Forbo siegling blizzard HP 160/400 AIR User manual

Siegling – total belting solutions

OPERATING MANUAL

BLIZZARD HEATING PRESS

Contents

3 English manual

27 German manual

siegling blizzard

splicing equipment

TM

2

Dieses Gerät darf nur von Personen

in Betrieb genommen werden, die

die nachfolgende deutsche oder englische

Betriebsanleitung gelesen und verstanden haben.

Този уред се допуска да се въвежда в

експлоатация само от лица, които са

прочели и разбрали следващото немско или

английско ръководство за експлоатация.

本设备只能由已阅读并了解以下英文、

中文或日文用户手册的人员使用。

Dette apparat må kun sættes i drift af

personer, som har læst og forstået den

følgende tyske eller engelske driftsvejledning.

This device should only be used by those

personnel who have read and understood

the following German or English user manual.

Seda seadet tohivad kasutusse võtta vaid

inimesed, kes on lugenud allpool esitatud

saksa- või eestikeelseid kasutujuhiseid ning neist

aru saanud.

Tämän laitteen saavat ottaa käyttöön vain

sellaiset henkilöt, jotka ovat lukeneet ja

ymmärtäneet seuraavan saksan- tai englanninkieli-

sen käyttöohjeen.

Cet appareil ne doit être mis en service

que par des personnes ayant lu et compris

les instructions de service ci-après en allemand ou

en anglais.

Αυτή η συσκευή επιτρέπεται να τεθεί

σε λειτουργία όνο από άτοα που έχουν

διαβάσει και κατανοήσει τι οδηγίε χρήση που

ακολουθούν στα Γερανικά ή στα Αγγλικά.

Questo dispositivo può essere utilizzato

solo da persone che hanno letto e com-

preso il seguente manuale in tedesco o inglese.

この装置は、次の英語、中国語または日本

語の取扱説明書をよく読んで理解した作

業員のみが使用するようにしてください。

Ovaj uređaj smiju puštati u rad samo

osobe koje su pročitale i razumjele upute

za uporabu u nastavku koje su napisane na

njemačkom ili engleskom jeziku.

Šo ierīci drīkst lietot tikai personas, kuras

ir izlasījušas un iepazinušās ar turpmāk

redzamo lietošanas instrukciju vācu vai angļu

valodā.

Šį prietaisą leidžiama pradėti eksploatuoti

tik asmenims, perskaičiusiems ir supra-

tusiems toliau pateiktą vokišką arba anglišką

instrukcijų žinyną.

Dit apparaat mag alleen door personen

in gebruik worden genomen die de

volgende Duitse of Engelse gebruiksaanwijzing

hebben gelezen en begrepen.

To urządzenie może być użytkowane

tylko przez osoby, które przeczytały i

zrozumiały następującą niemiecką lub angielską

instrukcję obsługi.

Este aparelho só pode utilizado por

pessoas, que tenham lido e compreendi-

do o Manual de instruções em alemão ou inglês

que se segue.

Acest aparat poate fi pus în funcţiune

doar de către persoanele care au citit și

au înţeles instrucţiunile de utilizare de mai jos în

limba germană sau engleză.

Bara personer som har läst och förstått

den här bruksanvisningen på tyska eller

engelska får ta den här apparaten i drift.

Toto zariadenie môžu uviesť do pre-

vádzky len osoby, ktoré si prečítali nas-

ledujúci návod na použitie v nemeckom alebo

anglickom jazyku a porozumeli jeho obsahu.

To napravo smejo zagnati samo osebe,

ki so prebrale in razumele naslednja

nemška ali angleška navodila za uporabo.

Este aparato solo deben emplearlo las

personas que hayan leído y comprendido

las siguientes instrucciones de uso (en alemán o

inglés).

Tento přístroj smějí uvádět do provozu

pouze osoby, které si přečetly následující

návod k obsluze v německém nebo anglickém

jazyce a rozumějí mu.

A készülék üzembe helyezését csak olyan

személyek végezhetik, akik elolvasták

az alábbi német vagy angol nyelvű használati

utasítást és megértették annak tartalmát.

3

WRONG or IMPROPER use of this splice press can result in damage to the press

and/or physical harm. This manual contains important information about product

function and safety. Please read and understand this manual BEFORE operating

the press. Please keep this manual available for other users and owners before

they use the heating press.

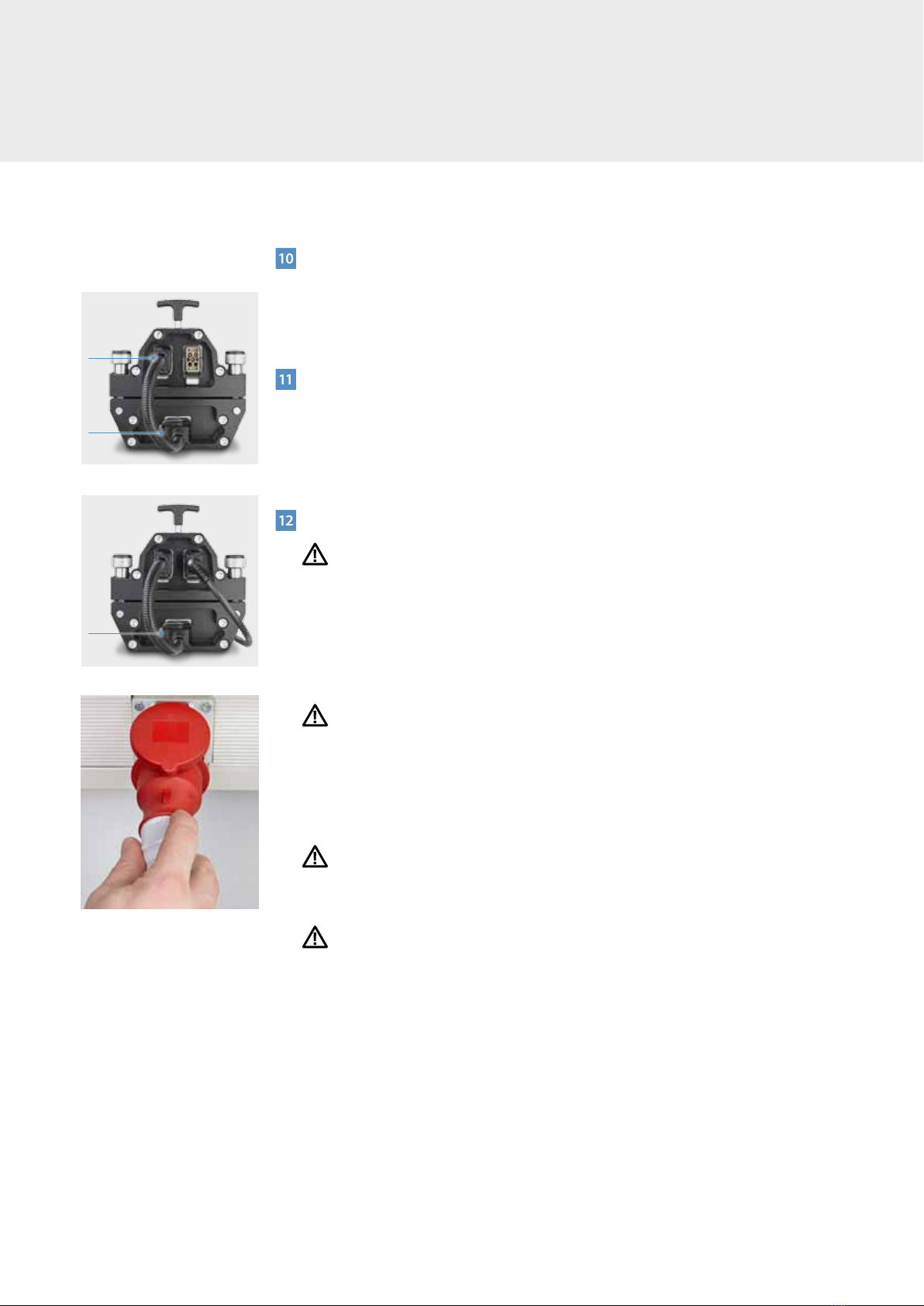

4 Main components

5 Technical data

6 Introduction

7 General safety rules

8 Safe operation

16 Plans and schemes

20 Wiring diagram of the

power supply cables

22 Wiring diagram

26 Technical assistance/

Manufacturer‘s notification

EC Declaration of conformity

OPERATING MANUAL

BLIZZARD HEATING PRESS

4

Top frame

Press connector bolts (4x)

Belt clamps nut (4x)

Belt clamps (2x)

MAIN COMPONENTS

Front connections

Front

controls

Handle

Front connections

Start button

Front controls

Timer

Top frame controller

Bottom frame controller

Air bleeder button

Pressure switch

Top jumper connection

Connection to the mains (inlet)

Bottom jumper connection

Bottom frame

5

230 (9.1)

84 (3.3) 84 (4.6)

Key dimensions

Key dimensions in mm and inches (in)

All imperial measurements have been rounded up.

TECHNICAL DATA

Delivery scope and accessories

The press will be delivered incl. cables transport

box as well an one set of silicone mats.

As accessories variant types of embossing mats,

glossy seperating paper an matt seperating

paper (VEZ) are available on request.

Blizzard

HP 160/400 AIR

Blizzard

HP 160/600 AIR

Blizzard

HP 160/800 AIR

Blizzard

HP 160/1000 AIR

Blizzard

HP 160/1200 AIR

Blizzard

HP 160/1500 AIR

Effective belt width [mm (in)] 400 (15.7) 600 (23.6) 800 (31.5) 1000 (39.4) 120 0 (47.2) 1500 (59)

Max. effective splice length

[mm (in)] 160 (6.3) 160 (6.3) 160 (6.3) 160 (6.3) 160 (6.3) 160 (6.3)

Weight Top part [kg (lb)] 12 (26.5) 15.8 (34.8) 19.1 (42.1) 22.5 (49.6) 26.2 (57.8) 31 (68.3)

Weight Bottom part [kg (lb)] 14.6 (32.2) 18.6 (41) 22.7 (50) 26.9 (59.3) 30.9 (68.1) 36.8 (81.1)

Total Weight [kg (lb)] 26.6 (58.6) 34.4 (75.8) 41.8 (92.1) 49.4 (108.9) 57.1 (125.9) 67.8 (149.5)

Length [mm (in)] 590 (23.2) 790 (31.1) 990 (39) 119 0 (4 6.8) 1390 (54.7) 1690 (66.5)

Width [mm (in)] 230 (9.1) 230 (9.1) 230 (9.1) 230 (9.1) 230 (9.1) 230 (9.1)

Height Top part [mm (in)] 118 (4.6) 118 (4.6) 118 (4. 6) 118 (4.6) 118 (4.6) 118 (4. 6)

Height Bottom part [mm (in)] 84 (3.3) 84 (3.3) 84 (3.3) 84 (3.3) 84 (3.3) 84 (3.3)

Max. pressure [bar (psi)] 2.5 (36.3) 2.5 (36.3) 2.5 (36.3) 2.5 (36.3) 2.5 (36.3) 2 (29)

Max. temperature [°C (°F)] 200 (392) 200 (392) 200 (392) 200 (392) 200 (392) 200 (392)

Transport dimensions (LxWxH) [mm] 875 x 370 x 350 875 x 370 x 350 1275 x 370 x 350 1275 x 370 x 350 1775 x 370 x 350 1775 x 370 x 350

Transport dimensions (LxWxH) [in] 34.5 x 14.6 x 13.8 34.5 x 14.6 x 13.8 50.2 x 14.6 x 13.8 50.2 x 14.6 x 13.8 69.9 x 14.6 x 13.8 69.9 x 14.6 x 13.8

Transport weight [kg (lb)] 42.1 (92.8) 49.9 (110) 61.9 (136.5) 69.5 (153.2) 83.8 (184.8) 94.5 (208.3)

Power requirements

1 phase [Volt / Amp/ Watt]

Art. No.

230 V/9 A / 2200 W

Art. No. 873399

110 V/14A / 1520W

Art. No. 873400

230 V/14A / 3200W

Art. No. 873401

110 V/14A / 1520W

Art. No. 873402

230 V/16A / 3680W

Art. No. 873403

110 V/14.5A/ 1600 W

Art. No. 873404

230 V/16A / 3680W

Art. No. 873405

110 V/14A / 1484 W

Art. No. 873406

230 V/16A / 3680W

Art. No. 873409

230 V/19.5 A /4500W

Art. No. 873412

230 V/16.0 A /3680 W

Art. No. 873413

230 V/13.0A / 3000 W

Art. No. 873414

3 phase [Volt / Amp / Watt]

Art. No.

400 V/11 A-5.5A-5.5 A/

7600 W

Art. No. 873407

400 V/12A-6.0 A-6.0A /

8990W

Art. No. 873408

480V/ 11 A-5.5 A-5.5 A /

8900 W

Art. No. 873410

400 V/16A-8.0 A-8.0 A /

11072W

Art. No. 873411

480V/ 13 A-6.5 A-6.5A/

10700 W

Art. No. 873415

6

INTRODUCTION

The Blizzard heating press is an all-in-one solution for splicing thermoplastic conveyor belts (e.g. PVC, polyurethane).

No external control box, air pump, or water cooling tank are required.

The heating presses are provided with electric heating and built in air cooling. The splice process runs fully automated.

If the belt is relatively thick a problem might occur where the outside of the belt is at the splicing temperature too long,

waiting for the inside to reach the required temperature. Melted material might flow away or discolor and fabrics might

shrink. To avoid this problem, the preheat option can be used. This option heats the belt up (outside and inside) to a tem-

perature just below the melting temperature. After the preheat stage, the inside splice temperature can be reached much

quicker, minimizing the risk for unwanted flow of material, discoloring or fabric shrinkage.

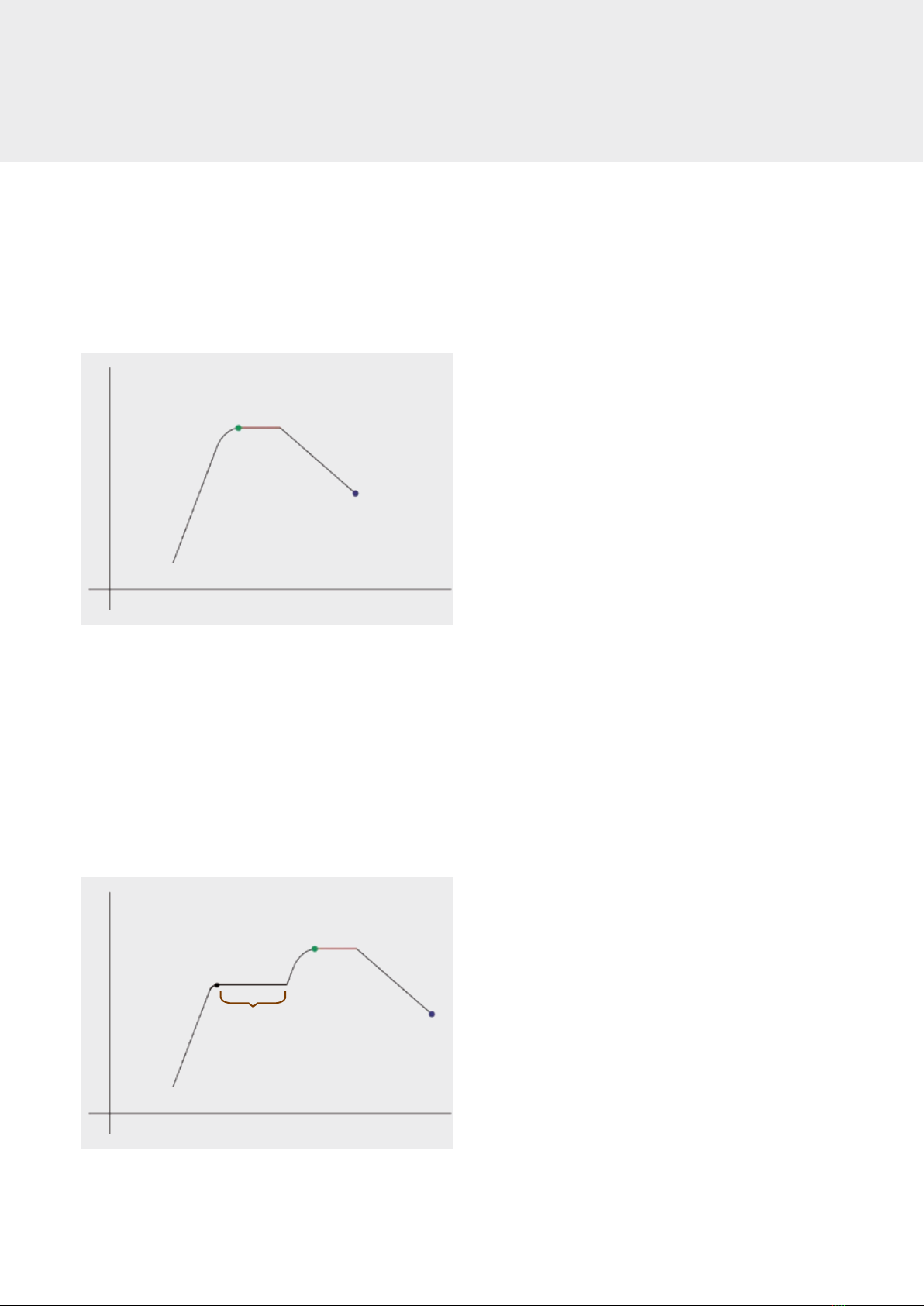

Basic process

• Splicepressureisappliedbyaninternalcompressor,

max. 2.5 bar (36.3 psi). Siegling Blizzard HP 160/1500 AIR:

max 2.0 bar (29 psi).

• Heatsuptoasplicetemperatureofmax.200°C(392°F)

• Keepsitatthesplicetemperature(adjustabledwelltime)

• Coolsdowntothecoolingtemperature

(safe temperature to take the belt out)

• Forthickerbeltsapreheattemperatureandpreheat

dwell time can be applied

• Thebottomheatingcanbesetlowerorhigherthan

the top heating

Graph of the basic process, program level 1

Settings:

Temperature

Time

Splicing

temperature

Dwell time

Cool down

temperature

(fans turn off))

Graph of a procss with prehating, program level 2

Settings:

Temperature

Time

Splicing

temperature Dwell time

Pre-heat

dwell time Cool down

temperature

(fans turn off)

Pre-heat

temperature

7

GENERAL SAFETY RULES

Signal words

“Danger” indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

The signal word is limited to the most extreme situations.

“Warning” indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

“Caution” indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe practices.

Safety symbol

This international safety symbol is used to identify

and call attention to specific safety matters.

Overall safety rules

Danger

To avoid severe personal injury or property damage, read

carefully and understand the following safety precautions.

Danger

Terminate electrical hazards by removing power cord

from wall receptacle or machine base inlet.

Warning

Terminate pressure related hazards by pressing

the red pressure relief button.

Caution

Press platens develop over 5 tons of clamping force.

When operating the press keep the four press connector

bolts in place by hand tightening.

Caution

Avoid temperature related hazards by handling press

components and belt once safely cooled.

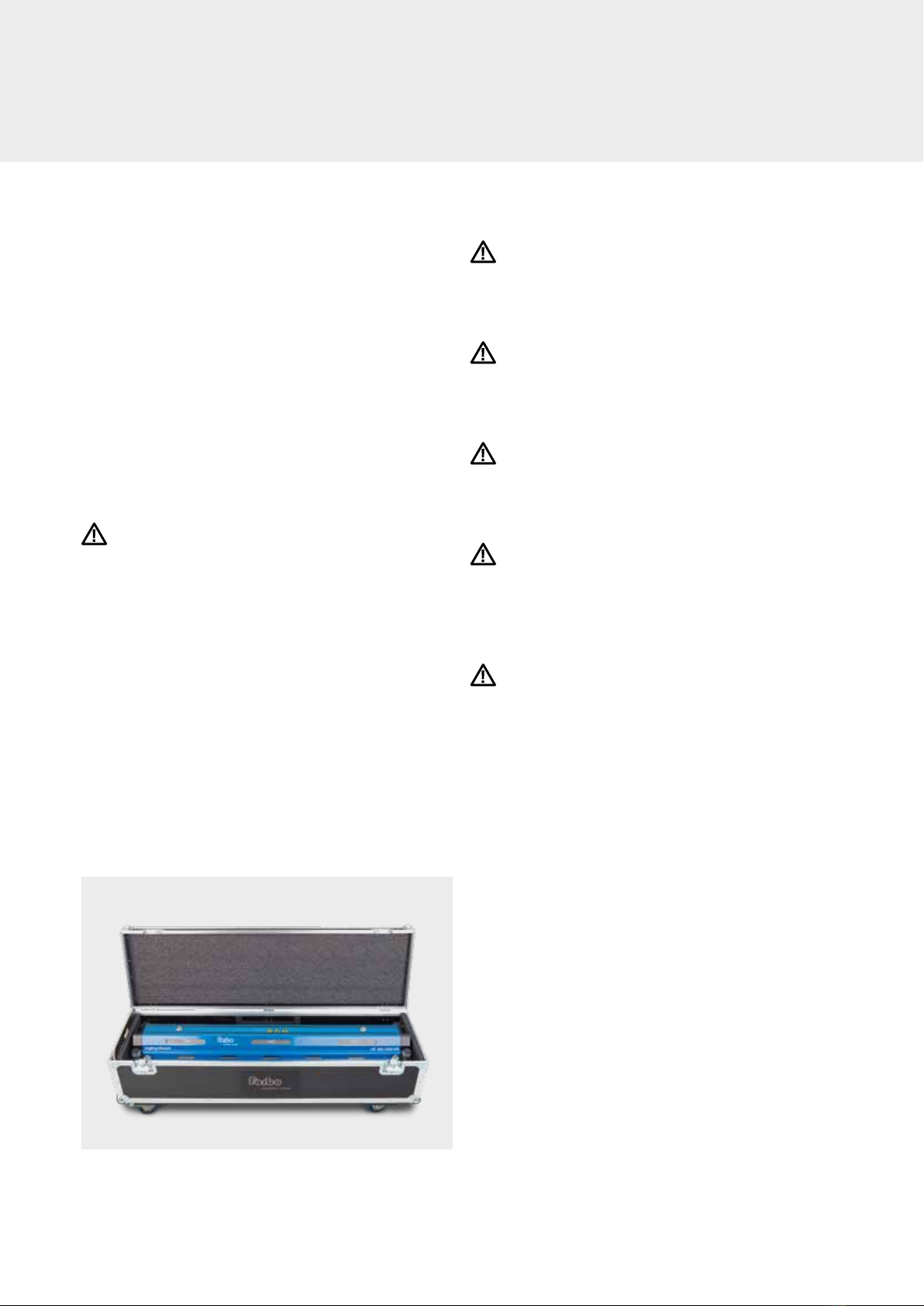

Flight case

• Blizzardheatingpressesaresuppliedwithaflightcasefor

both storage purposes and also for easy transport to

on-site jobs.

• SieglingBlizzard400–1500arepackagedinflightcases

with four wheels and an extension handle.

• Flightcasescanbestackedontopofeachother,butneed

to be secured during transportation.

• Allflightcasesfeatureanextendedhandleforeaseand

convenience in transport. Click in the grip of the flight case

to release the handle.

8

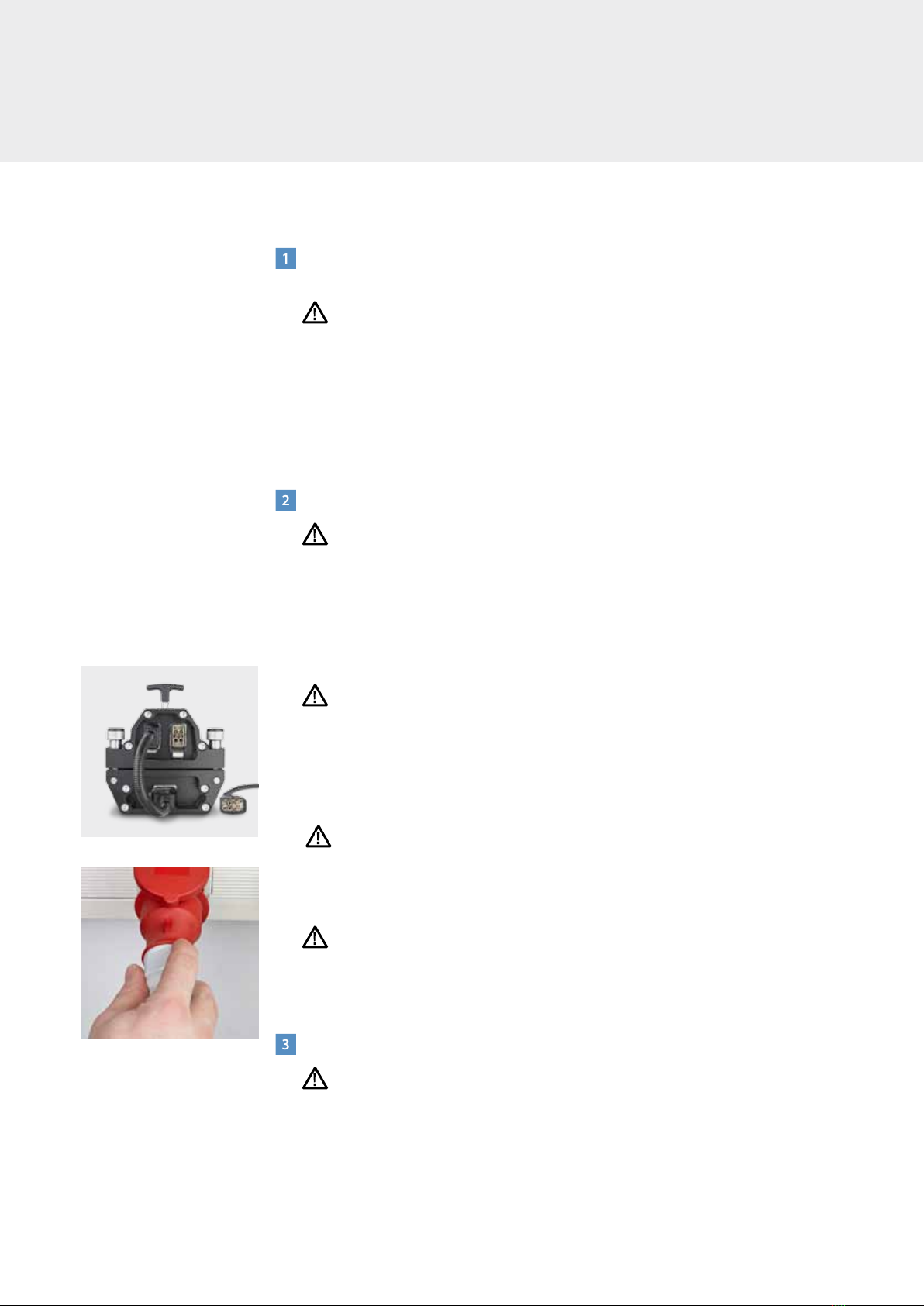

1

Locate a position in facility where appropriate voltage and power receptacles

are available to operate the heating press

Warning

Operating the press on incorrect voltage can cause serious damage and potential

hazards.

Before starting, ensure that you have enough belt material to cover the edges of the

press. The belt material for the edges must be the same type and have the same thick-

ness as the rest of the material.

2

Visually inspect power cord

Danger

a. Inspect cord for damage. Do not use power cord in a damaged state. Either replace

cord or have an electrician remove damaged section and reattach plug.

Electrician must refer to wiring diagram on page 22 for proper attachment.

b. Confirm compatibility between plug end and power receptacle. If incorrect,

find alternate power source or have electrician apply correct plug,

referring to wiring diagram on page 22.

Danger

c. Do not plug power cord into wall receptacle at this time. Later in the operation,

when ready to connect power follow these safe and proper operating procedures:

– First,connecttopandbottompresspartsbymeansofconnectioncable.(Fig.1)

– Second,plugpowercordintomachinebasepowerinlet.

– Third,insertplugendintowallreceptacle.(Fig.2)

Danger

– Neverleavepowercordpluggedintowallwhiledetachedfromunitasthiscould

lead to a serious electrical danger if it comes in contact with fluids, such as water.

Danger

d. All press power inlets and cable connectors have been supplied with keyed

(patterned) guide pins and bushings. This keying will prevent incorrect connection.

3

Remove press from flight case

Heavy object

Note: Use proper lifting techniques to avoid personal injury; ask for assistance for

removal from flight case if press is heavier than you are comfortable handling by

yourself.

Fig. 1

Fig. 2

SAFE OPERATION

9

4

Visually inspect press for damage

Warning

Broken or missing components can cause an unsafe working environment and

will likely cause additional damage to press and possible bodily injury.

Danger

a. Ensure all four press connector bolts are in good condition. Do not attempt to

operate the press if a bolt is broken or missing.

b. Inspect platens for potential damage.

c. Ensure platens are free of dirt/debris. If dirty, follow these cleaning instructions:

–Useammoniabasedcleanerswithcleantoweltogentlyremovedirt/debris.

Warning

– Donotcleanplatenswithaflammablesolution.

Caution

– Donotusewatertohosedowntheheatingpress.Ifpressneedstobecleaned,

use ammonia based solvent applied to a cloth and wipe down press. Dry press

with clean dry cloth.

d. Inspect all cables to ensure they are in good condition. If they are damaged,

do not use press until they are replaced.

5

Checking the heating press works

Forbo Siegling recommends inspecting the heating press twice a year.

Tools required

– Temperaturemeasurementdevice(accuracy±1°C)includingatemperaturesensor

– Pressuremeasurementdeviceincludingpressuresensor

– Straightedge

Use the tools listed to check the temperature, pressure and flatness of your Siegling

Blizzard heating press’s heating platens. If the heating press doesn’t comply with the

set parameters, we recommend sending in the heating press for calibration or repair.

Please get in touch with your Forbo Siegling contact for more details.

Warning

– Beforeapplyingthesensors,unplugtheheatingpressfromthepowersupply.

– Platensurfacesmaybehot.

6

Visually inspect silicone pads

Visually inspect silicone pads. Pads should be free of dirt/debris in order to obtain

a quality finished splice. Pads can also be cleaned using ammonia based cleaning

solution that is non-flammable and will not cause an adverse reaction with the splice.

10

SAFE OPERATION

7

Remove top beam (Fig. 3)

a. Loosen all four press connector bolts.

b. Using top beam handles located on end caps, remove top beam from press.

Heavy object

Depending upon width and weight of the press you have, you may require assistance

from another person.

c. Place beam on side, do not place the beam with the platen facing down. It is impor-

tant to keep platens in good working condition. Resting the beam on the side will

protect the platens from scratching or from getting dirty. Beams have rubber strip-

ping along the length of the press to protect from scratching (see photo).

8

Insert the prepared ends of the belt into the heating press

a. Place a clean silicone pad onto the clean bottom heating platen. Ensure the silicone

pad lies flat because any creases will impact the appearance of the finished splice.

The purpose of the silicone pads is to prevent the belt material from sticking to the

press’s heating platens.

b. Place the prepared ends of the belt onto the bottom heating platen. Please note:

the area heated is 160 mm wide and situated in the middle of the heating platen.

Please ensure that the areas to be heated are centered correctly. Depending on the

belt type, slight heat loss can occur in the outer areas of the heating zone. A prepared

finger splice or layer separation must be within the heating zone because any

material outside it won’t melt. (Fig. 4)

c. Please follow this procedure if you want to make a finger splice:

– Forspliceswithoutanyadditionalmaterials:Thefingersmustinterlockcompletely

and there must be no gaps between the fingertips.

Distance between the fingers = 0 mm

– Forspliceswithfilmonthetopface:Pushthefingersintooneanothercompletely

and draw a marking line (Fig. 5). Then pull the ends of the belt apart again until

there is a 6 mm distance between the lines. The distance between the figures is

2 mm. (Fig. 6)

d. Apply extra belt material to the edges of the belt to be spliced until all of the heating

press is covered over the entire area to be pressed. This prevents melted material

from being pressed out.

Caution

Ensure the belt material covers the entire width of the heating press so that even

pressure is applied and damage to the press prevented.

Fig. 5

Fig. 6

Fig. 4

Nominal width + 100 mm

Nominal width 400 – 1500 mm

160 mm

Area to be heated

Protective

rubber stripping

Handle

Handle

Press connector bolts (4 x)

Fig. 3

11

9

Install top beam

a. Carefully position top beam onto prepared belt ends; avoid disrupting prepared

belt ends and possibly separating the fingers.

Heavy object

If weight and length of top beam is difficult to handle by yourself, enlist assistance

of another person.

Danger

b. Center top beam so that all four connector bolts are free to fully rotate upwards.

This is necessary for proper press alignment. Hand tighten the bolts, ensuring they

are seated properly in spherical recess on top beam. (Fig. 9)

Caution

Do not allow users to get fingers caught in potential pinch points.

Danger

Press is capable of producing a pressure up to 2.5 bars (36.3 psi). Do not operate the

press with a missing or broken bolt as this can cause serious physical harm and/or dam-

age to press. If a bolt is missing or broken, replace with authorized factory parts only.

Warning

To ensure proper thread engagement, the prepared belt ends (including various pads)

cannot exceed 15 mm (0.59 in). This does not necessarily relate to the press’ heating

capability. Exceeding this thickness will not allow sufficient thread engagement of the

Connecting bolts to ensure safe clamping of the press, and can result in damage to the

press and personal danger.

Press connector bolts (4 x)

Fig. 9

Fig. 7

Fig. 8

e. Apply the clamping bars so that the fingers are secured firmly onto the bottom

of the press.

f. Depending on the splicing instructions for the material to be prepared, place film/

release paper/silicone pad onto the prepared heating zone. Ensure no creases form.

Incorrect: Area at the edge not covered (Fig. 7)

Correct: Area at the edge covered with extra belt material (Fig. 8)

Caution

Do not use any metal shim bars due to the risk of thermal bridges forming between the

top and bottom heating platen.

12

10

Remove clamp bars after top beam is secured

Failure to remove clamp bars may result in incomplete melt zone at ends of splices

that are full press width.

11

Connect umbilical power cable from top beam to bottom beam (Fig. 10)

a. Insert umbilical power cable connector into machine base umbilical cable connector.

b. Engage latch to lock plug in place. Forgetting to latch plug can result in intermittent

power supply to press base controls.

12

Connect power cord to press (Fig . 11)

Warning

It is extremely important that the power cord is attached to the press first and then to

the wall receptacle. Reversing these procedures can put personnel at risk of electrocu-

tion and may cause a damaging electrical arc.

a. Insert power cable connector to the machine base power outlet.

b. Engage latch to lock plug in place. Forgetting to lock plug can result in intermittent

power supply to the press.

Danger

c. Double check to ensure the voltage and receptacle is appropriate for the power

cable you are using. Incorrect, excessive power voltage can cause serious damage to

press and also present physical danger (i.e. 460 volt outlet feeding into a 230 volt

cable could cause a short circuit and/or fire).

d. Next, insert power cable plug into the appropriate wall receptacle. (Fig. 12)

Important

Only plug power cord into wall receptacle after power cord has been attached to the

tool.

Danger

e. User wiring of electrical plug to bare power cable end or hard wiring cable to junc-

tion box must be in accordance with the ‘Wiring diagram of power supply cable’

on page 20. Ensure proper cable diagram is used for cable being wired. Ensure the

correct plug is used. Only qualified personnel should perform this activity.

The heating press has 3 controllers:

1. The temperature controllers are located on the top beam.

a. Programming:

Splice temperature (max 200 °C/392°F), splice dwell time, cool down temperature.

2. The pressure controller is located on the bottom beam and controls the pressure up

to 2.5 bars/36.3 psi.

Fig. 10

Fig. 11

Fig. 12

SAFE OPERATION

Latch

Latch

Latch

13

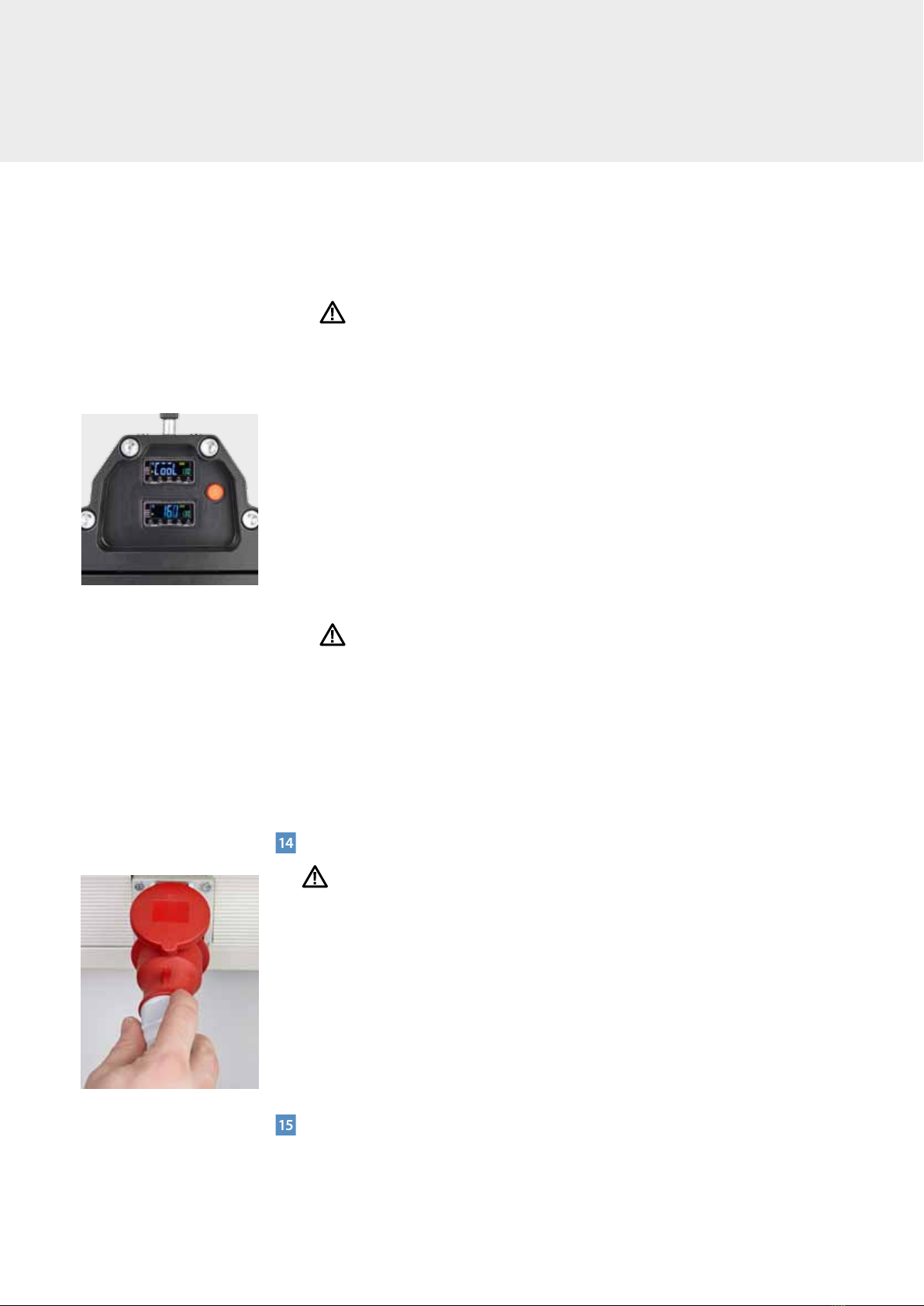

13

Configuration of the parameters

The Blizzard press has 2 digital controls, a pressure switch and an air bleeder. With all

these elements all the parameters of the process may be set. (Fig. 13)

a. Bottom digital controller

Controls: –Jointtemperatureandthecorrespondingdwelltime.

–Steppedtemperatureandthecorrespondingdwelltime.

–Coolingtemperature.

– Onthemainscreen(Fig.14),displaynº1showstheroomtemperature.Display

nº2showsthejointtemperature(preset173°C)Tochangethetemperaturepush

to increase the temperature, to lower it, and to modify the digit.

– Pushing weenterto“LAdJ”screen.If ispushed,“SP-0”willshowup.This

parameter shows the stepped temperature.

– Pushingagain “SoAK”showsup.Thisparameterrepresentsthedwelltime

(preset 240 seconds), corresponding to the joint temperature programmed in the

main screen. Therefore, push to increase the time, to lower it and to

modify the digit.

– Pushingagain thescreen“W6o-N”showsup.Thisparameterrepresentsthe

dwell time of the stepped temperature. To go back to the main screen push

On the main screen, if ispushed,“AL-1”willshowup.Thisparameterrepre-

sents the temperature cooling stops (preset 70°C).

b. Top digital controller

Controls: –Jointtemperature.

–Steppedtemperatureanddwelltime.

– Parametersareenteredinthesamewayasinthebottomdigitalcontrolsystem.

The only values that are not entered in this one are the joint temperature and the

coolingtemperature.Forinstance,“SoAK”and“AL-1”willnotshowup.

c. Pressure switch

Select the requiered pressure as well as the acceptable minimum pressure to

restart the compressor if there is any loss of air. (Forbo recommends to select

-0.2 bar), than the maximum one). When the press is connected to the mains,

the pressure shown is the actual one, that is 0 bar if it is not activated.

– Press“SET”key(shortpress)toaccesstoOUT1(on).Then,selectthemaximum

working pressure + o– (max. 2.5 bar). (Fig. 15)

– Pressagain“SET”(shortpress),toaccessOUT1(off).Select+ o– , to set

the pressure the compressor will turn on again to reach the maximum working

pressure previously set. This value shall be 0.2 bar less than the working pressure.

Warning

Make sure that this value is 0.2 bar less than the working pressure.

On the contrary, pressure regulator can be damaged.

– Pressagain“SET”(longpressforaround3seconds),andthemainscreenappears

again, showing the current pressure.

Fig. 15

Start button

Timer

Top

controller

Bottom

conroller

Air bleeder

button

Pressure switch

Fig. 13

Fig. 14

Function Key

Mode Key

Digit Key

Minus Key

Plus Key

Display nº 1

Display nº 2

14

SAFE OPERATION

The press includes a pressure relief device, that will hold 2.7 bar as the maximum

supplied pressure.

Warning

While in the main screen, avoid a long pressing of the SET key.

Ifyoudoit,thescreenwillshow“Unt”.Press“SET”(longpressforaround3seconds),

to return to the main screen.

d. Start button

When all the parameters and the belt have been prepared, start the process with the

button on the top frame, that will be lighted all along the process. (Fig. 16)

– Beforepressingstart,checkthatalltheboltsarefixed.

– Oncetheprocessisfinishedandthefansstopbecausethepresshasreached

thecooling temperature, a buzzer indicates that the process is finished. The buzzer

will not stop till it is deactivated.

e. Air bleeder

Once the process is finished, press the air bleeder to release the pressure.

Danger

Check that the start button is turned off, since if it is not, the air compressor will

supply pressure again, what may cause a physical danger an also a damage to the

press.

– Ifthepressisgoingtorepeataprocess,justpressthestartbutton,anditwill

automatically make another joint.

– Oncethepressureisreleased,dismantlecarefullythetoppartofthepress.

– Whenthepressisdisconnected,theparametersofthelastjointarestored.

14

Disconnect main power cable

Danger

a. It is critical to remove the power cord from the wall receptacle first. (Fig. 17)

b. Next, unlatch the cable connector from the machine base power inlet and gently

disconnect.

Following this sequence is critical for operator and bystander safety. Removing plug

from the wall receptacle first eliminates any current from flowing through the cable. If

this procedure is not performed first and the cable connector is removed initially, the

power cable remains energized and could cause serious and fatal shock if exposed to

water or other fluids.

15

Disconnect umbilical power cord from top beam

a. Unlatch cable connector.

b. Gently disconnect.

Fig. 16

Fig. 17

15

16

Remove top beam

a. Loosen all four press connector bolts.

b. Lift top beam off and place beam on side; do not place beam with platens facing

downward in contact with a surface.

Caution

Platen surfaces may be hot.

c. Remove top silicone pad and inspect splice. Elements of a properly installed endless

splice include:

– LimitedbutconsistentflowofPVC/Urethanematerialthroughthesplice.

–

Proper bonding, especially at the tips of the fingers. ‘Pin Holes’ should not be present

at finger tips.

– Bendingofthesplicejointshouldnotcreateanyseparationatthefingeredges.

– Noscorchingofthebeltcoverorbottomplyshouldbeevident.

17

Packing press in flight case

a. Reassemble top beam onto press, tighten all four press connector bolts, and install

clamp bars on press.

b. Carefully place press in flight case.

c. Close case and engage the locking latches.

18

Maintenance

a. The reading and the application of the advises of this handbook, besides the right

usage of the Blizzard, are the primary premises for the right maintenance and the

conservation of Forbo Siegling presses.

b. Forbo Siegling suggest a visual checking of all the system each time working with

Blizzard, pressure indicators and electrical connections. The usage of the products is

third people responsibility. Forbo Siegling only suggests in this handbook the right

procedures for the people and the equipment safety.

19

Solution to problems

Symptom Possible solution

No electric inlet Check the connection to mains

No electric inlet Check (only technicians) fuses, thermometers

and contactors in the control box.

No pressure Check pneumatic connections, and compressor.

Wrongly joining Check that the belt is centred in the plate.

Wrongly joining The parameters are not right. Check them and

try again to reach the perfect joining to each belt.

Thermometer shows. S.ERR The connection with the probe

16

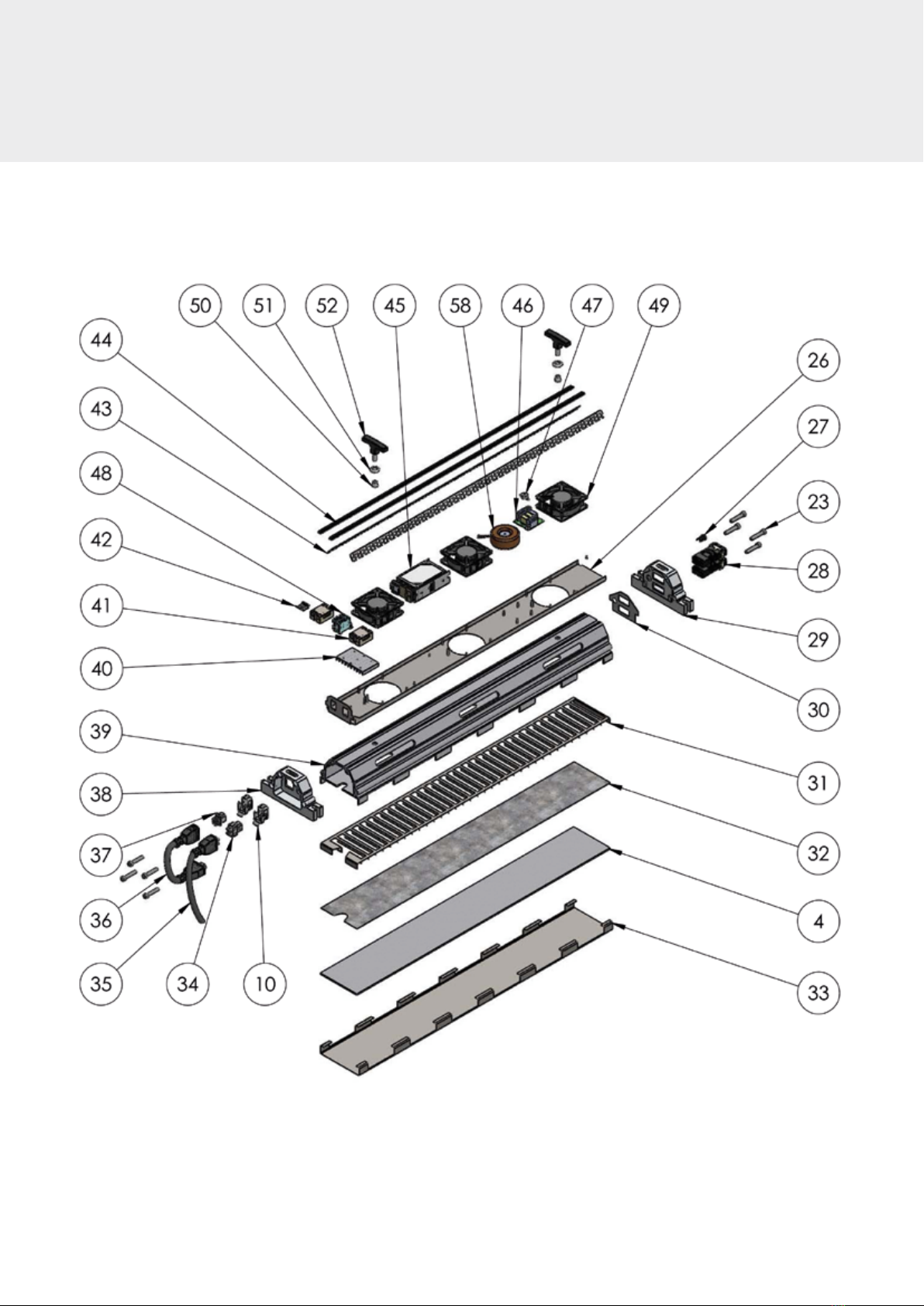

PLANS AND SCHEMES

Components of top frame

17

Components of bottom frame

18

PLANS AND SCHEMES

Components of the connections

Connection top E. – Bottom E. – Part Nº 36

Connection to the mains-part nº 35

19

List of components

Item no. Description code Qty.

11 Electrical connection base hanq

8 male with pins 1

37 Electrical connection base hanq

8 female with pins 1

53 Casing 3

54 Fitting 3

55 Electrical hose top-bottom

connection 1

56 Electrical connection base hanq

4 female with pins 1

57 Electrical hose three phase

connection 1

Item no. Description code Qty.

4 Resistance 1

10 Base connection 2

23 Screw DIN 912 M10x50 8

26 Top instrument carrier tray 1

27 Start buttom 1

28 Digital unit 2

29 Thermometers top front 1

30 Thermometers top instrument carrier 1

31 Top cooling grille 1

32 Plate 1

33 Top platen 1

34 Base inner piece 1

35 Main connection 1

36 Conexión superior-inferior 1

37 Jumperconnection 1

38 Bases top front 1

39 Top frame 1

40 Relay holder 1

41 Relay 2

42 Carril 1

43 Perforated plate 2

44 Nonslip rubber 2

45 Power source 1

46 Digital plate 1

47 Buzzer 1

48 Borna s=4 4

49 Fan A441352 3

50 Part 1 handle 2

51 Part 2 handle 2

52 Handle 2

58 Transformer 150 VA 1

Item no. Description code Qty.

1 Belt clamps bolt 4

2 Belt clamps 2

3 Bottomplaten 1

4 Resistance 1

5 Plate epoxy 1

6 Wood 1

7 Silicone bag 1

8 Bottom frame 1

9 Base bottom instrument carrier 1

10 Base connection 1

11 Base inner piece 1

12 Base bottom front 1

13 Bolt pin 4

14 Bottom instrument carrier tray 1

15 Nonslip rubber 2

16 Carril 1

17 Pressure 1

18 Compressor 1

19 Relay 1

20 Pressure regulator 1

21 Valve 1

22 Bottom main switch instrument carrier 1

23 Screw DIN 912 M10x50 8

24 Pressure switch bottom front 1

25 Bolt nut M12 4

Components of top frame Components of bottom frame

Components of the connections

20

European and UK cable

WIRING DIAGRAM OF THE

POWER SUPPLY CABLES

mono phase 230 V

three phase 230 V III

three phase 400 V III

three phase 400 V III + N + T

greygrey

brown

black

black

blue

blue

black

blue

blue

brown

black

greygrey

brown

black

brown

black

greygrey

brown

black

brown

black

GROUND

GROUND

GROUND

GROUND

Other manuals for siegling blizzard HP 160/400 AIR

1

This manual suits for next models

5

Table of contents

Languages:

Other Forbo Power Tools manuals

Popular Power Tools manuals by other brands

Shindaiwa

Shindaiwa M242/EVC Owner's/operator's manual

Josef Kihlberg

Josef Kihlberg JK24-690 Repair instructions

Surtek

Surtek TB572A User manual and warranty

Atlas Copco

Atlas Copco LH 11 Safety and operating instructions

CHESTER

CHESTER 836 TURRET MILL Operation manual

Fox

Fox F23-730 PLUS Assembly and operating manual