foras 5FES 50HZ Technical manual

DV/DM/DC/DTR

®

Use and installation instruction manual

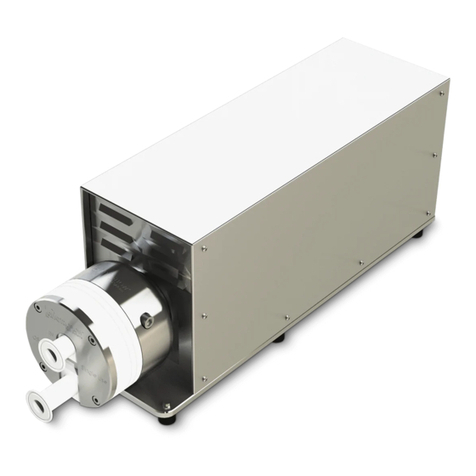

CLOSE-COUPLED 5"PUMPS

5FES 50HZ

[D-CE]

2006/42/CE; 2006/95/CE; 2004/108/CE; 2000/14/CE (followed procedure: annex V);

87/404/CE: 97/23/CE (Cat.1, Mod.A).

[N-A]

EN 60034…; EN 60204-1; EN 60335-1; EN 60335-2-41; EN 61000; EN 55014; EN ISO

12100-1; EN ISO 12100-2; EN ISO 14121-1; EN ISO 3744

Manufacturer and depositary of tecnical documentation:

PENTAX S.p.A.

Viale dell’Industria, 1

37040 Veronella (VR) - Italy

Gianluigi Pedrollo (President)

Veronella (VR), 01/06/2011

Tel. +39 0442 489500 - Fax +39 0442 489510 - www.pentax-pumps.com - E-mail: com@pentax-pumps.it

Sede amministrativa e stabilimento: Viale dell’Industria, 1 - 37040 Veronella (VR) Italy

Manufacturer and depositary of tecnical documentation:

PENTAX S.p.A.

Viale dell’Industria, 1

37040 Veronella (VR) - Italy

Gianluigi Pedrollo (President)

Veronella (VR), 01/06/2011

Gianluigi Pedrollo

DICHIARAZIONE DI CONFORMITÀ

Si dichiara che i prodotti sono conformi

alle prescrizioni delle direttive [D-CE] e

costruiti nel rispetto delle norme

armonizzate [N-A].

DECLARATION OF CONFORMITY

The listed products comply with the

requirements of the Directives [D-CE] and

are built in accordance with the updated,

current regulations [N-A].

CLOSE-COUPLED 5" PUMPS

Use and installation instruction manual ENGLISH

- EN -

During installation, maintenance and use of the

appliance, carefully follow the instructions

provided in the manual. Carefully read the

instruction manual in all its parts before carrying

out any operation on the pump.

In the case of appliances without a plug, a means

of disconnecting the power supply, with omni-

polar contact separation that fully disconnects

under overvoltage category III, must be installed in

the power supply system according to the current

installation rules.

This equipment is not intended to be used by

persons (including children) with reduced physical,

sensoryor mentalcapabilities,orlackofexperience

and knowledge, unless they have been supervised

or instructed on the use of the appliance by a

person who is responsible for their safety.

This appliance can be used by children over the

age of 8 and by people with reduced physical,

sensory or mental capabilities or lack of experience

and knowledge if they have been supervised or

instructed on the safe use of the appliance and

understand the hazards involved. Children must

not play with the appliance. Cleaning and user

maintenance should not be performed by children

without supervision.

Do not use the electric pump in swimming pools,

basins, ponds and in similar places when people

are in the water.

The appliance must be powered by means of a

residual current device, with residual operating

current not greater than 30 mA.

Three-phase appliances must be protected against

short-circuitsand overloadsbya class 10 protection

device, in accordance with IEC 60947-4. Set the

rated current according to the value shown on the

rating plate.

Before starting any work on the electric pump,

make sure it has been disconnected from the

power supply and cannot be accidentally

reconnected.

If the power cable is damaged, it must be replaced

by the Manufacturer, their service centre or

qualified personnel.

The maximum head of the pump is indicated in metres,

on the rating plate applied on the pump, and on the

cover of the manual.

The pump can work continuously at the maximum

temperature indicated on the rating plate (+40°C).

Refer to the “INSTALLATION” and “HYDRAULIC

CONNECTIONS” chapters to install the equipment.

Electrical connection and rotation direction of

functional components (three-phase motors).

SAFETY RULES

This instruction manual should be definitely referred to byall qualified technical

personnel in charge of installing, operating and servicing the appliance.

It should be properly kept and made available for reference on the installation site

of the electric pump.

Identification of the coded instructions provided in this manual

The safety notes in this instruction manual are marked with a general

hazard symbol. Failure to comply with them may cause serious damage

to health.

The safety notes marked with this symbol refer to electrical hazards.

Risks associated with failure to comply with safety rules

Failure to comply with safety rules may cause physical and material damage, as

well as environmental pollution.

Non-observance of safety rules may totally invalidate your warranty.

To name a few examples, failure to comply with these rules can result in:

• failure of the main machine functions or of the installation,

• impairment of maintenance operations,

• physical harm due to electrical or mechanical causes.

General

This appliance (pump or electric pump, depending on the model) was designed

and manufactured according to the most cutting-edge techniques, in full

compliance with the regulations in force, and subjected to strict quality control

procedures.

This instruction manual will help you not only to understand how the appliance

works, but also to get to know its possible applications.

This user manual contains important recommendations that are necessary for the

appliance to be properly and economically operated. These recommendations

must be observed in order to ensure reliability and durability, and to avoid any

risks of accidents resulting from improper use.

The appliance must be used for the intended applications and within the limits

described in the following paragraphs.

The activities related to handling, installing, using, servicing and disposing of

the product pose risks for human safety and for the environment that cannot be

constructively eliminated.

The main residual risks are electrical (electrocution) and mechanical ones

(injuries caused by sharp edges, abrasions or crushing).

All operations must be carried out with the utmost attention only by expert,

professional sta, equipped with appropriate personal protective equipment

and suitable tools, when the machine is disconnected. Failure to observe the

instructions provided in this manual and proper working practices will increase

health risks.

The manufacturer accepts no responsibility in case of accident or damage

caused by negligence, improper use of the electric pump, or failure to follow

the instructions described in this manual, or use in conditions other than those

permitted.

In the supply conditions, the electric pump has no moving or normally live parts

accessible from the outside.

The user must not disassemble the electric pump completely or partially,

nor make any changes or tamper with the product. If removed during

installation, guards must be refitted immediately.

Personal Protective Equipment (PPE)

During installation, routine and extraordinary maintenance, decommissioning

and disposal, use the personal protective equipment (PPE) specified below.

Additional PPE may be necessary, depending on the working conditions.

By properly using PPE, any residual health risks may be reduced.

Wear safety gloves

Translation of the original instructions

ENGLISH 5" CLOSE-COUPLED PUMPS

Protect your eyesight with safety goggles

Wear steel toe cap safety shoes, insulated from the ground

Wear a respirator if there is a risk of toxic, irritating or suocating fumes

Suitable clothing

During maintenance operations and in any case when the machine is

running in various modes, including its normal operating mode, avoid any

clothing or accessories that may get entangled in the moving parts of the

machine.

Declaration of conformity

The declaration of conformity, including the rules and regulations considered in

the design phase, is shown at the end of the manual.

Noise emission

The electric pump generates an A-weighted acoustic pressure lower than 70

dB(A).

1 PRELIMINARY INSPECTION

1.1 Delivery and packaging

The product is supplied in its original packaging, which includes this instruction

manual, and must remain packed until it is installed. The packed product must be

stored away from atmospheric agents.

Remove the appliance from the packaging and check that it is intact. Also check

whether the rating plate details match the desired ones. To properly read the

rating plate, refer to the instructions in this manual. In case of any discrepancies,

contact the supplier immediately, specifying the nature of the defects.

If in doubt about the machine safety or integrity, do not use it and contact

a professional service centre.

2 PRODUCT INFORMATION

The product model, main service specifications and serial number are shown

on the rating plate. It is important to provide these details when requesting

interventions or support and spare parts.

The product model is identified by an alphanumeric code shown on the rating

plate. The meaning of the characters making up the code is explained in Fig. 1.

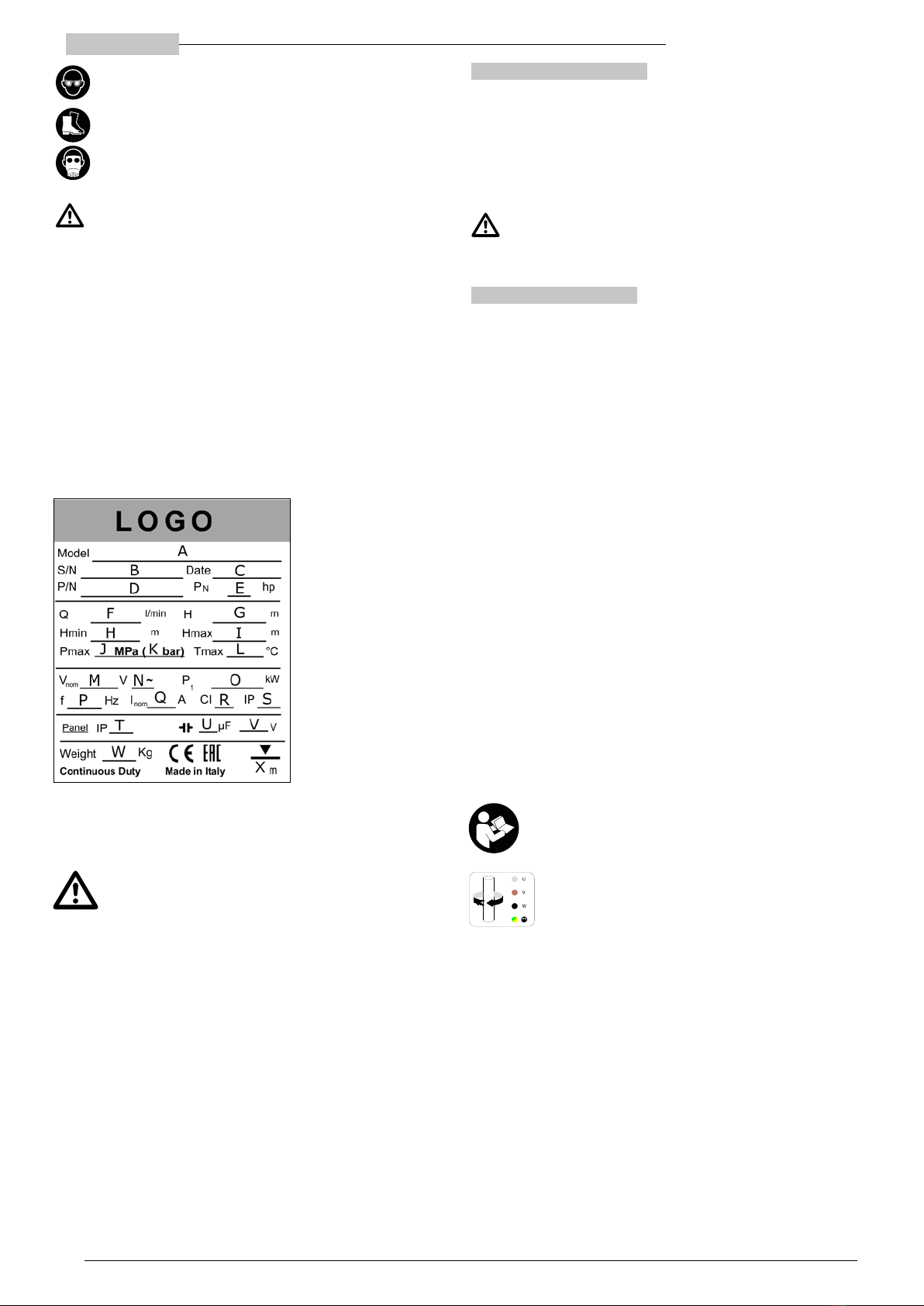

2.1 Pump rating plate

To properly read the rating plate, refer to the following instructions (Fig. 2). Please note that the information provided on the rating plate may be arranged dierently

from what is shown below. Refer to the symbols describing the reference fields.

Some information may not be available, depending on the model considered.

A) Pump identification code

B)Serial number

C) Production date

D)Product code

E) Rated power

F) Operating flow range

G)Operating head range

H)Minimum head (according to EN 60335-2-41)

I) Maximum head

J) Maximum pressure in MPa

K)Maximum pressure in bar

L) Maximum operating temperature

M)Rated power supply voltage

N)"3" (three-phase version) / "empty" (single-phase version)

O)Maximum power absorbed by the electric pump

P) Rated power frequency

Q)Current consumption

R)Insulation class (motor windings)

Fig. 2

S) Degree of protection of the electric pump

T) Degree of protection of the control panel (if present)

U) Capacitor capacity (single-phase motors)

V) Maximum capacitor voltage

W) Electric pump weight

X) Maximum immersion depth

2.2 Other plates

On the surface of the pump, there may be other plates depending on the model

that identify its features, compliance with rules and regulations or installation, use

and disposal provisions. See the following list.

Pay attention to the risks associated with the product installation,

maintenance and disposal.

Before installing and using the electric pump, carefully read the

instruction manual.

Rotation direction of functional components (three-phase motors).

Use and installation instruction manual ENGLISH

3 APPLICATIONS AND USE

3.1 Permitted use

These electric pumps are designed for applications such as water supply from

groundwater, pumping from a reservoir or tank, pressure increase or domestic

and small commercial or industrial utilities.

The electric pumps have an IPX8 protection rating.

The submerged electric pumps are designed to work while immersed in the liquid

and the surface electric pumps to work out of the liquid. The control panel has an

IP55 protection rating.

3.2 Pumped liquids

Clean, non-aggressive liquids, compatible with the electric pump component

materials. A liquid must have physical characteristics similar to those of clean

water at room temperature (1030 kg/m3maximum density and 2 cPs maximum

viscosity. If these limits are exceeded, contact the manufacturer).

Improper use can result in overheating of the machine and power cables,

with consequences such as failure and potentially fire.

Anysand contentinthewatermustnot exceed50g/m3.Highersandconcentration

will reduce the electric pump service life and increase the risk of blockage. Any

suspended solids must not exceed 0.5 mm in maximum size.

The pump can work continuously at the maximum temperature indicated on the

rating plate.

3.3 Conditions of use

• Maximum operating pressure (pump delivery pressure, given by the sum of the

pump inlet pressure and the pressure increase created by the pump): 15 bar.

The maximum pressure at the appliance inlet is determined by the pressure

increase created by the pump, so as not to exceed the maximum operating

pressure (see appropriate section).

• Sucked liquid maximum temperature: +40°C.

• Electrical supply voltage: refer to the rating plate.

• Maximum immersion depth: see the indication of the rating plate (max 20 m).

• Maximum number of consecutive hourly start-ups: 40.

3.4 Non-permitted use

Do not use the electric pump for applications other than those described

above and, in any case, not authorised by the manufacturer. Improper use may

cause serious damage (including death) to people, animals, objects and the

environment.

Do not use the electric pump in swimming pools, basins, ponds and in

similar places when people are in the water.

• Do not pump food liquids or human food products.

• Do not pump drinking water if adequately certified equipment is required for

this.

• Do not pump any liquids that are more viscous and/or denser than water,

unless specifically authorised by the manufacturer.

• Do not use the machine in potentially explosive environments or with

flammable liquids.

• Do not run the machine without any liquid.

• To avoid overheating, do not run the electric pump continuously at a flow rate

of zero or lower than 10% of the rated value. The pump is operated at best

within the range specified on the rating plate.

4 INSTALLATION – GENERAL

The electric pump is suitable for both vertical and horizontal installation. Electric

pumps with in-line ports can be installed in places occasionally subject to flooding

(as long as the electrical terminals of the power cable remain in a dry place).

The wire terminals of the power supply cable (wires or power outlet) must be

protected against water, humidity and atmospheric agents. Pay attention to the

protection rating of the control panel (IP55), if any.

Secure the control panel to the wall using the eyelets on it. It is recommended to

install it in a dry and sheltered place.

Before starting work on the machine, make sure that it has been

disconnected from the power supply network and that it cannot be

accidentally reconnected.

Always use the required PPE (refer to the relevant section).

If necessary in relation to the conditions of use and the working environment, we

suggest installing adequate devices to immediately but safely stop the machine,

in case of emergency.

4.1 Electrical connections

The connections must be exclusively performed by expert, authorised personnel

and in compliance with legal obligations, current regulations, recommended

technical practices and the following provisions.

Models without a plug are only intended for fixed applications (where the cables

cannot be disconnected and reconnected by the user). The cable terminals

must be connected in an electrical panel with at least an IP55 protection rating,

equipped with cable mechanical fixing systems independent of electrical

terminals, and an overvoltage category III omni-polar cut o switch preventing

the panel from being opened when the appliance is live.

Models equipped with plugs can be used in mobile applications, using only

electrical sockets provided with an earth contact. The following provisions apply

to both types.

Make sure the rating plate details match the rated voltage and frequency values.

Always connect the earthing cable of the electric pump and check the earthing

circuit for eectiveness before starting the pump up and on a regular basis.

The installer is responsible for making connections in accordance with the

regulations in force in the country of installation.

The appliance must be powered by means of a residual current device,

with residual operating current not greater than 30 mA.

Three-phase appliances must be protected against short-circuits and overloads

by a class 10 protection device, in accordance with IEC 60947-4. Set the rated

current according to the value shown on the rating plate. A manual reset device

is recommended.

4.2 Single-phase versions

The single-phase versions can be supplied complete with a control panel that

includes the capacitor or with the integrated capacitor (two-wire power cable, in

addition to the earth wire).

Otherwise, refer to the instructions below (fig. 3) and to the technical data plate

of the pump for the connection and when choosing the capacitor.

BLACK

BLUE or GREY

BROWN

Fig. 3

C

L

N

YELLOW/GREEN

⏚

In the single-phase versions up to 1.1 kW (50 and 60 Hz) and 1.5 kW (50 Hz),

the motor is protected against overloads by means of a thermal device (circuit

breaker) inserted in the winding.

Caution! The device automatically resets when the motor temperature

dropsbelowthedangerlevel.Theelectricpump mayrestartunexpectedly!

The single-phase powers 1.5 and 2.2 kW require external protection, if not

equipped with the control panel.

The rotation direction does not require any checks.

4.3 Three-phase versions

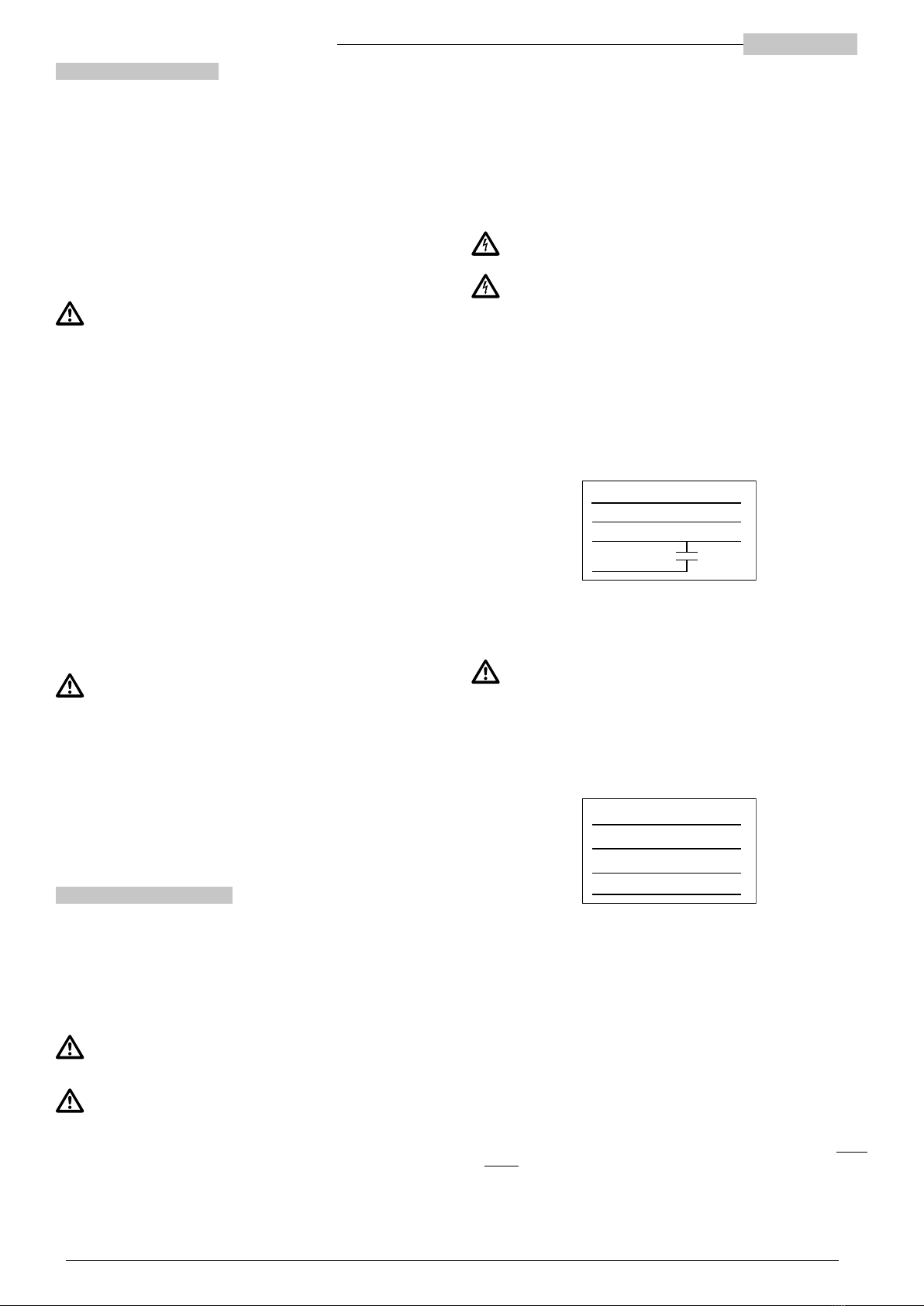

To connect the three-phase versions, refer to the indications below (fig. 4).

Fig. 4

BLUE or GREY

BROWN

BLACK

U

V

W

YELLOW/GREEN

⏚

Three-phase versions require external protection against overload and short-

circuit.

If the electrical connections have been made respecting the cyclic direction of

the phases, as in fig. 4, the direction of rotation is automatically corrected (it is

advisable to verify in any case, so as to avoid misunderstandings). Otherwise,

check the direction of rotation as described below.

4.3.1 Checking the direction of rotation

In the three-phase versions, the direction of rotation is determined by the

connection of the power supply and can be inverted. In this case, the performance

is significantly lower than the nominal ones. To check the correctness of the

connection, immerse the electric pump in the fluid to be pumped or install it in

line. Start it and proceed in one of the following two ways:

• During operation, measure the maximum power consumption with an

ammeter clamp. If the rotation direction is incorrect, the values will be nearly

double those specified on the rating plate.

• Alternatively, run the machine for a few seconds, then reverse the rotation

direction and repeat the operation. The correct direction is the one in which the

greatest flow rate is obtained.

To reverse the rotation direction, it is sucient to exchange two phases between

them.

Translation of the original instructions

ENGLISH 5" CLOSE-COUPLED PUMPS

4.4 Variable frequency drive (VFD) applications

For variable frequency installations (power supply via “inverter”), make sure the

frequency inverter can supply the rated voltage and at least 10% more current

than the rated value shown on the rating plate. To install and connect the device,

please refer to the manufacturer's instruction manual.

5 HYDRAULIC CONNECTIONS

Before starting any work on the electric pump or the motor, make sure

that the power supply is disconnected and it cannot be accidentally

restored.

Installing the electric pump can be complex and dangerous for people.

This operation must, therefore, be performed by competent, qualified

installers.

In case of breakage, the electric pump can release up to 50 cl of oil. Occasional

ingestion of oil is not dangerous for human health. The risk of an oil leak should

be limited as much as possible. Plan it during installation.

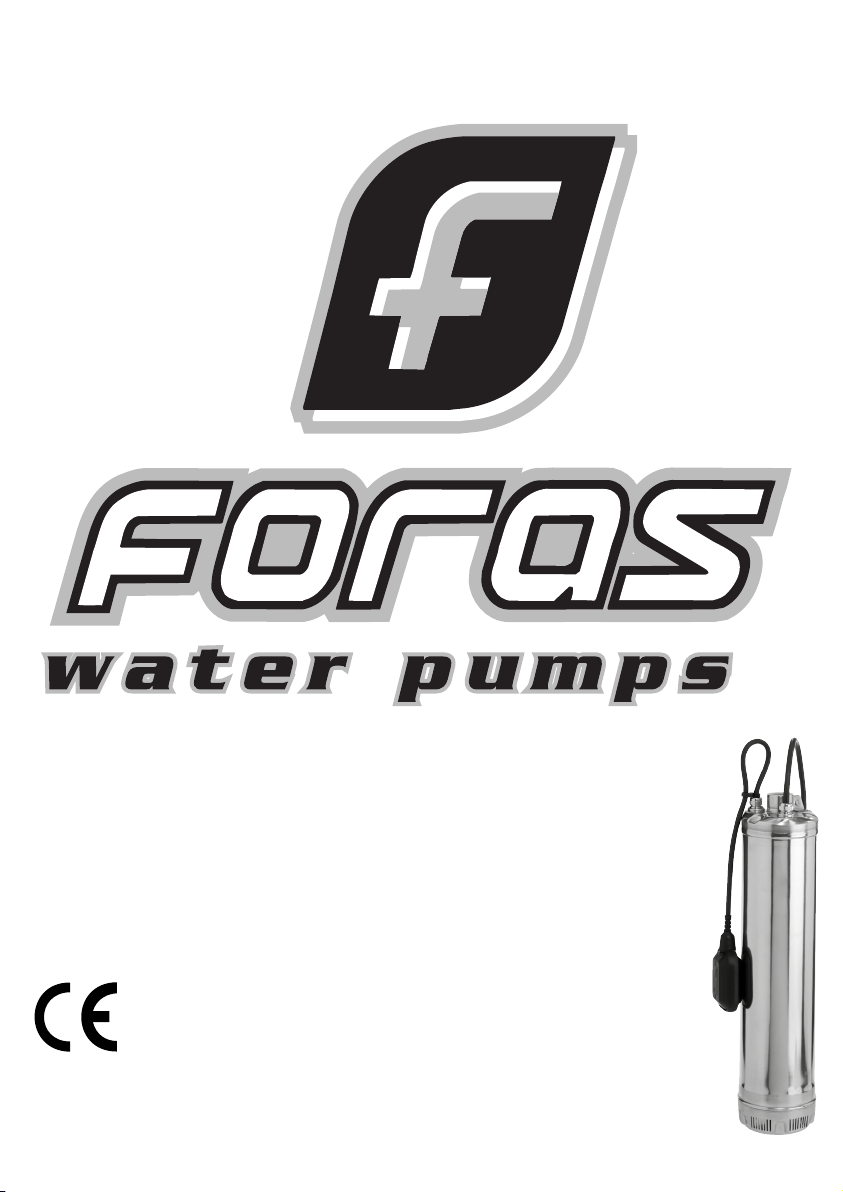

Refer to fig. A1 (submerged installation) and fig. A2 (surface installation) in the

appendix.

5.1 Delivery piping

The pipe diameter determines the flow rate and pressure available at the points

of use. Small diameter pipes reduce performance and increase water hammers

and the risk of cavitation. Adopt flow cross-sections as great as the piping length

(possibly with a larger diameter than that of the port of the electric pump).

It is advisable to install a non-return valve (B in fig. A1 and fig. A2), to avoid

emptying the delivery pipe following the shutdown of the electric pump and to

avoid backflow. Firmly tighten the piping on the port, without damaging it. The

electric pump can be installed both with a metal pipe and one in other material.

If you intend to use the delivery pipe to support the pump (e.g. fig. A1 and fig.

A2, left side), always check that it is suciently strong and rigid to withstand the

combined action of the starting torque, the liquid pressure, the vibrations and the

electric pump weight. Alternatively, in the case of submerged installations, it is

advisable to support the electric pump with a metal cable firmly secured to the

eyelet of the head and constrain the electric pump with respect to rotation. For

surface installations, the electric pump can be supported by securing it directly

with clamps (D in fig. A2, right side).

5.2 Installation in the well

The maximum diameter of the electric pump is 129 mm. Check that the well has

no restrictions or obstacles hindering the descent of the electric pump. The gap

between the electric pump and the walls of the well must be adequate for the

required flow rate. An internal well diameter of at least 140 mm is recommended.

The motor is cooled by the water flow inside the electric pump. Therefore, a

minimum speed value is not required.

Secure the power cable to the delivery pipe using specific clamps (fig. A1).

Do not underestimate the risk of falling and drowning if the installation is to be

carried out in a large well, in a tank or in a reservoir.

Make sure that there is no risk of toxic, suocating fumes or harmful or potentially

explosive gases in the work atmosphere. Use appropriate PPE, if necessary.

It is recommended to check that the well is not obstructed along its entire length.

Lower the electric pump into the well to avoid damaging the electric cable.

Do not use the power cable to lower or support the electric pump in the well.

5.2.1 Minimum and maximum immersion

In order not to draw in air through the filter, the electric pump must be immersed

in the liquid up to at least half its height and in any case, not less than 30 cm from

the bottom (MIN level in fig. A1). Ensure sucient immersion so as to guarantee

this condition when the liquid in the well reaches the minimum level. Dry running

or with air mixed with liquid can cause serious damage to the electric pump and

irregular performance.

The maximum immersion depth (MAX level in fig. A1) is shown on the rating plate.

5.2.2 Models with float

The models fitted with a float start automatically when the float exceeds

approximate angle of 45° with respect to the horizontal line. The motor stops

automatically when the float drops below the horizontal line again. During

installation, it is necessary to verify that:

1) The float is free to move in both directions without getting stuck or caught.

Remove any obstacles. Check all the space around the electric pump, in all

directions allowed.

2) The electric pump only starts when the liquid reaches a level that is at least

equal to the minimum prescribed immersion (see the previous section) and

stops before the liquid drops below this level. Adjust the free length of the float

cable to achieve the desired result.

5.3 Surface installation

Models with in-line ports are designed to be installed between two pipe sections.

Refer to fig. A2 in appendix.

Make sure that the misalignment between the two pipes does not generate an

excessive load on the electric pump connections. It is advisable to install a flexible

section on at least one of the two sides (E in fig. A2). Adequately support the

pipes so as to avoid transmitting excessive force or torque to the ports of the

electric pump.

We recommend installing shut-o valves on the outlet and, if the line is

pressurised, at the pump inlet, so as to perform maintenance without draining

the hydraulic system (C in fig. A2).

If the electric pump sucks from a non-pressurised line (e.g. a well or a tank, at a

higher height than that of the exposed surface) it is necessary to install a foot or

non-return valve along the suction pipe to prime the pump (B in fig. A2).

The pump does not have a filler cap. If the pump is installed with suction life, it is

advisable to install a fitting that allows air to be filled and vented.

5.3.1 Checking the maximum suction pressure and NPSH

It is necessary to check that the sum of the suction pressure (P in) and the

maximum pump pressure increase (H max, in bar) is lower than the maximum

pump pressure (P max, in bar). In any case, the maximum suction pressure must

not exceed the value on the rating plate.]

Also check that the NPSH available at the electric pump inlet is higher than the

value required by the pump and take an adequate safety margin into account

so as to avoid the risk of cavitation. To calculate the available NPSH, use the

following formula:

NPSH = pb x 10.2 - Hv – Hs

pb: Absolute pressure of the liquid being sucked, with a running pump [bar].

Hv: Vapour pressure [m] depending on the liquid temperature [m]

Hs: Safety margin [m] (minimum 0.5)

The required NPSH values are specified in the characteristic curves shown in the

appendix (fig. A3). Look for the frequency (columns) and family (rows) reference

charts.

If the required NPSH value (fig. A3) exceeds the available NPSH value calculated

with the above formula, the pump with negative suction head must be installed

at a depth, in metres, equal to the dierence between the two values. In closed

circuits, install the water pump unit/expansion vessel at the pump inlet and

pressurise the circuit.

6 MECHANICAL INSTALLATION

6.1 Machine handling

To lift the machine, use only suitable, properly marked devices (e.g. CE marking)

in good working condition. Do not exceed the load capacity of the least resistant

device among all those used (lifting lug, shackle, hook, carabiner, chain, rope,

hoist or other). Only use hooks with safety triggers. Use adjustable lifting lugs or

check their maximum load capacity for non-axial loads.

Pay attention to suspended loads. Do not stand under them. Pay attention

to people, animals and objects in the work area. Use appropriate work

area marking tools and delimiters, where necessary. Do not operate the

pump or let it pass over people.

The appliance can be moved manually.

Check the mass indicated on the rating plate and/or on the packaging.

6.2 Fastening

Secure the unit so that it remains stable and cannot move during operation, using

the delivery pipe or by securing the pump body directly.

Models equipped with brackets must be fixed using these methods.

7 START-UP AND PROLONGED STOP

Before starting the electric pump, it is necessary to fill it and the suction pipe with

water (the whole circuit, if the plant is closed). If an electric pump with positive

suction head is installed, perform the following operations manually.

Otherwise, if a negative suction head system is installed or the suction line is

pressurised, it is sucient to open the valves, vent the air and wait for filling. In

closed circuits, load the system from the highest point and vent air at the same

time. During the first few seconds of operation, the pump will expel further air. If

the circuit is closed, vent it with appropriate valves.

Pay attention to leaks. Use appropriate PPE to protect against mechanical

and chemical risks.

Slowly open the valves during venting, avoiding sudden manoeuvres; do

not direct the jet towards people, animals or electrical appliances.

After prolonged downtime, check the pump for proper priming before starting it,

and vent the pipes, if necessary.

If a long period of inactivity is foreseen and/or the machine needs to be emptied

of liquid, disconnect it from the pipes and tilt it to let the liquid out.

Use and installation instruction manual ENGLISH

8 MAINTENANCE AND SUPPORT

The electric pump does not require special maintenance.

Havetheelectricpumprepairedonlybypersonnelauthorisedbythe manufacturer

so as to keep your warranty valid and not to impair the safety of the appliance.

Use only original spare parts or parts approved by the manufacturer.

Always use the required PPE (refer to the relevant section).

Before starting any work on the electric pump, make sure it has been

disconnected from the power supply and cannot be accidentally

reconnected.

Caution! In the event of an overload shutdown, appliances equipped with

automatic reset circuit breaker switches will automatically restart when

the temperature drops below the danger level.

It is advisable to check the condition of cables (especially at the cable glands)

every month and clean the filters and/or suction grille.

If the power cable is damaged, it must be replaced by the Manufacturer,

their service centre or qualified personnel.

8.1 Spare parts

Use original spare parts or parts approved by the manufacturer, in order to avoid

any risks to the service personnel’s and users’ health. Contact the supplier and/or

check the spare parts tables (see technical catalogue) for information.

9 EMERGENCY MANAGEMENT

9.1 Fire

• The only machine part exposed to a fire hazard is the motor and does not

involve any of its external parts.

• In the event of a fire, use extinguishers approved for electrical devices

9.2 Liquid spills

• The pumped liquid may escape from the machine as a result of installation,

start-up, maintenance or disposal, unforeseen breakages or excessive wear of

sealing devices.

• If spills can be dangerous or harmful to human, animal or environmental

health, install a waterproof collecting basin around the machine.

9.3. Oil spills

• In case of breakage, the electric pump can release up to 50 cl of oil (non-toxic).

Occasional ingestion of oil is not dangerous for human health. The risk of an oil

leak should be limited as much as possible.

10 TROUBLESHOOTING

For the solution of problems related to the electric pump operation, follow the

instructions in the table below. If you do not have the necessary knowledge and

skills, contact qualified personnel. Always use PPE (see relevant section) and

appropriate tools. If the problem cannot be solved by following the instructions in

the table, contact a professional, authorised service centre.

11 DISPOSAL

The devices marked with this symbol may not be disposed

of in domestic waste but disposed of in appropriate local

collection centres for Waste Electrical and Electronic

Equipment (WEEE), or delivered to the distributor who is

required to collect them.

Domestic WEEE (single-phase electric pumps with <3 kW

power) must be handed in to private or local collection

centres, retailers or repairers, at no cost.

Industrial WEEE (all products not classified as domestic)

must be delivered to specific collection centres or retailers

or repairers.

The product is not potentially dangerous for human health and the environment

as it does not contain any harmful substances pursuant to Directive 2011/65/

EU (RoHS), but if released into the environment it will adversely impact the

ecosystem.

The illegal or improper disposal of the product involves severe criminal and/or

administrative penalties.

11 TROUBLESHOOTING

FAULT/MALFUNCTION SOLUTION

1) The electric pump does not get started

or stops unexpectedly

• For single-phase models with a control panel: check that the switch is set on “I”. If the manual reset thermal

magnetic switch is present, press the reset button. Check that the capacitor is intact.

• For single-phase models without a control panel: check that the installed capacitor is correct, connected correctly

and undamaged.

• For models with a float, check the travel of the float and lift it manually to check that it works.

• Check whether the circuit breakers and residual current devices have been enabled; check that fuses (if any) are

intact.

• Check the electrical connection to the mains.

• Make sure the mains supply voltage is on.

• FOR PROFESSIONAL MAINTENANCE TECHNICIANS ONLY: make sure the pump can rotate freely and power

consumption does not exceed the value on the rating plate.

2) The electric pump gets started but

does not deliver any flow, dispenses

irregularly, or the flow rate is much

lower than values specified on the

rating plate

• For submerged units: check that the filter is not clogged and that the pump is submerged at least to the specified

minimum limit

• For surface units: check that the pump is primed and does not cavitate

• Make sure there is no air in the hydraulic conduit; vent pipes

• For three-phase models: check the rotation direction

APPENDICE / APPENDIX / APPENDICE / ANHANG / APÉNDICE / / BIJLAGE / LISA / PRIEDAS / PIELIKUMS

/ ZAŁĄCZNIK / ПРИЛОЖЕНИЕ / BILAGA / EK / LIITE

APPENDIX

Fig. A1 Fig. A2

MIN

MAX

A

B

00130212OPM 03/2019

A

D

D

A

C

C

A

A

EE

E

B

00130213OPM 03/2019

Table of contents

Popular Water Pump manuals by other brands

Crane

Crane Barnes UltraSTEP installation manual

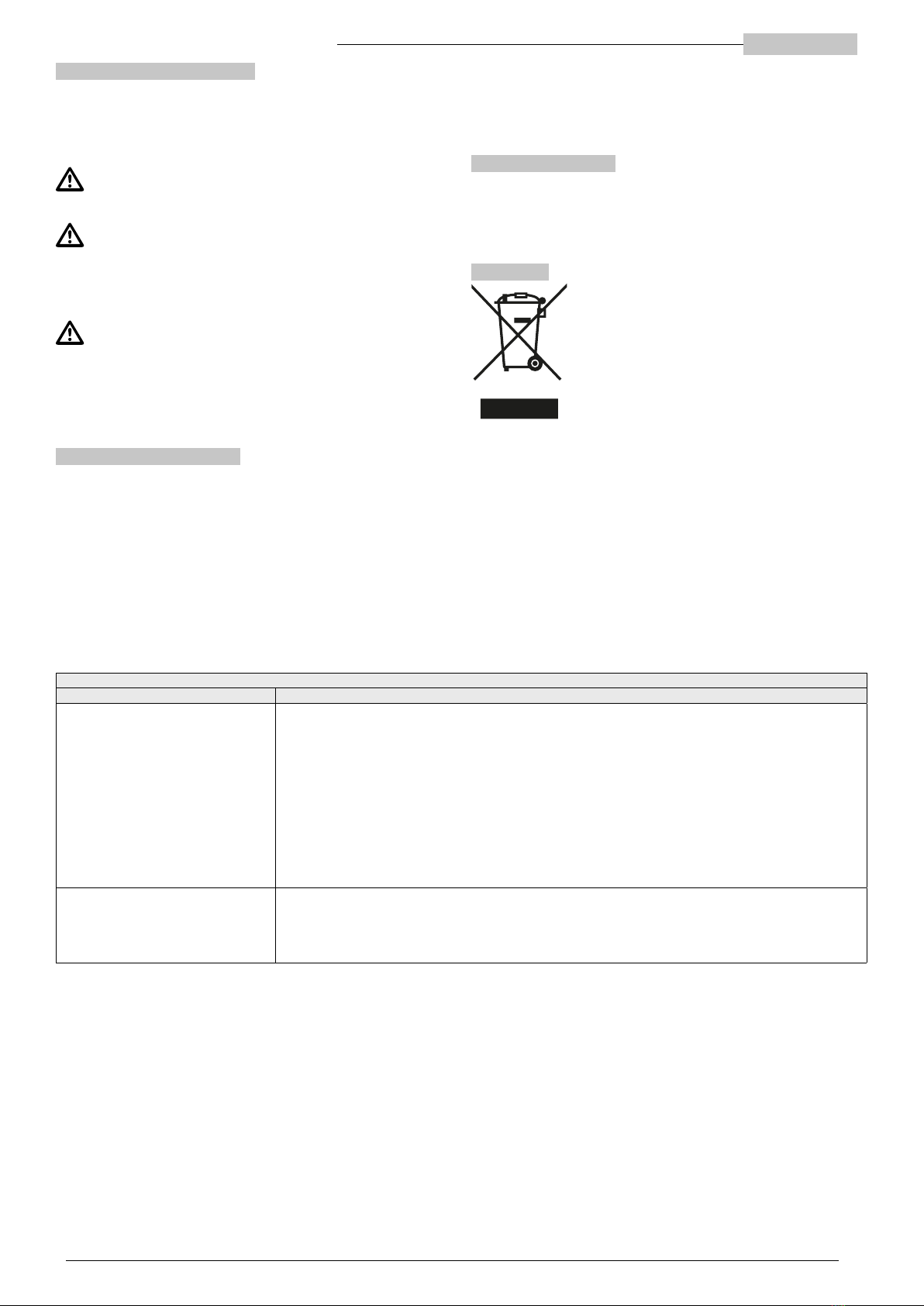

MDM

MDM ValuFlo 750 Installation and service manual

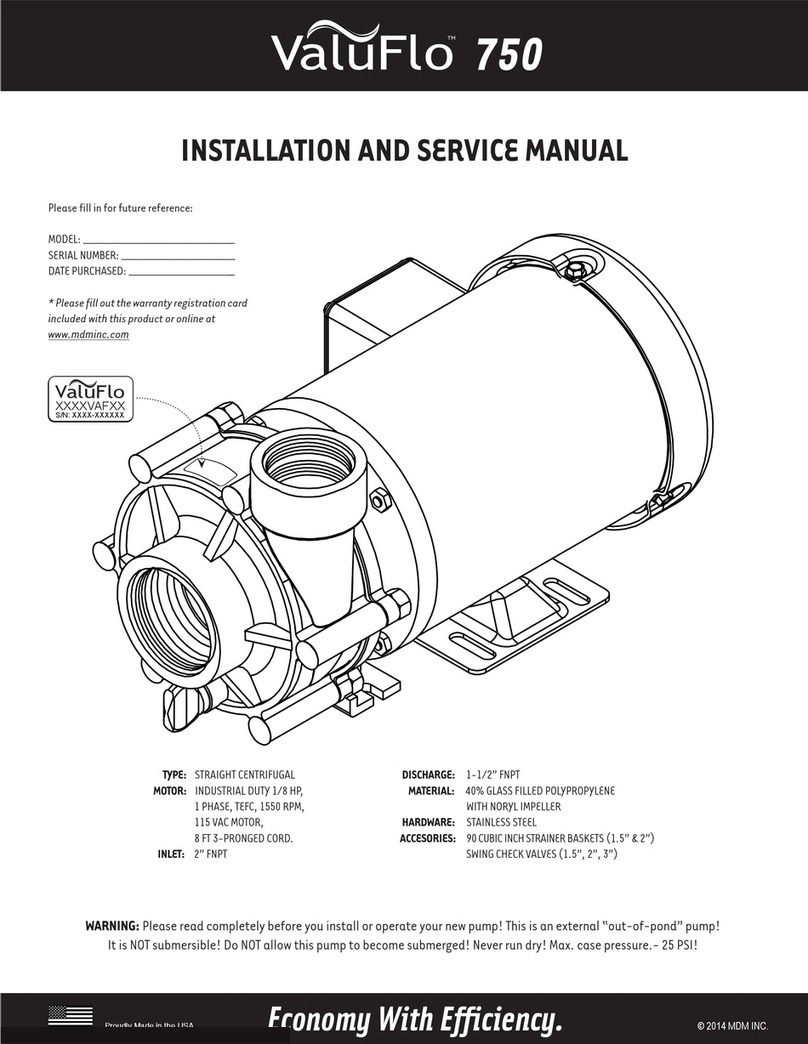

Sotera

Sotera FILL-RITE SV Series Owners installation, operation, and safety manual

Kremlin-Rexson

Kremlin-Rexson EOS 60-C980-HD manual

TE Connectivity

TE Connectivity 314979-1 Customer's manual

ubbink

ubbink Cascademax Series manual

Xylem

Xylem GEMK Installation, operation and maintenance instructions

Kremlin-Rexson

Kremlin-Rexson AIRMIX 08-120 Disassembly/Reassembly

Grundfos

Grundfos SR Installation and operating instructions

Grundfos

Grundfos DB instructions

Everbilt

Everbilt UT03301 Use and care guide

dosatron

dosatron D9 Green Line owner's manual