One can set the log capacity to 250mm, 330mm or 500mm by adjus-

ting the ram/push-plate stroke to the wedge and securing the new

position of the stop-plate using the special cotter pin.

The push-plate will then shift back as far as the new stop-plate positi-

on without ever reaching to maximum stroke.

Should you again require splitting to the maximum log capacity, re-

lease the star-knob and shift it to the right hand side.

Now the push-plate will perform travel back to the maxim ram exten-

sion stroke.

Tighten and secure the star-knob before getting back to work.

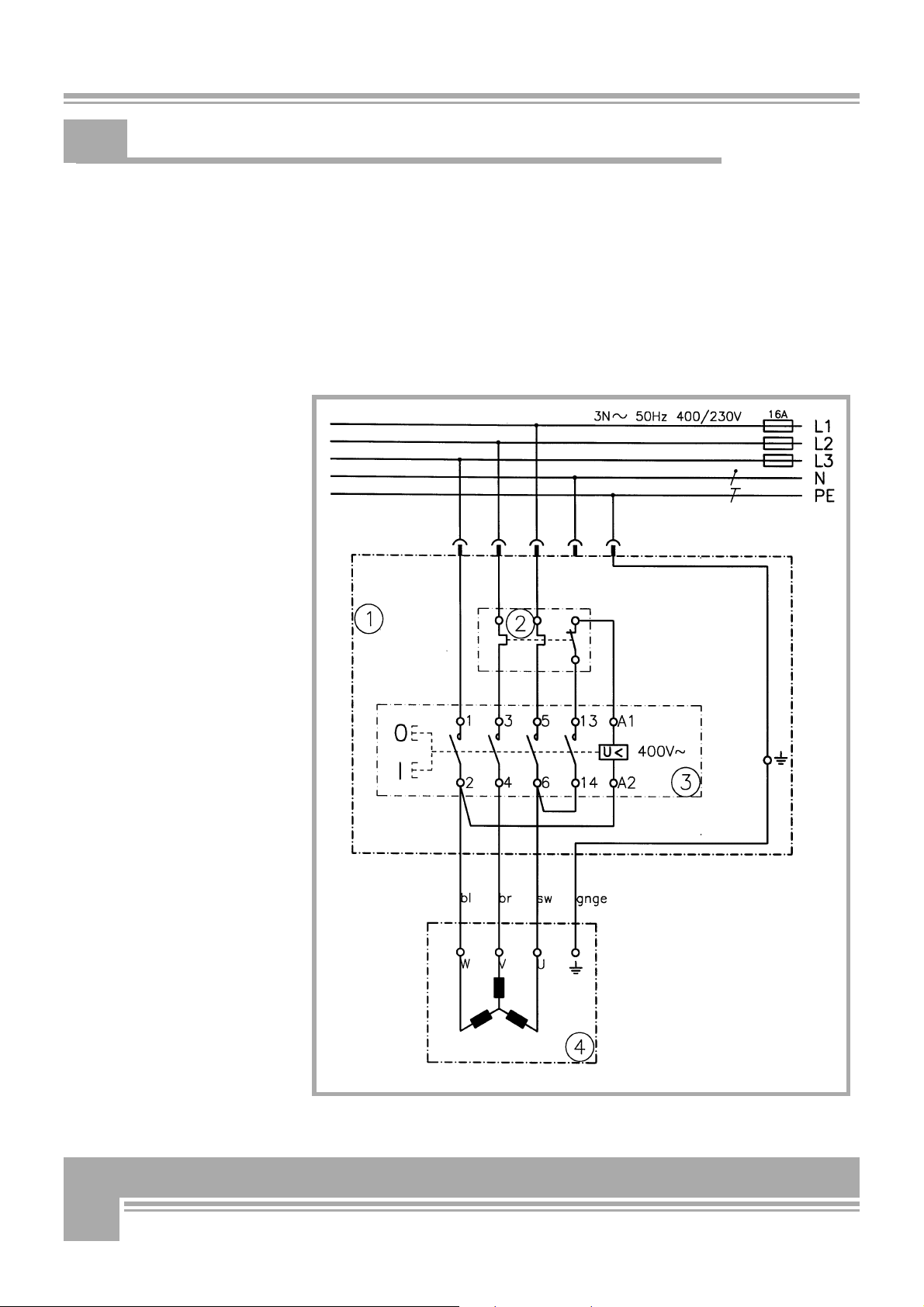

5.9 Hydraulic specifications

The splitter features an independant hydraulic plant with tank and

pump. The hydraulic tank is located on the chassis of the machine and

is always supplied by the manufacturer with a first hydraulic oil fill.

At cold temperatures the oil viscosity in the tank is relatively high.

For this reason you should refrain from cold start-up (and splitting) at

low ambient temperature in order to avoid damaging the hydraulic cir-

cuit and ancillary lines on the machine.

In order to assure top hydraulic performance of your processor even

at cold winter temperatures, make sure to first run the machine idle

for a few minutes so that it is fully cycled before start-up.

The splitter is hydraulically controlled by means a control valve

whose fine default-setting is performed by the manufacturer before

delivery. Do not alter these settings.

5.10 Operation

Start the gasoline motor and switch the splitter on.

Load a chunk centrally on the log-carriage.

Use wedge-lift levers to adjust the height of the splitting wedge de-

pendind on the size of your logs.

Now push both handles down at the same time to start the cycle and

engage the ram that will immediately start advancing to the wedge.

DO NOT RELEASE THE CONTROL HANDLES UNTIL THE CYCLE IS

COMPLETELY OVER AND THE LOG IS SPLIT.

Should any emergency arise and stopping be required,simply set both

control handles free from your grip. When doing this,the ram will im-

mediately travel all the way backto start position.

As soon as the log is completely split,release both control handles and

let the ram travel backto start position and be ready for a new cycle.

As soon as the log is completely split,release both control handles and

let the push-plate travel backto start position and be ready for a new

cycle after clearing the wood sticks from the extension table.