Forney 140 MP User manual

Other Forney Welding System manuals

Forney

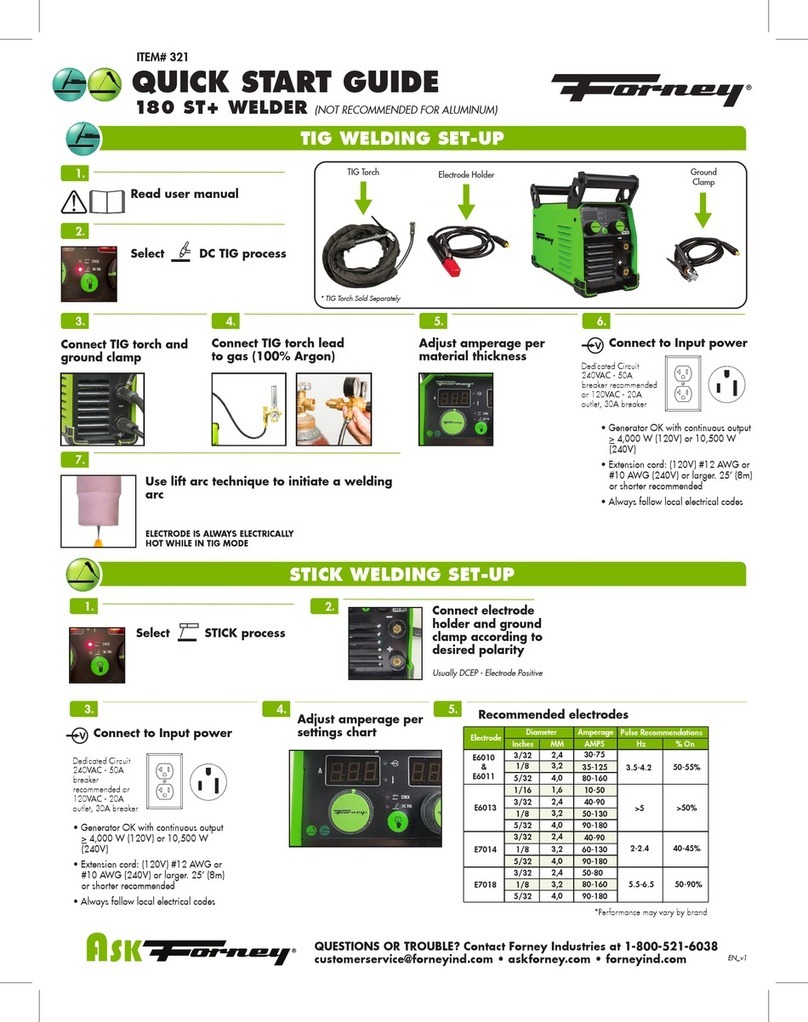

Forney 180 ST+ User manual

Forney

Forney FLEX 30 PLASMA ST User manual

Forney

Forney 210 MIG User manual

Forney

Forney 220 MP User manual

Forney

Forney 410 User manual

Forney

Forney Easy Weld 261 User manual

Forney

Forney 700P User manual

Forney

Forney Easy Weld 180 ST User manual

Forney

Forney Easy Weld User manual

Forney

Forney 270 User manual

Forney

Forney 95FI-A User manual

Forney

Forney Easy Weld 180 ST User manual

Forney

Forney Easy Weld 20P User manual

Forney

Forney 430 User manual

Forney

Forney 96FI-A User manual

Forney

Forney 242 User manual

Forney

Forney 317 User manual

Forney

Forney 220 ST User manual

Forney

Forney 210 User manual

Forney

Forney 270 MIG User manual

Popular Welding System manuals by other brands

Lincoln Electric

Lincoln Electric INVERTEC V350-PRO CE Technical specifications

ESAB

ESAB Buddy Arc 145 instruction manual

CIGWELD

CIGWELD 636804 use instructions

Red-D-Arc

Red-D-Arc DC-400 Operator's manual

Hobart Welding Products

Hobart Welding Products Spool Gun DP 3035-10 owner's manual

Elettro

Elettro HI-MIG 3000 SYNERGIC instruction manual