Somat SPC-75S Installation and operating instructions

Operation/Service Manual

SPC-75s Close Coupled Pulping System

165 Independence Ct, Lancaster Pa 17601 (Ph:800-237-6628) (Fax:717-291-0878)

To better serve your needs in the future, please record your equipments information

below.

Model Number: SPC-75

Serial Number:

Service Company:

Service Phone Number:

Rep/ Dealer:

Rep/Dealer Phone Number:

Somat Service Dept: 800-237-6628 x 176

Somat Parts Dept: 800-237-6628 x 133

To expedite service or parts, please have the above information available before you call.

The serial number of your machine is located inside of the main electrical control panel

for your Somat equipment.

SOMAT COMPANY

LIMITED WARRANTY

SOMAT COMPANY warrants each new product manufactured by it to be free from defects in

material and workmanship under normal use and service, which does not include normal wear

of parts, ("normal use and service", with respect to Pulpers, Presses, water Hydra-Extractors,

Waste Handling and Processing Systems, shall mean the handling only of waste items of the

types listed in the SOMAT®Quotation or Sales Order therefore and within the LIMITATIONS

THEREIN set forth), its obligation under this warranty being limited to repairing or replacing any

part or parts thereof, free of charge INCLUSIVE of labor to remove and replace, f.o.b. factory from

which shipped, which shall, within one year from initial start-up of the SOMAT®System or from

date of original installation of the product if not a system be returned to SOMAT®at the factory

from which shipped, with transportation charges prepaid, and which SOMAT's examination shall

disclose to its satisfaction to have been thus defective. This warranty shall not apply to any

product or part which shall have been repaired or altered by any person not employed or

retained by SOMAT®, so as in the judgment of SOMAT®to affect its operation and reliability, nor

which has been installed, operated, or maintained contrary to SOMAT®OPERATION or

PREVENTIVE MAINTENANCE INSTRUCTION MANUALS or to other written instructions or

drawings approved by SOMAT®, nor which has been subject to misuse, negligence, or accident.

This warranty shall not apply should the SOMAT®System be initially started up without a duly

authorized SOMAT®representative present.

EXCEPT AS HEREIN EXPRESSLY STATED, NO WARRANTY, EXPRESS, IMPLIED OR BY LAW,

(INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE), IS MADE BY SOMAT; AND IN ANY EVENT SOMAT’S

LIABILITY, WHETHER IN CONTRACT, TORT, STRICT LIABILITY, OR UNDER ANY WARRANTY, OR

OTHERWISE, SHALL NOT EXCEED THE PURCHASE PRICE RECEIVED BY IT AND SHALL IN NO

EVENT INCLUDE ANY CONSEQUENTIAL, INCIDENTAL, PUNITIVE OR OTHER SPECIAL

DAMAGES.

NO CHANGE IN THIS WARRANTY AND LIMITATION OF LIABILITY AND NO SUBSTITUTE

THEREFORE (WHETHER INCORPORATED IN A PURCHASE ORDER OR OTHERWISE) SHALL BE

EFFECTIVE UNLESS SPECIFICALLY SET FORTH IN A WRITTEN INSTRUMENT SIGNED BY AN

OFFICER OF SOMAT®.

Rev. 02/10

Table of Contents:

SPC-75S, SPC-75UDT

Introduction……………………………………………………………………………..

Safety Instructions

General Description & Definitions

Installation………………………………………………………………………………..

Unpacking

Mechanical Installation

Plumbing Installation

Electrical Installation

Start-up……………………………………………………………………………………..

Forms & Lists

Warranty Validation

Operation…………………………………………………………………………………

Cleaning & Maintenance……………………………………………….

Cleaning

Maintenance

Troubleshooting

Replacement Parts………………………………………………………….

Pulper

Extractor

Electrical Panel

Safety Precautions and Warnings

READ THE MANUAL

COMPLETELY BEFORE ATTEMPTING TO OPERATE THE UNIT.

HIGH VOLTAGE!

DO NOT PERFORM ANY REPAIRS TO MOTORS OR CONTROL SYSTEMS

WITHOUT TURNING OFF THE MAIN POWER.

ALWAYS

TURN THE MAIN POWER OFF

AND LET ALL MOTORS COME TO A STANDSTILL

BEFORE DOING ANY MAINTENANCE ADJUSTMENTS OR CLEANING OF THE UNIT.

BEFORE STARTING, BE SURE

ALL PERSONNEL ARE CLEAR

OF MOVING PARTS.

KNOW LOCATION AND FUNCTIONS OF ALL

START/STOP BUTTONS

AND SAFETY

SWITCHES.

DURING PERIODIC MAINTENANCE,

CHECK ALL SAFETY SWITCHES

TO BE SURE THEY

ARE OPERATING PROPERLY.

DO NOT REMOVE

OR ALTER GUARDS.

DO NOT REMOVE

SAFETY LABELS. IF LABELS ARE MISSING OR DESTROYED, CONTACT

FACTORY FOR REPLACEMENT.

DO NOT OBSTRUCT

ELECTRICAL PANELS OR PUSH BUTTONS.

GOOD HOUSEKEEPING

IS THE MOST IMPORTANT SAFETY PROCEDURE.

Safety Precautions and Warnings

This equipment has locations which are hazardous and cause severe injury or death if

warnings are not followed. Always turn off power before reaching into any unit!

Maintenance to be performed by trained and authorized personnel.

This equipment has moving parts operating at

high speeds! Death or serious injury can occur

if warnings are not followed.

This equipment has moveable lids

protecting you from moving parts. Do not

alter safety devices or guards. Do not reach

into any part of the unit with the power

turned on.

This equipment uses High Voltage! Only

trained and authorized personnel should

perform maintenance on the electrical

components of this machine.

This equipment has moving parts that can

crush and cut. Do not alter safety devices or

guards. Do not reach into any part of the

unit with the power turned on.

Caution: Damage will occur to this equipment if unsafe objects are fed into the

machine(s). Keep these items out of the machine(s) to avoid component failure and

unwanted downtime. When in doubt, keep it out of the machine(s)!

Glass, Bottles, Jars

Cans Silverware

Metal of any kind !

China Pans Wood

Towels / Rags Scrub-Pads

Always turn the power off before servicing the pulper!

GENERAL DESCRIPTION

The SOMAT® system prepares solid waste materials for disposal by transforming the materials, with water,

into a pulp. This transformation takes place in a unit called a Pulper which is designed to pulp all forms of

paper, plastic, foil, and food waste. The waste material is fed manually or automatically to the Pulper. The

continual down flow of water and the rotation of the Pulper impeller create a strong vortex action which pulls

the waste down against the cutting blades of the impeller. The resultant slurry is then forced through a

perforated stainless steel Sizing Ring surrounding the impeller.

Items such as tin cans, silverware, nails, bolts and other non-palpable objects which may be inadvertently fed

into the Pulper are separated out of centrifugal force and gravity and are caught in the junk box within the

Pulper. This junk box should be emptied manually during cleanup.

TYPICAL PULPER

The SOMAT® System is

designed to pump the mixture of

macerated solids and water,

called slurry, to the Hydra-

Extractor® where the slurry is

reduced to a semi-dry pump.

Within the Hydra-Extractor®, the

slurry is carried by a helicoid

screw within a perforated tubular

screen. The water passes

through the screen and is

pumped back to the pulping unit.

The solids continue up the

helicoid screw to a compression

chamber or plug area where

additional water is removed by

extrusion. The solids in this area

are called the plug. This plug is

broken up at the Hydra-

Extractor® discharge opening by

a cutter and the pulp then falls

out of the discharge chute. TYPICAL HYDRA-EXTRACTOR®

This system is capable of reducing the volume of average non-compacted waste by approximately 80

percent.

The system is powered by electric motors with the associated controls housed in Som-A-Trols (electric

control panels). Since, in the course of operation, some water is absorbed by the pulp, fresh make-up

water is supplied to the Pulper automatically through a solenoid valve which responds to a water level

sensor.

In addition to the basic system as discussed to this point, numerous additional items of equipment may or

may not be required to comprise a specific system.

DEFINITIONS – GENERAL

1. Pulper - SOMATdevice that contains an impeller and security ring to grind solid waste. The

resultant mixture of waste particles and water is called slurry.

2. Hydra-Extractor- Inclined screw-type press for removing transport water from pulp.

3. Slurry - A water solution containing a low percentage of suspended solids.

4. Pulp - Semi-dry solid from which transport water has been extracted.

5. Som-A-Trol- Electrical control panel, including motor starters and sequencing controls

for automatic operation of the SOMATsystem.

6. Slurry Pump - Specially designed pump used to transport slurry from a SOMAT

Pulper to Hydra-Extractor.

7. Return Pump - Specially designed pump used to return water from Hydra-Extractorto SOMAT

Pulpers.

8. Water Level Control - a PLC controlled function utilizing time based programming.

9. Chemical Additive Pump - A proportioning type Additive pump that adds de-foaming, deodorizer,

and/or buffering solutions to the process water.

* 10. Pulp Screw Conveyor - Transport screw used for conveying pulp to a point remote

from Hydra-Extractor.

* 11. Distributing Type Pulp Screw Conveyor - Transport screw with discharge ports throughout its

length for even distribution in large haul-away containers.

* 12. Water economizing tank-Reservoir for return water used in large systems.

* Optional equipment which may not be furnished with your Pulping System.

DEFINITIONS – COMPONENTS

SOMATPULPER:

1. Tank - Pulping or grinding chamber of the SOMATPulper.

2. Impeller - Rotating metal plate with Cutting Blades and Tungsten Carbide teeth which de-fiber

and pulp the waste and along with the Security Ring provides a shearing action for non-fibrous

waste.

3. Security Ring - Perforated stainless steel ring surrounding the impeller through which all slurry

must pass after waste is pulped. Dimensions of security ring holes controls particle size of

materials leaving the Pulper.

4. Junk Box - Chamber in bottom of tank that segregates non-pulpable materials from tank.

HYDRA-EXTRACTOR:

1. Screw - Vertical helix which lifts and compresses solids from the slurry and permits water to

drain off by gravity.

2. Screen - Mesh screen that surrounds the screw, through which water drains off.

3. Plug - Mass of pulp extending beyond last helix of the screw. The force required to extrude the

plug squeezes additional water from pulp.

4. Brush - Nylon brush attached to edge of screw helix which serves to clean the screen.

5. Plug Cutter – Assists in breaking apart waste to discharge down the chute

GENERAL:

1. Throttling Valve - Full ported gate valve used to control water flow.

2. Timer - Electrical device used to automatically shut down the SOMATSystem at a pre-

determined time.

3. Fresh Water Solenoid - Electric valve used to control fresh water make-up to the SOMAT

System.

4. Motor Operated Valve - (MOV) Electric valve used to control return water flow in the system.

5. PLC- Computer controller designed to handle pulper and extractor operation.

Installation

UNPACKING

The crate containing your SOMAT®Pulper will contain the following items:

Pulper

Tray, if so equipped

Som-A-Trol®Panel

Misc. parts box containing:

ALL UNITS:

Anti-Vibration Pads

Installation Drawings

UDT UNITS ONLY:

Stainless Steel Lid

Stainless Steel Cone Adapter (Unless shipped directly to table manufacturer).

UDT Gasket

TRAY ONLY:

Gasket & Hardware

Return Water Assembly

TROUGH ONLY:

Trough Gasket & Hardware

Trough Nozzles & Throttling Gate Valves

(See Installation Drawing for quantity)

OPTIONAL EQUIPMENT:

Remote Push Button Station

Trough Magnet & Hardware

Feed hood

MECHANICAL INSTALLATION

HIGH TANK MODELS:

1) Put the pulper/extractor into position as shown on the Installation Drawings.

2) Place the Anti-Vibration Pads under each leg of the Pulper and Hydra-Extractor®.

3) TRAY FEED UNITS ONLY - Install the tray to the Pulper (if it was not already installed at the

factory) using the provided gasket material and hardware.

4) TROUGH FEED UNITS ONLY - Install the provided trough gasket between the Pulpers

inlet and the trough outlet and secure with the provided hardware.

UDT MODELS:

1) Cut a hole in the top of the table as shown in the Installation Drawing using the following

diameter: SPC-75S Pulper - 22" Diameter hole

2) Center the provided UDT Cone beneath the opening and weld it into place as shown.

Please follow print detail for welding instructions.

3) Put the Pulper into position.

4) Place the anti-vibration pads under each leg of the Pulper and Hydra-

Extractor®.

5) Install the UDT gasket onto the Pulper tank and around the outside of the adapter cone.

*see image on next page

6) Adjust the Pulper and Hydra-Extractor®legs so that the rubber UDT gasket provides a

water tight seal with 2” clearance between Pulper and table.

7) Install the provided trough gasket between the Pulpers inlet and the trough outlet and

secure with the provided hardware.

MOUNTING OF THE GRABBER MAGNETS:

Preferred: Locate per detail below and weld into place.

Optional: Drill four 7/32” diameter holes into the trough as shown below. Seal the heads of

the provided screws with silicone and attach the magnet.

RECOMMENDED POSITION OF THE GRABBER MAGNETS

MOUNTING DETAIL OF TROUGH

PIPING INSTALLATION

1) PIPING FOR FRESH WATER LINES AND DRAIN LINES NOT SUPPLIED BY SOMAT

®

.

2) PIPE SIZES TO BE IN ACCORDANCE WITH SOMAT

®

RECOMMENDATIONS.

3) ALL FITTINGS MUST BE PRESSURE RATED DRAINAGE TYPE.

4) KEEP DRAINS ACCESSIBLE TO UNIT. DO NOT INSTALL DRAINS UNDER SOMAT

®

EQUIPMENT.

5) NO EXTERNAL STRAIN TO BE EXERTED ON SOMAT

®

EQUIPMENT.

6) PROTECT ALL SOMAT

®

EQUIPMENT AND PIPING FROM FREEZING AND

CONDENSATION.

7)

ALL PIPING TO BE IN ACCORDANCE WITH STATE AND LOCAL PLUMBING CODES.

8)

“F” = FURNISHED BY SOMAT / “NF” = NOT FURNISHED BY SOMAT

FRESH WATER:

*NOTE: In Massachusetts, the Public Water Supplier shall be contacted regarding the proper

backflow prevention device to be installed. *

1) Bring a 1/2" cold water line for theSPC-75S, to the pre-piped fresh water assembly. (See

enclosed diagram and Installation Drawings)

2) Bring a 1/2" hot water line to the pre-piped fresh water assembly on the Hydra-Extractor

(see enclosed diagram and Installation Drawing).

HYDRA-EXTRACTOR®OVERFLOW AND PULPER DRAIN:

1) Install 1-1/2" pipe from the Hydra-Extractor®overflow to floor drain (DO NOT REDUCE).

2) Install 2" pipe from the Pulper drain to floor drain (DO NOT REDUCE).

RETURN PIPING FOR UNITS WITH A TRAY FEED ONLY:

1) Install the pre-piped return water assembly onto the return pump (if not already factory

installed) (see enclosed diagram and Installation Drawings).

2) Install one side of the provided tubing over the return water elbow on the feed tray and

the other side onto the pump return water assembly (if not already factory installed).

3) Install the provided hose clamps at each connection.

RETURN PIPING FOR UNITS WITH A TROUGH:

1) Pipe from the return pump to the supplied trough end flush nozzle and silver saver

connections as well as to the optional trough nozzles as shown in the trough detail on the

Installation Drawing using the provided throttling gate valves

NOTE: All Pre-Piped Assemblies are hand tightened for shipping purposes only.

ELECTRICAL INSTALLATION

1)

PRE-WIRED CONTROL PANELS, OPERATOR DEVICES & ELECTRIC VALVES BY

SOMAT.

2)

INSTALL CONDUITS FROM PANEL TO PREWIRED JUNCTION BOX, PULL

MOTOR WIRES AND CONTROL WIRES THRU SEPERATE CONDUIT AND DO THE

FINAL TERMINATIONS.

2) GROUND ALL ELECTRICAL EQUIPMENT.

3) CONTROL CIRCUIT TO BE 115 VAC AND/OR 24VDC NOMINAL.(SEE APPROVED

DRAWINGS)

4) ALL SOM-A-TROL PANELS ARE TO BE WIRED IN ACCORDANCE TO LOCAL,

STATE AND/OR NATIONAL ELECTRIC CODE (NEC 1993) SPECIFICATIONS.

5) INTEGRAL PUSH BUTTONS ARE LOCATED IN PANEL DOOR AND PRE-WIRED AT

FACTORY. OPTIONAL REMOTE PUSH BUTTON STATION IF SUPPLIED; TO BE

MOUNTED & WIRED AT WORK STATION BY ELECTRICIAN. (BRACKET

REQUIRED BY CUSTOMER).

PANEL & OPTIONAL REMOTE PBS MOUNTING:

1) Mount the Som-A-Trol®in a suitable location (see Installation Drawings) so that the

bottom of the panel is at least 42" above the finished floor or in accordance with

ADA requirements.

2) Install the Optional Remote Push Button Station onto the Dish Table or at another

convenient location. (See Diagram and Installation Drawings.)

MOUNTING PATTERN FOR THREE HOLE PUSH BUTTON STATIONS

SUPPLYING THE SOM-A-TROL®WITH POWER

Bring the (4 wire) customer power supply to the top right side of the Som-A-Trol®

and connect to the panel disconnect and ground lug. (See Diagram and

Installation Drawings.)

All close couple systems are prewired; there is a prewired junction box mounted

to the side of the extractor shell. Inside this prewired junction box there will be

terminals that are the same as in the panel. Install conduits from the panel to the

pre-wire junction box, pull the motor wires and control wires thru these conduits

separately and do your final wire terminations matching numbers from panel to

pre-wire junction box.

REMOTE PUSH BUTTON STATION

Mount the remote push button station, run the conduit from the remote push

button station to the prewired junction box then pull the wires from the remote

push button station to the prewired junction box and do your final hookups in the

prewired junction box.

WARNING:

Improper connection of the equipment grounding conductor can result in a risk of

electrical shock. An equipment grounding conductor must be run with the circuit

conductors and connected to the pulper/extractor grounding terminal.

This manual suits for next models

1

Table of contents

Other Somat Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Vertiv

Vertiv Liebert MCV Series Installer/user guide

Aerotech

Aerotech ABRS Series manual

hager

hager tehalit.FWK Plus Mounting instructions

Schmalz

Schmalz VCBL-G-K1 operating instructions

Redline Engineering

Redline Engineering 500HWC manual

Lennartsfors

Lennartsfors IronHorse IH 2055 Classic Operator's manual

HYDAC FILTER SYSTEMS

HYDAC FILTER SYSTEMS LVU-CD-10 Operating and maintenance instructions

Humboldt

Humboldt PROMAT HM-4187H product manual

RAIMONDI

RAIMONDI BULLDOG ADV Use and maintenance manual

Schwarz

Schwarz SB10B operating instructions

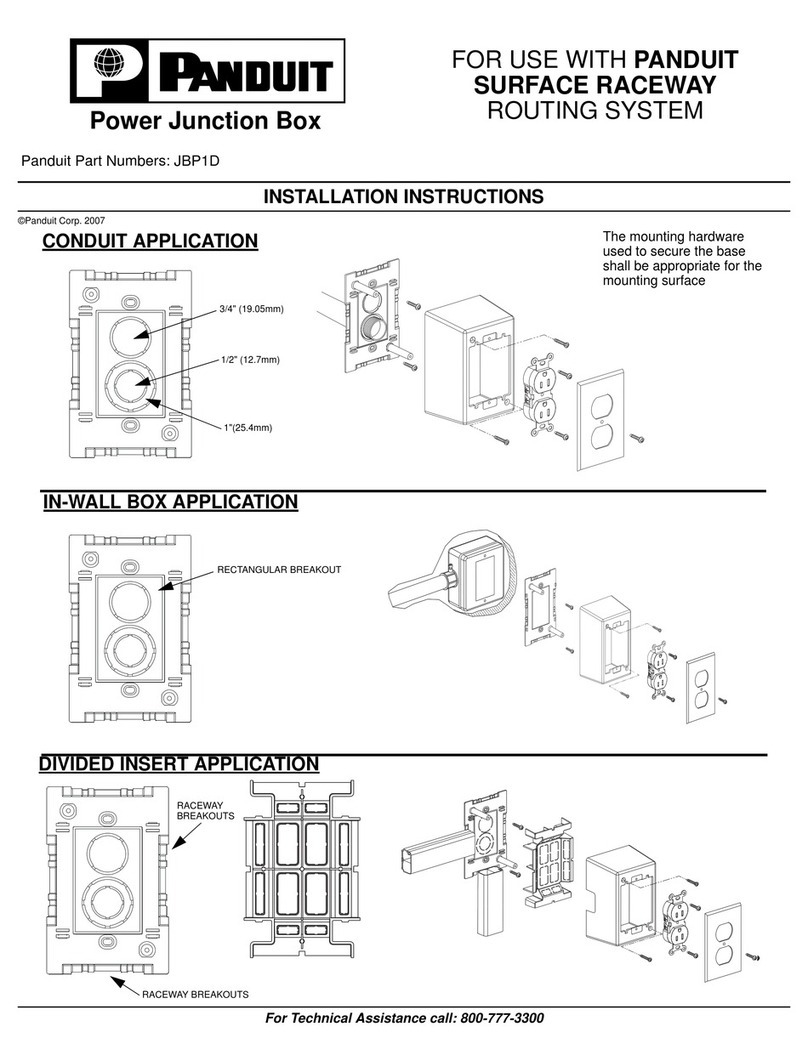

Panduit

Panduit JBP1D installation instructions

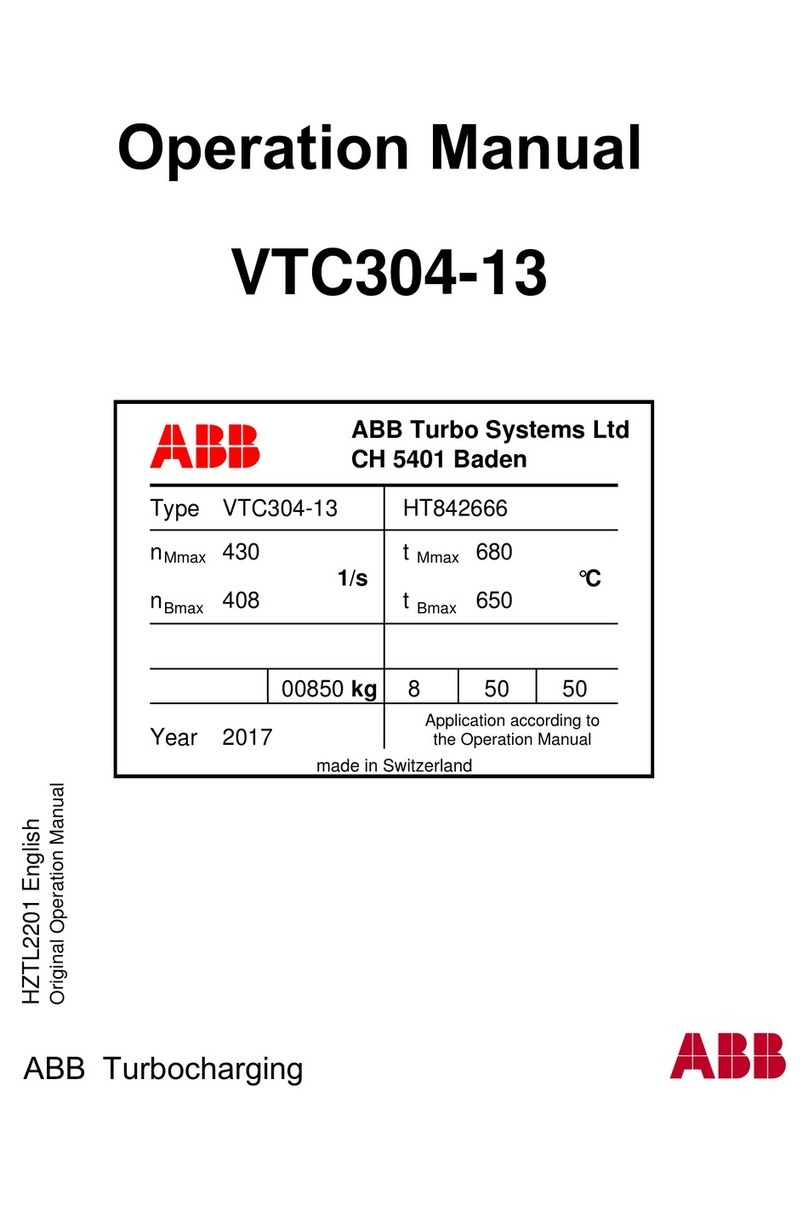

ABB

ABB VTC304-13 Operation manual