EPIC CART E40L User manual

EPIC CART

Owner’s Manual

TABLE OF CONTENTS

SAFETY INFORMATION.......................................................................................1-6

OPERATIONAND SERVICE INFORMATION......................................................7-28

Before initial use..............................................................................................................................7

Key switch, direction selector, battery power display....................................................................8

Accelerator pedal, combination brake and park brake pedal, horn................................................9

Operating the vehicle...................................................................................................................... 10-11

Vehicle cleaning and care, battery replacement...............................................................................12-13

Prolonged Storage............................................................................................................................14

Battery charging...............................................................................................................................15

Troubleshooting, hydrometer...........................................................................................................16

Using A Hydrometer....................................................................................................................... 17

Battery maintenance .......................................................................................................................18-19

Inspection, Specific Gravity Testing.................................................................................................20

Open-Circuit Voltage Test...............................................................................................................21

Watering ...........................................................................................................................................21

Charging ...........................................................................................................................................22

Cleaning........................................................................................................................................... 23

Storage, battery terms explained........................................................................................................23-25

General Maintenance Items List....................................................................................................... 25-27

Common Trouble Shooting List........................................................................................................27-28.

SPECIFCIATION.......................................................................................................................... 29

SAFETY INFORMATION

Owner’s Manual

1

This manual has been designed to assist in maintaining the vehicle in accordance with procedures

developed by the manufacturer. Adherence to these procedures and troubleshooting tips will ensure the

best possible service from the product. To reduce the chance of personal injury or property damage, the

following must be carefully observed:

GENERAL

Good common sense and prudent driving practices do more to prevent accidents and injury than all of the

warnings and instructions combined. The manufacturer strongly suggests that all users and maintenance

personnel read this entire manual paying particular attention to the CAUTIONS and WARNINGS

contained therein.

EPIC CART reserves the right to make design changes without obligation to make these changes on units

previously sold and the information contained in this manual is subject to change without notice.

EPIC CART is not liable for errors in this manual or for incidental or consequential damages that result

from the use of the material in this manual.

These vehicles are designed and manufactured for off-road use. Some communities may permit these

vehicles to be operated on their streets on a limited basis and in accordance with local ordinances.

With electric powered vehicles, be sure that all electrical accessories are grounded directly to the battery (-) post.

Never use the chassis or body as a ground connection.

Refer to GENERAL SPECIFICATIONS for vehicle seating capacity.

Never modify the vehicle in any way that will alter the weight distribution of the vehicle, decrease

its stability, or increase the speed beyond the factory specification. Such modifications can cause

serious personal injury or death.

Vehicles that are capable of higher speeds must limit their speed to no more than the speed of other

vehicles when used in various environment. Additionally, speed should be further moderated by the

environmental conditions, terrain, and common sense.

GENERAL OPERATION

Always:

⚫

Use the vehicle in a responsible manner and maintain the vehicle in safe operating condition.

⚫

Read and observe all warnings and operation instruction labels affixed to the vehicle.

⚫

Follow all safety rules established in the area where the vehicle is being operated.

⚫

Reduce speed to compensate for poor terrain or conditions.

⚫

Apply service brake to control speed on steep grades.

SAFETY INFORMATION

Owner’s Manual

2

⚫

Maintain adequate distance between vehicles.

⚫

Reduce speed in wet areas.

⚫

Use extreme caution when approaching sharp or blind turns.

⚫

Use extreme caution when driving over loose terrain.

⚫

Use extreme caution in areas where pedestrians are present.

MAINTENANCE

Always:

⚫

Maintain the vehicle in accordance with the manufacturer’s periodic service schedule.

⚫

Ensure that repairs are performed by those that are trained and qualified to do so.

⚫

Follow the manufacturer’s maintenance procedures for the vehicle. Be sure to disable the vehicle before

performing any maintenance. Disabling includes removing the key from the key switch and removal of a

battery wire.

⚫

Insulated any tools used within the battery area in order to prevent sparks or battery explosion caused by

shorting the battery terminals or associated wiring. Remove the batteries or cover exposed terminals with

an insulating material.

⚫

Check the polarity of each battery terminal and be sure to rewire the batteries correctly.

⚫

Use specified replacement parts. Never use replacement parts of lesser quality.

⚫

Use recommended tools.

⚫

Determine those tools and procedures not specifically recommended by the manufacturer will not

compromise the safety of personnel nor jeopardize the safe operation of the vehicle.

⚫

Support the vehicle using wheel chocks and jack stands. Never get under a vehicle that is supported by a

jack. Lift the vehicle in accordance with the manufacturer’s instructions.

⚫

Maintain the vehicle in an area away from exposed flame or persons who are smoking.

⚫

Be aware that a vehicle that is not performing as designed is a potential hazard and must not be operated.

⚫

Test driving the vehicle after any repairs or maintenance. All tests must be conducted in a safe area that is

free of both vehicular and pedestrian traffic.

⚫

Replace damaged or missing warning, caution, or information labels.

⚫

Keep complete records of the maintenance history of the vehicle.

Use extreme caution and, if unsure as to the potential for injury, refer the repair or maintenance to a qualified

mechanic.

FOR THE USER

1.GENERALSAFETY PRACTICES

1.1 Introduction

Like other machines, EPIC CART can cause injury if improperly used or maintained. Part II contains

broad safety practices applicable to EPIC CART operations. Before operation, the user shall establish such

additional specific safety practices as may reasonably be required for safe operation.

1.2 Nameplates, Markings, Capacity, and Modifications

1.2.1 The user shall maintain in a legible condition all nameplates, warnings and instructions which are

supplied by the manufacturer.

SAFETY INFORMATION

Owner’s Manual

3

1.2.2 The user shall not perform any modification or addition which affects capacity or safe operation or make

any change not in accordance with the owner’s manual without the manufacturer’s prior written

authorization. Where authorized modifications have been made, the user shall ensure that capacity,

operation, warning and maintenance instruction plates, tags or decals are changed accordingly.

1.3 Changing and Charging Storage Batteries for Electric Personnel and Burden Carriers

1.3.1 The user shall require battery changing and charging facilities and procedures to be in accordance with

appropriate paragraphs.

1.3.2 The user shall periodically inspect facilities and review procedures to be certain that appropriate

paragraphs, are strictly complied with and shall familiarize carrier operators with it.

2. OPERATING SAFETYRULESAND PRACTICES

2.1 General

2.1.1 Safeguard the pedestrians at all times. Do not drive EPIC CART in a manner that would endanger

anyone.

2.1.2 Riding on the EPIC CART by persons other than the operator is authorized only on personnel seat

provided by the manufacturer.

2.1.3 When an EPIC CART is to be left unattended, stop it, apply the parking brake, stop the engine, or turn off

power, turn off the control or ignition circuit, and remove the key if provided. Block the wheels if

machine is on an incline.

2.1.4 Use only approved EPIC CART in hazardous locations, as defined in the appropriate safety standards.

2.1.5 Operators shall not add to, or modify, the EPIC CART.

2.2 Driving

2.2.1 Observe all traffic regulations, including authorized speed limits. Under normal traffic conditions keep to

the right. Maintain a safe distance, based on speed of travel, from a vehicle ahead; and keep the EPIC

CART under control at all times.

2.2.2 Do not pass another vehicle traveling in the same direction at intersections, blind spots, or at other

dangerous locations.

2.2.3 Keep a clear view of the path of travel, observe other traffic and personnel, and maintain a safe

clearance.

2.2.4 Slow down or stop, as conditions dictate, and activate the sound-producing warning device at cross

aisles and when visibility is obstructed at other locations.

2.2.5 Ascend or descend grades slowly.

2.2.6 Under all driving conditions the EPIC CART shall be operated at a speed that will permit it to be brought

to a stop in a safe manner.

2.2.7 Do not indulge in dangerous activities, such as stunt driving or horseplay.

2.2.8 Avoid running over loose objects, potholes, and bumps.

2.2.9 To negotiate turns, reduce speed to improve stability, then turn hand steering wheel or tiller in a smooth,

sweeping motion.

2.2.10 It is recommended that the slope of the road does not exceed 25%, the top of the slope and the slope

must be smooth and transitioned to prevent the bottom of the vehicle and the pavement collision. When the

slope is more than 25%, the signage is recommended.At this point, you must drive the vehicle very carefully.

SAFETY INFORMATION

Owner’s Manual

4

2.3 Loading

2.3.1 At the beginning of each shift during which the EPIC CART will be used, the operator shall check the

EPIC CART condition and inspect the tires, warning devices, lights, battery, speed and directional

controllers, brakes, and steering mechanism. If the EPIC CART is found to be in need of repair or in

any way unsafe, the matter shall be reported immediately to the designated authority and the EPIC

CART shall not be operated until it has been restored to sage operating condition.

2.3.2 Do not make repairs or adjustments unless specifically authorized to do so.

2.3.3 Do not operate an EPIC CART with a leak in the battery.

2.3.4 Do not use open flames for checking electrolyte level in storage battery.

3. MAINTENANCE PRACTICES

3.1 Introduction

3.1.1 Carriers may become hazardous if maintenance is neglected. Therefore, maintenance facilities trained

personnel, and procedures shall be providing such facilities may be on or off the premises.

3.2 Maintenance Procedures

3.2.1 Maintenance and inspection of all EPIC CART shall be performed in conformance with the

manufacturer’s recommendations and the following practices.

(a) A scheduled preventive maintenance, lubrication, and inspection system shall be followed.

(b) Only qualified and authorized personnel shall be permitted to maintain, repair, adjust, and inspect

carriers.

(c) Block chassis before working underneath it.

(d) Operation to check performance of the EPIC CART shall be conducted in an authorized area

where safe clearance exists.

(e) Before commencing operation of the EPIC CART, follow the manufacturer’s instructions and

recommended procedures.

(f) Avoid fire hazards and have fire protection equipment present in the work area. Do not use an

open flame to check level or leakage of battery electrolyte.

(g) Properly ventilate the work area.

(h) Brakes, steering mechanisms, speed and directional control mechanisms, warning devices, lights,

governors, guards, and safety devices shall be inspected regularly and maintained in a safe

operating condition.

(i) Special EPIC CART or devices designed and approved for hazardous area operation shall be

inspected to ensure that maintenance preserves the original approved safe operating features.

(j) Carriers shall be kept in a clean condition to minimize fire hazards and facilitate detection of loose

or defective parts.

(k) Modification and additions which affect capacity and safe machine operation shall not be

performed by the customer or user without manufacturer’s prior written authorization; where

authorized modifications have been made, the user shall ensure that capacity, operation, warning,

and maintenance instruction plates, tags, or decals are changed accordingly.

(l) Care shall be taken to ensure that all replacement parts are interchangeable with the original parts

and of a quality at least equal to that provided in the original equipment.

SAFETY INFORMATION

Owner’s Manual

5

MAINTENANCEAND OPERATIONS

1. GENERALSAFETY PRACTICES

1.1 Introduction

Like other machines, EPIC CART can cause injury if improperly used or maintained. This section contains

broad safety practices recommended for safe EPIC CART operations. Before operation, the controlling party

should establish such additional specific safety practices as may be reasonably required for safe operations.

Experience has shown that EPIC CART which comply with the provisions stated in part II of this standard are

safe when properly operated in accordance with the safety and operation is enhanced when the EPIC CART is

operated within a specific set of operation instructions, safety rules and practices established to meet actual

operating terrain and conditions.

The safety information contained in part II is intended to provide the controlling party with basic safety

information and to encourage the controlling party to implement an EPIC CART safety program.

It is suggested and recommended that Part II be reprinted in the EPIC CART manufacturer’s operation and

service manuals to encourage safe operations and practices at the controlling party’s facility.

1.2 Safety Survey

The controlling party shall perform a safety survey periodically, and as conditions warrant to their premises, to

identify areas where EPIC CART should not be operated and to identify possible hazards.

1.2.1 Wet and Loose Terrain

Wet grassy areas and loose terrain may cause an EPIC CART to lose traction and may affect stability. Wet areas

and loose terrain shall be chained or roped off to prevent EPIC CART operations or be identified by a suitable

warning not to operate EPIC CART in this area due to wet and loose terrain.

1.2.2 Sharp Turns, Blind Corners, Bridge Approaches

Sharp turns, blind spots, bridge approaches and other potentially hazardous areas shall be either chained or

roped off to prevent EPIC CART operations or identified with a suitable warning to the operator of the nature

of the hazard and stating the proper precautions to be taken to avoid the hazard.

2. MAINTENANCE

2.1 Introduction

2.1.1 EPIC CARTs may become hazardous if maintenance is neglected or improperly performed. Therefore,

maintenance facilities, trained personnel, and procedures in accordance with the manufacturer’s

recommendations should be provided by the controlling party.

2.2 Preventive Maintenance

A regularly scheduled inspection and preventive maintenance program in accordance with the manufacturer’s

recommendations should be established.

2.2.1 Personnel

Only qualified, trained, and authorized personnel shall be permitted to inspect, adjust, and maintain EPIC

CART.

2.2.2 Parts and materials

Only manufacturer’s recommended replacement parts and materials shall be used.

SAFETY INFORMATION

Owner’s Manual

6

2.2.3 Ventilation

Maintenance and storage areas shall be properly ventilated to avoid fire hazards in accordance with applicable

fire codes and ordinances.

2.2.4 Maintenance Safety Procedures

All maintenance shall be performed in accordance with the manufacturer’s recommended safety procedures as

outlined in the manufacturer’s operation and service manuals. The following list of recommended safety

procedures are general in nature and in no way supersede the manufacturer’s specific instructions.

2.2.4.1 Following manufacturer’s instructions for immobilizing EPIC CART before beginning any

maintenance.

2.2.4.2 Block chassis before working underneath EPIC CART.

2.2.4.3 Before performing any maintenance on an electric EPIC CART, disable the electrical system in

accordance with the manufacturer’s instructions.

2.2.4.4 Use only properly insulated tools when working on electrically powered EPIC CART or around

batteries.

2.2.4.5 The controlling party shall not perform any modification or addition which affects capacity or safe

operation or make any change not in accordance with owner’s manual without the manufacturer’s

prior written authorization. Where authorized modifications have been made, the controlling party

shall ensure that capacity, operation, warning and maintenance instruction plates, tags or decals are

changed accordingly.

3. OPERATING SAFETY RULESAND PRACTICES

3.1 Operator Qualifications

3.1.1 Only authorized persons shall be allowed to operate EPIC CART, it is recommended that no persons

be allowed to operate EPIC CART except those persons who possess a valid motor vehicle driver’s

license.

3.1.2 The controlling party shall display the operation and safety instructions as recommended by the EPIC

CART manufacturers and the safety rules in a conspicuous place near the EPIC CART rental area or

EPIC CART pick-up area. It is also recommended, as with all motor vehicles, that the warning “Do not

operate EPIC CART when under the influence of alcohol or drugs.” Be posted in a conspicuous

location.

OPERATION INFORMATION

Owner’s Manual

7

OPERATION INSTRUCTIONS

Read all of manual to become thoroughly familiar with this vehicle. Pay particular attention to all Notes,

Cautions and Warnings

Thank you for purchasing this vehicle. Before driving the vehicle, we ask you to spend some time reading this

Owner’s Manual. This guide contains the information that will assist you in maintaining this exceptionally

reliable vehicle.

This vehicle has been designed and manufactured as a “World Vehicle.” Some countries have individual

requirements to comply with their specifications: therefore, some sections may not apply in your country.

Most of the service procedures in this guide can be accomplished using common automotive hand tools.

BEFORE INITIAL USE

Read, understand, and follow the safety label on the dashboard panel. Be sure you understand how to operate the

vehicle, its equipment and how to use it safely. Maintaining superior performance depends to a large extent on

the operator.

Before a new vehicle is put into operation, the items shown in the INITIAL SERVICE CHART must be

performed (Ref Fig.1).

Vehicle batteries must be fully charged before initial use. Check for correct tire inflation. See GENERAL

SPECIFICARIONS.

Determine and record braking distance required to stop vehicle for future brake performance tests.

Remove the protective clear plastic, which protect the seat bottom and back rest during shipping, before placing

the vehicle in service.

ITEM

SERVICEOPERATION

Batteries

Charge batteries

Seats

Remove protective plastic covering

Brakes

Check operation and adjust if necessary

Establish acceptable stopping distance

Tires

Check air pressure (see SPECIFICATIONS)

On Board Charger

-

Fig.1 Initial Service Chart

WARNING To prevent overheating that may cause severe damage to the charger and create the

potential for fire, do not block or obstruct the airways.

OPERATION INFORMATION

Owner’s Manual

8

Fig. 2

The On-Board chargers do come with the vehicle and are located under the seat to prevent damage from the elements.

CONTROLSAND INDICATORS

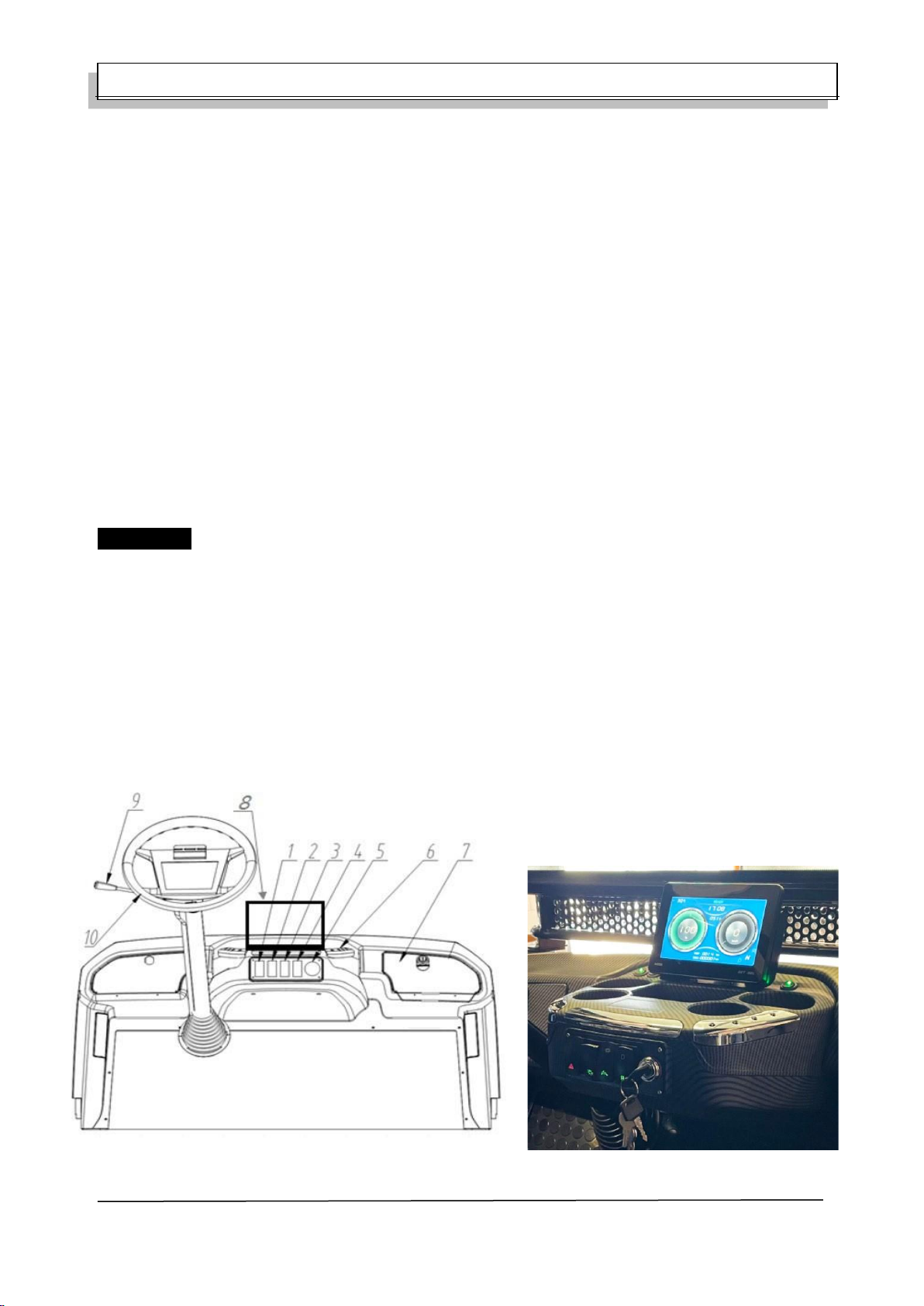

Vehicle controls and indicators consist of:

1.Hazard Switch Button; 2. Headlights Switch Button.

3. Hi/Low Speed Switch Button 4. Forward/Reverse Switch

5. Ignition Switch 6. Tee Holder

7. Locked Door Panel 8. 7-inch speedometers

9. Combination Switch 10. Steering wheel

KEY SWITCH

Located on the dash panel, this switch enables the basic electrical system of the vehicle to be turned on and off

by turning the key. To prevent inadvertent operation of the vehicle when left unattended, the key should be

turned to the ‘OFF’ position and removed (Ref Fig 2).

DIRECTION SELECTOR

WARNING

To prevent loss of control, do not move direction selector while the vehicle is in motion. Moving the

selector will result in a sudden slowing of the vehicle and the beeping of a warning device.

Located on the dash panel, this switch permits the selection of either ‘FWD’ (forward), ‘REV’(reverse) or neutral

(the position between forward and reverse). Vehicle should be left in neutral when unattended (Ref Fig.2).

BATTERYPOWER DISPLAY

Located on the dash, the speedometer indicates the amount of usable power in the batteries (Ref Fig.2).

it’s a Multifunction speedo meters, integrated with back-up camera

OPERATION INFORMATION

Owner’s Manual

9

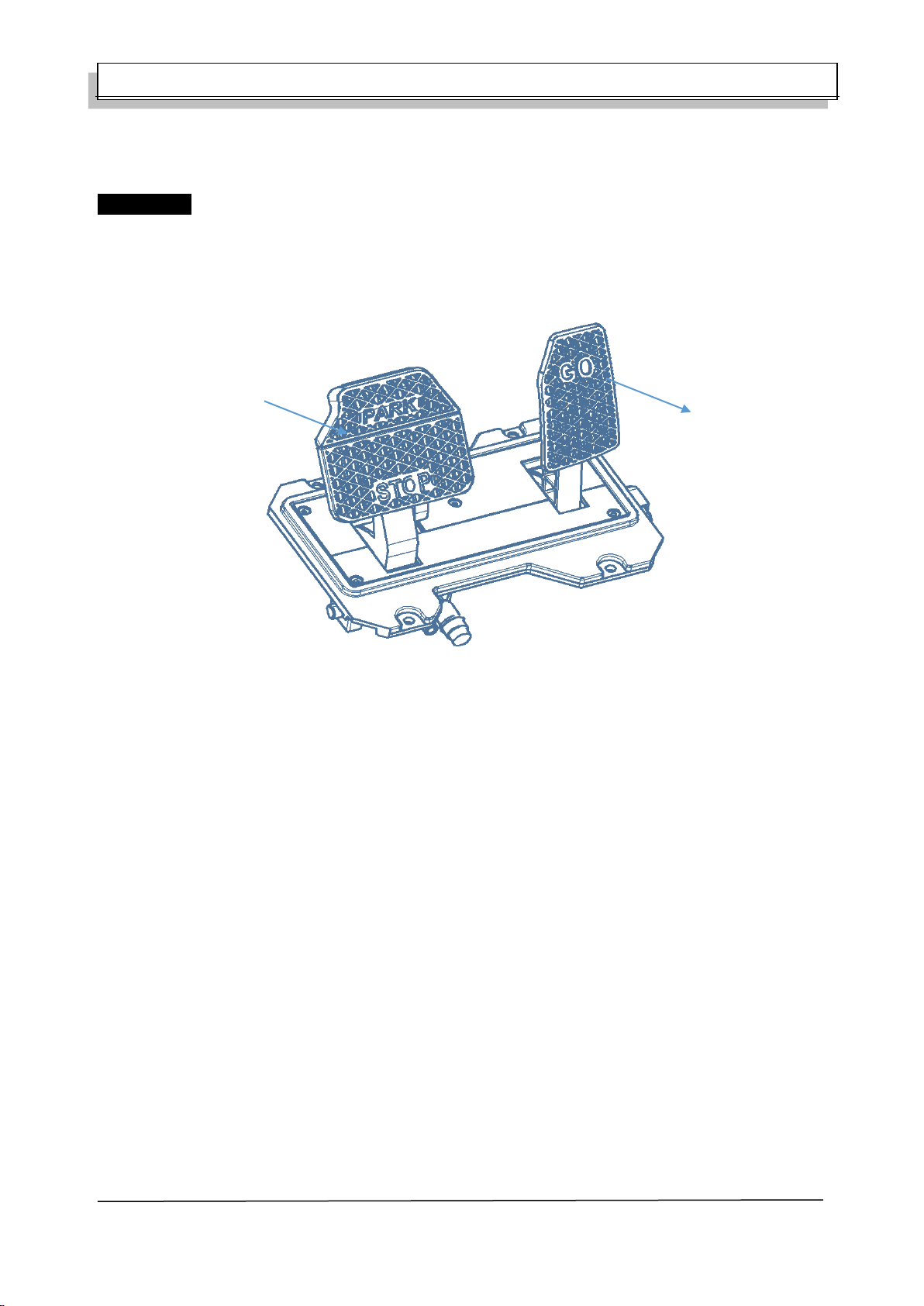

ACCELERATOR PEDAL

WARNING Unintentional movement of the accelerator pedal will release the park brake and may cause

the vehicle to move which could result in severe injury or death.

With the key switch ‘ON,’ depressing the accelerator pedal starts the motor. When the pedal is released, the

motor will stop (Ref Fig 3). To stop the vehicle more quickly, depress the service brake.

Acceleration pedal

Fig 3

If key switch is ‘ON” and park brake is set, depressing the accelerator inadvertently will release the park brake

and will cause the vehicle to move which could cause severe injury or death.

Depressing the accelerator pedal will release the park brake if it is engaged. This is a feature to assure the vehicle

is not driven with the park brake engaged. Depressing the accelerator pedal is not the preferred method of

releasing the park brake.

NOTE: Depressing the lower section of the brake pedals the preferred method of releasing the park brake to

assure the longest service life of brake components.

Parking Brake

The brake pedal (Fig 3) does not have parking brake function, EPIC Cart use EMB for parking, its operated by

the magnetic system to control the brake pad.

There is one EMB Switch located on the controller box, the EMB is 3-way switch.

“ON,” stands for the cart at normal running status, when you release the accelerator pedal or stop on the hill, the

EMB will be engage, the cart will stop

“OFF,” stands for the cart park in the garage and whole cart no power consumption, just keep very little current

to the EMB, so cart will not roll down in the garage.

“Manual EMB,” stands for the cart will be able to be towed, the EMB has release.

Brake pedal

OPERATION INFORMATION

Owner’s Manual

10

HORN

The horn is operated by pushing the horn button located on (Ref Fig.4)

Fig. 4

OPERATING THE VEHICLE

CAUTION Improper use of the vehicle or the lack of proper maintenance may result in damage or

decreased performance.

Read and understand the following warnings before attempting to operate the vehicle.

WARNING to reduce the possibility of severe injury or death resulting from loss of vehicle control, the

following warnings must be observed:

When driving vehicle, consider the terrain, traffic conditions and the environmental factors which effect the

terrain and the ability to control the vehicle.

Use extra care and reduced speed when driving on poor surfaces, such as loose dirt, wet grass, gravel, etc.

Stay in designated areas and avoid extremely rough terrain.

Maintain a safe speed when driving downhill. Use service brake to control speed when traveling down an incline.

A sudden stop or change of direction may result in loss of control.

Slow down before and during turns.All turns should be made at reduced speed.

OPERATION INFORMATION

Owner’s Manual

11

WARNING To reduce the possibility of severe injury or death resulting from improper vehicle operation,

the following warnings must be observed:

Refer to GENERALSPECIFICATIONS for seating capacity.

Depressing accelerator pedal will release foot operated park brake and may cause inadvertent vehicle movement.

Turn the key to the ‘OFF’ position whenever the vehicle is parked.

To prevent inadvertent movement when the vehicle is to be left unattended, engage the park brake, move

direction selector to forward position, turn key to ‘OFF’ position and remove key.

Make sure that the direction selector is in correct position before attempting to start the vehicle.

Always bring the vehicle to a complete stop before shifting the direction selector.

Do not take vehicle out of ‘gear’ while in motion (coast).

Check the area behind the vehicle before operating in reverse.

All occupants must be seated. Keep entire body inside vehicle and hold on while vehicle is in motion.

The lifespan, the reliability of the work and the economic efficiency of the use of EPIC Lifted Cart,all depend to a

large extent on the running-in at the initial stage of use. The running-in mileage is 800 kilometers. If conditions

permit, it is best to extend it to 1500Km.

The new cart must go through a running-in before it is officially used. During the running-in period, it should run

at a lower speed. Generally, it cannot be fully loaded and absolutely cannot be operated with overload. The

purpose of running-in is to allow the parts and components to performa stage of running-in, improve its surface

quality and matching accuracy, and avoid early wear and tear of the vehicle.

The following regulations shall be complied with during the integration period

●Avoid fast starting, rapid growth and unnecessary tight braking.

●During the running-in period, the vehicle speed must be strictly controlled within 20Km/h.

●Frequently check whether the battery, electric control, and motor connection wires are loose due to heat.

Frequently check the temperature of the reducer, rear axle, wheel hub and brake drum. If there is overheating

(greater than 60°C), check and eliminate the fault.

●When the running-in mileage reaches 500Km, check the tightness of the steering system, front

suspension and wheel nuts and tighten if necessary. After the running-in period, the user should replace the

lubricating oil and rear axle gear oil during the shifting period.

●During the running-in period, the battery cannot be deeply discharged. After the running-in

period expires, the battery is not allowed to be over-discharged. Over-discharge will quickly

damage the battery.

●If the vehicle mileage is less than 60% of the rated continuous mileage when the vehicle is used for the

first time, please stop using the vehicle and notify the company's after-sales department as soon as possible to

find out the reason. The vehicle is used for more than one month,and the company is no longer responsible for

the compensation of the entire battery pack. Within half a year, due to battery manufacturing quality problems,

the company promises quality warrantyfor damaged batteries.

OPERATION INFORMATION

Owner’s Manual

12

VEHICLE CLEANING AND CARE

VECHILE CLEANING

WARNING To reduce the possibility of severe injury or vehicle damage, read and understand all

instructions supplied by manufacturer of pressure washer.

CAUTION When pressure washing exterior of vehicle, do not use pressure in excess of standard

requirement. To reduce the possibility of cosmetic damage, do not use any abrasive or reactive solvents

It is important that proper techniques and cleaning materials be used. Using excessive water pressure may cause

severe injury to operator or bystander, damage to seals, plastics, seat material, body finish or electrical system.

Do not use pressure in excess of standard requirement to wash exterior of vehicle.

Clean windshield with lots of water and a clean cloth. Minor scratches may be removed using a commercial

plastic polish.

Normal cleaning of vinyl seats and plastic or rubber trim requires the use of a mild soap solution applied with a

sponge or soft brush and wipe with a damp cloth.

The painted surfaces of the vehicle provide attractive appearance and durable protection. Frequent washing with

lukewarm or cold water and mild detergent is required to preserve the painted surface.

Occasional cleaning and waxing with non-abrasive products designed for ‘clear coat’ automotive finishes will

enhance the appearance and durability of the painted surfaces.

Corrosive materials used as fertilizers or for dust control can collect on the underbody of the vehicle. These

materials will cause corrosion of underbody parts unless flushed occasionally with plain water. Thoroughly clean

any areas where mud or other debris can collect. Sediment packed in closed areas should be loosened to ease its

removal, taking care not to chip or otherwise damage paint.

Lubrication maintenance

●The brake fluid of electric vehicles is checked once a month, and if there is a shortage of fuel, it must be

added in time (the lack of fuel will affect driving safety).

●Grease for the front wheel hub, front wheel bearing, brake pedal linkage, and steering system will be refilled

once next year. The oil product model 3# general lithium-based grease. The transmission gear oil is replaced

once a year. Users can choose gear oils with different viscosity levelsaccording to the atmospheric temperature

in the region.

GL-4 90 (used in southern or northern summer) GL-80W/90 (severe cold area or northern winter, -35℃or

below)

OPERATION INFORMATION

Owner’s Manual

13

●Change the gear oil once a year for the rear axle. The oil model is GL-5 90 (used in summer in the south or

north) or GL-5 80W/90 (in severe cold areas or winter in the north, -35℃ or below) gear oil. It is 1.2 liters.

When replacing, first unscrew the oil drain plug, drain the gear oil, clean, and install the oil drain plug, and then

add new gear oil from the filling hole.

Battery Replacement

Remove battery hold downs and cables. Lift batteries out with a commercially available lifting device.

If the batteries have been cleaned and any acid in the battery rack area neutralized as recommended, no corrosion

to the battery racks or surrounding area should be present. Any corrosion found should be immediately removed

with a putty knife and a wire brush. The area should be washed with a solution of sodium bicarbonate (baking

soda) and water and thoroughly dried before priming and painting with a corrosion resistant paint.

The batteries should be placed into the battery racks and the battery hold downs tightened to 45 - 55 in. lbs. (5 - 6

Nm) torque, to prevent movement but not tight enough to cause distortion of the battery cases.

Inspect all wires and terminals. Clean any corrosion from the battery terminals or the wire terminals with a

solution of sodium bicarbonate (baking soda) and brush clean if required.

WARNING To prevent battery explosion that could result in severe personal injury or death, extreme

care must be used with aerosol containers of battery terminal protectant. Insulate the metal container to

prevent the metal can from contacting battery terminals which could result in an explosion.

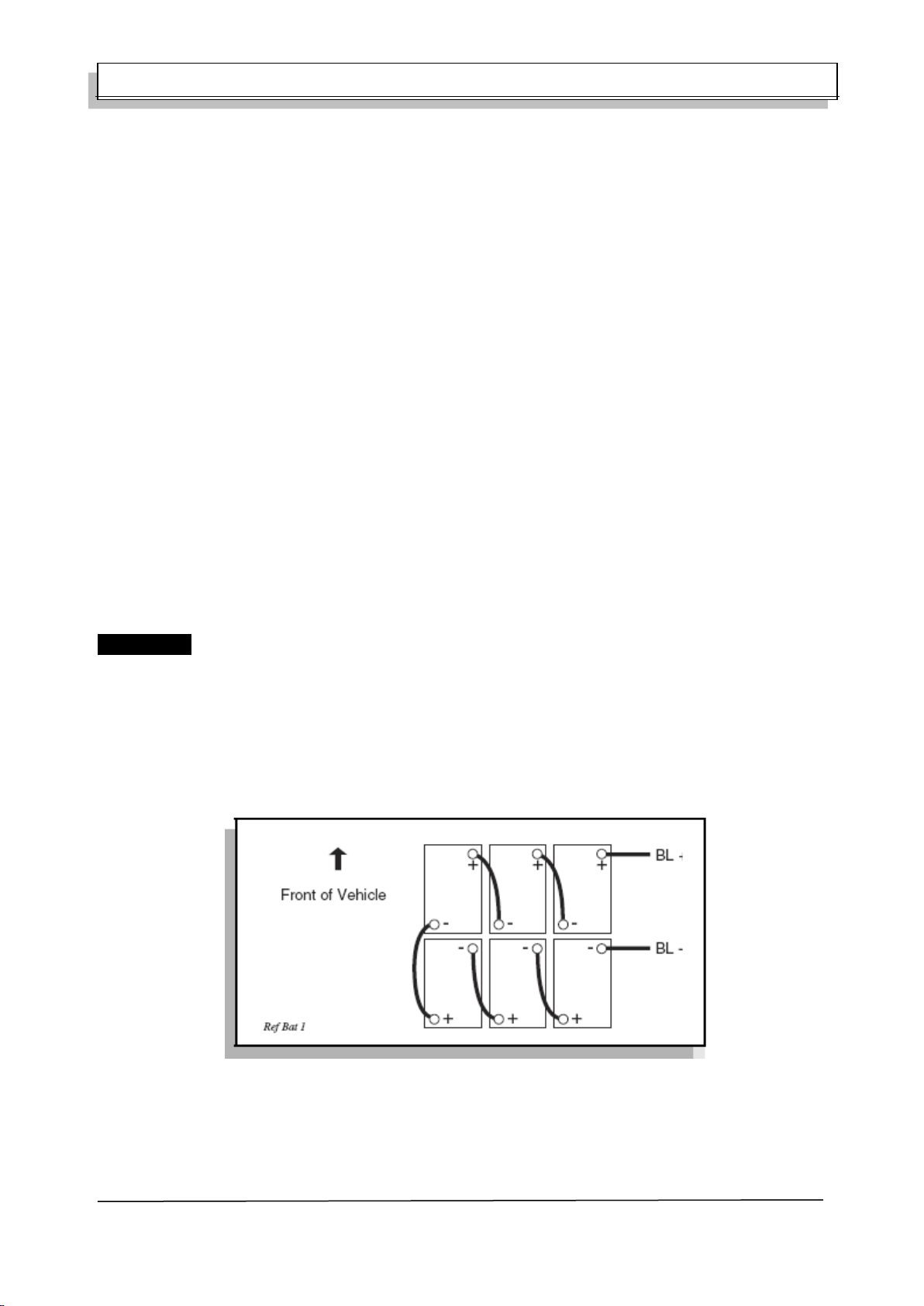

Use care to connect the battery wires as shown (Ref Fig. 5). Tighten the battery post hardware to 50 70 in. lbs. (6

-8 Nm) torque. Protect the battery terminals and battery wire terminals with a commercially available protective

coating.

Fig.5

OPERATION INFORMATION

Owner’s Manual

14

Prolonged Storage

CAUTION Battery charger, controller and other electronic devices need to be disconnected since they

will contribute to the premature discharge of batteries.

During periods of storage, the batteries will need attention to keep them maintained and prevent discharge.

In high temperatures the chemical reaction is faster, while low temperatures cause the chemical reaction to slow

down. A vehicle that is stored at 90° F (32° C) will lose .002 of specific gravity each day. If a fully charged

battery has a specific gravity of 1.275, and the battery is allowed to sit unused, it will become partially

discharged. When it reaches 1.240, which it will do in less than twenty days, it should be recharged. If a battery

is left in a discharged state, sulfating takes place on and within the plates. This condition is not reversible and

will cause permanent damage to the battery. In order to prevent damage, the battery should be recharged. A

hydrometer can be used to determine the specific gravity and therefore the state of charge of a battery.

In winter conditions, the battery must be fully charged to prevent the possibility of freezing (Ref Fig. 29 on page

23). A fully charged battery will not freeze in temperatures above -75° F (-60° C). Although the chemical

reaction is slowed in cold temperatures, the battery must be stored fully charged, and disconnected from any

circuit that could discharge the battery. For portable chargers, disconnect the charging plug from the vehicle

receptacle. The batteries must be cleaned, and all deposits neutralized and removed from the battery case to

prevent self-discharge. The batteries should be tested or recharged at thirty-day minimum intervals.

BATTERYCHARGING

The battery charger is designed to fully charge the battery set. If the batteries are severely deep cycled, some

automatic battery chargers contain an electronic module

that may not activate, and the battery charger will not function. Automatic chargers will determine the correct

duration of charge to the battery set and will shut off when the battery set is fully charged. Always refer to the

instructions of the specific charger used.

Before charging, the following should be observed:

CAUTION Do not overfill batteries. The charging cycle will expel electrolyte and result in component

damage.

•The electrolyte level in all cells must be at the recommended level and cover the plates.

OPERATION INFORMATION

Owner’s Manual

15

NOTE

Fig. 6

⚫The charging must take place in an area that is well ventilated and capable of removing the hydrogen gas

that is generated by the charging process. Aminimum of five air exchanges per hour is recommended

⚫The charging connector components are in good condition and free from dirt or debris.

⚫The charger connector is fully inserted into the vehicle receptacle.

⚫The charger connector/cord set is protected from damage and is located in an area to prevent injury that may

result from personnel running over or tripping over the cord set.

⚫The charger is automatically turned off during the connect/disconnect cycle and therefore no electrical arc is

generated at the DC plug/receptacle contacts.

In our chargers, there is a jiggle switch inside charger receptacle. The switch is part of the interlock

system that prevents the vehicle from being driven when the charger plug is inserted in the vehicle charging

receptacle. (Fig 7)

Fig. 7

OPERATION INFORMATION

Owner’s Manual

16

TROUBLESHOOTING

In general, troubleshooting will be done for two distinct reasons. First, a battery that performs

poorly and is outside of the manufacturer’s specification should be identified in order to replace it

under the terms of the manufacturer’s warranty. Different manufacturers have different

requirements. Consult the battery manufacturer or a manufacturer representative for specific

requirements.

The second reason is to determine why a particular vehicle does not perform adequately.

Performance problems may result in a vehicle that runs slowly or in a vehicle that is unable to

operate for the time required.

A new battery must mature before it will develop its maximum capacity. Maturing may take up to

100 charge/discharge cycles. After the maturing phase, the older a battery gets, the lower the

capacity. The only way

to determine the capacity of a battery is to perform a load test using a discharge machine following

manufacturer’s recommendations.

A cost-effective way to identify a poorly performing battery is to use a hydrometer to identify a

battery in a set with a lower-than-normal specific gravity. Once the particular cell or cells that are

the problem are identified, the suspect battery can be removed and replaced. At this point there is

nothing that can be done to salvage the battery; however, the individual battery should be replaced

with a good battery of the same brand, type, and approximate age.

Hydrometer

A hydrometer is used to test the state of charge of a battery cell (Ref Fig. 8). This is performed by

measuring the density of the electrolyte, which is accomplished by measuring the specific gravity

of the electrolyte. The greater the concentration of sulfuric acid, the denser the electrolyte

becomes. The higher the density, the higher the state of charge.

WARNING To prevent battery explosion that could result in severe personal injury or

death, neverinsert a metal thermometer into a battery. Use a hydrometer with a built-in

thermometer

OPERATION INFORMATION

Owner’s Manual

17

NOTE

Fig.8

Specific gravity is the measurement of a liquid that is compared to a baseline. The baseline is water which is

assigned a base number of 1.000. The concentration of sulfuric acid to water in a new golf car battery is 1.280

which means that the electrolyte weighs 1.280 times the weight of the same volume of water. A fully charged

battery will test at 1.275 -1.280 while a discharged battery will read in the 1.140 range.

Do not perform a hydrometer test on a battery that has just been watered. The battery must go through at

least one charge and discharge cycle in order to permit the water to adequately mix with the electrolyte.

The temperature of the electrolyte is important since the hydrometer reading must be corrected to 80° F (27° C).

High quality hydrometers are equipped with an internal thermometer that will measure the temperature of the

electrolyte and will include a conversion scale to correct the float reading. It is important to recognize that the

electrolyte temperature is significantly different from the ambient temperature if the vehicle has been operated.

UsingA Hydrometer

1. Draw electrolyte into the hydrometer several times to permit the thermometer to adjust to the electrolyte

temperature and note the reading. Examine the color of the electrolyte. A brown or gray coloration indicates a

problem with the battery and is a sign that the battery is nearing the end of its life.

2. Draw the minimum quantity of electrolyte into the hydrometer to permit the float to float freely without

contacting the top or bottom of the cylinder.

OPERATION INFORMATION

Owner’s Manual

18

3. Hold the hydrometer in a vertical position at eye level and note the reading where the electrolyte meets the

scale on the float.

4. ρ25℃= ρt +0.0007(t-25)

ρ25℃——25℃electrolyte specific gravity ;ρ

t ——t℃electrolyte specific gravity.

5. Test each cell and note the readings (corrected to 80° Fig. 30 Hydrometer F or 27° C). A variation of fifty

points between any two cell readings (example 1.250 -1.200) indicates a problem with the low reading cell(s).

As a battery ages the specific gravity of the electrolyte will decrease at full charge. This is not a reason to replace

the battery, providing all cells are within fifty points of each other.

Since the hydrometer test is in response to a vehicle exhibiting a performance problem, the vehicle should be

recharged and the test repeated. If the results indicate a weak cell, the battery or batteries should be removed and

replaced with a good battery of the same brand, type, and approximate age.

BATTERY MAINTENANCE

Our experience shows that the key to achieving optimum performance and long life is a solid battery

maintenance program using the simple procedures

outlined here.

Equipment:

We recommend the following equipment for use in battery care and maintenance:

Recommended Equipment:

◆

◆Wrench

◆Distilled Water

◆Voltmeter

◆Hydrometer

◆Thermometer

◆Post Cleaner

◆Baking Soda

◆Vaseline

◆Goggles & Gloves

CAUTION:Always wear protective clothing, gloves, and goggles

When handling batteries, electrolyte, and charging your battery.

This manual suits for next models

2

Table of contents