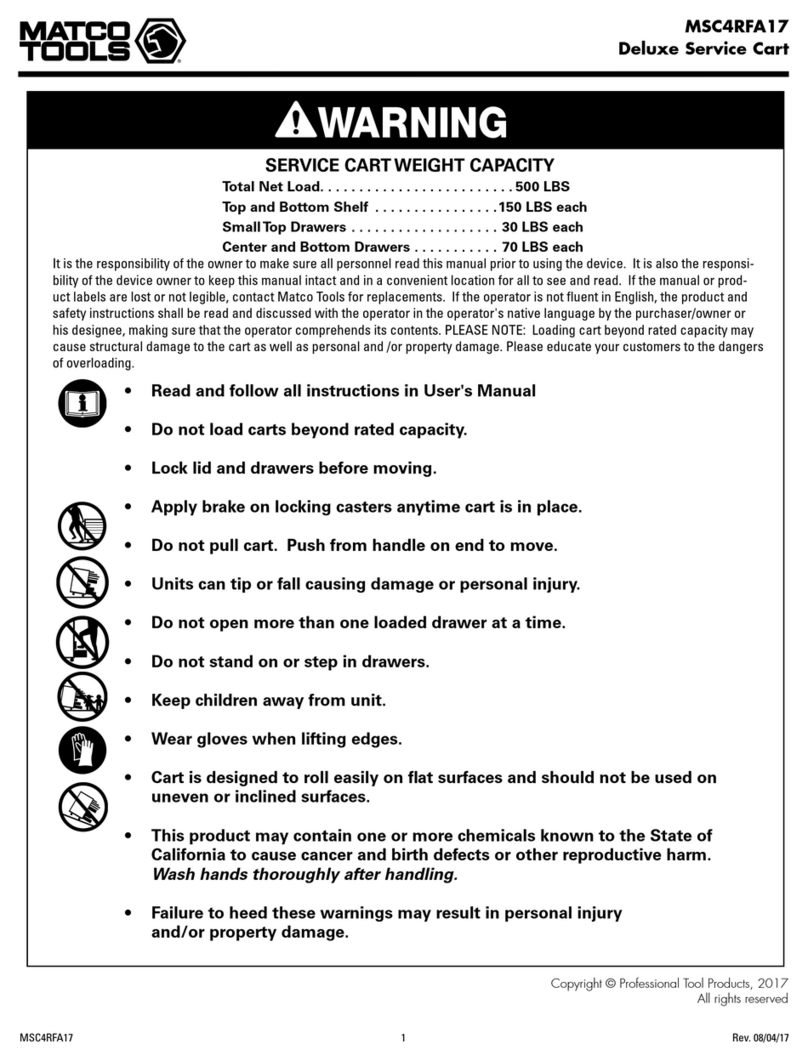

Forest-Master ZERO BARROW User manual

No Strain, Self Levelling Barrow

IMPORTANT: Read this manual fully before assembly

and use and observe all safety rules and operating

instructions

ZERO

BARROWPatented

Zero Barrow

Contents

Technical Specification 2

Exploded Diagram 3

Parts List 4

Assembly 5

Operation 11

Safety 14

Warranty 15

2

Technical Specification

Length 1400 mm 55 ins

Width 710 mm 28 ins

Height (excluding tub) 650 mm 26 ins

Weight (excluding tub) 14 kg 31 lbs

Wheel Size 4.80 / 4.00 x 8

Max Tyre Presure 2.0 bar 30 p.s.i.

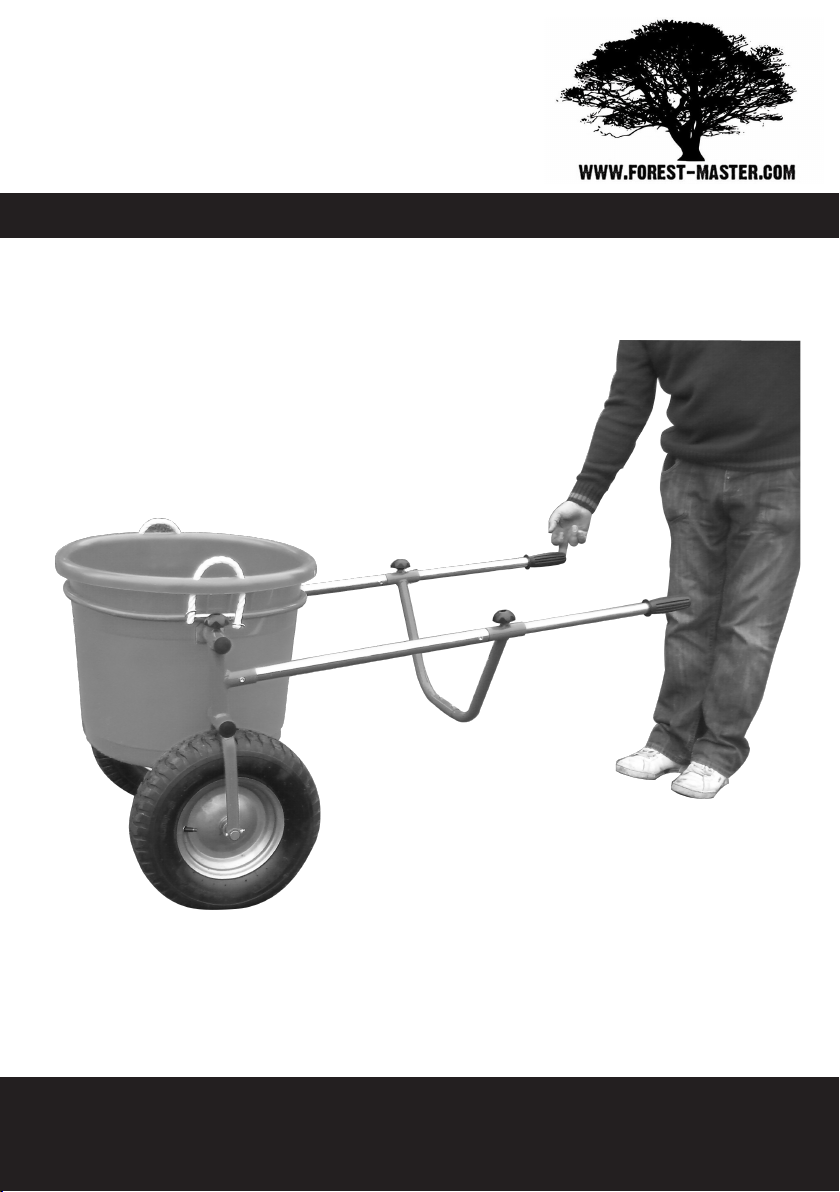

Zero Barrow 3

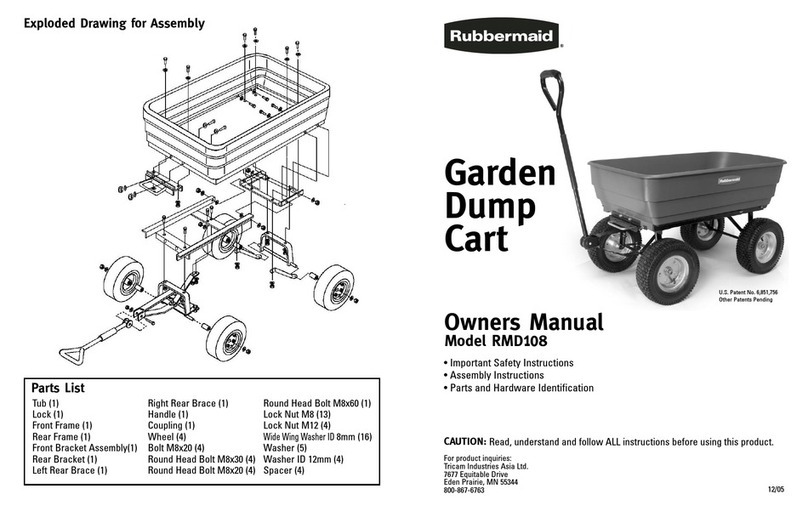

Exploded Diagram

1234

5

17

16 6

7

8

9

10

11

12

13

14

15

18

2

9

Zero Barrow

Parts List

4

Item Description Qty

1 30 mm handle tube 2

2 M6 x 35 cap head bolt 4

3 M8 hand wheel 4

4 25 mm handle tube 2

5 Hand grip 2

6 Brace 2

7 Sleeve 1

8 M6 flange nut 6

9 M6 x 40 cap head bolt 2

10 Fork 2

11 M12 axle bolt 2

12 Wheel 2

13 M12 plain washer 6

14 Axle 1

15 M6 x 5 grub screw 2

16 Lifting ring front part 1

17 Lifting ring rear part 1

18 Self tapping screw 2

Assembly

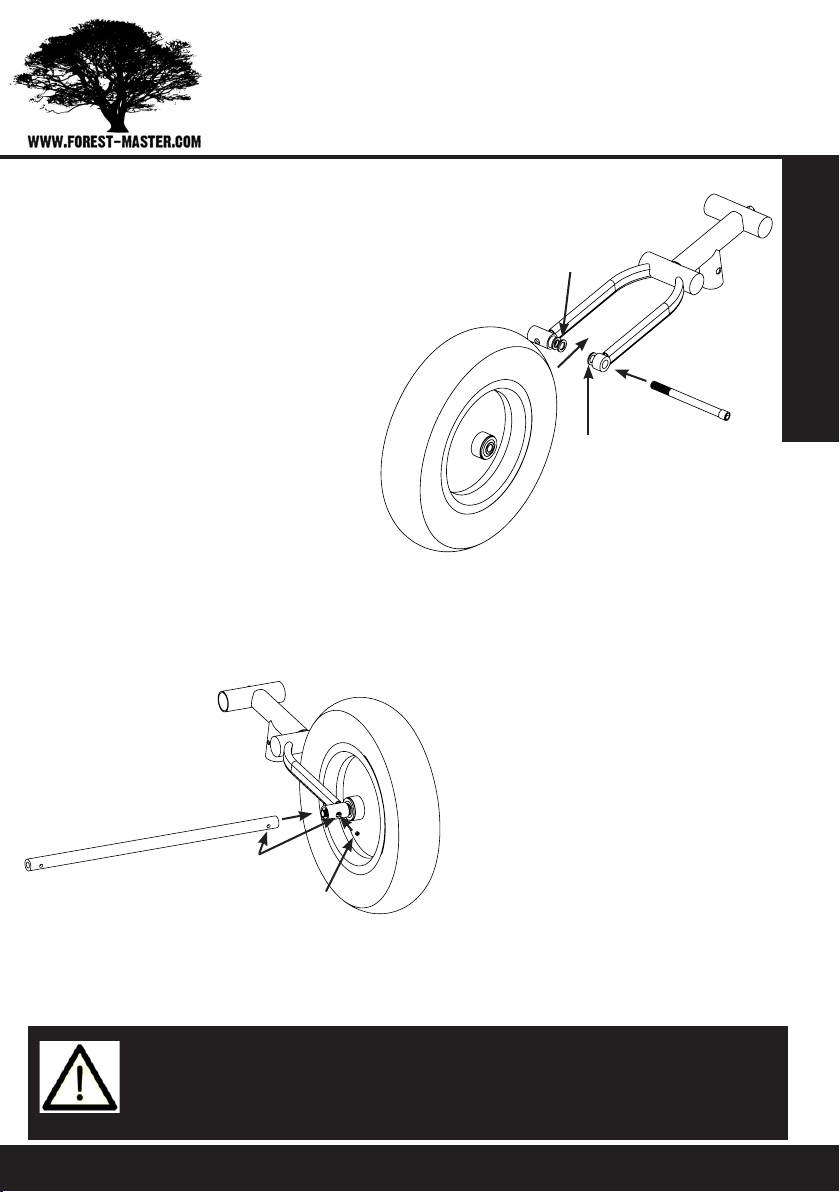

STEP 1:

Place a wheel (12) between

the legs of a fork (10). Insert

an axle bolt (11) through the

outside (narrower) guide and

through a plain washer (13)

placed between the outside

guide and the wheel. Locate

a second plain washer (13)

between the wheel and the

inside guide then insert

the axle bolt all the way

through. Note that the

outside guide is recessed so

that the bolt head is a flush

fit.

STEP 2:

Insert one end of the axle (14)

into the inner guide and locate

on the axle bolt. Screw in but

do not fully tighten the axle

bolt using an Allen key. Ensure

that the hole in the end of the

axle aligns with the hole in the

underside of the inner guide

then while holding the axle

steady, tighten the bolt.

PLAIN WASHER

PLAIN WASHER

ALIGN HOLES

GRUB SCREW

IMPORTANT: The barrow is supplied with 6 plain washers

as depending on the fit of the wheel, it may be necessary

to fit 2 washers on one side to space the wheel correctly.

Zero Barrow 5

Assembly

STEP 4:

Insert a 30 mm diameter han-

dle (1) into the locating tube

on the back of one of the forks.

Insert an M6 x 40 cap head

bolt (9) into the larger hole in

the outside of the locating tube

and through the locating tube

and the handle tube. Secure

with an M6 flange nut (8). Note

that the head of the cap head

bolt should sit inside the large

hole in the locating tube. See

note on Page 7.

STEP 3:

Repeat the procedure for the second wheel, ensuring that plain

washers are used each side of the wheel to correctly space it

and that the grub screw is correctly located and tightened.

LARGER HOLE

Zero Barrow6

Assembly

NOTE: One end of the 30 mm handle tube has two equal

diameter holes and the other has a large and small hole.

In Steps 4 & 5 you must insert the end with two equal di-

ameter holes into the mount on the fork. In addition, the

larger of the two holes at the other end should be orient-

ed to the outside of the handle.

STEP 5:

Repeat for the other 30 mm

handle tube and fork.

STEP 6

Insert each of the 25 mm

diameter handle tubes (4)

into a 30 mm diameter

handle and secure with

an M6 x 35 mm cap head

bolt (2) and an M6 nut (8).

Note that the head of the

bolt should sit inside the

larger hole in the 30 mm

handle tube.

Zero Barrow 7

Assembly

STEP 8:

Slide the brace top tubes

over both 25 mm handle

tubes so that the brace

rests against the ends of

the 30 mm handle tubes.

Insert an M8 handwheel (3)

into the nut on top of each

brace top tube and tighten

to secure the brace.

STEP 7:

Insert a brace (6) into

one end of the sleeve (7)

and secure with an M6

x 35 cap head bolt (2)

and M6 nut (8). Note the

larger diameter holes

in the sleeve should be

uppermost and the head

of the bolt should sit in

the large hole. Repeat for

the second brace.

LARGE HOLE

Zero Barrow8

Assembly

STEP 9:

If your barrow was purchased

without a tub or the tub was

packaged separately then it

will be necessary to join the

two halves of the lifting ring.

Insert the ends of the ring

half (17) into the connecting

tubes of ring half (16) and

secure with the self tapping

screws (18). The ends of the

half ring (17) are pre-drilled

for the screws.

STEP 10:

Insert one of the lifting

ring pivot tubes into one

of the fork top tubes then

compress the ring and

insert the opposite pivot

tube into the opposite

fork top tube.

Zero Barrow 9

Zero Barrow

Assembly

10

STEP 11:

Screw the two remaining M8

handwheels (3) into the nuts

on the top of the fork top

tubes but do not tighten.

STEP 12:

Push a handgrip (5) over

the end of each of the 25

mm handle tubes. Ensure

they are fully located on the

handles.

Zero Barrow 11

Operation

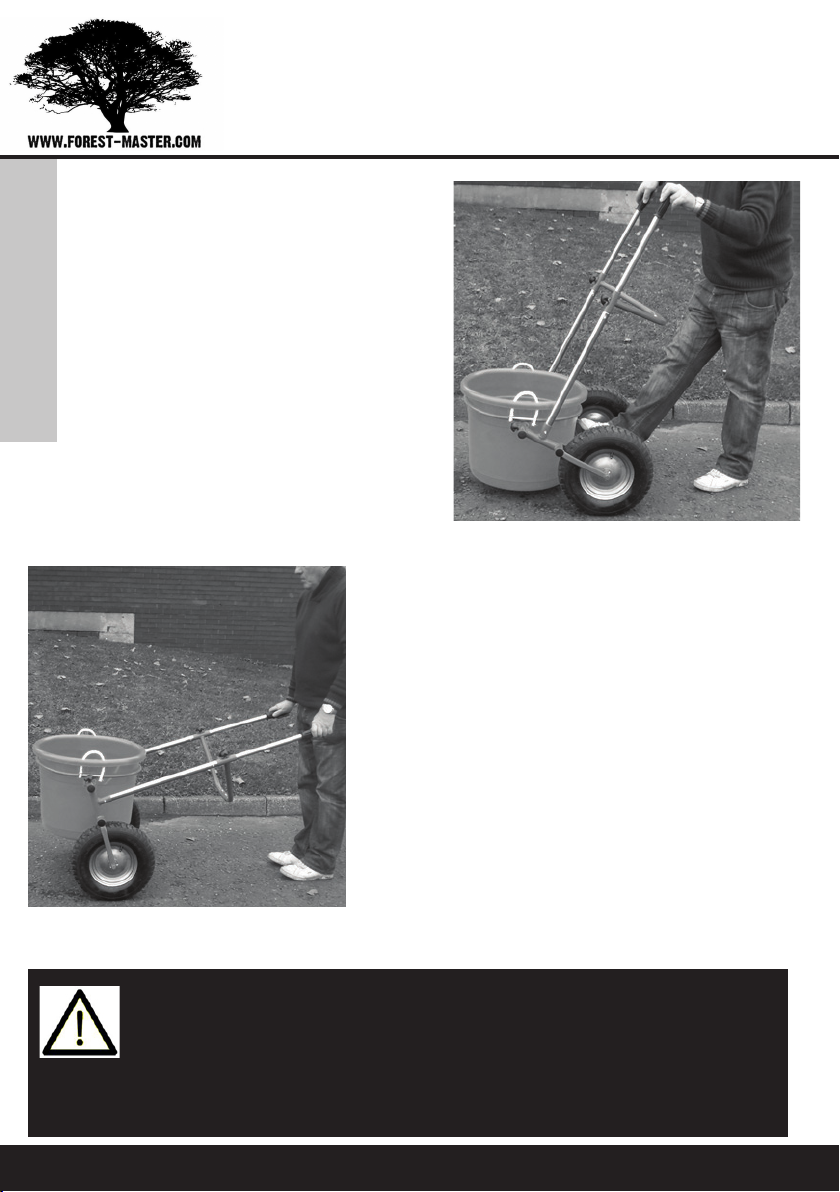

STEP 2:

Drag or lift the tub over the

front of the ring so it sits

within the ring.

STEP 1:

Position the barrow behind

the tub with the handles

tipped forward so that the

ring sits on the ground.

NOTE: The M8 handwheels on top of the forks should be

loose so that the lifting ring is free to pivot.

Lifting a tub

Operation

12 Zero Barrow

Step 3:

Place a foot on the axle and

pull back on the handles.

Step 4:

Lower the handles so that

the tub is over the axle.

NOTE: To lower a tub to the ground, place a foot on the

axle and lift the handles up and forward to lower the ring

to the ground. It is important to place a foot on the axle

to avoid the barrow moving backwards into the user.

To remove the tub simply lift or drag it clear of the ring.

Zero Barrow 13

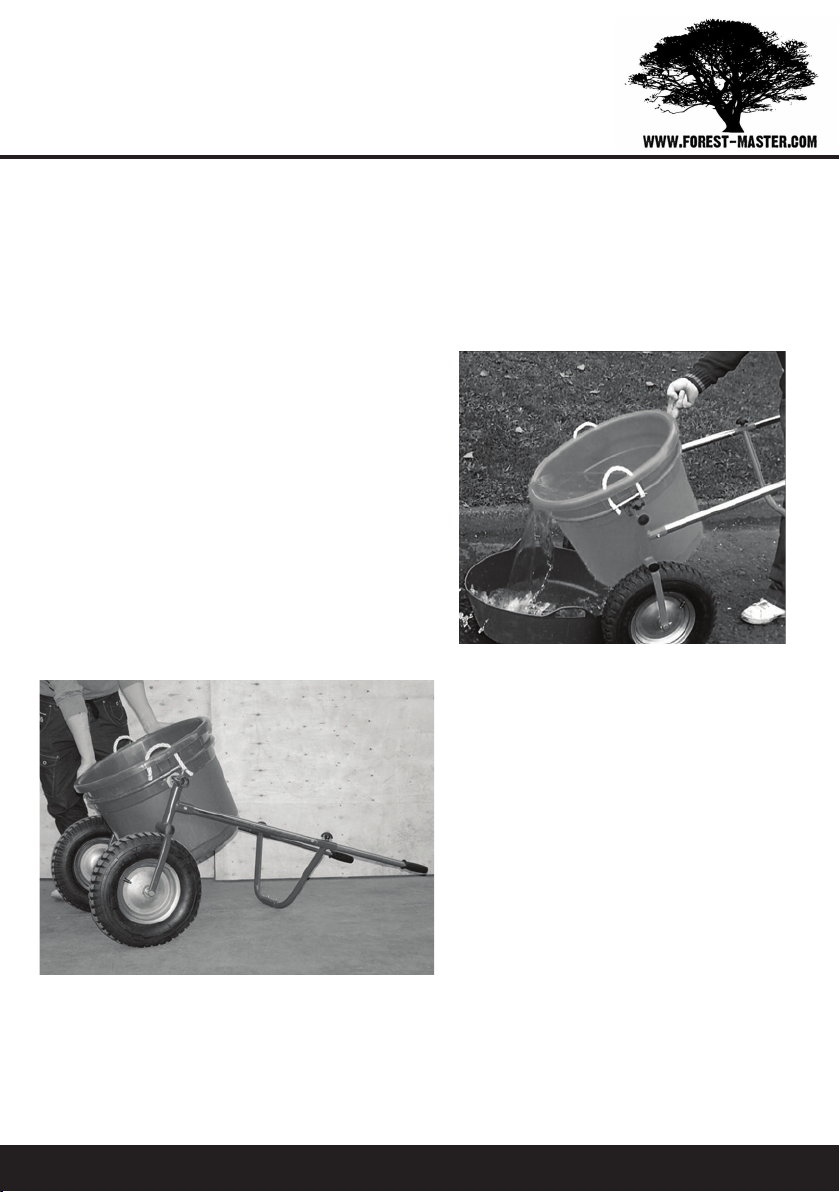

Emptying a Tub

It is possible to empty the tub without removing it from the

barrow, in a number of different ways depending on which is

most convenient to the user.

For lighter loads, the tub

can be tipped from behind

while still holding the bar-

row.

With heavier loads the

brace can be rested on the

ground and the tub tipped

from the side using two

hands.

It is also possible to tighten the hand wheels on top of the forks,

to stop the tub pivoting. The tub can then be emptied by raising

the handles as in a conventional barrow, this however is gener-

ally the least convenient.

Zero Barrow14

Safety

IMPORTANT SAFETY INFORMATION

Please read these instructions carefully. Note the safe oper-

ational requirements, warnings & cautions. Use the product

correctly and with care for the purpose for which it is intend-

ed. Failure to do so may cause damage and/or personal injury

and will invalidate the warranty. Please keep these instruc-

tions safe for future use.

Before using the barrow always check that all nuts and bolts

are secure and that the barrow is not damaged.

Check that the tyres are evenly inflated to a suitable pressure

for the load you are carrying. Do not exceed the maximum

pressure of 2.0 bar / 30 p.s.i.

Operation

Loading the Tub

Generally the tub is loaded on the ground ready positioned

within the ring or then lifted or dragged into the ring as

shown on Page 11. However the tub can be filled when already

raised in the ring. It is advisable when loading liquids this

way to lock the tub by tightening the handwheels however the

handwheels must be loosened before raising the handles.

Zero Barrow 15

Warranty

Warranty

This product carries a one (1) year limited warranty against

defects in workmanship and materials. Should this product

become defective within the stated warranty period, return it

to the store with proof of purchase, and it will be replaced or

repaired free of charge.

Should this product become defective, contact the store

where it was purchased and either replacement parts will be

issued, it will be repaired or it will be replaced free of charge.

IMPORTANT: NO RESPONSIBILITY IS ACCEPTED FOR

INCORRECT USE OF THIS PRODUCT.

Zero Barrow16

NOTE: It is our policy to continually improve products and as such

we reserve the right to alter data, specifications and component

parts without prior notice.

Manufactured under license for Forest Master Limited.

Registered Office:

Forest Master Ltd, Industry Road, Heaton, Newcastle Upon Tyne,

NE6 5XB, United Kingdom.

Tel: +44 191 2966939

Table of contents