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

FOG Enforcer • 2014 Beeler Road • Wilson, NC 27893 • Phone (844) 235-0369

FOG

ENFORCER

GREASE ENFORCER

FOG Enforcer • 2014 Beeler Road • Wilson, NC 27893 • Phone (844) 235-0369 MNLGE 4

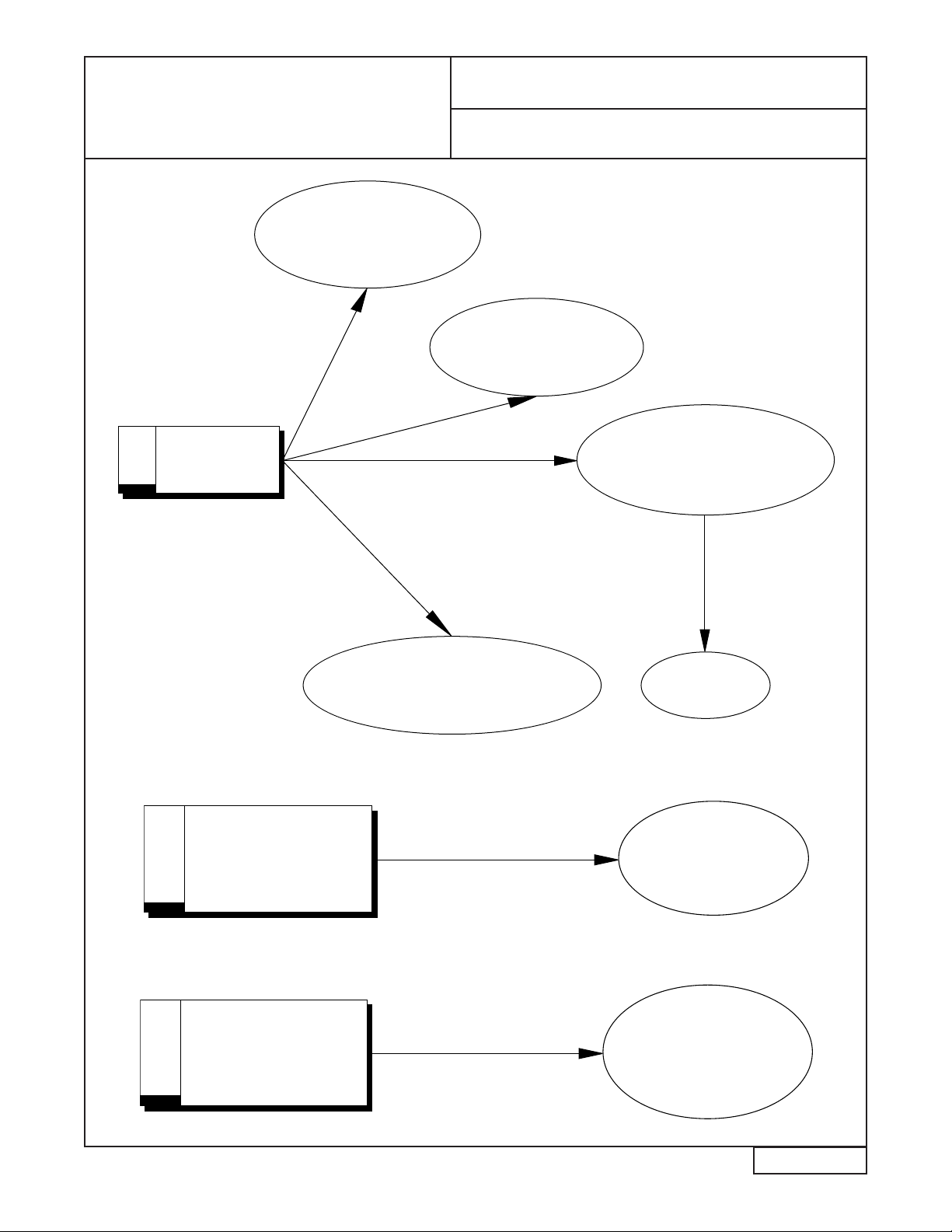

Operation Flowchart

GREASE / OILS

LIFT PUMP

SOLIDS LIFT

PUMP

RECOVERED GREASE / OILS

COLLECTION CONTAINER

AUTOMATIC

SOLIDS

TRANSFER PUMP

MODULE

AUTOMATIC

GREASE / OILS

RECOVERY UNIT

SYSTEM CONTROL

PANEL

INLET FLOW

CLEANED

EFFLUENT FLOW

RE-FLOW LINE

REMOTE

SEPARATION TANK

OUTLET FLOW

RECOVERED COARSE SOLIDS

COLLECTION CONTAINER

COARSE SOLIDS

REMOVAL

UNIT

1. Grease/Oil/Solids bearing ow enters the separator tank from the kitchen. Wastes im-

mediately separate into oating & non-oating (heavier than water) components.

2. Time controller activates Grease Enforcer to begin automatic separation operation. Solids

Cycle

3. Lift pump #2 activates and lifts heavier-than-water solids from the solids hopper

installed in the separator tank. This ow passes through the dual solids removal units,

where coarse solids are separated, dewatered, and emptied into the waste container.

4. The efuent passes through the solids removal units into the FOG Enforecer automatic

grease & oil removal unit, where ne solids are trapped and automatically removed from

the system.

5. The cleaned water passes through the FOG Enforcer and is returned to the separator

tank. Grease Cycle

6. Lift pump #1 activates, lifting accumulated fats, oils and grease from the top 2 - 3” on the

separator tank. Any coarse solids in this ow are separated through the solids removal

component, and any ne solids are removed using the eductor pump on the FOG Enforcer.

7. The fats, oils and grease separate from the efuent in the FOG Enforcer The “cleaned”

efu-ent passes through the FOG Enforcer and is returned to the separator tank.

8. The motors & heaters in the FOG Enforcer activate, skimming the fats, oils & grease out

and depositing them into a grease collection container.

9. The backwash lines activate periodically during the FOG Enforcer skimming cycle to

maintain static liquid level in the Big Dipper unit for optimum skimming efciency.

©2017 FOG Enforcer All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

FOG

ENFORCER

GREASE ENFORCER

FOG Enforcer • 2014 Beeler Road • Wilson, NC 27893 • Phone (844) 235-0369 MNLGE 5

System Control

Grease Enforcer System Control

The Grease Enforcer is designed with the exibility to service a variety of situations. The system

control panel may be easily programmed to provide up to six cleaning cycles per day (most applica-

tions require only one or two daily cycles). Setting the cleaning cycles is a simple process. Inside

the system control panel are two 24-hour timers. Each timer controls a grease cycle and a solids

cycle. The timers in turn are controlled by two selector switches. These selector switches determine

how long each cycle will run for. The selector switches are labelled “Light”, “Medium”, and

“Heavy”. The operator determines the setting according to which setup works best with the

installation/facility. Pushing in one (1) tab on the timer starts the Grease Enforcer cleaning cycle.

Each cleaning cycle can take up to four (4) hours (when the “Heavy” cycle is selected for both the

Grease & Solids cycle). Therefore, a maximum of one tab should be pushed in on either timer each

four hour period.

When the system senses a tab in the “On” position, a pre-programmed logic controller (part

#PLC-1) is activated. The PLC-1 automatically controls timing sequences that ensure the pumps,

heaters, motors and other components needed to provide grease & solids removal operate in the

proper sequence. The PLC-1’s operating cycle is programmed and tested at FOG Enforcer, and

cannot be altered by non-factory personnel. The operating cycle & timing sequences are displayed

on an instruction sheet provided with the system.

The Grease Enforcer is designed to operate with 230 volt three phase power. The system requires 30

amp rated fuses on the supply input. The system has individual internal fusing for each major

component group. Shutting off power to the Grease Enforcer will not harm the internal electronics

or programming.

The system is supplied with a mechanic’s cycle, which enables the Grease Enforcer to operate

at 1/10 normal time. This allows the Grease Enforcer to operate each cycle ten times faster than

normal, allow-ing the operator to check each cycle to ensure full operation. To operate the

mechanic’s cycle, simply press the button in the Control Panel labelled “Mechanic’s Cycle”.

There is also a feature that allows the grease removal unit to drain itself out. The utilize this feature,

push the button labelled “Tank Drain” on the Control Panel when the Grease Enforcer is not actively

en-gaged in either the Grease or Solids cycle. Pushing this button activates the eductor pump,

emptying the grease removal unit. This feature allows for ease of periodic cleaning of the FOG

Enforcer grease removal component included with the system.

Note: This equipment must be installed to comply with all national, state, and local

electrical & plumbing codes for your area. Installation should only be performed by

a qualied, licensed electrician & plumber.

Note: Caution should be used when working with any electrical device. Shutting off

power to the Grease Enforcer will not harm the internal electronics or

programming.

©2017 FOG Enforcer All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

FOG

ENFORCER

GREASE ENFORCER

FOG Enforcer • 2014 Beeler Road • Wilson, NC 27893 • Phone (844) 235-0369 MNLGE 6

Timer Operation

The FOG Enforcer Grease/Solids Timer System offers a great deal of exibility to match the needs of your

kitchen. This improved version incorporates dual 24-Hour Timers coupled with dual selector switches (one each

for solids removal cycle and grease removal cycle). The selector switch provides three settings (heavy,

medium and light) in order to best handle the grease and solids loading from your kitchen operation. If you

have high loadings of solids but a minimal loading of grease, simply set the Solids selector switch at “Heavy”

and the Grease selector switch to “Light,” or vice versa if it’s the other way around.

Grease Cycle Operation:

Three different grease cycles are operator selectable for lift pump running duration of 30 minutes (light), 60

minutes (medium), and 120 minutes (heavy). Grease & oils skimming, solids removal, system ushing and

AST timing reect these settings.

The grease timer (clock) should be set to the desired running time for the grease lift cycles (presumably right

after meals). The grease cycle is programmed to run one cycle and wait for the next “ON” occurrence on the

24-hour timer to run again. The grease cycle takes precedence over the solids cycle - if the solids cycle were

running, it would pause in order to allow the grease cycle to be completed. The solids cycle begins again upon

grease cycle completion.

Solids Cycle Operation:

The frequency of solids lift cycles is operator selectable. Solids lift cycles occur every 120 minutes (light), 60

minutes (medium), or 30 minutes (heavy) as determined by selector switch position. Solids removal, ushing,

and AST operation match frequency with the solids cycle.

The solids timer (clock) should be set to the time when the solids removal process begins and the pins on the

24-hour solids timer are turned to their “ON” position. The solids operation ends when the “OFF” setting is

reached. The solids program begins at the initial “ON” occurrence and repeats (loops) until the timer reaches

the “OFF” settings.

©2017 FOG Enforcer All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

7

32

1

4

5

AM

7

8

9

10

11

12

1

234

5

PM

8

9

10

11

12

12

6

7

9 3

Time-of-day

indicator point

Tabs not punched in

indicate “OFF” setting

Tabs punched in indicate

“ON” setting

TO SET TIMER:

1. Push on/off tabs on the outer ring of timer

inwardinto dial at desired“ON” times. Only

one tab is needed to start the Grease Enforcer

cycle.

2. TurndialCLOCKWISE one ormore

complete revolutionsuntilthepresenttime is

alignedwith the time-of-day indicator point.

3. Always set one cycle timer to run at least 2

hours after the previous cycle. The “Heavy”

setting for both the grease & solids cycle runs

for 2 hours. The grease & solids cycles cannot

run simultaneously.

FOG

ENFORCER

GREASE ENFORCER

©2017 FOG Enforcer All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

FOG Enforcer • 2014 Beeler Road • Wilson, NC 27893 • Phone (844) 235-0369 MNLGE 7

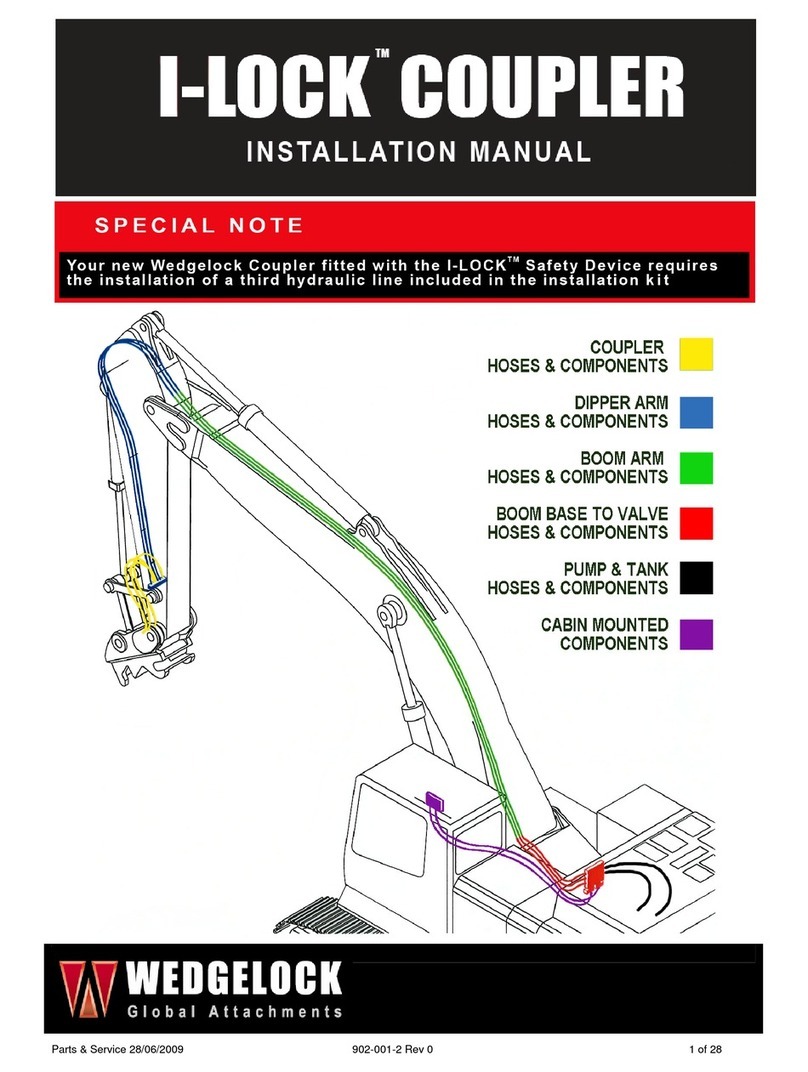

Installation Schematic

Note: The remote separator tank is not provided by FOG Enforcer.

The remote separator tank will be designed by the engineer to be a passive grease trap.

Grease Enforcer

LIFT PUMPS

DUAL

COARSE SOLIDS

REMOVAL SYSTEM

GREASE/OILS

RECOVERY UNIT WITH

AUTOMATIC SOLIDS

TRANSFER

CONNECTION

FOR FACILITY

VENT

COARSE SOLIDS

SUCTION PIPE

FLOATING GREASE/OILS

PICK-UP SUCTION PIPE

STATIC

WATER

LEVEL

ACCESS COVER

3” REFLOW LINE

REFLOW

LINE

12” RACEWAY FOR HOSES

TO SEPARATOR TANK

EFFLUENT FLOW FROM

KITCHEN

2” AUTOMATIC

SOLIDS

TRANSFER

DISCHARGE LINE

2” SOLIDS TRANSFER

DISCHARGE LINE

12” RACEWAY FOR HOSES

TO SEPARATOR TANK

GROUND

LEVEL

FOR FURTHER EQUIPMENT

DETAIL SEE SYSTEM PRODUCT

DIMENSION AND SPECIFICATION

PAGES

CLEANED

EFFLUENT

FLOW

DISCHARGE

SOLIDS HOPPER

REMOTE SEPARATOR TANK

HOT WATER

CONNECTION

3/4” FEMALE

CONNECTOR

CONTROL

PANEL

GREASE/OILS

SUCTION PIPE

TYPICAL SITE LAYOUT FOR FOG ENFORCER MODEL

GREASE ENFORCER WITH DUAL

COARSE SOLIDS REMOVAL MODULES SERVICING

IN-GROUND CONCRETE SEPARATOR

NOTES:

1. 12” RACEWAY CONDUITS USE 22 DEGREE FITTING TO MAKE

ANY RADIUS.

2. THE REMOTE SEPARATOR TANK AND ACCESS COVER ARE NOT

PROVIDED BY FOG ENFORCER.

3. THE FACILITY MUST SUPPLY A MINIMUM 3/4”, 12 GPM WATER

SUPPLY FOR THE OPERATION OF THE EDUCTOR PUMP.

FOG RNFORCER PROVIDES A 3/4” FEMALE CONNECTOR TO

CONNECT TO THIS WATER SUPPLY.

COARSE

SOLIDS

SUCTION PIPE

FOG

ENFORCER

GREASE ENFORCER

FOG Enforcer • 2014 Beeler Road • Wilson, NC 27893 • Phone (844) 235-0369 MNLGE 8

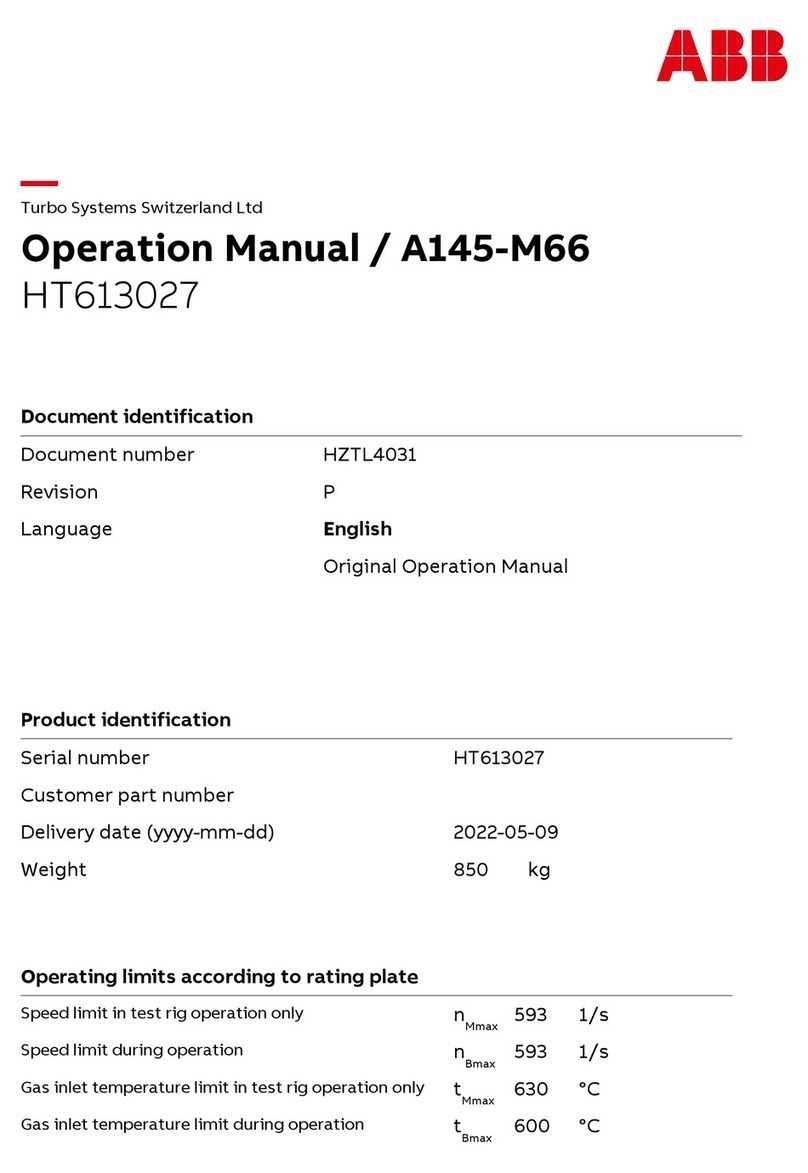

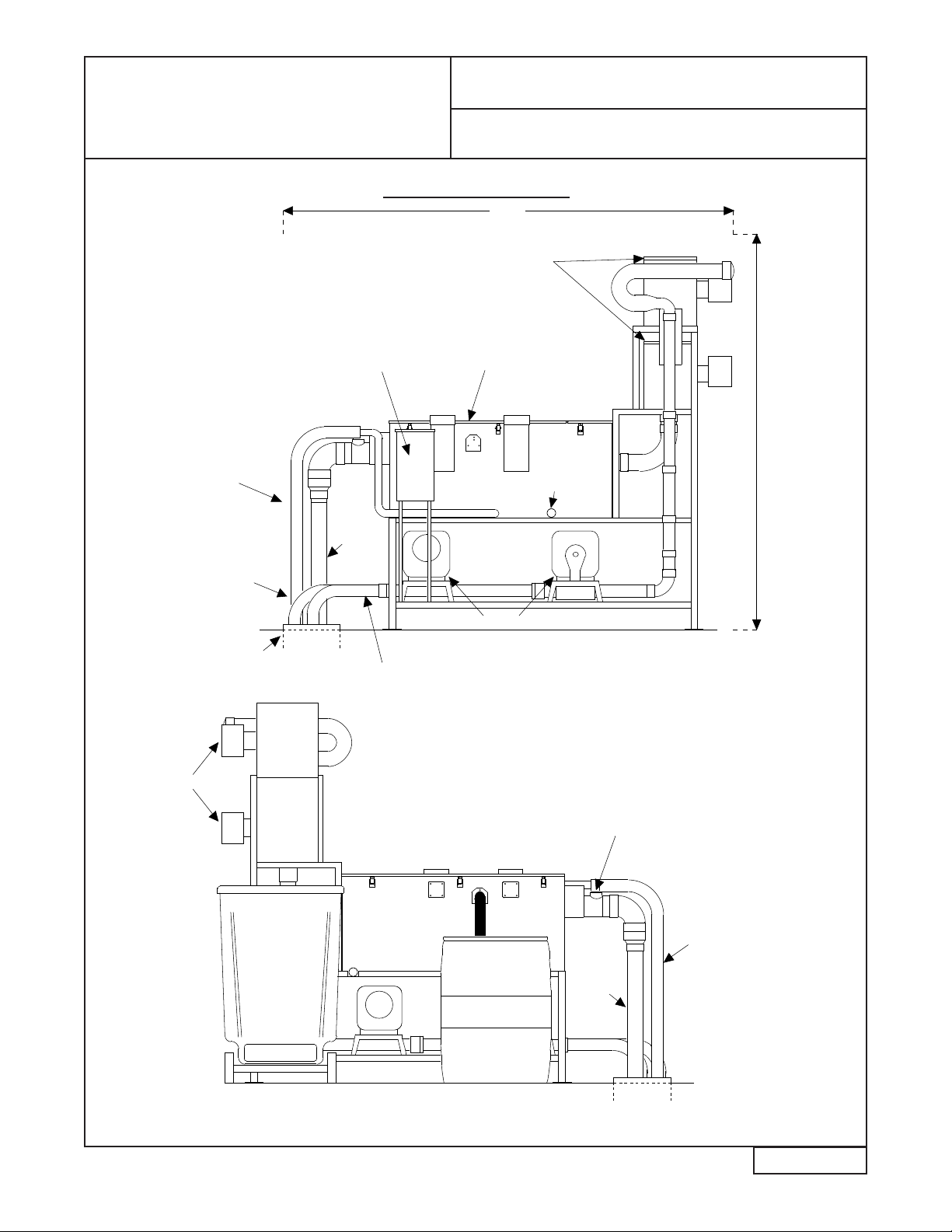

Side Views

Grease Enforcer

SYSTEM CONTROL

PANEL

GREASE/OILS

RECOVERY UNIT WITH

AUTOMATIC SOLIDS

TRANSFER

DUAL COARSE SOLIDS REMOVAL

SYSTEMS

2” SOLIDS TRANSFER

DISCHARGE LINE

COARSE SOLIDS

SUCTION PIPE FROM

BELOW GROUND SEPARATOR

12” RACEWAY CONDUIT

LIFT PUMPS

GREASE/OILS SUCTION PIPE FROM

BELOW GROUND SEPARATOR

101”

86”

SOLIDS REMOVAL

MOTOR

ENCLOSURES

3”

REFLOW

LINE

2” SOLIDS TRANSFER

DISCHARGE LINE

CONNECTION FOR

FACILITY VENT

SIDE VIEW PUMP/

CONTROL SIDE

SIDE VIEW COLLECTION SIDE

©2017 FOG Enforcer All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

OUTLET

OUTLET

3”

REFLOW

LINE

COARSE SOLIDS

COLLECTION

CONTAINER

GREASE/OILS

COLLECTION

CONTAINER

HOT WATER

CONNECTION

3/4” FEMALE

CONNECTOR

FOG

ENFORCER

GREASE ENFORCER

©2017 FOG Enforcer All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

FOG Enforcer • 2014 Beeler Road • Wilson, NC 27893 • Phone (844) 235-0369 MNLGE 9

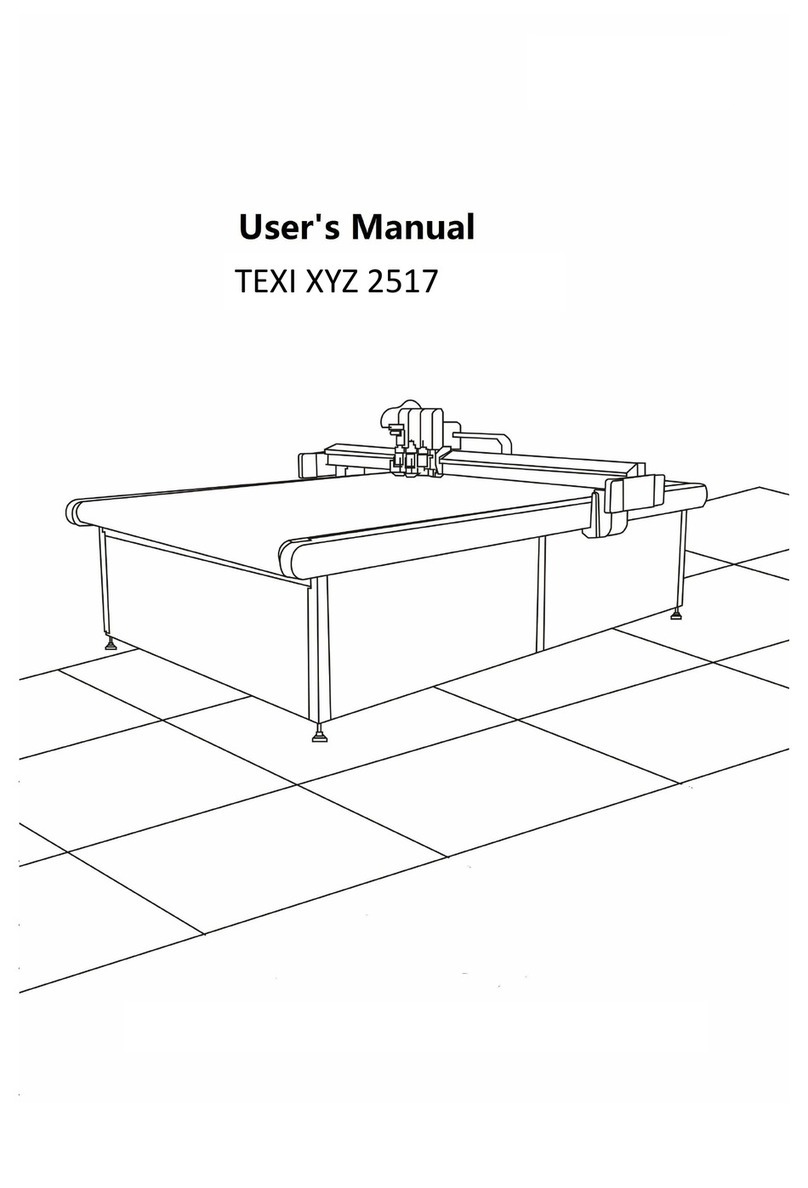

Top View

Grease Enforcer

FOG ENFORCER

GREASE/OILS

RECOVERY UNIT

12” RACEWAY

CONDUIT

2” SOLIDS TRANSFER

RETURN LINE FROM

OUTLET OF REMOTE

SEPARATOR TANK

BACKFLUSH

LINE

COARSE SOLIDS

SUCTION PIPE FROM

BELOW GROUND

SEPARATOR

GREASE/OILS SUCTION PIPE FROM

BELOW GROUND SEPARATOR

GREASE/OILS

COLLECTION

CONTAINER

COARSE SOLIDS

COLLECTION CONTAINER

TOP VIEW

113”

65”

101”

84”

DUAL

COARSE

SOLIDS

REMOVAL

SYSTEM

CONTROL

PANEL

MINIMUM FOOTPRINT

3” REFLOW LINE

FOG

ENFORCER

GREASE ENFORCER

©2017 FOG Enforcer All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

FOG Enforcer • 2014 Beeler Road • Wilson, NC 27893 • Phone (844) 235-0369 MNLGE 10

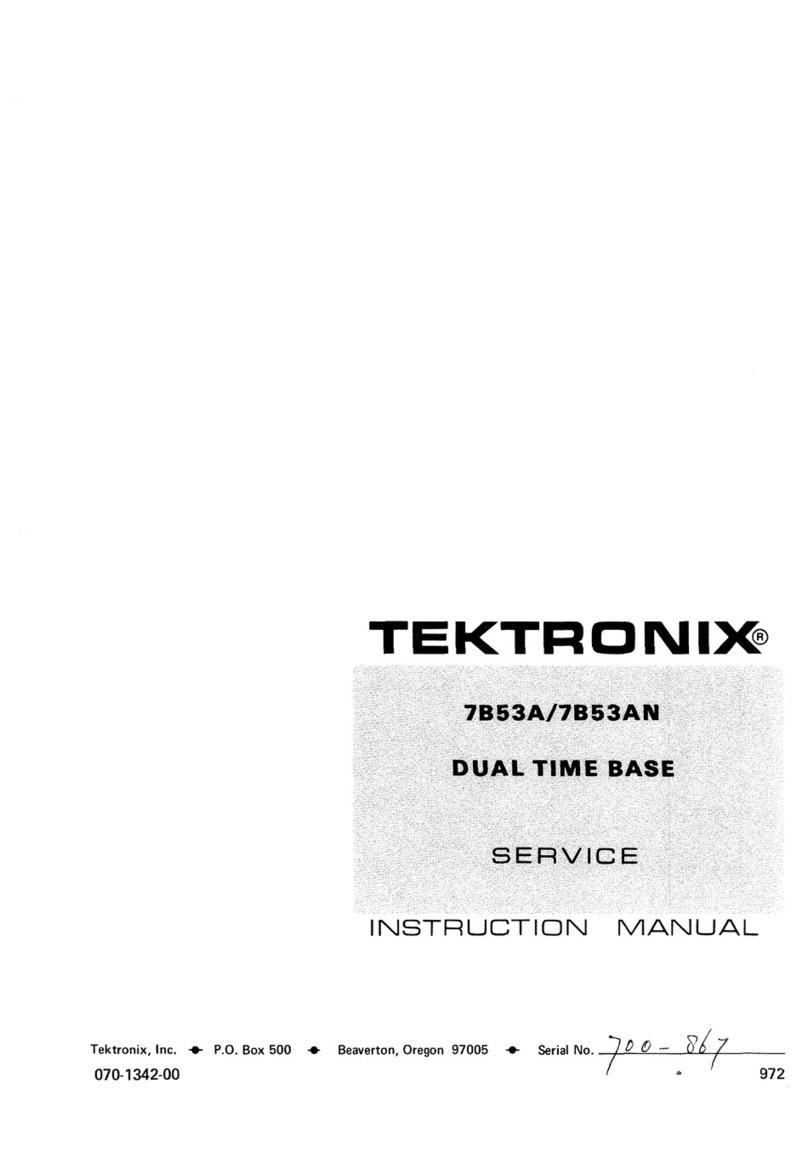

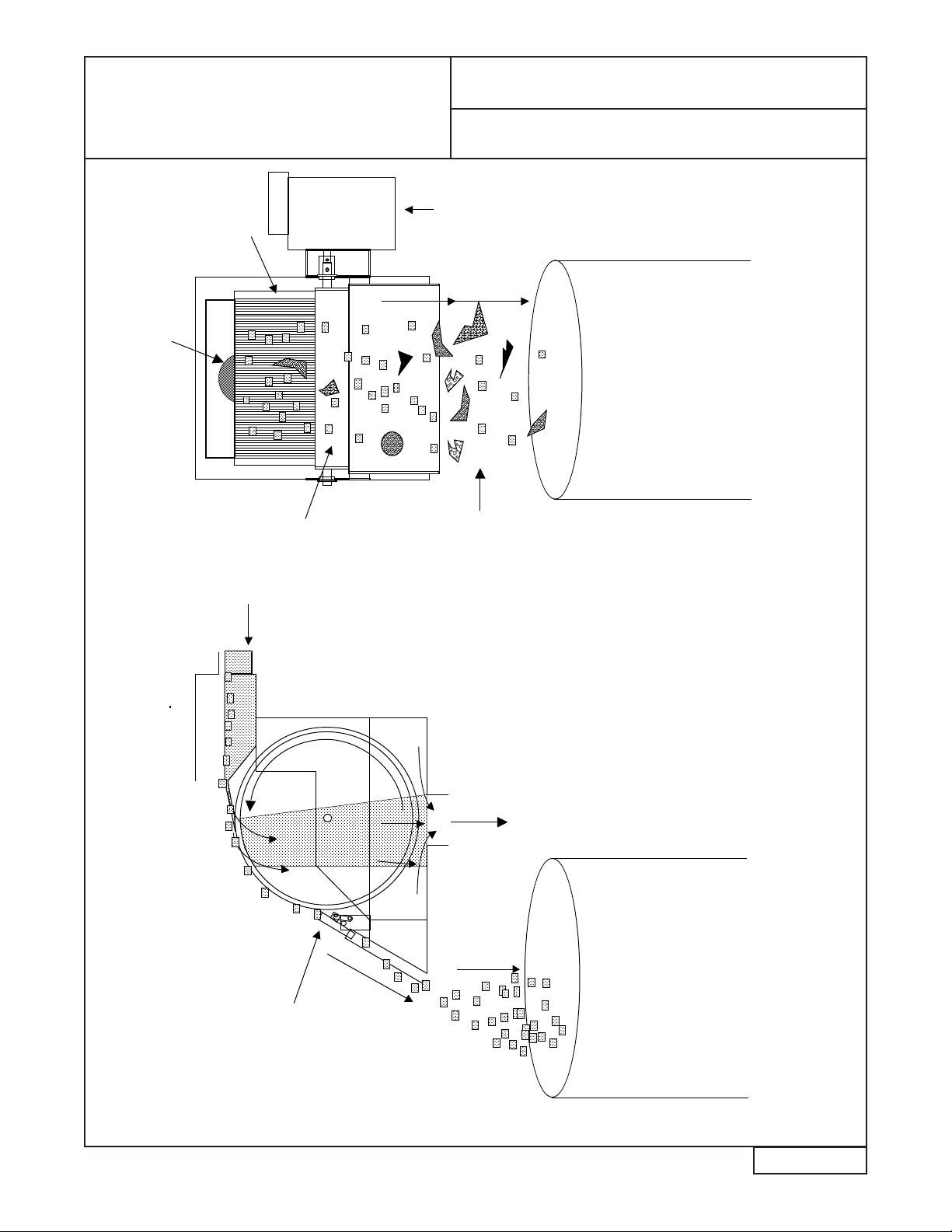

Solids Removal Operation

Solids Removal Operation Schematic & Part Identication*

Inlet Plenum

Screen

Scraper

Screened

Solids Drop

Into Waste

Container

Flow From

Separator

INLET Screen

Scraper

Screened

Solids Drop

Into Waste

Container

INLET

Drum

Screen

Motor

Housing

Solids

Collection

Container

Solids

Collection

Container

Front ViewSide View

Screened Flow

Enters The FOG

Enforcer

Automatic Grease

& Oils Removal

Unit

*These Systems WILL NOT OPERATE unless the cover is attached

FOG

ENFORCER

GREASE ENFORCER

FOG Enforcer • 2014 Beeler Road • Wilson, NC 27893 • Phone (844) 235-0369 MNLGE11

DAILY

Empty grease and solids collection containers. Wash containers if necessary.

WEEKLY

Check wheel wiper blades for build-up of ne solids. If build-up is present, wipe or spray

clean.

Inspect the dual Big Flipper® coarse solids removal screen for ne solids buildup. It may

easily be sprayed with hot water or wiped clean.

The bottom of the Big Dipper tank should be checked for ne solids accumulation. If

build-up of ne solids has accumulated, solids should be removed by stirring the bottom

with a long handled spatula or using a “wet vac” or by using the “Tank Drain” sequence.

Inspect the grease outlet sump for build-up of congealed fats or ne solids. Wipe off any

accumulation.

QUARTERLY

Grease the drive cam on each of the Grease Enforcer’s diaphragm lift pumps. There is a

grease tting on the drive cam’s housing. (Please see Page 26 “Grease Enforcer Diaphragm

Pump Identication”)

Check hose connections (quick disconnect) for tight t.

ANNUALLY

Replace FOG Enforcer’s wiper blades (part # PB-3).

Inspect FOG Enforcer Wheel Drive Sprockets (part # WDS-1) for wear. Replace if

necessary.

Check FOG Enforcer’s motor-to-wheel drive shaft coupling (part # NSC-1) for slippage.

Re-place if necessary.

Check lift pump diaphragms for wear or leaks.

Make sure GOPA assembly is secure and in place. (Please see Page 10 “Grease/Oils Pickup

Assembly”)

©2017 FOG Enforcer All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

Maintenance Instructions

FOG

ENFORCER

GREASE ENFORCER

©2017 FOG Enforcer All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

FOG Enforcer • 2014 Beeler Road • Wilson, NC 27893 • Phone (844) 235-0369 MNLGE 12

Wait Seven Minutes

No grease

collected

in

container

Make sure oily

water is pumped

into grease

removal unit

Check lift pump

hose connections

for leaks

Check lift pumps for

leaks

Remove

grease

removal unit

lid

Clean wiper blades,

collection trough,

and outlet hose

Make sure wiper

blades are

attached properly

Replace wiper

blades when

worn

Set

Superceptor

timer to "On"

position

Hold down

safety

switch

Make sure

skimmer

wheel turns

If skimmer motor

does not activate,

motor must be

replaced

If skimmer motor

activates, make

sure safety switch is

fully depressed

when lid is fastened

to unit

Check

heater

assembly

If heater does not

begin to feel warm in

15 minutes, heater

must be replaced

Make sure GOPA

assembly is 1.5" to 2"

below static water level

in separation tank

Grease Enforcer Troubleshooting

FOG

ENFORCER

GREASE ENFORCER

©2017 FOG Enforcer All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

FOG Enforcer • 2014 Beeler Road • Wilson, NC 27893 • Phone (844) 235-0369 MNLGE 13

Excessive water

observed in grease

collection unit

Check timer for

excessive

"On"cycles

Objectionable

odor

Make sure grease/oil

is being properly

skimmed from unit

Check for excessive

sediment buildup in

bottom of unit

Empty solids container

and/or grease collector

more frequently

Clean after

emptying

If installed, spray surface of

solids removal screen with

hot water

Grease Enforcer Troubleshooting

No solids collected in

collection container

Ensure cover is

securely in place

over solids

removal units

FOG

ENFORCER

GREASE ENFORCER

©2017 FOG Enforcer All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

FOG Enforcer • 2014 Beeler Road • Wilson, NC 27893 • Phone (844) 235-0369 MNLGE 14

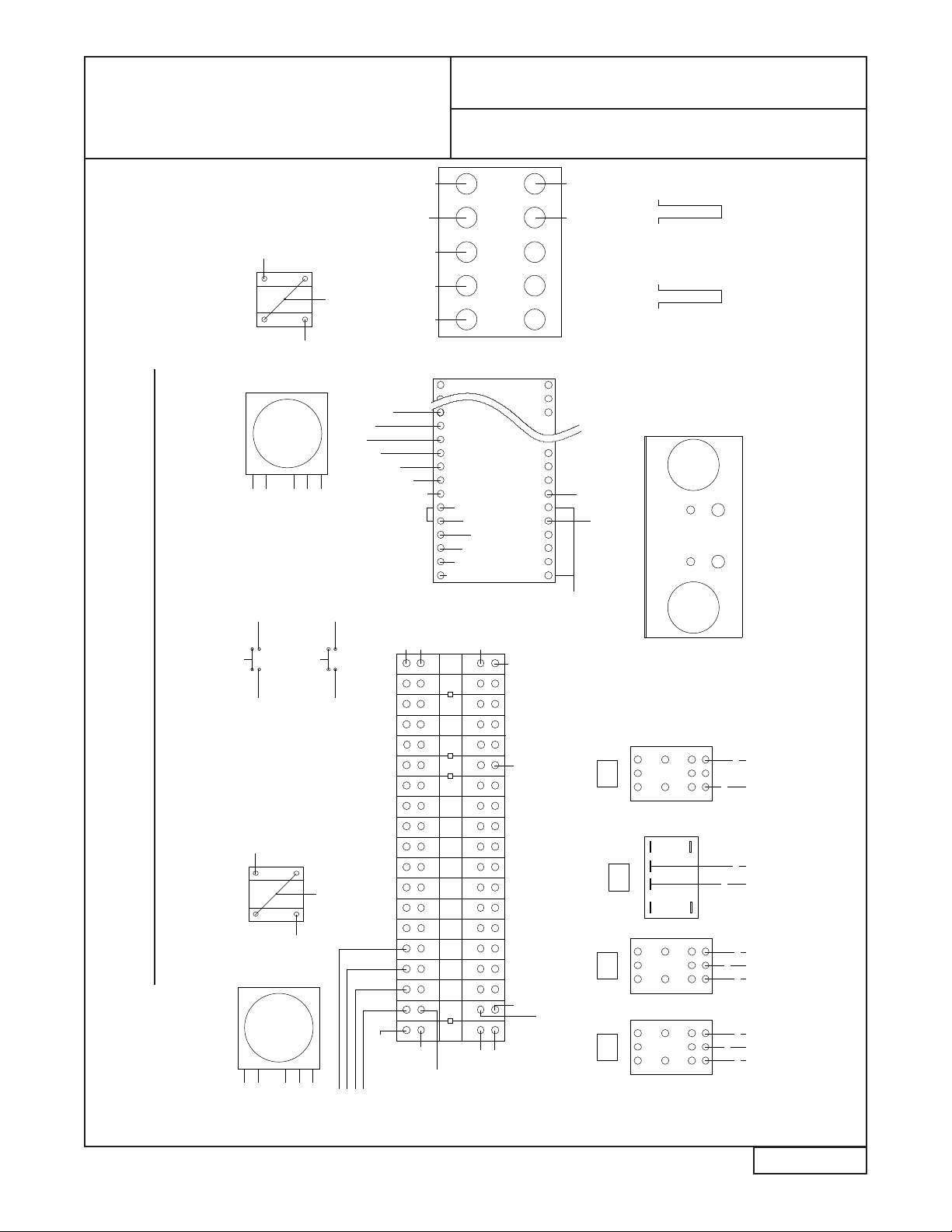

Control Panel Wiring Diagram

Grease Enforcer Control Panel Wiring Diagram

C

COIL

NC

NO

R1

AB

C

A

NO

NC

COIL

B

R2 R4

C

A

NO

NC

COIL

B

STRAIN-RELIEF LAYOUT

(TOP VIEW)

PLC CONTROLLER

INPUTS

OUTPUTS

BACKFLUSH

GREASE REMOVAL UNIT

GRD GRD

1

BLK

2

RED

3

BLUE

J JJ

F1

6A

F2

6A

F3

6A

F4

2A

F5

2A

4 5 6 7 8 8

F1 F2 F3

R3

J

7 7 9

PUMP #1

GREASE LIFT PUMP #2

SOLIDS LIFT

SOLIDS

SEPARATOR

GREASE REMOVAL

UNIT

4 5 6 4 5 6 7 8

7 7 7PLC0 PLC1 PLC5

8

9

PLC IN 0

R3

R3

F4 F5

1

4 F1

R1

R2

2

5

R2

F2

R1

6

3

R2

F3

R1

2

7 F4

R3A

R4A R4C

TIM 3

8F5

PLC

TIM

R4C

PLC

OUT

+24

PLC

PUMP #1

PUMP #2

BLACK

RED

BLUE

L3

L2

L1

GROUND GREEN

PLC

12

7PLC2

7

PLC IN 1

9

8

3

4 3

4

H L

M

SELECTOR SWITCH

PLC IN 6

PLC IN 5

9

TIMER

GREASE CYCLE CONTROLS

SOLIDS CYCLE CONTROLS

SELECTOR SWITCH

PLC IN 2

7

9

1 DAY

24 HOUR

TIMER

PLC IN 4

8

TIMER

PLC IN 3

4 3

9

H

3

L

4

M

7 PLC 4

TIM

TIM

GREASE CONT

SOLIDS CONT

MECH CYCLE

R1A R2A

PLC

MTC SWITCH

MECHANIC'S TIMING CYCLE

(MOMENTARY CONTACT)

PLC 3

MDC SWITCH

MECHANIC'S DRAINING CYCLE

(MOMENTARY CONTACT)

8

MDC

CONTROL PANEL LAYOUT

(TOP VIEW)

GREASE

TIMER

SOLIDS

TIMER

MTC MDC

SOLIDS

SELECTOR

GREASE

SELECTOR

PLC 3

7

1 DAY

24 HOUR

TIMER

BACKWASH

AST

PUMP

SOLIDS

SEPARATOR

SOLIDS

SOL VLV

BACKWASH

VLV

PUMP #1

(GREASE)

PUMP #2

(SOLIDS)

POWER

INPUT

BACKWASH SOLIDS

SEPARATOR

AST

SOLIDS

PUMP

GREASE

REMOVAL

UNIT

BLACK

RED

WHITE BLACK

RED

WHITE

BLACK

WHITE

BLACK

WHITE

SGBA76543210COM1

OUT

COM1

OUT

R1 R2 R3 R4

SOLIDS

SOL VLV/MDC

BACKWASH

VLV

654321015

87 9GRD

MECH

SW.

GREASE

TIMER

SOLIDS

TIMER

L. SOLIDS

SW.

LINE

H. GREASE

SW.

L. GREASE

SW.

NEUTRAL

GROUND

+24VDC OUT

0VDC OUT

DC IN COM

FOG

ENFORCER

GREASE ENFORCER

©2017 FOG Enforcer All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

FOG Enforcer • 2014 Beeler Road • Wilson, NC 27893 • Phone (844) 235-0369 MNLGE 15

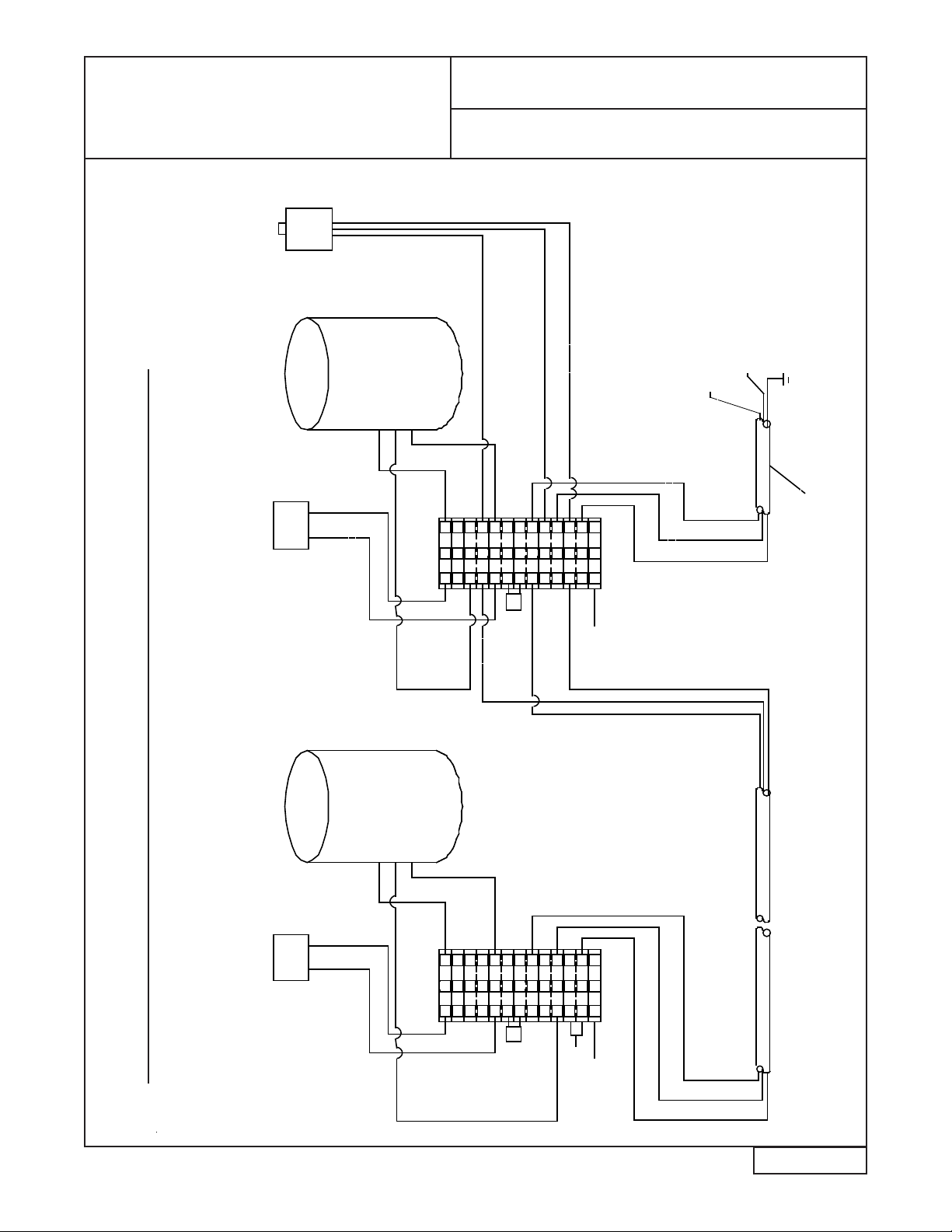

Grease Removal

Component Wiring Diagram

Wiring Diagram For FOG Enforcer Grease & Oils Removal Unit

MOTOR

BLUE

BLUE

RUN

CAPACITOR

PUSH-BUTTON

SWITCH

MOTOR/HEATER ENCLOSURE

MOTOR

BLUE

BLUE

RUN

CAPACITOR

PUSH-BUTTON

SWITCH

BL

RED

BLACK

RED

WHITE

9

8

10

4

5

6

2

G

1

3

JUMPER

7

WHITE

DISTRIBUTION

BLOCK

G

THERMOSTAT

HEATER

RED

BLACK

CONNECTING CORD

WHITE

BLACK

RED

9

8

WH

4

6

5

2

G

1

3

7

HEATER

THERMOSTAT

BLACK

WHITE

GRED

BLANK

GROUND

RED

WHITE

BL

JUMPER

GROUND

BLANK

DISTRIBUTION

BLOCK

10

MOTOR/HEATER ENCLOSURE

G

R3

R3

GREEN

BLACK

GREEN

GREEN

TO CONTROL PANEL

WHITE

WHITE

BLACK BLACK

FOG

ENFORCER

GREASE ENFORCER

©2017 FOG Enforcer All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

FOG Enforcer • 2014 Beeler Road • Wilson, NC 27893 • Phone (844) 235-0369 MNLGE 16

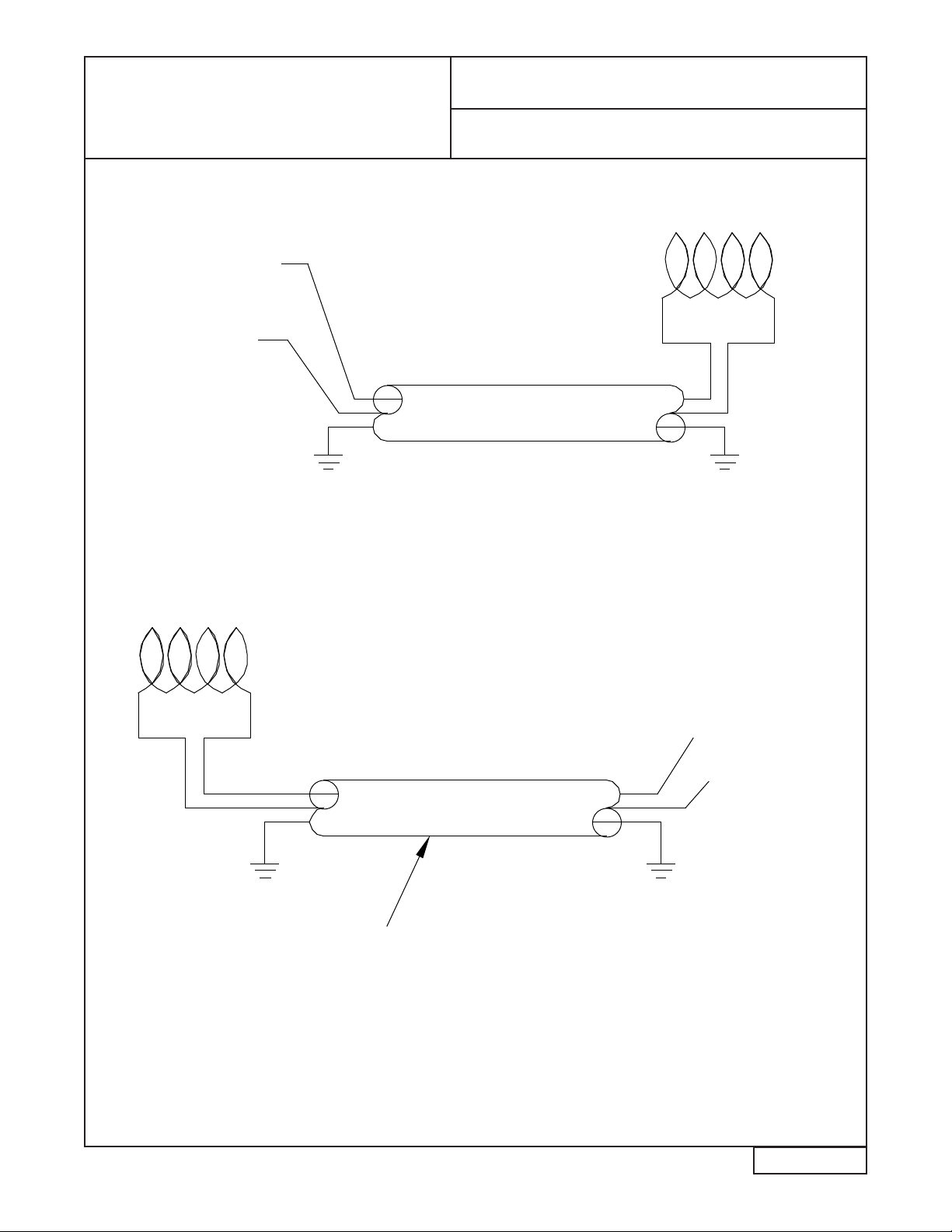

Coarse Solids Removal Wiring

Diagram

CONTROL PNL

RELAY 4

BLACK

WHITE

GREEN

MOTOR

BLACK

RED

WHITE

BLUE

BLUE

RUN

CAPACITOR

9

10

7

5

6

3

1

2

4

8

G

DISTRIBUTION

BLOCK

G

BLACK

GROUND IN SYSTEM

CONTROL PANEL

BLANK

JUMPER

GREEN

208-240 VAC POWER CORD

FROM SYSTEM CONTROL PANEL

WHITE

LOWER UNITUPPER UNIT

WHITE

RED

BLACK

BLANK

JUMPER

10

9

G

G

8

7

6

5

4

3

2

1

BLUE

BLUE

GROUND

DISTRIBUTION

BLOCK

WHITE

BLACK

RUN

CAPACITOR

MOTOR

GREEN

BLUE

BLACK

LID

INTERLOCK

SWITCH

CONTROL PNL

RELAY 4

BLACK

GREEN

BLACK

Wiring Diagram For Dual Coarse Solids Removal Units

UPPER UNIT

LOWER UNIT

FOG

ENFORCER

GREASE ENFORCER

©2017 FOG Enforcer All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

FOG Enforcer • 2014 Beeler Road • Wilson, NC 27893 • Phone (844) 235-0369 MNLGE 17

Miscellaneous Component Wiring

Diagrams

BACKWASH SOLENOID

D/B POSITION 7

PLC OUTPUT 4

BLACK

WHITE

GREEN

SOLIDS TRANSFER SOLENOID

FROM CONTROL PANEL

208-240 VAC LEAD

GREEN

PANEL

GROUND IN CONTROL

GREEN

B/D POSITION 7

PLC OUTPUT 3

BLACK

WHITE

FOG

ENFORCER

GREASE ENFORCER

©2017 FOG Enforcer All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

FOG Enforcer • 2014 Beeler Road • Wilson, NC 27893 • Phone (844) 235-0369 MNLGE 18

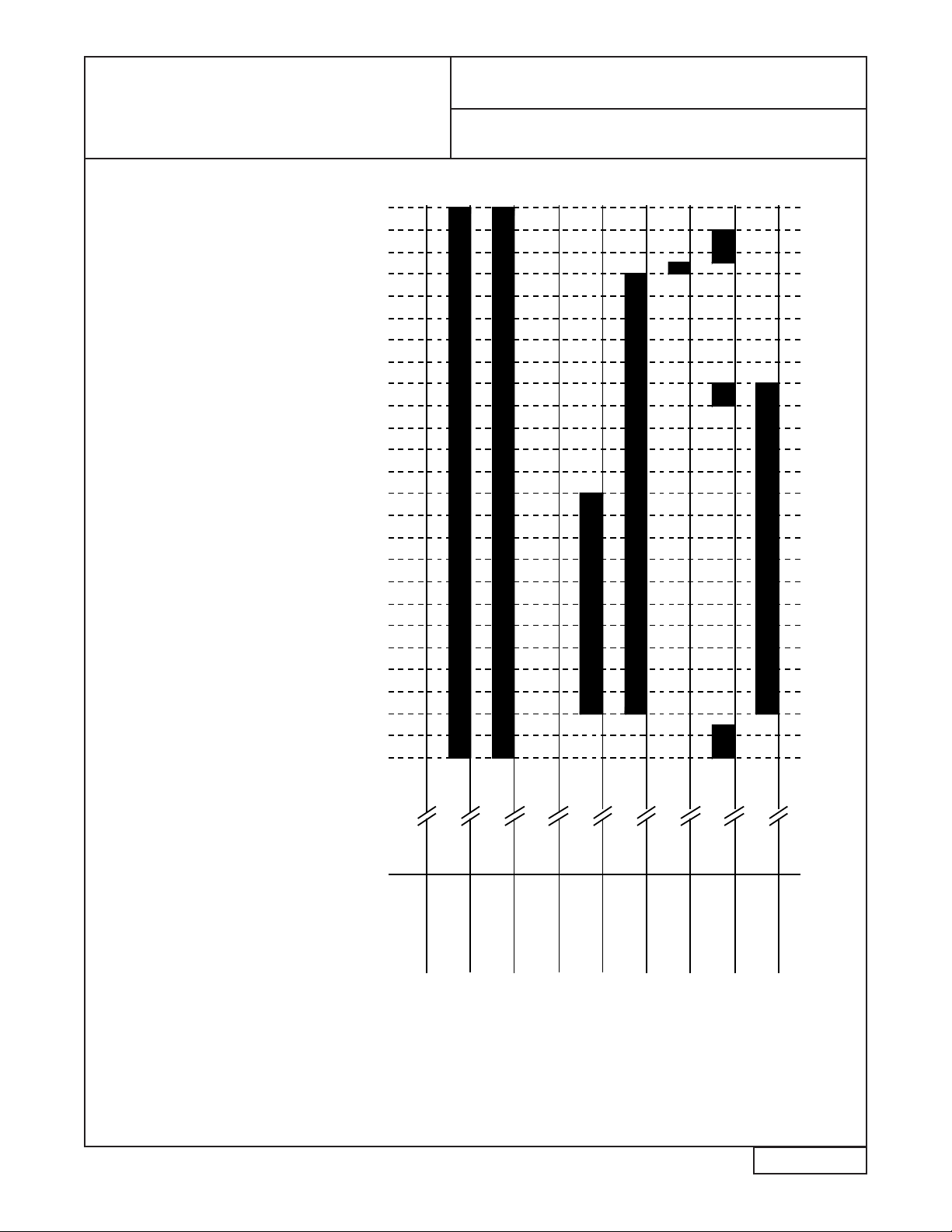

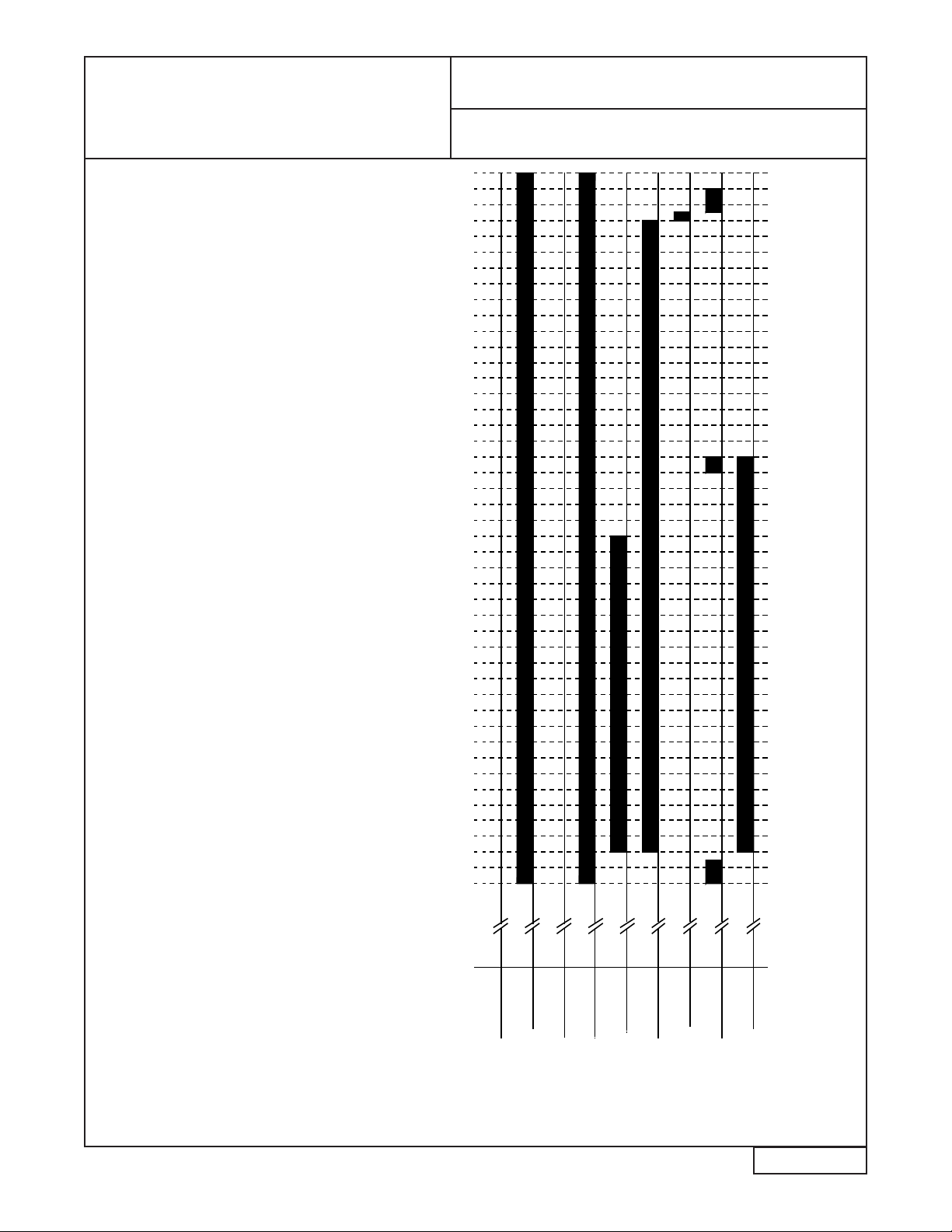

Grease Timing Chart

GREASE ENFORCER GREASE TIMING CHART

Not To Be Altered By Non-Factory Personnel

PRE-PROGRAMMED OPERATION SEQUENCE STEPS. EACH STEP IS EQUAL TO 2 MINUTES.

SEQUENCE BEGINS WHEN 24-HOUR TIME CONTROLLER OUTPUT SWITCHES FROM OFF TO ON (INPUT

#1) AND STOPS WHEN THE CYCLE IS COMPLETE. POSITION OF THE GREASE SELECTOR SWITCH DE-

TERMINES THE LENGTH OF TIME THAT GREASE IS REMOVED FROM THE TRAP.

0 2 4 6 810 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50

OFF

ON

GREASE/OILS LIFT PUMP

SOLIDS TRANSFER PUMP

BACKWASH VALVE

SOLIDS SEPARATOR UNIT

INPUT #0

INPUT #1

OUTPUT #0

OUTPUT #2

OUTPUT #3

OUTPUT #4

OUTPUT #5

GREASE REMOVAL UNIT

INPUT #5

INPUT #6

"LIGHT" GREASE SELECTOR SWITCH POSITIONS SHOWN

MECHANIC'S CYCLE

(SHORT CYCLE)

TIME CONTROLLER INPUT

(GREASE TIME CLOCK)

LIGHT GREASE

(SELECTOR SWITCH)

HEAVY GREASE

(SELECTOR SWITCH)

FOG

ENFORCER

GREASE ENFORCER

©2017 FOG Enforcer All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

FOG Enforcer • 2014 Beeler Road • Wilson, NC 27893 • Phone (844) 235-0369 MNLGE 19

Grease Timing Chart

GREASE ENFORCER GREASE TIMING CHART

Not To Be Altered By Non-Factory Personnel

PRE-PROGRAMMED OPERATION SEQUENCE STEPS. EACH STEP IS EQUAL TO 2 MINUTES.

SEQUENCE BEGINS WHEN 24-HOUR TIME CONTROLLER OUTPUT SWITCHES FROM OFF TO ON

(INPUT #1) AND STOPS WHEN THE CYCLE IS COMPLETE. POSITION OF THE GREASE SELECTOR

SWITCH DETERMINES THE LENGTH OF TIME THAT GREASE IS REMOVED FROM THE TRAP.

0 2 4 6 810 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70

OFF

ON

GREASE/OILS LIFT

PUMP

SOLIDS TRANSFER

PUMP

BACKWASH VALVE

SOLIDS SEPARATOR

UNIT

INPUT #0

INPUT #1

OUTPUT #0

OUTPUT #2

OUTPUT #3

OUTPUT #4

OUTPUT #5

GREASE REMOVAL

UNIT

INPUT #5

INPUT #6

"MEDIUM" GREASE SELECTOR SWITCH POSITIONS SHOWN

HEAVY GREASE

(SELECTOR SWITCH)

LIGHT GREASE

(SELECTOR SWITCH)

TIME CONTROLLER INPUT

(GREASE TIME CLOCK)

MECHANIC'S CYCLE

(SHORT CYCLE)

FOG

ENFORCER

GREASE ENFORCER

©2017 FOG Enforcer All rights reserved • Patented/Patents Pending • Specifications subject to change without notice

FOG Enforcer • 2014 Beeler Road • Wilson, NC 27893 • Phone (844) 235-0369 MNLGE 20

Grease Timing Chart

GREASE ENFORCER GREASE TIMING CHART

Not To Be Altered By Non-Factory Personnel

PRE-PROGRAMMED OPERATION SEQUENCE STEPS. EACH STEP IS EQUAL TO 2 MINUTES.

SEQUENCE BEGINS WHEN 24-HOUR TIME CONTROLLER OUTPUT SWITCHES FROM OFF TO ON

(INPUT #1) AND STOPS WHEN THE CYCLE IS COMPLETE. POSITION OF THE GREASE SELECTOR

SWITCH DETERMINES THE LENGTH OF TIME THAT GREASE IS REMOVED FROM THE TRAP.

0 2 4 6 810 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 62 64 66 68 70

OFF

ON

BACKWASH VALVE

SOLIDS SEPARATOR UNIT

INPUT #0

INPUT #1

OUTPUT #0

OUTPUT #2

OUTPUT #3

OUTPUT #4

OUTPUT #5

GREASE REMOVAL

UNIT

78767472 908886848280

LIGHT GREASE

(SELECTOR SWITCH)

INPUT #5

INPUT #6

"HEAVY" GREASE SELECTOR SWITCH POSITIONS SHOWN

MECHANIC'S CYCLE

(SHORT CYCLE)

TIME CONTROLLER INPUT

(GREASE TIME CLOCK)

HEAVY GREASE

(SELECTOR SWITCH)

GREASE/OILS LIFT PUMP

SOLIDS TRANSFER PUMP

FOG

ENFORCER

GREASE ENFORCER

Table of contents