HONDA ENGINE STARTUP

Position the On/Off lever and fuel valve to the ON

position, and the throttle lever to the idle position ( ).

If starting a cold engine, position the choke lever in the

CLOSED position indicated by the full choke icon ( ). A

warm engine may only need partial or no choke ( ).

Gently pull the recoil starter until mild resistance is

felt, then pull sharply to turn over the engine. Allow the

recoil starter to gently return to the retracted position.

Repeat pulling the recoil starter as needed until the

engine is running.

As the engine warms up, begin moving the choke lever

slowly to the OPEN position ( ). If the engine stalls,

repeat the entire startup process and proceed more

slowly in transitioning the choke from CLOSED to OPEN.

Allow the engine a few minutes to warm up in the idle

position before starting compaction.

To start compaction, move the throttle lever to the

FAST position, indicated by the icon of a rabbit ( ).

OPERATING THE PLATE COMPACTOR (EITHER ENGINE)

To begin the compaction process, set the throttle

to the FAST position ( ). The plate compactor will begin to travel forwards. Do not force the

plate compactor forward or attempt to retard its motion; its travel speed is pre-set for optimal

compaction.

Do not operate this machine with the throttle lever set to anything other than IDLE ( ) or FAST

( ); engine speeds in between idle or full throttle will cause premature wear to the clutch and

belts and provide inadequate compaction; such wear and tear is misuse and is not covered under

warranty.

Keep both hands on the plate compactor handle as it travels down your compaction surface,

and use gentle pressure on the handle to steer it as required.

To briefly pause compaction, set the throttle to the IDLE ( )position. Do not attempt to hold a

moving machine in a fixed position. Do not leave an idling compactor unattended. If the machine

will be unattended, follow the shutdown instructions listed under the “Powering off the Plate

Compactor” section.

Do not over-compact your soil. Not only is over-compaction a bad practice for jobsite

preparation, leading to a weaker substrate, but over-compaction may also have damaging effects

on your compactor, including increased wear and tear, as well as transmit a high hand-arm

vibration to the operator.

For useful suggestions on how to achieve the ideal level of soil compaction, see the “Tips for

Proper Compaction” section. If you are ever in doubt of how to prepare your surface for proper

compaction, consult your jobsite engineer for guidance.

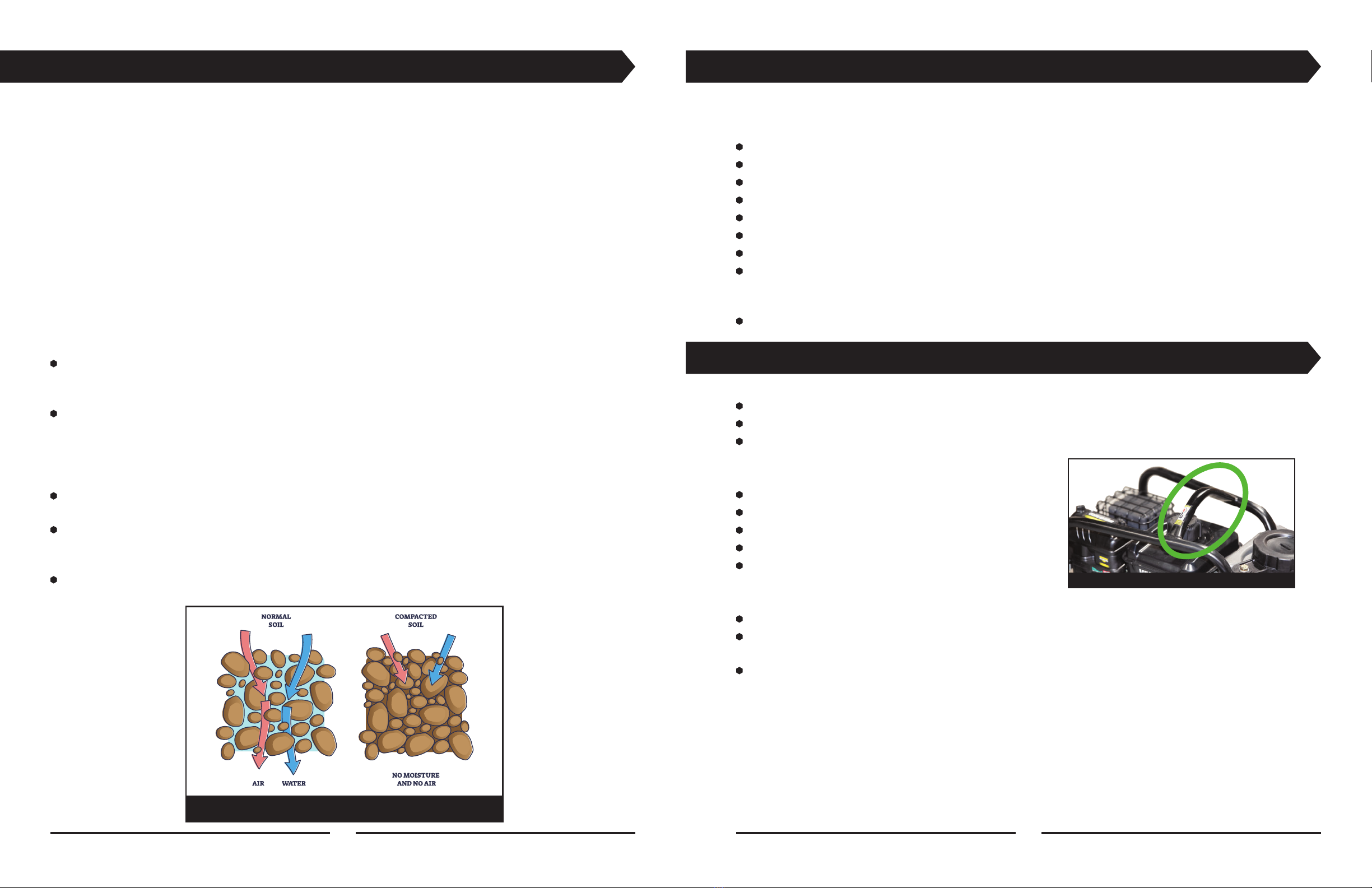

HONDA ENGINE OPERATION (1)

HONDA ENGINE OPERATION (2)

ON/OFF LEVER

THROTTLE

LEVER

CHOKE

LEVER

FUEL

VALVE

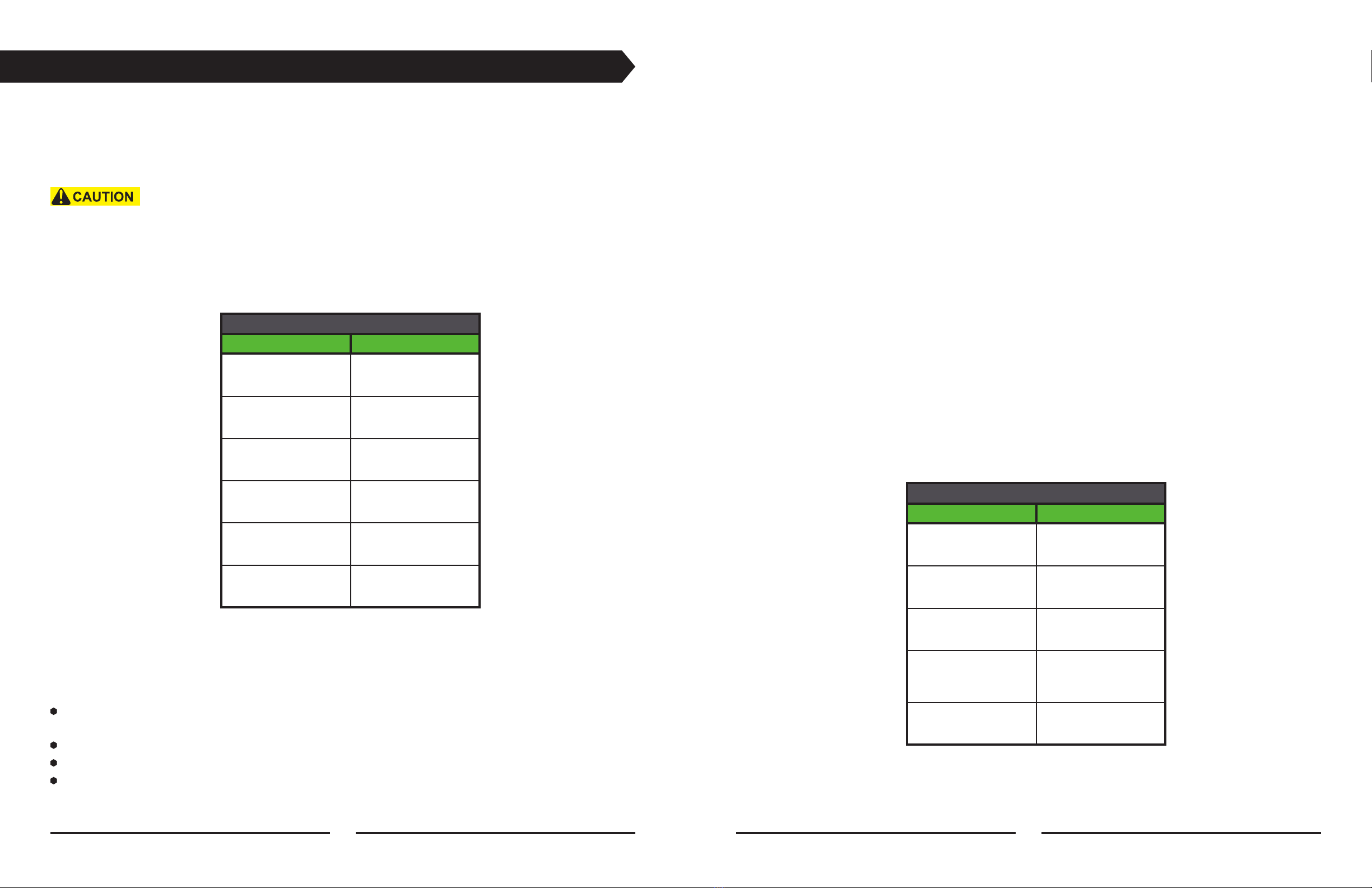

USING THE WATER TANK

This single-direction plate compactor features an integrated water tank to distribute water under

the plate compactor. While compacting soil, water under the plate compactor can help with

jobsite dust control in dry climates. When finishing asphalt, adding water under the compactor

is imperative to improve surface finish of the asphalt and to prevent asphalt from sticking to the

bottom of the compactor.

The water tank can be filled by inserting a fill hose through the

slotted cap. The cap will help retain the hose while filling.

Alternatively, the cap can be removed when pouring water in.

To start or adjust the flow of water, open the water valve.

Always use clean water from a known source. Debris or hard

water will clog the distribution bar, reducing performance of the

water system. The distribution bar can be removed for

cleaning; frequent cleaning should be a point of routine

maintenance.

The water tank can be removed by lifting the tank off the

compactor. Depending on the model, the hose clamp holding the

water hose to the water distribution bar may need to be removed

to fully remove the water tank.

POWERING OFF THE PLATE COMPACTOR

To shut down the plate compactor during the workday, when further work is expected within 24

hours, position the throttle lever in the STOP ( ) position (Vanguard) or position the On/Off lever

to the OFF position (Honda).

To shut down the Honda engine equipped plate compactor and prepare it for short-term

storage (between 1 day and 30 days), position the throttle lever to the IDLE ( ) position while

the engine is still running, then position the fuel On/Off lever to the OFF position. Allow the

engine to consume the fuel in the carburetor until the engine shuts off, then turn the engine On/

Off switch to the OFF position. This procedure allows the carburetor to empty its fuel, which

reduces the chance for gumming or plugging of the carburetor.

For the Vanguard engine, there is no special power-down sequence for short-term (1 to 30 day)

storage. Follow the standard shutdown procedure listed above.

When preparing plate compactors of either engine type for short-term storage, it is always

recommended to treat the fuel with a fuel stabilizer to help ensure it is ready for its next

operation.

To prepare the plate compactor with either engine for extended storage (more than 30 days),

see the “Extended Storage” section.

EMERGENCY SHUTDOWN PROCEDURE

HONDA ENGINE: To shut down the Honda engine equipped plate compactor in an emergency

situation, position the On/Off switch to the OFF position.

VANGUARD ENGINE: To shut down the Vanguard engine equipped plate compactor in an

emergency situation, position the throttle lever to the STOP ( ) position.

WATER VALVE

WATER TANK & SPRAY BAR

8 9