4FM6FF & FM8FF (Electric & Petrol

Assembly

Safety

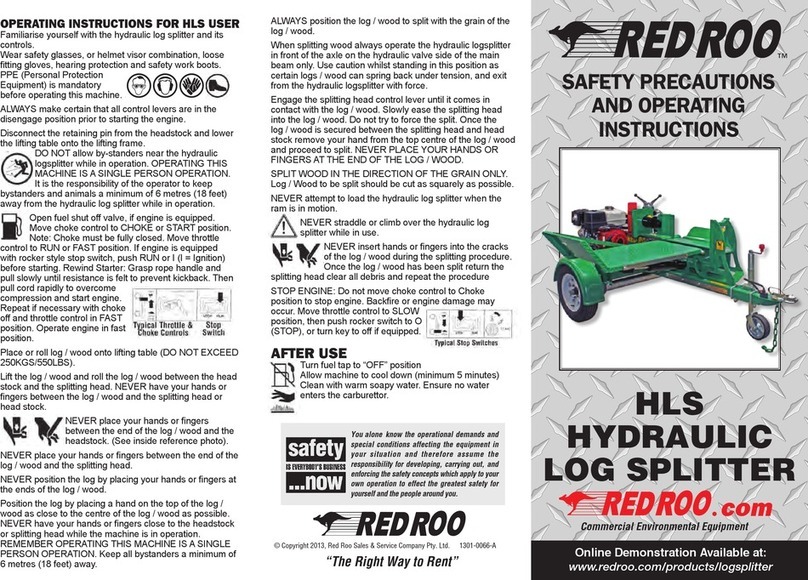

UNDERSTAND YOUR LOG SPLITTER: Read and understand the owner’s manual and labels

affixed to the log splitter. Learn its application and limitations as well as the specific potential

hazards peculiar to it.

DRUGS, ALCOHOL AND MEDICATION: Do not operate the log splitter while under the influence

of drugs, alcohol, or any medication that could affect your ability to use it properly.

AVOID DANGEROUS CONDITIONS: Use the log splitter on the ground, on the stand supplied

or one of the stands available as accessories. Ensure the stand, if used, is securely assembled.

Keep your work area clean and well lit. Cluttered areas invite injuries. Do not use the log splitter

in wet or damp areas or expose it to rain. Do not use it in areas where fumes from paint,

solvents or flammable liquids pose a potential hazard.

INSPECT YOUR LOG SPLITTER: Check your log splitter before turning it on. Keep guards in

place and in working order. Form a habit of checking to see that keys and adjusting wrenches

are removed from tool area before turning it on. Replace damaged, missing or failed parts

before using it.

DRESS PROPERLY: Do not wear loose clothing, gloves, neckties or jewellery (rings, wrist

watches). They can be caught in moving parts.

Protective electrically non conductive gloves and non-skid footwear are recommended when

working. Wear protective hair covering to contain long hair, preventing it from getting caught

in machinery.

PROTECT YOUR EYES AND FACE: Any log splitter may throw foreign objects into the eyes. This

can cause permanent eye damage. Always wear safety goggles. Everyday eyeglasses have only

impact resistant lenses. They are not safety glasses.

Stand behind and to the right of the machine when operating it. Do not bend over the machine

to operate it, this is an awkward operating position that has the operator bring their face close

to the machine, and thus risk being struck by wood chips or debris.

EXTENSION CORDS: Improper use of extension cords may cause inefficient operation of the

log splitter which can result in overheating. Be sure the extension cord is no longer than 10m

and its cross section is no less than 2.5mm2to allow sufficient current flow to the motor.

Avoid use of free and inadequately insulated connections. Connections must be made with

protected material suitable for outdoor use.

AVOID ELECTRICAL SHOCK: Check that the electric circuit is adequately protected and that it

corresponds with the power, voltage and frequency of the motor. Check that there is a ground

connection, and a regulation differential switch upstream.

Ground the log splitter. Prevent body contact with grounded surfaces: pipes, radiators, ranges,

and refrigerator enclosures.

Never open the push button box on the motor without first unplugging the machine from

the mains. Make sure your fingers do not touch the plug’s metal prongs when plugging or

unplugging the log splitter.

AVOID BURNS: Avoid contact with hot oil, exhaust fumes and hot surfaces. Do not touch the

engine or exhaust, these parts get extremely hot from operation and remain hot for a time after

the unit is turned off. Allow the engine to cool before doing maintenance or adjustment.

PETROL ENGINE: DO NOT operate the log splitter in an enclosed area. The exhaust fumes

contain carbon monoxide an odourless and deadly gas. Operate this unit only in a well ventilated

area.

Always stop the engine before moving the machine. Do not alter or adjust any part of the

machine or engine that is sealed by the manufacturer or distributor. Always check before use,

as specified in the manufacturers handbook.

Symbol on

the machine