Parts & Service 28/06/2009 902-001-2 Rev 0 4 of 28

INTRODUCTION

OUR FOCUS IS….

THE OPERATOR, because operators and their co-workers deserve safer work sites.

OUR PURPOSE....

Transforming the world’s excavators into highly productive, safe and user-friendly tool carriers.

OUR VALUES….

PIONEERING, we are continually pushing in new directions. We are building a reputation as the

industry innovators through constantly looking for ways to make excavator operators’ lives better.

And we look to new opportunities in new markets, reaching customers that others don’t.

COMMITTED - we are committed to our customers, our people, our community and New Zealand.

We are committed to the cause of simple, user-centric design and we are committed to safety,

without compromise.

COLLABORATIVE - we maximize the value we add to our customers’ business by working in

active, collaborative partnerships.

We are onside: we take time to listen, we encourage honest dialogue, we look for opportunities on

their behalf, we think proactively as well as responsively.

COURAGEOUS - we are bold and intrepid in our quest for earth-moving innovation. We do not turn

back at the first hurdle. We are determined (the earth wasn’t moved in a day!) Our attitude is robust

and our product testing rigorous. We honor the Kiwi pioneering spirit and are proud to uphold it.

FAMILY - we believe people need to be treated as they are family. We look to build long-term

relationships both internally and externally through an honest, down-to-earth approach. We believe

business success is crucial – but not at the expense of people.

OUR MISSION….

CREATING HUMAN ATTACHMENTS

A business that builds stronger, more enduring human relationships

A business that creates uniquely user-centric products

The Wedgelock Quick Coupler was originally developed by Graham Calvert at Waikanae Engineering, NZ

in 1987. The company and its reputation have since grown into a global leader in the design, manufacture

and distribution of excavator attachments

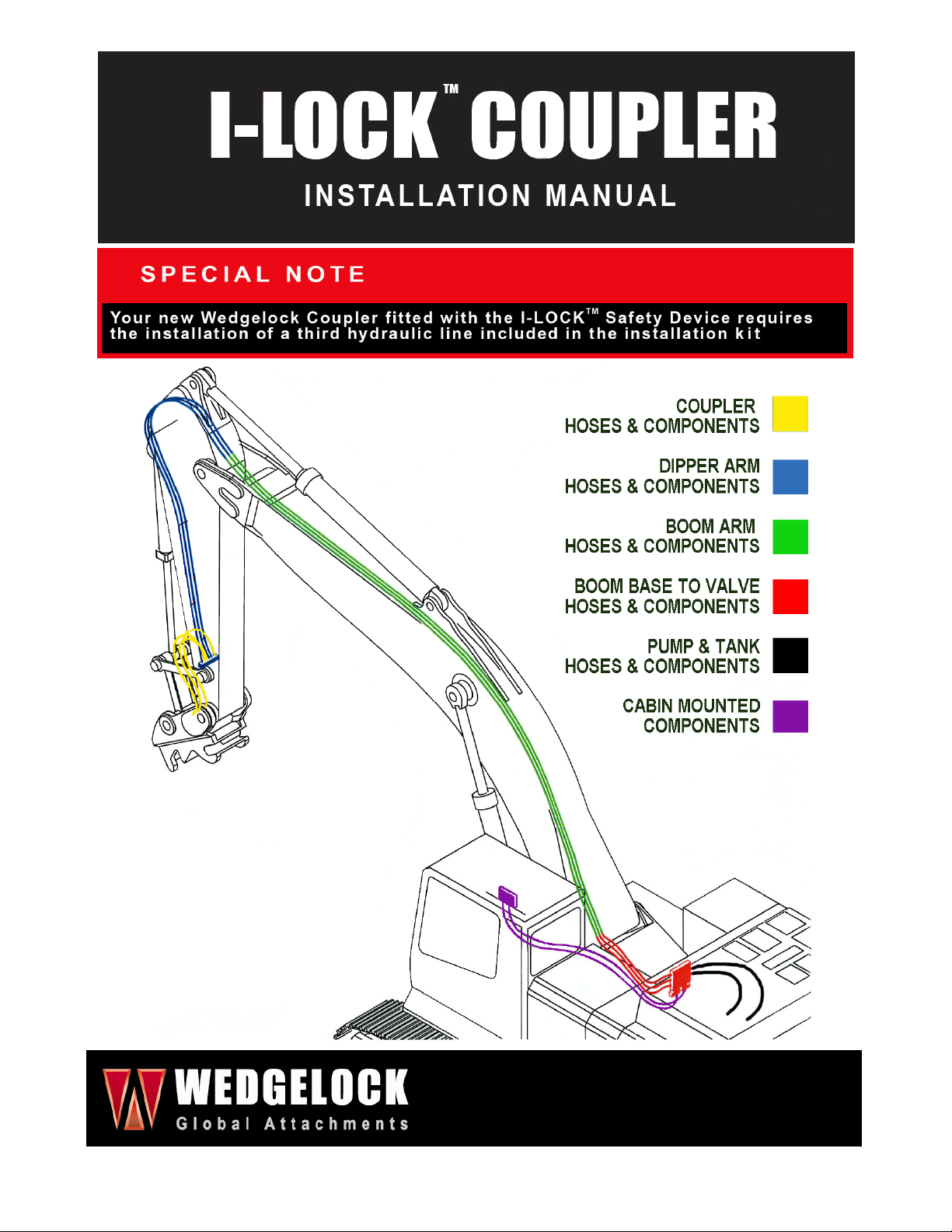

Over the years Wedgelock has developed a complete range of excavator attachments to cater for

machines from 1 tonne to 100 tonne. Spearheading the range is the I-Lock™ Coupler.

Changes in law and safety standards have piloted the design and development of the I-Lock™ Coupler, a

world first in coupler safety. The I-Lock™ Coupler incorporates all the original features of a standard

Wedgelock Hydraulic Coupler but with the added I-Lock™ Safety System.