6

Table of contents

1. STANDARDS AND GENERAL WARNINGS................................................................................... 6

1.1 TESTING AND INTENDED USE.................................................................................................. 7

1.2 INTRODUCTION........................................................................................................................... 7

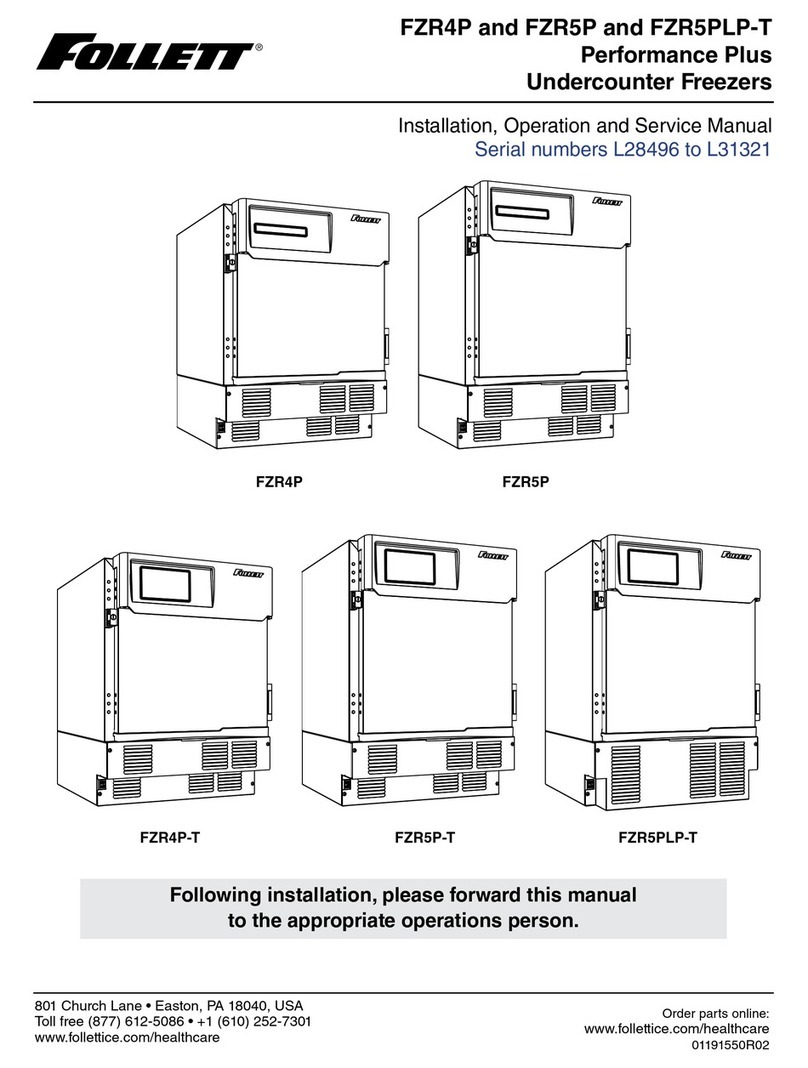

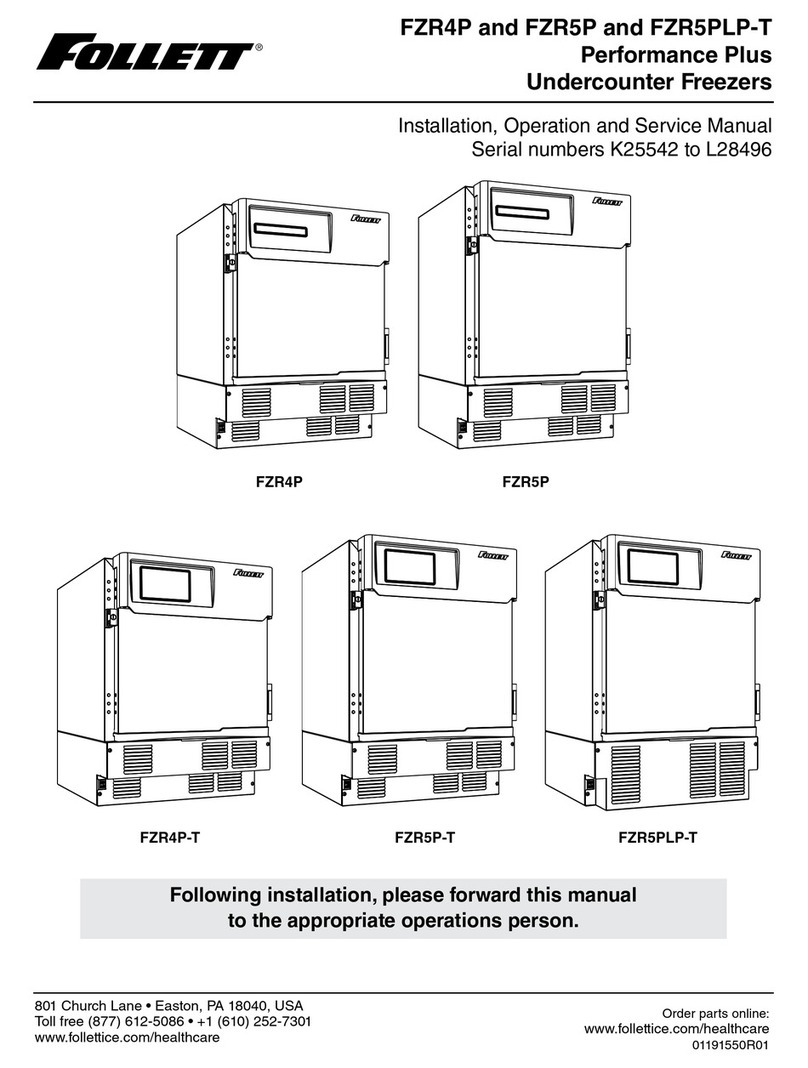

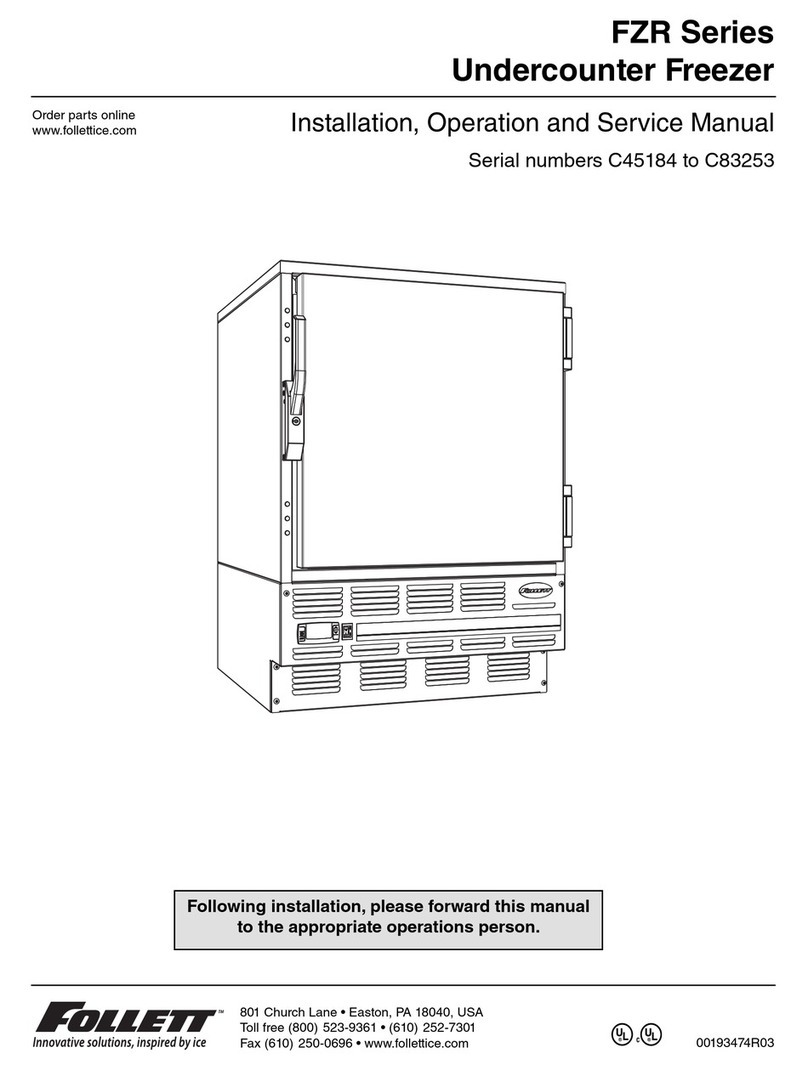

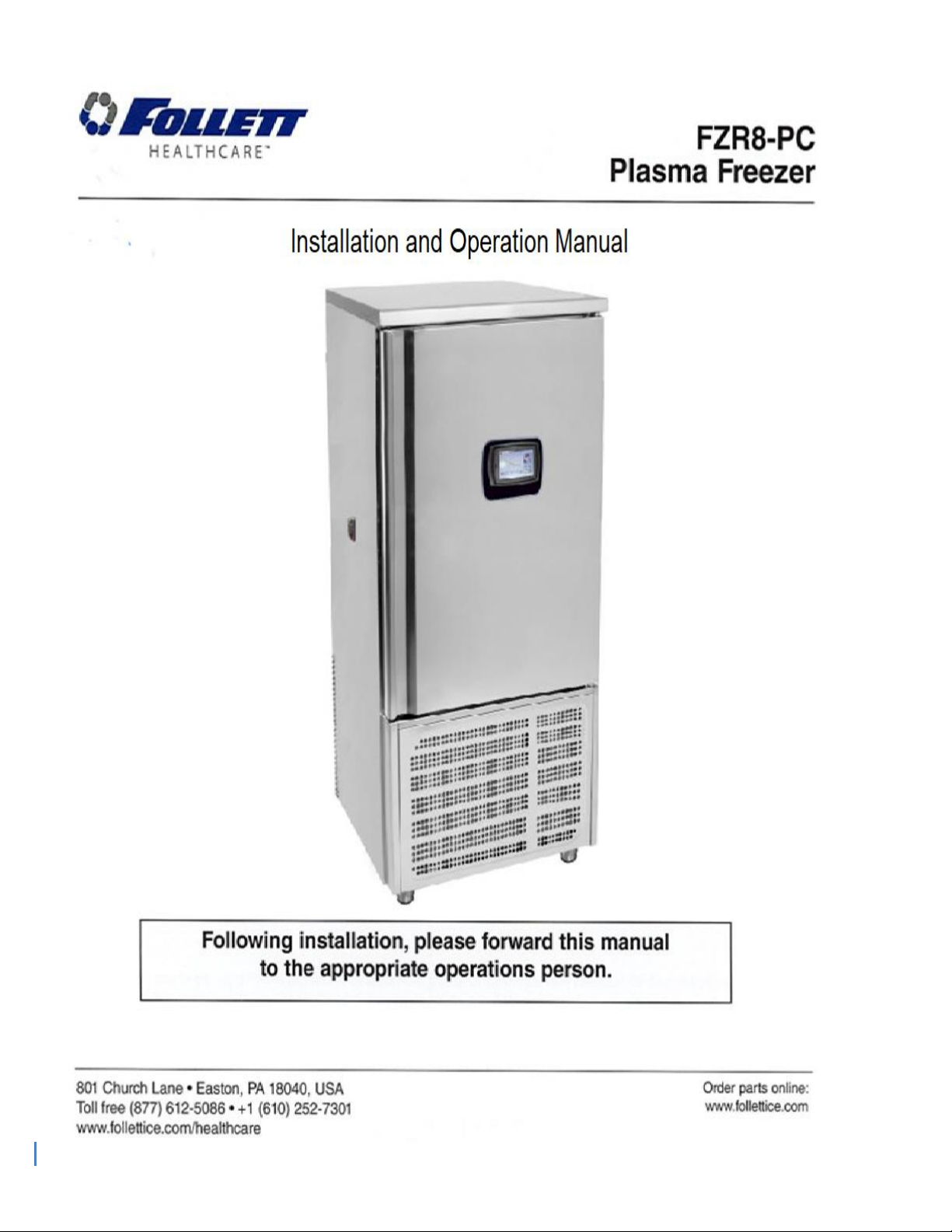

1.3 PRODUCT DESCRIPTION........................................................................................................... 8

1.4 CERTIFICATION........................................................................................................................... 8

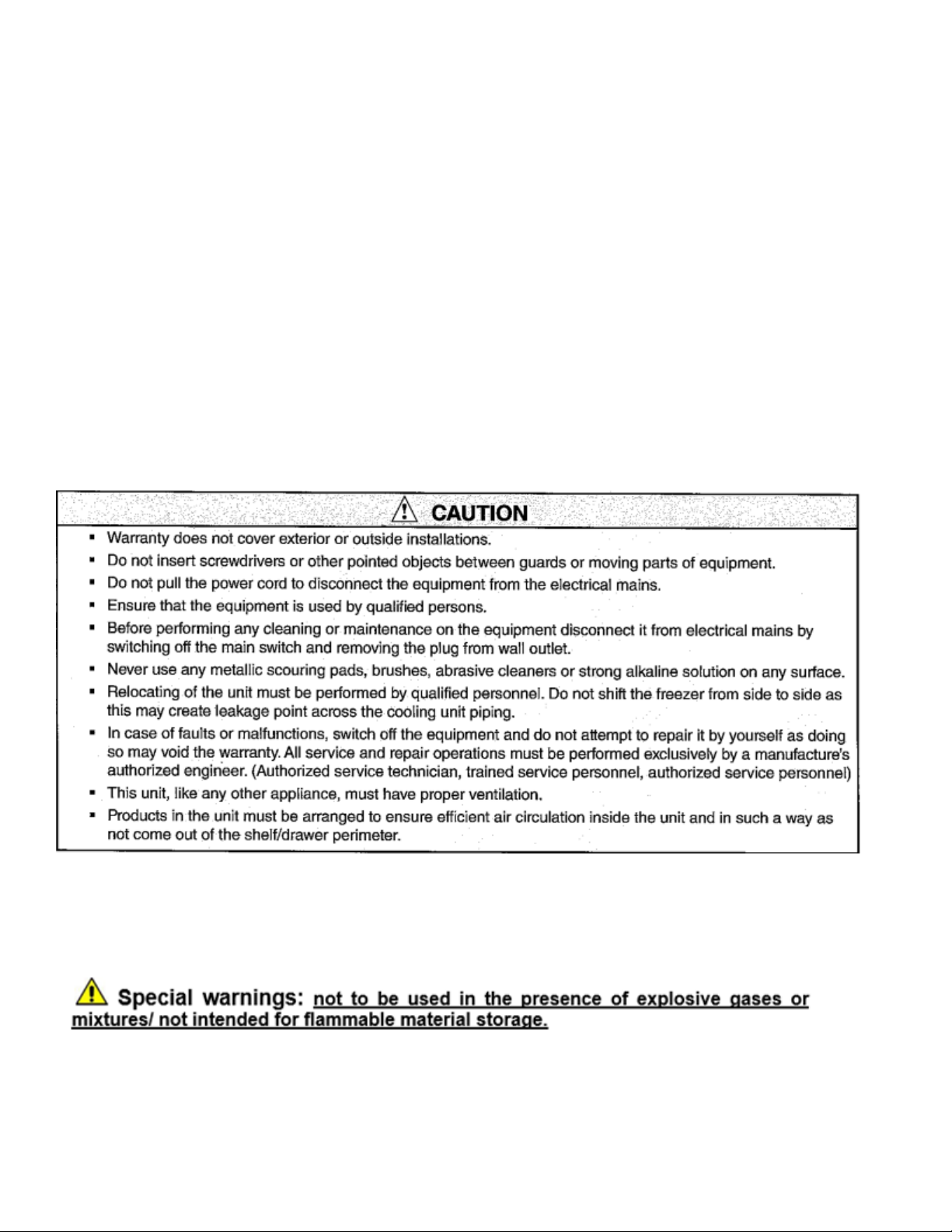

1.5 GENERAL SAFETY WARNINGS................................................................................................. 8

1.6 CUSTOMER’S RESPONSIBILITIES .......................................................................................... 10

1.7 CUSTOMER SERVICE REQUESTS .........................................................................................10

1.8 ORDERING OF SPARE PARTS ................................................................................................ 10

1.9 PRODUCT CONFIGURATION................................................................................................... 10

1.10 MATERIALS AND REFRIGERANTS ....................................................................................... 10

1.11 WARNING LABELS.................................................................................................................. 12

2. INSTALLATION............................................................................................................................. 13

2.1 TRANSPORTATION AND HANDLING ...................................................................................... 13

2.2 POSITIONING............................................................................................................................12

2.3 WIRING AND ELECTRICAL HOOK-UP..................................................................................... 15

2.4 SET UP OPERATIONS .............................................................................................................. 15

2.5 AIRFLOW REQUIREMENTS ..................................................................................................... 16

2.6 RE- LOCATION...........................................................................................................................16

2.7 SCRAPPING AND DISPOSAL...................................................................................................16

2.8 REMOTE ALARM CONNECTION.............................................................................................. 17

3. OPERATION / OPERATIONAL GUIDANCE....................................................................................16

3.1 STARTING CYCLE......................................................................................................................19

3.1.1 TIME CYCLE........................................................................................................................ 19

3.1.2 PRODUCT TEMPERATURE CYCLE.................................................................................. 19

3.1.3 COMPLETION OF PROCESSING / END OF SHIFT…………………………………………20

3.2 USER MENU................................................................................................................................ 22

3.2.1 USB OPTION ........................................................................................................................23

3.2.2 I/O STATUS...........................................................................................................................24

3.2.3 HACCP DOWNLOAD............................................................................................................ 24

3.2.4 USING A PROPERTY SOFTWARE TO TRACE HACCP DATA......................................... 25

3.2.5 ACCESS THE SOURCE HACCP FILES ............................................................................. 28

4. BASIC SERVICE DIAGNOSTIC ......................................................................................................30

4.1 ALARM CODES...........................................................................................................................30

4.2 ALARM CODE DETAILS............................................................................................................29

5. DEFROST.........................................................................................................................................30

6. CLEANING / INSPECTION...............................................................................................................30

7. TFT DISPLAY SOFTWARE UPDATE PROCEDURE.......................................................................31

8. CALIBRATING THE TFT SCREEN..................................................................................................32