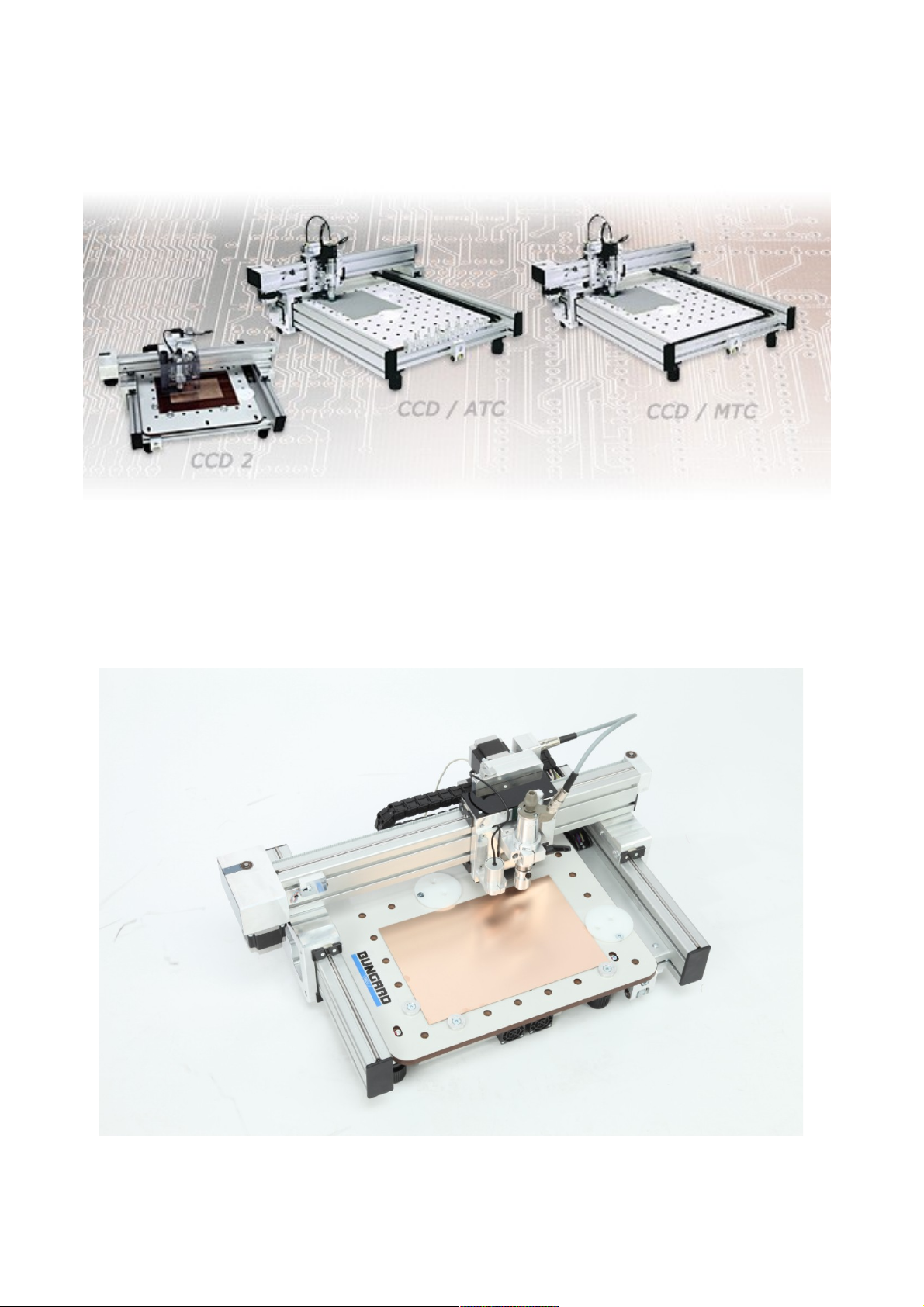

CCD

Operator's manual Page 2 /35

Table of content

General......................................................................3

Special features:...................................................3

Mechanic:............................................................3

Spindle:................................................................3

Drive system:..................................................4

Software:.........................................................4

Technical Data..........................................................5

General.................................................................5

Comparison..........................................................5

pplications.........................................................5

Options.................................................................6

ccessories..........................................................6

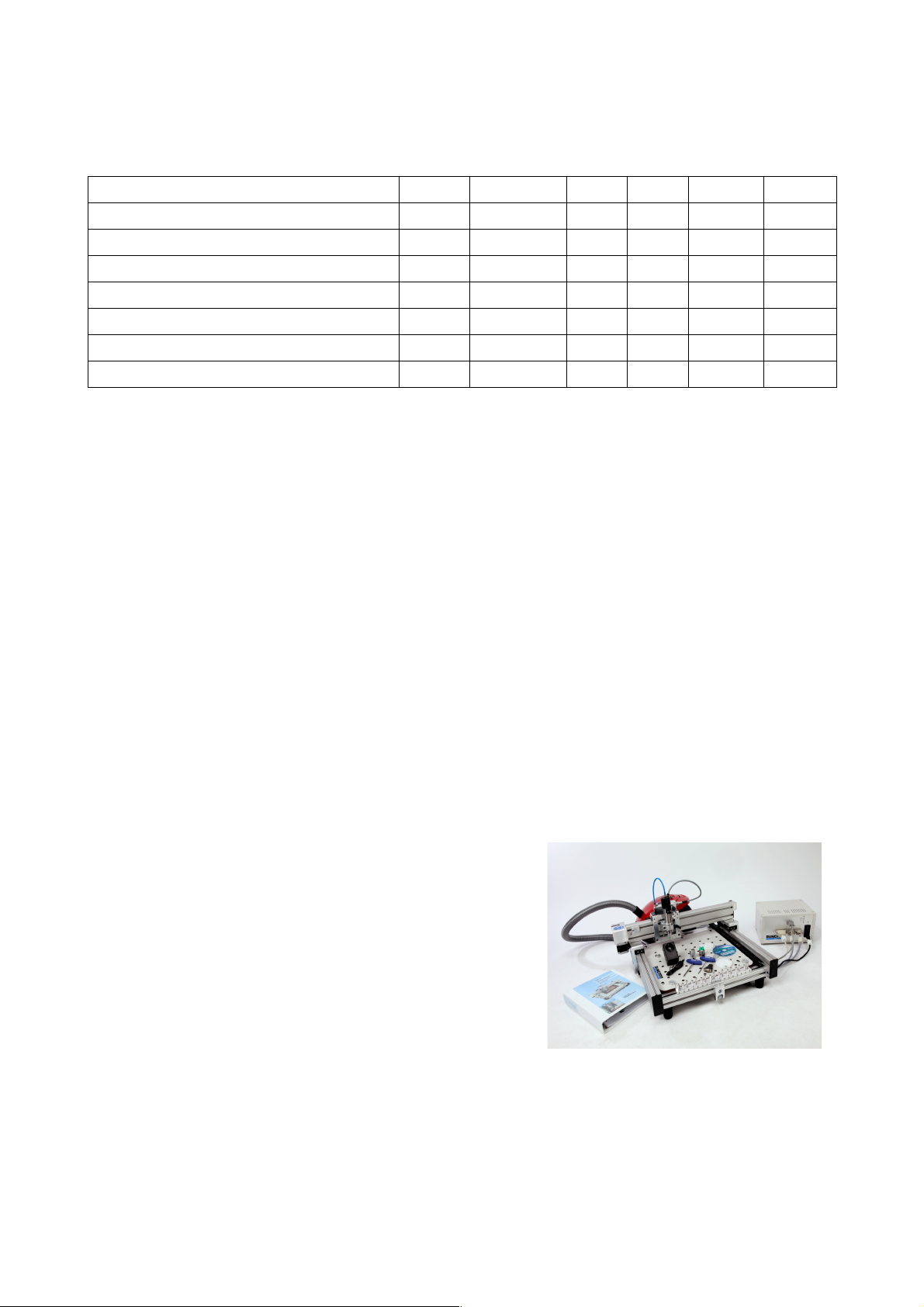

mount of delivery..............................................6

Safety instructions.....................................................7

General.................................................................7

Emergency Stop Facilities...................................7

Protection against contact with moving parts.......7

Location...............................................................7

Noise....................................................................8

Dust......................................................................8

Power supply.......................................................8

Maintenance.........................................................9

Tools....................................................................9

Documentation.....................................................9

Short Instructions/Setup..........................................10

Installation Manual RoutePro3000.........................18

Detailed Instructions...............................................20

Control unit and mechanics..........................20

Power supply................................................20

Control unit...................................................20

Mechanics Unit..................................................21

Set up.................................................................21

( TC) Compressed air connection...............21

Vacuum cleaner............................................22

Mounting the spindle....................................22

Spindle accessories.......................................23

Drill pressure foot.........................................23

Depth limiter.................................................23

( TC) Tool slots...........................................25

(MTC) Tool change......................................25

Maintenance..................................................25

Fixing the boards..........................................26

Clamp fixing.................................................26

Span fixing....................................................26

Reference pins / Isolation milling.................26

dhesive tape................................................26

Vacuum fixation...........................................26

Drilling bare boards......................................27

Pre-sensitized base material..........................27

Etched PCBs.................................................27

Routing.........................................................27

Engraving......................................................27

Drill and route parameter........................................28

Standard drill.....................................................28

Parameter......................................................28

Spade type drill..................................................29

Microvia-drill ....................................................29

Slot drill.............................................................29

Flex drill............................................................29

Isolation milling tool .......................................29

Routing parameters.......................................30

SC/FT...............................................................30

Routing parameter.........................................30

RPU ................................................................31

Routing parameter for RPU........................31

V-Cut-Router ..................................................32

Parameter:.....................................................33

3-Flute router.....................................................33

Diamond patterned router..................................33

Contour finishing router.....................................34

Guarantee................................................................34

Disclaimer of warranty...........................................34

Copyright................................................................34