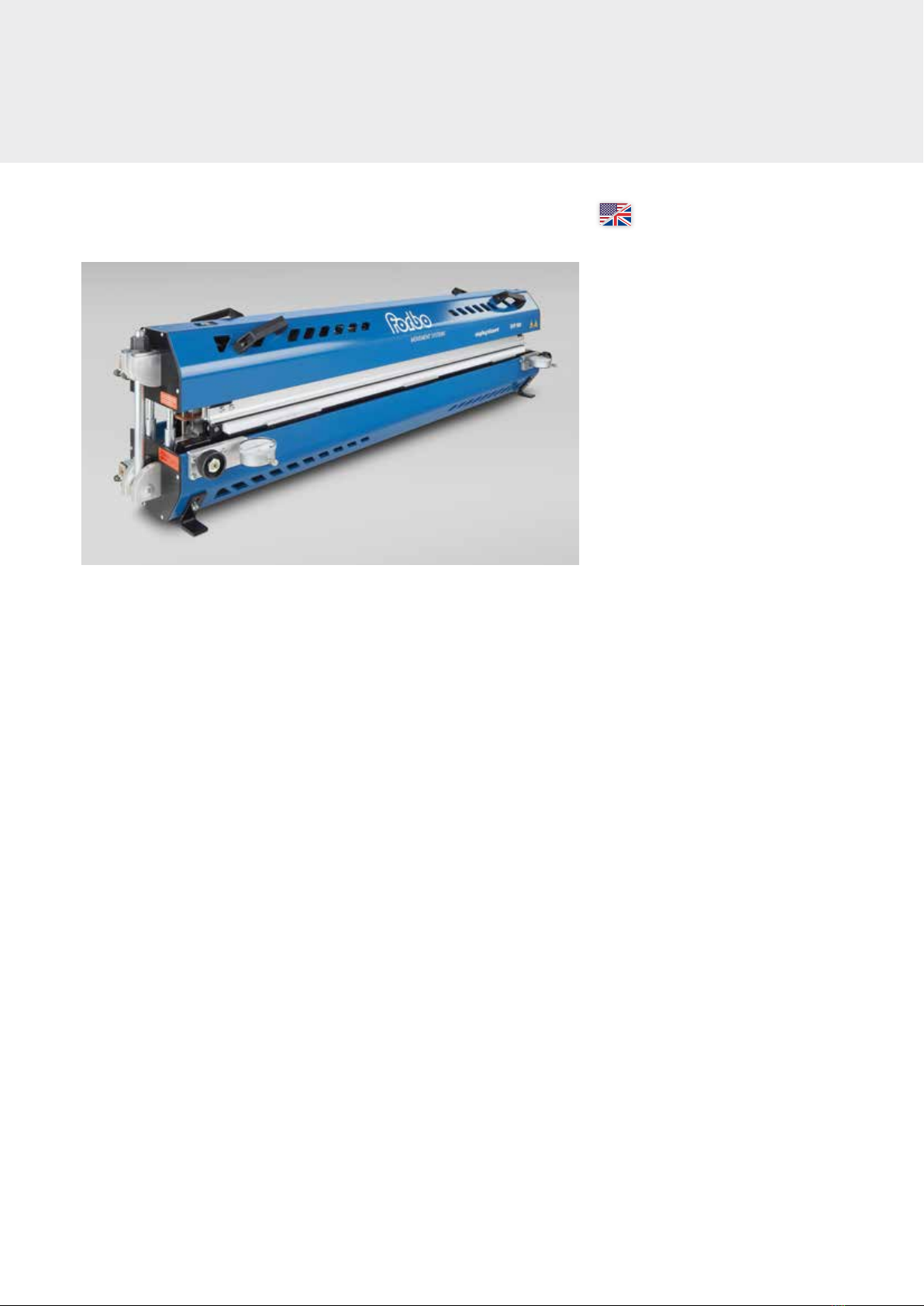

Forbo Blizzard SHP X00 User manual

Siegling – total belting solutions

OPERATING INSTRUCTIONS

BLIZZARD SLIM HEATING

PRESS (SHP) X00

Contents

3 English manual

33 German manual

siegling blizzard

splicing equipment

®

2

Dieses Gerät darf nur von Personen

in Betrieb genommen werden, die die

nachfolgende Betriebsanleitung gelesen

und verstanden haben.

Този уред трябва да се използва само

от лица, които са прочели и разбрали

следното ръководство за употреба.

本设备仅供阅读并理解以下使用手册

的人员使用

Dette apparat må kun sættes i drift af

personer, som har læst og forstået den

følgende driftsvejledning.

This device should only be used by

those personnel who have read and

understood the following user manual.

Seda seadet tohivad kasutada vaid ini-

mesed kes on lugenud kasutusjuhendit.

Tämä laite on tarkoitettu vain henkilöille,

jotka ovat lukeneet ja ymmärtäneet

kyseisen käyttöoppaan.

Cet appareil ne doit être mis en service

que par des personnes ayant lu et

compris les instructions de service

ci-après.

Αυτή η συσκευή επιτρέπεται να τεθεί σε

λειτουργία όνο από έλη του προσωπι-

κού που έχουν διαβάσει και κατανοήσει

τι οδηγίε χρήση που ακολουθούν.

Questo dispositivo può essere utilizzato

solo da persone che hanno letto e

compreso il seguente manuale.

この装置は、次の取扱説明書をよく読んで

理解した作業員のみが使用するようにして

ください 。

Ovaj uređaj mogu koristiti samo osobe,

koje su pročitale i razumjele upute

za upotrebu.

Šo ierīci drīkst lietot personāls, kurš ir

izlasījis un sapratis lietošanas instrukcijas.

Šį prietaisą leidžiama pradėti eksploatuoti

tik asmenims, perskaičiusiems ir supra-

tusiems toliau pateiktą instrukcijų žinyną.

Dit apparaat mag alleen door personen

in gebruik worden genomen die de

volgende gebruiksaanwijzing hebben

gelezen en begrepen.

To urządzenie może być użytkowane

tylko przez osoby, które przeczytały i

zrozumiały następującą instrukcję obsługi.

Este aparelho só pode utilizado por

pessoas, que tenham lido e compreendi-

do o Manual de instruções que se segue.

Acest aparat poate fi pus în funcţiune

doar de către persoanele care au citit și

au înţeles instrucţiunile de utilizare de

mai jos.

Bara de personer som har läst och

förstått den här bruksanvisningen får

använda den här apparaten.

Toto zariadenie môžu uviesť do prevádz-

ky len osoby, ktoré si prečítali nasledujúci

návod na použitie a porozumeli jeho

obsahu.

To napravo smejo uporabljati samo

osebe, ki so prebrale in razumele

naslednja navodila za uporabo.

Este aparato solo deben emplearlo

las personas que hayan leído y compren-

dido las siguientes instrucciones de uso.

Tento přístroj smějí uvádět do provozu

pouze osoby, které si přečetly následující

návod k obsluze a rozumějí mu.

A készülék üzembe helyezését csak olyan

személyek végezhetik, akik elolvasták az

alábbi használati utasítást és megértették

annak tartalmát.

3

OPERATING INSTRUCTIONS

BLIZZARD SHP X00

ENGLISH

Contents

4 Safety

6 Description

9 Preparation

12 Operating the device

30 Maintenance and repairs

32 Information from the manufacturer/

customer service,

EC declaration of conformity

These instructions provide important information on how the device works

and how to use it safely. Don’t use the device until you have read and understood

the instructions. Keep these instructions in a handy place for other users so that

they can read them before using the device.

Incorrect or improper usage can cause damage to the device and the conveyor

belt, as well as injury to the operative and other people.

4

1 SAFETY

These instructions provide important information on serious

risks associated with operating the Blizzard SHP X00, impor-

tant technical information and processes applied.

Symbols are used to highlight this important information

and indicate as follows:

This symbol is always used in conjunction with a

hazard and the relevant signal word.

In the text, key signal words mean as follows:

Danger means a personal hazard with a high level of risk,

which, if not prevented, will be fatal or result in serious

injury.

Warning means a personal hazard with an average level

of risk, which, if not prevented, could be fatal or result in

serious injury.

Caution means a personal hazard with an average degree

of risk, which, if not prevented, might result in a minor or

moderate injury.

Notice is a warning about damage to property and the

environment.

The device may only be operated in the following circum-

stances:

– In compliance with its intended use

– In compliance with the operating instructions

– When in perfect condition and only with the original

accessories

– When operatives are aware of safety requirements and

hazards

– If servicing and maintenance work has been

carried out correctly (only by the manufacturer or

appropriately qualified staff).

1.2 Intended use

The Blizzard SHP X00 is designed for melt splicing homoge-

neous belt material (Siegling Fullsan) up to a maximum tem-

perature of 230 °C. The ends of the belt are butt spliced in

the press under pressure and temperature.

The Blizzard SHP X00 is a heating press used for assembly

purposes and not suitable for continuous operation. After

several heating processes (5 to 8 cycles), the press needs to

cool down to room temperature before it’s used again.

It’s not intended to be used for any other purposes.

1.3 Organizational measures

The operating instructions must always be kept near the

device and within easy reach. In addition to these operating

instructions, abide by general legal and other mandatory

regulations on accident prevention and environmental pro-

tection.

To reflect special operational features, further instructions

can be added to the operating instructions, regarding:

– Work organization and procedures

– The personnel deployed

– Supervisory and reporting duties

1.1 General safety information

The Blizzard Slim Heating Press (SHP) X00 is a state-of-the-art

device and governed by the EC Machine Directive’s health

and safety requirements. Nevertheless, using it may cause

injury to life and limb of the user or third parties, as well as

damage to the machine and other property.

5

1.5 Moving the device

Unplug the device from the power supply every time you

move it somewhere else. Reconnect the device to the mains

before switching it on again.

If lifting the device, only use lifting gear and equipment with

sufficient load-bearing capacity. Only attach lifting gear or

equipment to the handles or ring bolts (see section 2). Make

sure that no parts of the device can fall off or become loose

while it’s being transported.

Warning

Make sure that the top and bottom section of the press are

properly screwed together.

1.6 Further important information

Danger

Opening the device entails a risk of accidents.

Conversions and maintenance work may only be carried out

by trained and skilled personnel. Repairs may only be car-

ried out by the manufacturer or people appointed by the

manufacturer.

Notice

Fire hazard. Ensure that you can always access the heating

press and it’s not covered over when it’s cold.

Danger

The devices are not protected from electrical overload.

Therefore, the operator must ensure that the electrical

installation is protected from overload in the place it is oper-

ated. A device’s electrical components must be inspected/

checked frequently. Any obvious faults, such as loose con-

nections, must be put right immediately.

Only personnel who have been briefed and read the operat-

ing instructions are permitted to use the device. Frequent

checks are to be made to ensure that people are complying

with the operating instructions and are aware of safety

requirements and hazards.

Take the following precautions to minimize the risk of injury:

– Wear closely fitting clothing

– Tie long hair back

– Take jewelry, including rings, off before starting work

Make sure that all the device’s safety and hazard instructions

are observed and easy to read.

If the device starts behaving abnormally, switch it off

immediately and report the fault to the department/person

concerned.

Don’t modify, add to or convert the device without the

manufacturer’s approval. Anyone who makes subsequent

additions to, or conversions of the device, is responsible for

ensuring compliance with the EU directive.

Only original spare parts meet the technical requirements

specified by the manufacturer and guarantee that the

device will work perfectly.

1.4 Selecting and briefing personnel

The device may only be operated by personnel who are

qualified and have been briefed to do so.

Work on the device’s electrical components may only be

carried out by the manufacturer or people appointed by the

manufacturer.

6

2 DESCRIPTION

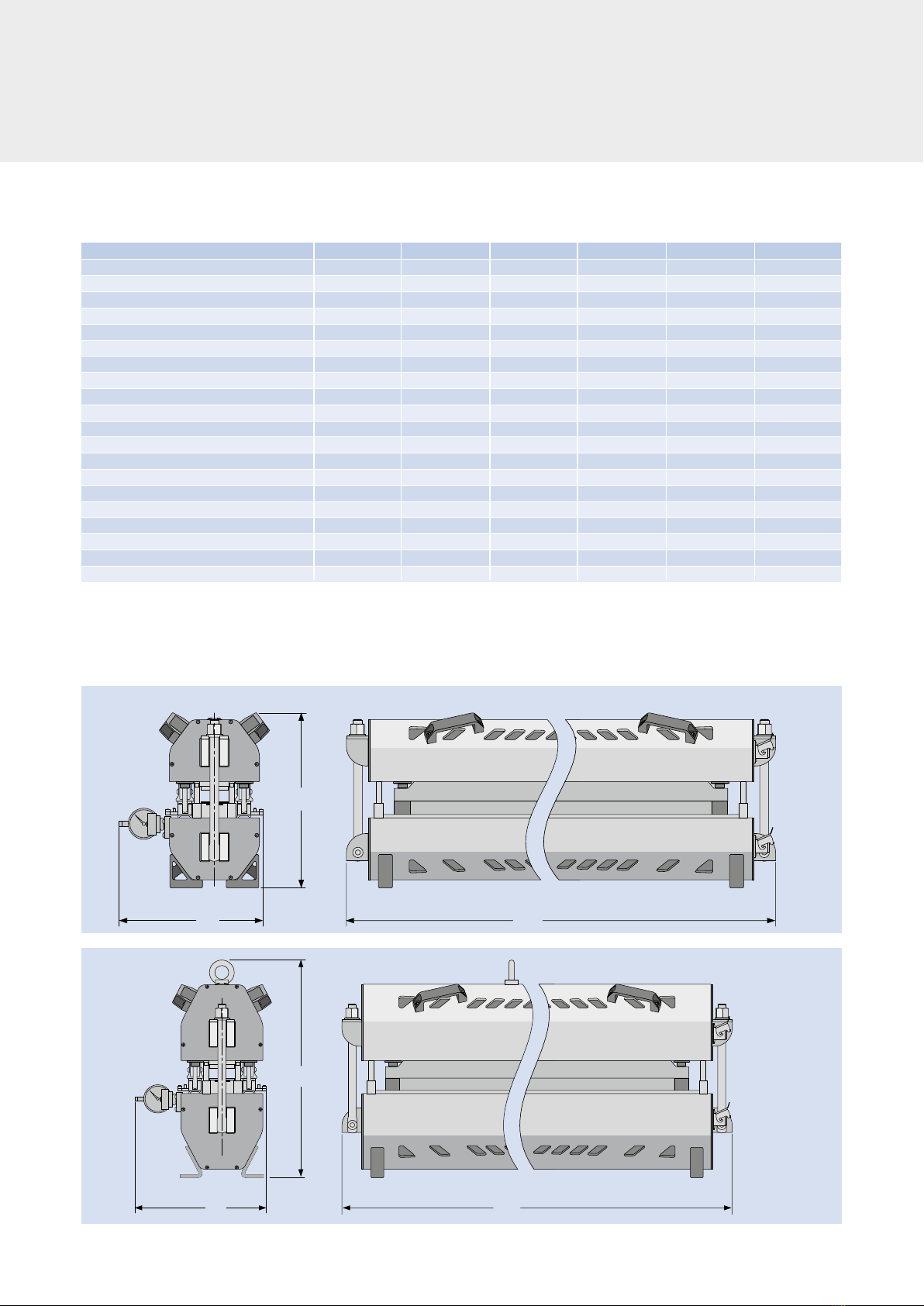

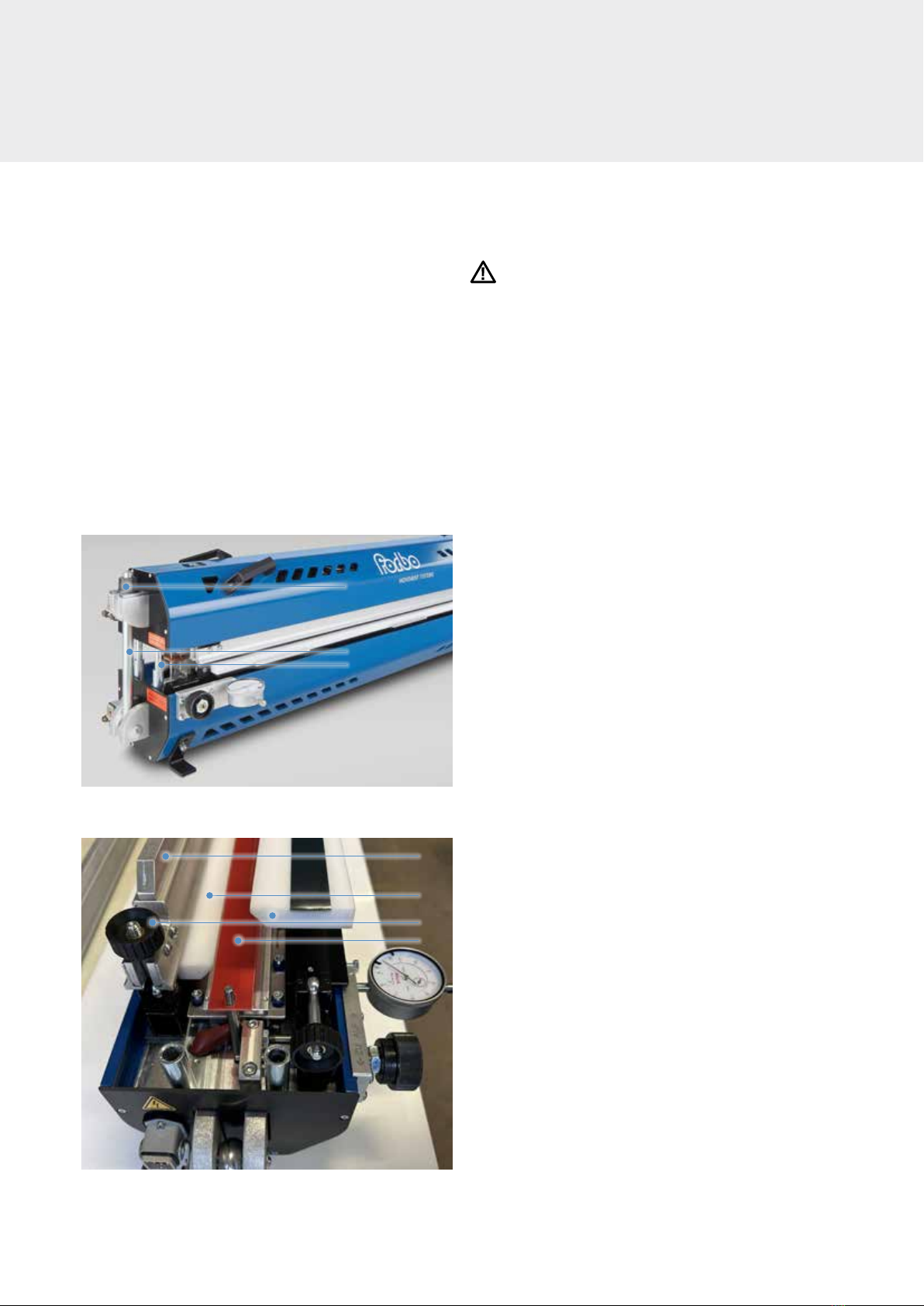

2.1 The Blizzard SHP’s X00 (basic device) design and components

Bottom section

Top section

Air inlets for cooling

Handles (4x)

Compressed air regulator

Connectors (2x)

Fig. 2.1.1 (left)

Please note: The SHP 1500 and SHP 2000 have ring bolts

on the top section so they can be transported.

Fig. 2.1.2

Inlays

Belt holder (2x)

Knurled nuts (4x)

Top section

Eye bolt with collar nut (2x)

Dial gauges (2x)

(can be removed when device is transported)

Belt set screws (2x)

Centering bolts (4x)

Laminated fabric inlays top and bottom

Fig. 2.1.3

7

SHP 1500 / SHP 2000

SHP 600 … SHP1200

H

H

L

L

B

B

SHP 300 SHP 600 SHP 900 SHP 1200 SHP 1500 SHP 2000

Belt width max. (at 90°) [mm (in)] 300 (11.8) 600 (23.6) 900 (35.4) 1200 (47.2) 1500 (59.1) –

Belt width min. (at 90°) [mm (in)] – 300 (11.8) 600 (23.6) 900 (35.4) 1200 (47.2) –

Belt length min. with belt holder [mm (in)] approx. 840 (33) approx. 840 (33) approx. 840 (33) approx. 840 (33) approx.1000 (39.4) –

Butt splice – compression [mm (in)] 0– 3 (0 – 0.12) 0– 3 (0 – 0.12) 0– 3 (0 – 0.12) 0– 3 (0 – 0.12) 0– 3 (0 – 0.12) –

Effective heating plate width [mm (in)] – 720 (28.3) 1020 (40.2) 1320 (52) 1620 (63.8) –

Effective heating plate length [mm (in)] 10 (0.4) 10 (0.4) 10 (0.4) 10 (0.4) 10 (0.4) –

Total length of heating press (L) [mm (in)] 284 (11.2) 284 (11.2) 284 (11.2) 284 (11.2) 284 (11.2) –

Total width (W) [mm (in)] 663 (26.1) 931 (36.7) 1231 (48.5) 1531 (60.3) 1831 (72.1) –

Total height (H) [mm (in)] 325 (12.8) 325 (12.8) 325 (12.8) 325 (12.8) 405 (15.9) –

Total weight [kg] approx. 28 approx. 41 approx. 57 approx.68.5 approx. 101 –

Voltage [V] 230 230 230 230 230 –

Power [W] not known 2 x 800 2 x 1200 2 x 1500 2 x 1800 –

Heating up time to 200°C [min] not known – approx. 8 approx. 8 – –

Cooling down time from 200°C to 45 °C [min] not known – approx. 9 approx. 9 – –

Cooling medium Air Air Air Air Air –

Air pressure factory setting [bar] 1.2 1.2 1.2 1.2 1.2 –

Air pressure max. [bar] 2.5 2.5 2.5 2.5 2.5 –

Time for pressure generation [min] approx. 1:00 approx. 1:00 approx. 1:00 approx. 1:00 approx. 1:00 –

Heating temperature max. [°C] 230 230 230 230 230 –

Fans [quantity] 2 4 5 7 9 –

2.2 Technical info basic device

The figures apply to the 230 V version.

Main dimensions in mm and inches (in). All Imperial measurements have been rounded up.

* If a belt is spliced and narrower than the maximum belt width specified, the area where the belt is heated must be covered all over with belt material

in the same thickness. The belt holders must also be shimmed to prevent bending.

8

2.6 How it works

Insert the ends of the belt you want to splice in the center of

the bottom section of the press. Then add the top section

and screw it on tight.

Pressure and temperature are then built up in the closed

heating press between the electric heating plates. As a

result, the belt material you have inserted will melt. The

ends will fuse after a specified period (heating and holding

time). The splice will have the physical properties required

when it has cooled down.

For more information on how the heating press works, refer

to Operating the device in section 4.

2.5 Wear parts/consumables

876130 876131 876132 876133 876134 876135

2 x laminated fabric inlays 30 (compensation profile made of laminated fabric, length 30 mm, width just like the nominal width of the press)

876136 876137 876138 876139 876140 876141

2 x laminated fabric inlays 25 (compensation profile made of laminated fabric, length 25 mm, width just like the nominal width of the press)

––––––

2 x laminated fabric inlays 18 (compensation profile made of laminated fabric, length 18 mm, width just like the nominal width of the press)

876142 876142 876142 876142 876142 876142 Set of shims (2 pcs., laminated fabric, length 30 mm, width 50 mm, thickness = belt thickness – 0.1 mm)

– – 876114 – – – Adjustment aid (width matches the nominal width of the press)

876143 876144 876145 876146 876147 876148 Set of matte soft film (length 50 mm, width to match the nominal width of the press)

– – – – – – Silicone pad for inverted pyramid pattern (NP) (length 50 mm, width to match the nominal width of the press)

876100 876102 876104 876106 876108 Set, consisting of the following items:

Blizzard SHP basic device (230 V)

Control device HPS 2-H

Power and connection cable

Tool case

2 x laminated fabric inlays 30 (compensation profile made of laminated fabric, length 30 mm, width just like the nominal width of the press)

Adjustment aid

876149 876150 876151 876152 876153 876154 1 inlay on both the right/left (combi for Center Drive [CD] and Positive Drive [PD1 and PD2] belt types)

2.4 Scope

SHP 300 SHP 300

SHP 900 SHP 900

SHP 1500 SHP 1500

SHP 600 SHP 600

SHP 1200 SHP 1200

SHP 2000 SHP 2000

Designation

Designation

Article number for the press type:

Article number for the press type:

Accessories (not included in the scope. Need to be ordered separately).

2 DESCRIPTION

9

3.1 Prepare the heating press for use

Before operating the device, the following steps must be carried out each time to ensure it

works properly. Check the following points have been complied with:

3.2 Transport

The device should be transported in its carry case. The device should be moved/used with

the aid of suitable lifting gear (minimum lifting capacity see section 2.2 Technical

Information). Before moving the device, unplug it from the power supply.

Only ship and transport the device when it has cooled down and in compliance with

the safety regulations.

Please note:

When transporting, make sure that heating presses are only

transported or stored when they are closed. (This is the best way to protect the

heating surfaces from damage).

Warning

Make sure that the top and bottom section of the press are properly screwed together.

When taking the device out of the carry case or transporting it, take special care.

Do not stand under suspended loads during transport.

Only lift up the heating press as indicated (by the 4 handles or the ring bolts).

3.3 Positioning

The Blizzard SHP X00 may only be placed on surfaces that are not heat sensitive. Otherwise,

this could cause damage to materials that are not heat resistant, or present a fire hazard. The

surface the device is placed on must be able to withstand the static load caused by the

weight of the heating press.

Notice

Fire hazard. Ensure that you can always access the heating press and it’s not covered over

when it’s cold.

3.4 Electrical installation

The mains voltage must tally with the device’s operating voltage. The leads are supplied in

pluggable form.

3 PREPARATION

10

3 PREPARATION

3.5 Accessories

– Soft film/textured film

– Laminated fabric inlay (compensation profiles made of laminated fabric), (see fig. 2.1.3)

– Adjustment aid, (see fig. 4.2.4)

– Extra material.

If possible, use the material that the belt to be spliced is made of.

– Shims (see fig. 4.2.6).

Inspect all accessories before you use them. They must be clean and in perfect condition.

3.6 Pressure generation and monitoring

The heating press has an integrated pneumatic assembly for pressure generation and

monitoring. The pressure hose in the top section is filled when the heating process is

started by pressing start/stop on the control device’s keypad.

Once the heating process is completed, it’s emptied again automatically.

Before the heating process, the display on the pressure regulator shows the current

setpoint. (Fig. 3.6.1)

Factory-adjusted setpoint: 1.2 bar

Maximum setpoint permitted: 2.5 bar

Adjust the pressure required for the splice (see splicing instructions). Proceed as follows:

1. Press the key in the middle underneath the display until “bar” is shown.

2. Adjust the bar setpoint by pressing the arrow keys.

3. Press the key in the middle four times. The new setpoint has now been stored.

The operating pressure (actual value) is displayed during the heating process. This can

increase due to the thermal expansion of the air.

This is normal and requires no intervention by the operative.

Notice

A setpoint that’s higher than 2.5 bars is not permitted, poses a safety risk and will destroy

the heating press.

Notice

The press may only be started if closed.

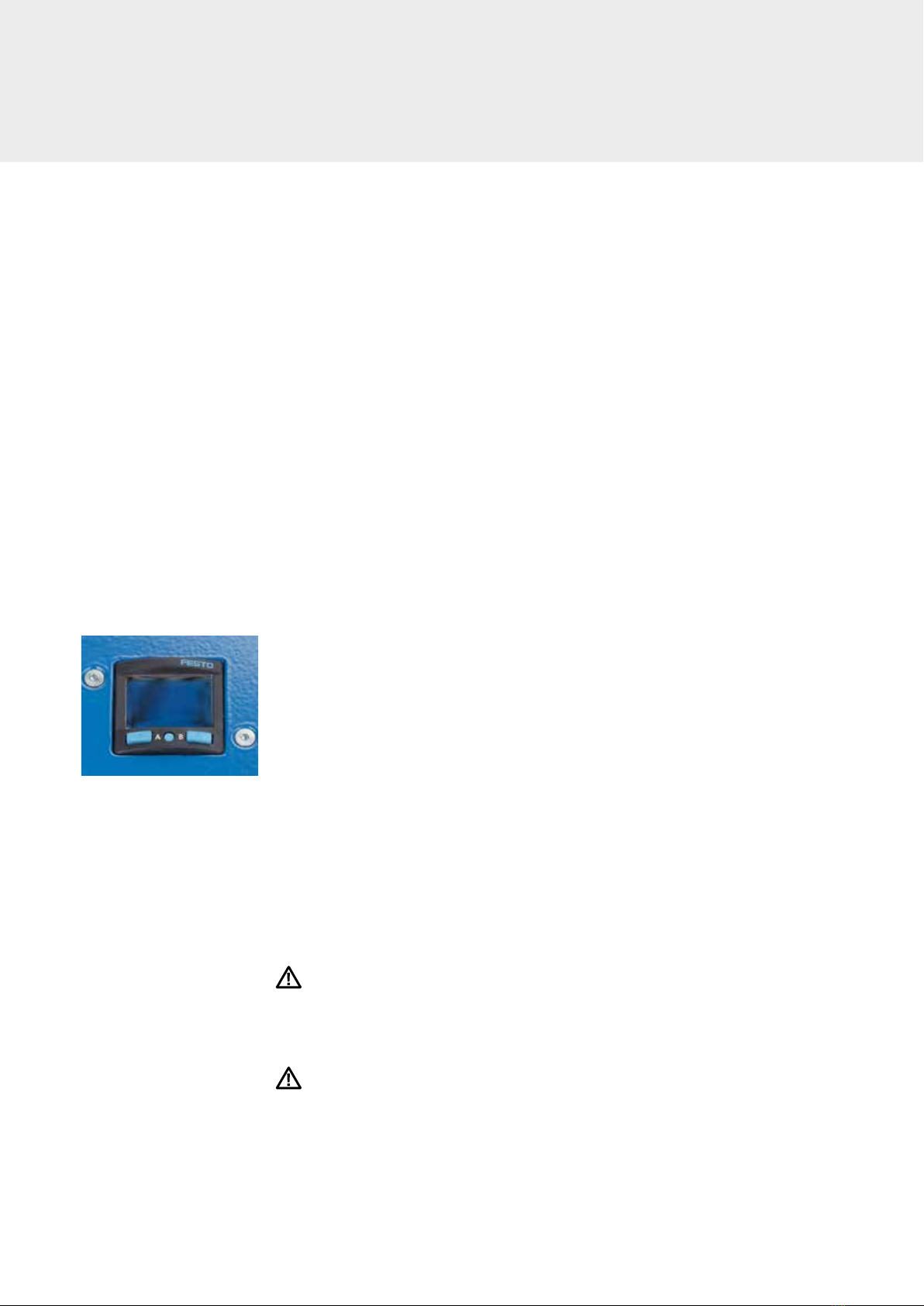

Fig. 3.6.1

11

3.7 Temperature control/temperature limitation

Some parts of the heating press will get very hot during operation, so the press must only

be touched in specified areas.

Notice

The heating plates must not exceed a temperature of 230°C. If this temperature is exceeded,

it will destroy the heating elements. The power supply will be interrupted.

3.8 Air cooling system

The heating plates with the belt material are cooled with air. There are fans in the lower

and top section of the heating press which blow cold air over the heating plates after the

heating process and hold-down time to cool down the press.

In order to have no negative impact on the cooling process, the openings to let the air in

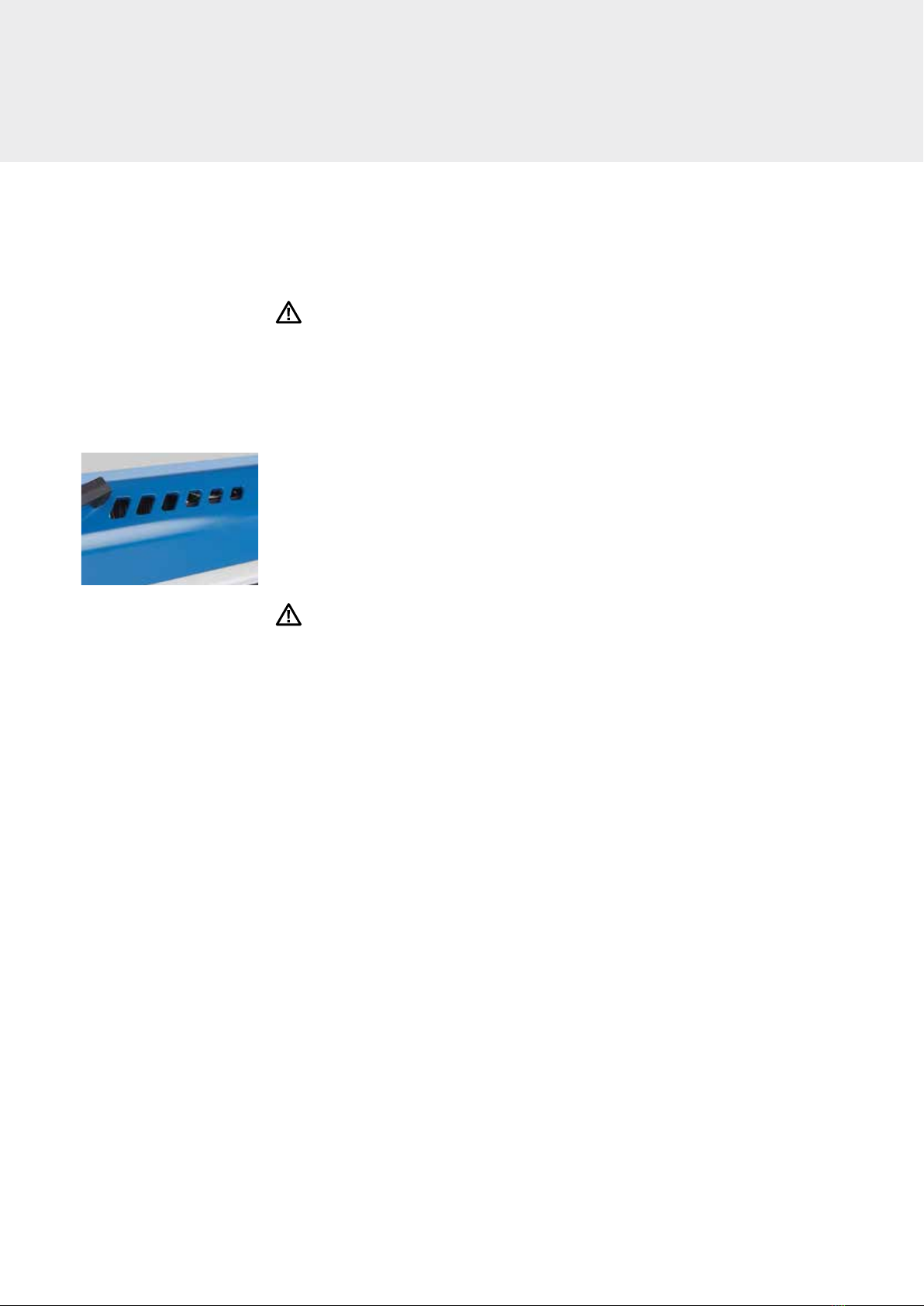

and out must not be covered (fig. 3.8.1).

After reaching the cooling temperature, the fans switch off automatically.

Warning

After cooling, the press can still be hot.

Therefore, only hold the heating press by the handles/ring bolts.

You can only transport the press once it’s cooled down.

Fig. 3.8.1

12

4 OPERATING THE DEVICE

Warning

Check the heating press for damage before you start any

heating process.

Please note:

When making splices, always observe the splicing instruc-

tions for the relevant belt type.

4.2 Inserting the belt

in the heating press

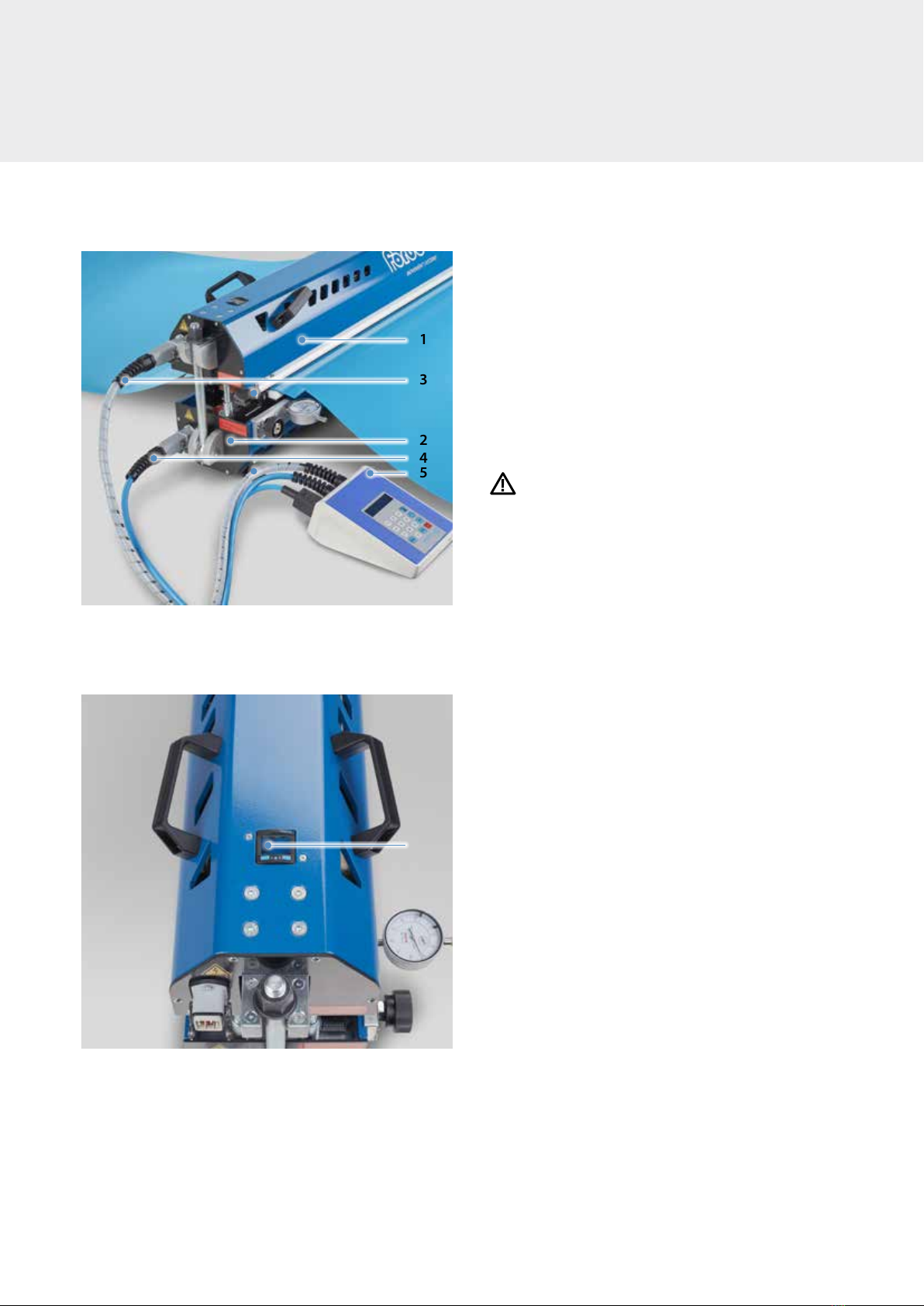

1. Loosen the collar nuts (1) and open out the eye bolts (2).

(Fig. 4.2.1)

2. Lift the top section off the bottom section without

tilting it and place it on the centering bolt (3) on a flat

surface.

3. Remove the upper belt holders (4) on both sides.

Loosen the knurled nuts (5) on the belt holders and

open out the eye bolt. (Fig. 4.2.2)

4. Add the inlays (6) for the belt to be spliced to the press.

Position the laminated fabric inlay (7) in the bottom part

of the press using the positioning hole. (Fig. 4.2.2)

Please note:

There are the following inlays:

– for FLT belts (included)

– for CD, PD1, PD2 belts (accessories).

The following variants of the laminated fabric inlays are

available:

– 30 mm long (for FLT)

– 25 mm long (for CD)

– 18 mm long (for PD1)

4.1 Preparing the heating press

1

4

7

5

6

2

3

Fig. 4.2.1

Fig. 4.2.2

13

5. Prepare the two ends of the belt for splicing.

6. If high impact pressure is to be generated later: Move the

belt holder outward as far as it will go (only for FLT belt

material). To do so, use the belt set screws (8) on the bot-

tom section. (Fig. 4.2.3)

Please note: Higher impact pressure is useful if the cut-

ting edge of the belt material is not very clean/straight.

Notice

In the case of center drive and positive drive types, the

right tooth pitch needs to be made on the splice.

Therefore, precisely adjust the infeed unit according

instructions.

7. Place the soft film (9) or textured mat for the type of belt

over the width of the press on the heating surface.

(Fig. 4.2.3)

8. Use the adjustment aid (10) to adjust the first end of the

belt. Position the adjustment aid based on the perfora-

tions. (Fig. 4.2.4)

Fig. 4.2.3

Fig. 4.2.4

9

10

8

14

10. Insert the first end of the belt (11) in the middle (under-

side at the bottom), attach the belt holder and affix the

inserted belt material with knurled screws (12). (Fig. 4.2.5)

Notice

If the belt is narrower than the nominal width of the

press, the rest of the area to be heated must be lined

with extra material to compensate for the difference. The

belt holders must also be shimmed to prevent bending.

If the heating surface on the bottom part of the press is

not covered with material, pressure distribution will be

poorer. At the same time, there is a risk of overheating or

the material not melting. (Not shown in fig. 4.2.5)

11. Press the end of the belt flush against the adjustment aid

and fix it in its final position by tightening the knurled

screws (12) evenly. (Fig. 4.2.5)

12. Remove the adjustment aid (13). (Fig. 4.2.5)

14. Apply slight pressure to position the second end of the

belt (14) at the front to the first end of the belt and tight-

en the belt holder (15) evenly on both sides using the

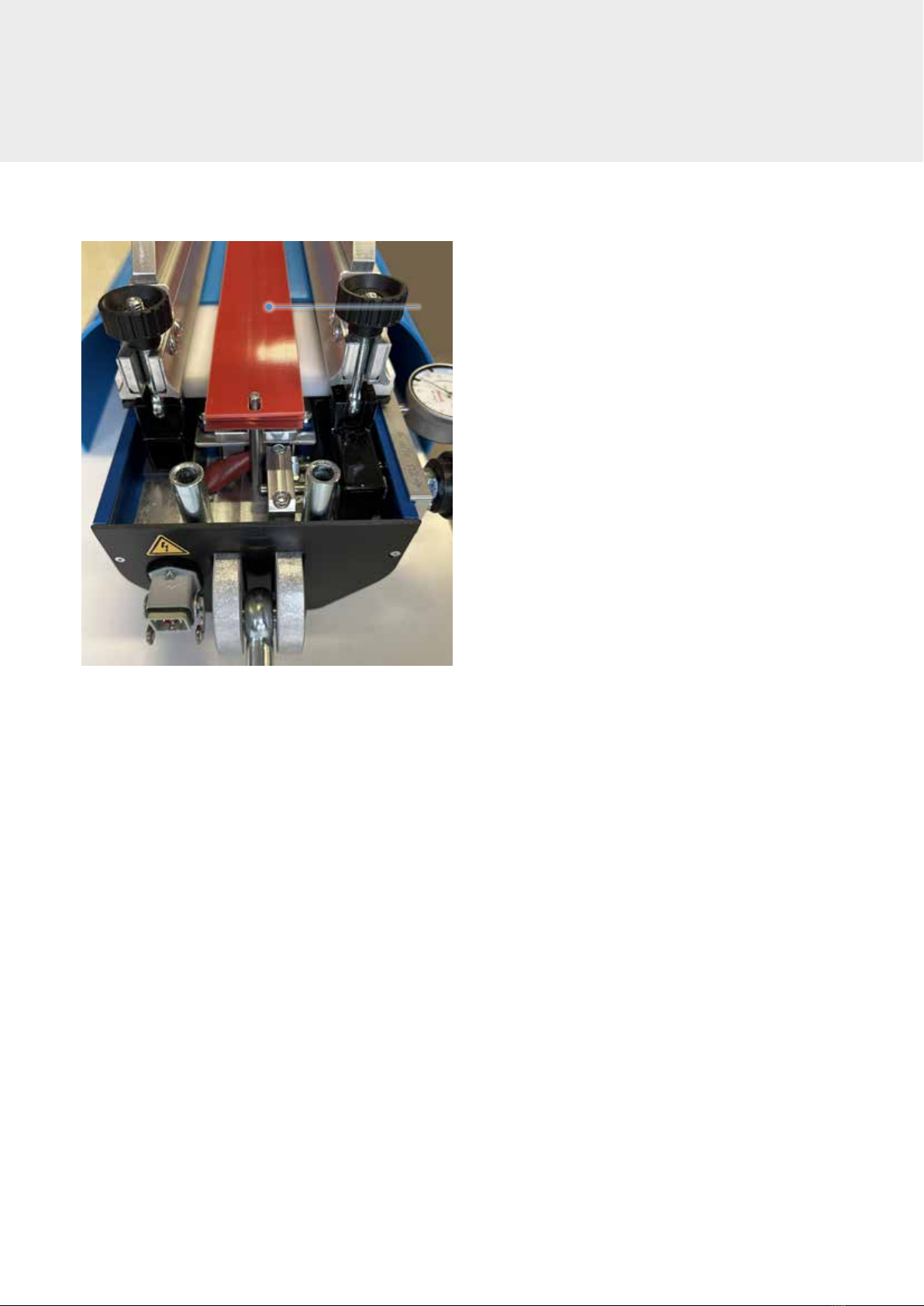

knurled screws (16). (Fig. 4.2.6)

15. If required, compress the belt material (only for FLT belt

material) using the belt set screws (17). One turn equals

1 mm of compression. The infeed must be the same on

both sides and can be read accurately on the dial gauge.

(Fig. 4.2.6)

Please note: This is only required if it wasn’t possible

to create any slight impact pressure manually in step 14,

or the edges have the belt edges aren’t neat or straight.

Notice

In the case of center drive and positive drive types, the

right tooth pitch needs to be made on the splice.

Therefore, precisely adjust the infeed unit according

instructions.

16. Place the piece of belt (18) or the shims (19) on both sides

of the area to be spliced. The shims must be 0.1 mm thin-

ner than the belt material. They prevent the bonded

material from seeping out of the sides. (Fig. 4.2.6)

Fig. 4.2.5

Fig. 4.2.6

11

14

13

15

16

18

12

17

19

4 OPERATING THE DEVICE

15

Fig. 4.2.7

17. Depending on the belt type, apply cover material over

the full heating surface over the entire width and posi-

tion and the second laminated fabric inlay (20) on the

cover material. (Fig. 4.2.7)20

16

Warning

There’s a risk of crushing injuries when you close the heating

press.

1. Place the top part of the press on the bottom part of the

press.

The centering bolts (1) on the top section must engage

with the centering holes (2) on the bottom section.

2. Fold up the eye bolt (3) with collar nut and tighten the

collar nut by hand.

4.3 Closing the heating press

1

2

3

Fig. 4.3.1

4 OPERATING THE DEVICE

17

4.4 Connect the heating press to

the mains

1. Connect the top section (1) and bottom section (2) to

the control device (5) with the connecting cables (3/4)

and close the plug lock. (Fig. 4.4.1)

Note:

The plugs are coded with color markings.

They also have different cross-sections and can only be

plugged into the relevant socket on the device.

2. Connect the control device (5) to the power supply.

(Fig. 4.4.1)

Warning

Risk of fire and damage due to overload of the power

supply. Therefore, please read the information stated on

the heating press’s rating plate. If necessary, provide a

separate power connection for the heating press. Only

connect the power supply when the top part of the

press and bottom part of the press are connected to the

control unit.

– Check the air pressure on the pressure regulator (6) and

adjust if necessary. To do so, see section 3.6 on Pressure

Generation and Monitoring (Fig. 4.4.2)

Please note:

The compressed air supply is automatically regulated by

an integrated compressor. The air pressure of 1.2 bar was

set in the factory and may only be changed to a maxi-

mum of 2.5 bar in exceptional cases.

During the heating process, the pressure in the press

may increase due to thermal expansion. This is normal

and requires no intervention by the operative.

1

5

6

2

3

4

Fig. 4.4.1

Fig. 4.4.2

18

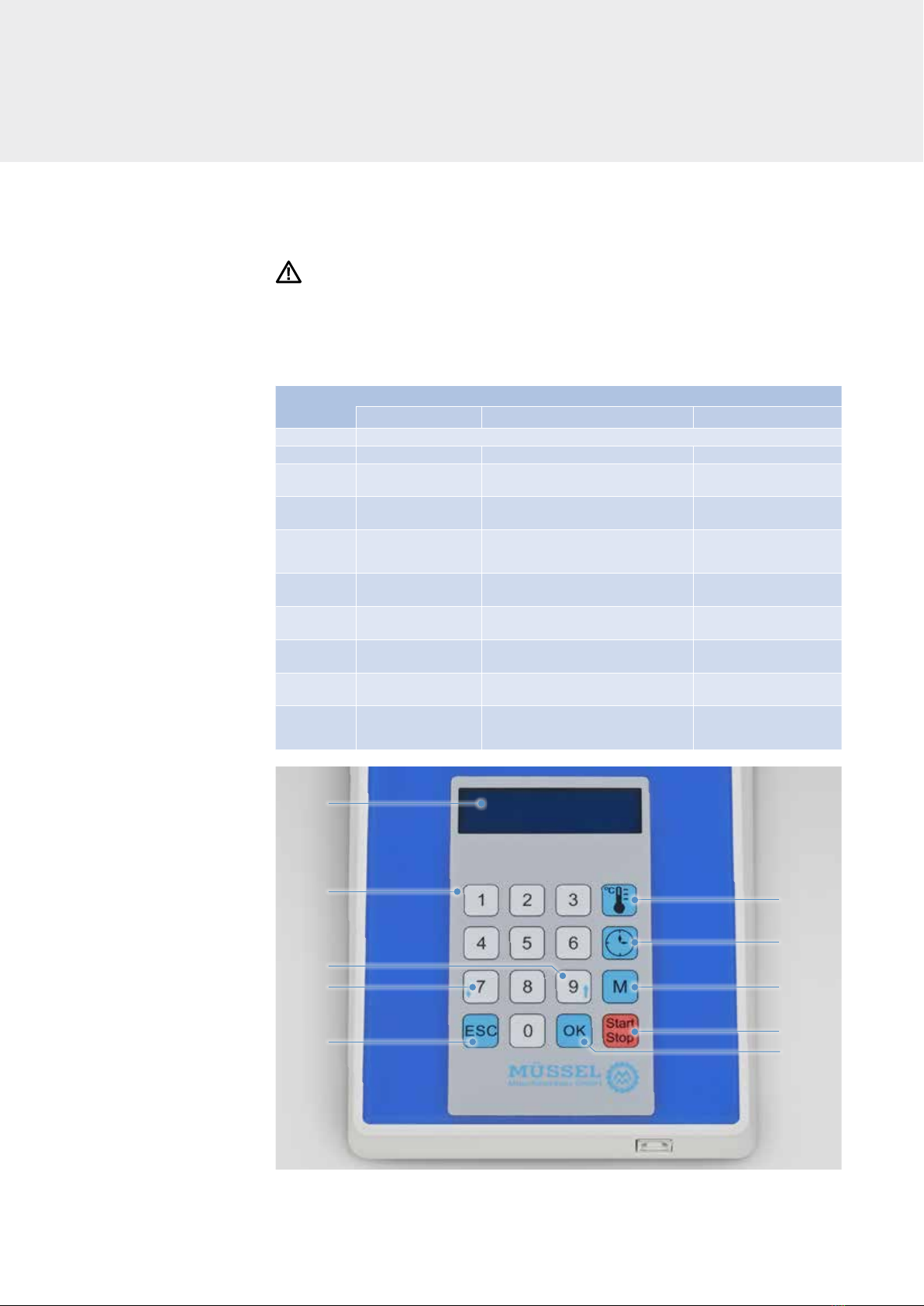

The control device’s controls and displays

4.5 Adjust the control device and heat the splice

Notice

The operative is responsible for entering the right splicing parameters.

1

2

4

5

3

6

7

8

9

10

4 OPERATING THE DEVICE

Designation

Function

Standard Parameter adjustment Pressing procedure

1 Backlit LCD display with 2 x 16 characters

2

(numeric keypad)

no function Value input no function

3no function Selection of the setting function

Selection of the press type no function

4no function Selection of the setting function

Selection of the press type no function

5no function

Exiting the setting function without changing

the parameters or exiting the settings menu.

Cancelling the interruption

request

6no function Invoking the setting function selected Confirming the interruption

request

7Starting the pressing

process no function Interrupting the

pressing process

8Invoking the belt or

press menu no function no function

9Invoking the time menu no function Setpoint display

for the holding time

10 Invoking the

temperature menu no function

Displaying the setpoint- or

actual temperatures in the

Heating plates

19

After switching on, the device checks the plausibility of the internal real-time clock.

If the device detects an error, the user is expected to enter the current time and date.

The time and date are entered using the numeric keys. Press OK to confirm the entry made.

The HPS 2 then checks the entry and expects the user to confirm the set time.

The temperature control device is ready for operation when this screen appears:

In the first line, the current configuration of the HPS 2 appears in the form of a ticker with

the following content:

<Press-type><Belt-type><AdV><[Set temperature of the top heating plate] – [F/V]>

<[Set temperature of the bottom heating plate]-[F/V]><hold-down time -[F/V]>

F means: The value of the parameter equals the value stored in the list of belt types

V means: The user changed the value of the parameter.

The progress bar in the second row moves continuously from left to right.

Operating the device

The temperature control device is switched on when the heating press is connected to the

mains. A welcome text and the current firmware version appears on the device’s display.

(HPS2 > heating press control 2)

Please note:

If the software detects an error, an error message appears (see page 27).

20

This menu item can be switched off

by the HPS2 configuration program.

Select the belt type, press type or belt type new

Pressing the M key opens the menu concerned.

The menu structure is shown in the figure on the left.

The <belt-type>, <press-type> or belt type new> functions can be selected by pressing the

7 or 9 keys and opened by pressing OK.

4 OPERATING THE DEVICE

Table of contents

Languages:

Other Forbo Power Tools manuals