Forster Products Co-Ax User manual

1

User Instructions for the Forster Products Co-Ax

®

Reloading Press

Issue 4

1.0 GENERAL INFORMATION

The Co-Ax® Reloading Press is designed for two main

purposes:

1. Rifle and pistol case resizing and bullet seating.

2. Rifle and pistol primer seating.

The Co-Ax Press accepts any 7/8" X 14 rifle or pistol reloading

die. For proper press operation, you must use our aluminum

Cross Bolt Die Lock Rings (two are provided in the Important

Parts Packet – see Figure 2) on either your own dies or on our

Forster Products Reloading Dies. Using our Cross Bolt Die

Lock Rings is important for two reasons:

•They keep the Co-Ax Press T-Slot free from wear that may

be caused by other harder steel lock rings.

•They are the proper thickness to allow the dies to “float” in

the T-Slot for optimal reloading.

CAUTION

PRODUCT DAMAGE

•Do not drop or expose the Co-Ax Press to sudden

stresses.

Failure to comply with these instructions may result in

product damage.

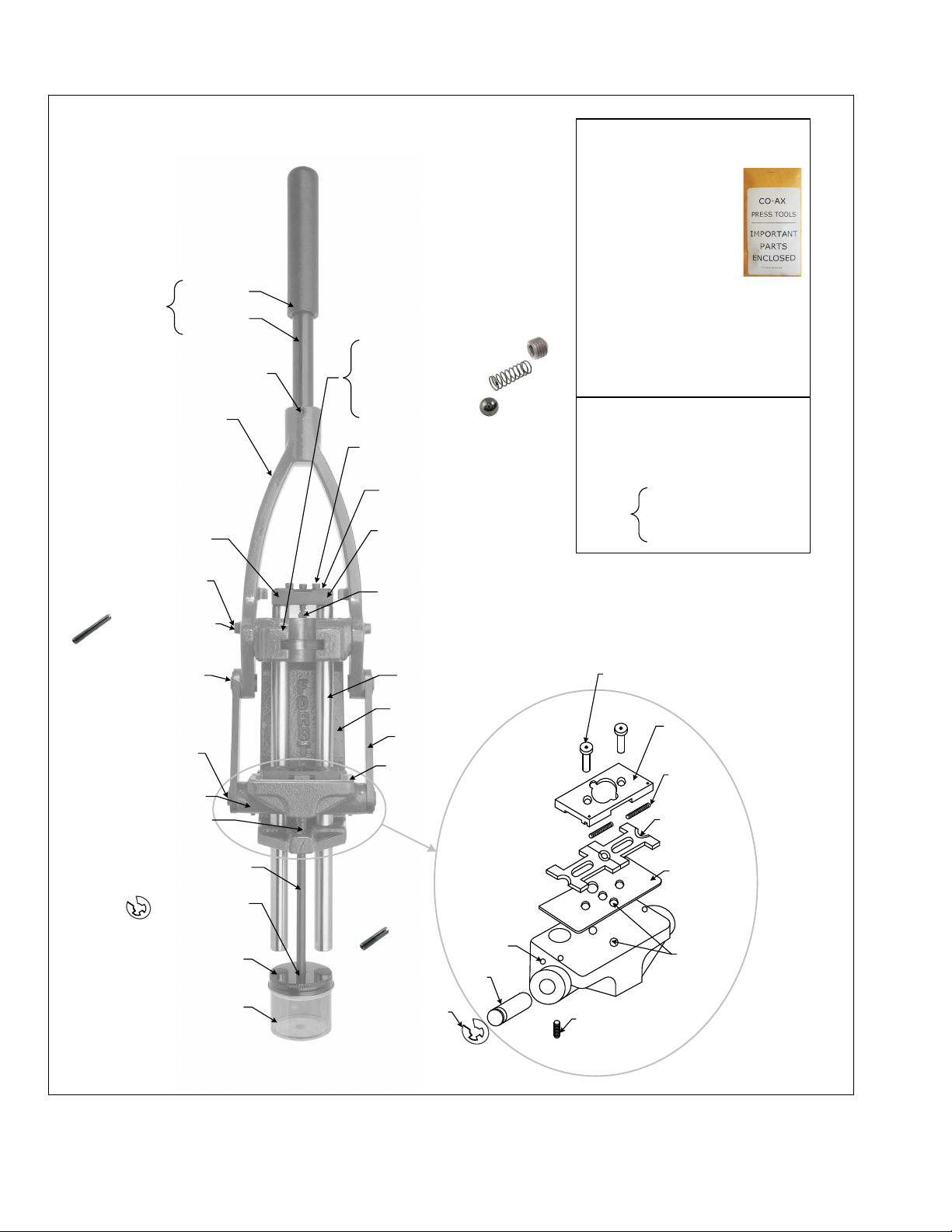

2.0 SHIPPING PACKAGE CONTENTS (See Figure 2.)

Your shipping package should contain the following:

•Section A: Co-Ax Press with all components not noted in

Sections B and C already assembled.

•Section B: Important Parts Packet.

•Section C: Loose Components.

3.0 SAFETY INFORMATION

WARNING

PERSONAL INJURY

•Avoid possible pinch points.

Failure to comply with these instructions could result

in death or serious injury.

Always wear safety glasses.

4.0 MOUNT THE CO-AX PRESS TO A WORK SURFACE

The Co-Ax Press may be directly mounted to a work bench, or

to a board for later use on the range or in the field. Due to the

extreme mechanical advantage engineered in the Co-Ax

Press, only two “C” clamps are needed to fasten the board-

mounted Co-Ax Press to a working surface.

1. See Figure 11 on the back page for a scale drilling

template.

2. Drill four ¼” holes. Mount the Co-Ax Press using ¼” lag

bolts.

5.0 SETUP AND ASSEMBLY

5.1 Install the Handle

1. Insert the Handle into the B3 Yoke Handle Casting (-055).

2. Using the 1/8 Allen Wrench (SHORTARMHEXKEY1/8),

tighten the Handle Set Screw (¼-28) (-014).

Note: A short handle with a ball end is available separately for

use when less leverage is needed. See Section 9.0.

5.2 Install the Primer Catcher (See Figure 1.)

1. From below, insert the threaded part of the Primer Drop

Tube (-053) through the hole in the Primer Catcher Cap

(-050).

2. Screw the Primer Catcher Cap to the Primer Catcher Cup

(-051).

3. Pass the Primer Drop Tube through the middle hole in the

bottom of the Frame Casting (-031).

4. Screw the Primer Drop Tube into the tapped hole in the

bottom of the Guide Block Casting (-045) until finger tight.

Figure 1. Primer Catcher Installation

5.3 Adjust the Jaw Opening Screw (-044) (See Figure 2.)

The Jaw Opening Screw controls the amount the lower

Shellholder Jaws open to accept cases when the Handle is

raised to its highest position. Adjust the Jaw Opening Screw’s

height so that the Shellholder Jaws completely open when the

handle is in the full up position against overhead stops, but not

too far that it could damage the Shellholder Housing (-037).

2

Figure 2. Co-Ax Reloading Press (028271) Nomenclature

B3 Yoke Handle Casting

(028271-055)

3X Top Shell Holder Jaws

(028271-016) (See Figure 8.)

Top Shell Holder

Jaw Block

(028271-017)

Locator

(028271-018) (See Figure 9.)

Primer Catcher Cap

(028271-050)

Primer Catcher Cup

(028271-051)

Primer Drop Tube

(028271-053)

1/8 Allen Wrench

(

SHORTARMHEXKEY1/8)

Section B. Important Parts

Packet

5/32 Allen Wrench

(

SHORTARMHEXKEY5/32)

2X Guide Rod

(028271-048)

2X Pin “C”

(028271-047)

3X Socket Head Cap Screw

(10-24x ½”)

(SCR10-24X1/2SHEADCAP)

Large Primer Seater Assembly

(028271-102) (See Figure 7.)

2X Pin “B”

(028271-032)

2X Link

(028271-034)

2X Pin “A”

(028271-026)

2X Roll Pin

(1/8" x 1" for Pin “A”)

(028271-026A)

Guide Block Casting

(028271-045)

Primer Drop Tube

Retaining Ring

(028271-052)

Wear Plate

(028271-046)

Jaw Opening Screw

(028271-044)

2X Socket Set Screw 10-24x3/8" for Pin “C”

(028271-054)

2X Button Head Screw (10-24x5/8")

(028271-020)

2X Roll Pin (1/8"x5/8")

(028271-038)

4X E-Ring (½”)

(028271-035)

Shell Holder Jaw Housing

(028271-037)

2X Jaw Pressure Spring

(028271-039)

Frame Casting

(028271-031)

“S” Lower Shell Holder Jaws

(001231) (See Table 1)

(Holes not used.)

Handle Set Screw (¼-28)

(028271-014)

2X Button Head Screw

(10-24x5/8") (not shown)

(028271-020)

2X Pin “C”

(028271-047)

Wear Plate

(028271-046)

Primer Catcher Cap

(028271-050)

Primer Drop Tube Retaining Ring

(028271-052)

7/64 Allen Wrench

(

SHORTARMHEXKEY7/64)

Small Primer Seater Assembly

(028271-101) (See Figure 7.)

Section A. Co-Ax Press with All Components Not Noted

in Sections B and C Already Assembled

Lock Ring Detent Screw (5/16")

(028271-028)

Lock Ring Detent Ball

(028271-030)

Lock Ring Detent Spring

(028271-029)

Two Cross Bolt Lock Rings

(028271-101)

Primer Drop Tube

(028271-053)

Primer Catcher Cup

(028271-051)

Section C. Loose Components

Handle Grip

(028271-011)

Handle Tube

(028271-013)

Handle

Handle Grip

(028271-011)

Handle Tube

(028271-013)

Handle

3

6.0 CASE SIZING AND BULLET SEATING

6.1 Choose the correct lower shell holder for the caliber being sized/seated.

•Table 1 shows the three lower shell holders available for the Co-Ax Press.

•Figure 3 shows how to use the on-line FORSTER PRODUCTS TOOL SEARCH BY CARTRIDGE to find which lower shell

holder to use with your particular caliber,

Table 1. Lower Shell Holder Specifications

Name

(Order

Number)

Description Dimensions

“S” Lower

Shell Holder

Jaws

(001231)

Factory

installed on

the Co-Ax

Press with

large ends

aligned; ready

for reloading.

•Spring-loaded; automatically open

and close on the case head when

the case is inserted in the die and

the Co-Ax Press handle is lowered

for full length resizing, allowing the

case to float. When the handle is

raised and the case is extracted

from the die, these jaws

automatically open and release

the case.

•Set of two.

Small ends hold:

.343” to .422” rim

.343"

Large ends hold:

.468” to .562” rim

.468"

Side View

“LS” Lower

Shell Holder

Jaws

(001251)

Available

separately.

•Accommodates a wide range of

very large and very small case

heads.

•Spring-loaded; automatically open

and close on the case head when

the case is inserted in the die and

the Co-Ax Press handle is lowered

for full length resizing, allowing the

case to float. When the handle is

raised and the case is extracted

from the die, these jaws

automatically open and release

the case.

•Set of two.

Small ends hold:

.312” to .375” rim

.312" .312"

Large ends hold:

.531” to .625” rim

.531"

Side View

Large End

.065"

Small End

.070"

Lower Shell

Holder

Adapter

Plate

(AP1000)

Available

separately.

•For use with those few calibers

that the “S” or “LS” Shell Holder

Jaws do not accommodate.

Requires a caliber-specific shell

holder (not available through

Forster Products).

•Not spring-loaded.

•

Single plate.

Without Caliber-Specific

Shell Holder

With Caliber-Specific

Shell Holder

Case Rim Diameter Comparison

.312" to .375"

.343" to .422"

“S” Shell Holder Jaws

“LS” Shell Holder Jaws

.468" to .562"

.531" to .625"

300" 400" 500" 600"

Complete contact of shell holder to case - case held securely.

Incomplete contact of shell holder to case - case still held securely as determined by user.

4

Figure 3. On-line Search for Lower Shell Holder Jaws

1. Go to the FORSTER PRODUCTS TOOL SEARCH BY

CARTRIDGE at search.forsterproducts.com.

2. Input your cartridge name (223 Rem is used here as an

example). Click on the “Search” button.

3. The search should return a screen similar to that shown

below. The Lower Shell Holder Jaw information is at the

bottom of the table.

6.2 Change/Adjust the Lower Shell Holders (if

Needed)

6.21 Change/Adjust the “S” or “LS” Lower Shell

Holder Jaws (See Figure 4.)

Figure 4. Lower Shell Holder Jaws Change/Adjustment

Step 1: Using the provided 1/8 Allen

wrench, loosen the two Button Head

Screws (-020).

Step 2.

Carefully lift off the

subassembly containing:

•Two Button Head Screws

•Shell Holder Jaw Housing (-037)

•Two Jaw Pressure Springs (-039)

•“S” or “LS” Shell Holder Jaws

•Wear Plate (-046).

Step 3: Remove the two Button

Head Screws and set them aside.

Set the component stack on a work

surface.

Step 4.

Carefully turn the

component stack over.

Step 5. Carefully slide the Wear

Plate off and set it aside. This is to

prevent the two Jaw Pressure

Springs from coming loose too

soon.

Step 6. Remove the “S” or “LS”

Shell Holder Jaws and the two Jaw

Pressure Springs, in that order.

Step 7.

Ensure the ends of the

selected pair of Shell Holder Jaws

are correctly matched and insert

them in the Shell Holder Jaw

Housing.

Step 8: Replace the two Jaw

Pressure Springs.

Step 9: Replace the Wear Plate.

Ensure the rounded edge of the

Wear Plate is placed over the two

Jaw Pressure Springs.

Step 10: Carefully turn the

component stack back over.

Step 11: Carefully pick up the

component stack and replace the

two Button Head Screws.

Step 12: Replace the subassembly

on the Co-Ax Press and tighten the

Button Head Screws.

5

6.22 Optional Lower Shell Holder Adapter Plate

Installation

1. Remove the Lower Shell Holder Jaws Subassembly

following the instructions in Section 6.21 and set aside.

2. Remove the two Button Screws from the Lower Shell

Holder Jaws Subassembly and place them in the

corresponding holes in the Lower Shell Holder Adapter

Plate.

3. Place the Lower Shell Holder Adapter Plate on the Co-

Ax Press and tighten the Button Head Screws.

4. Using the 5/64 Allen wrench (provided separately with

Adapter Plate) tighten the set screw against the shell

holder.

6.3 Adjust the Sizing/Seating Die in the Co-Ax

Press T-Slot (See Figure 5.)

1. Unscrew the die approximately two-thirds out of the

Cross Bolt Die Lock Ring, ensuring that its screw is

centered in front.

Figure 5. Reloading Die Adjustment in the Co-Ax Press

T-Slot

2. Lower the Handle all the way down against the stop.

3. While holding the Lock Ring with one hand, screw the die

through the Lock Ring until it makes contact with the

Shell Holder Jaws.

4. Using the provided 7/64 Allen wrench, tighten the Lock

Ring in place on the die, just tight enough to keep the Die

Lock Ring under tension. Do not over tighten: the die

must be allowed to float in the T-Slot for proper

alignment.

For specific Forster Products Sizing and Seating Die

Instructions, go to forsterproducts.com, then click on PDF

Library/Instructions.

7.0. PRIMER SEATING

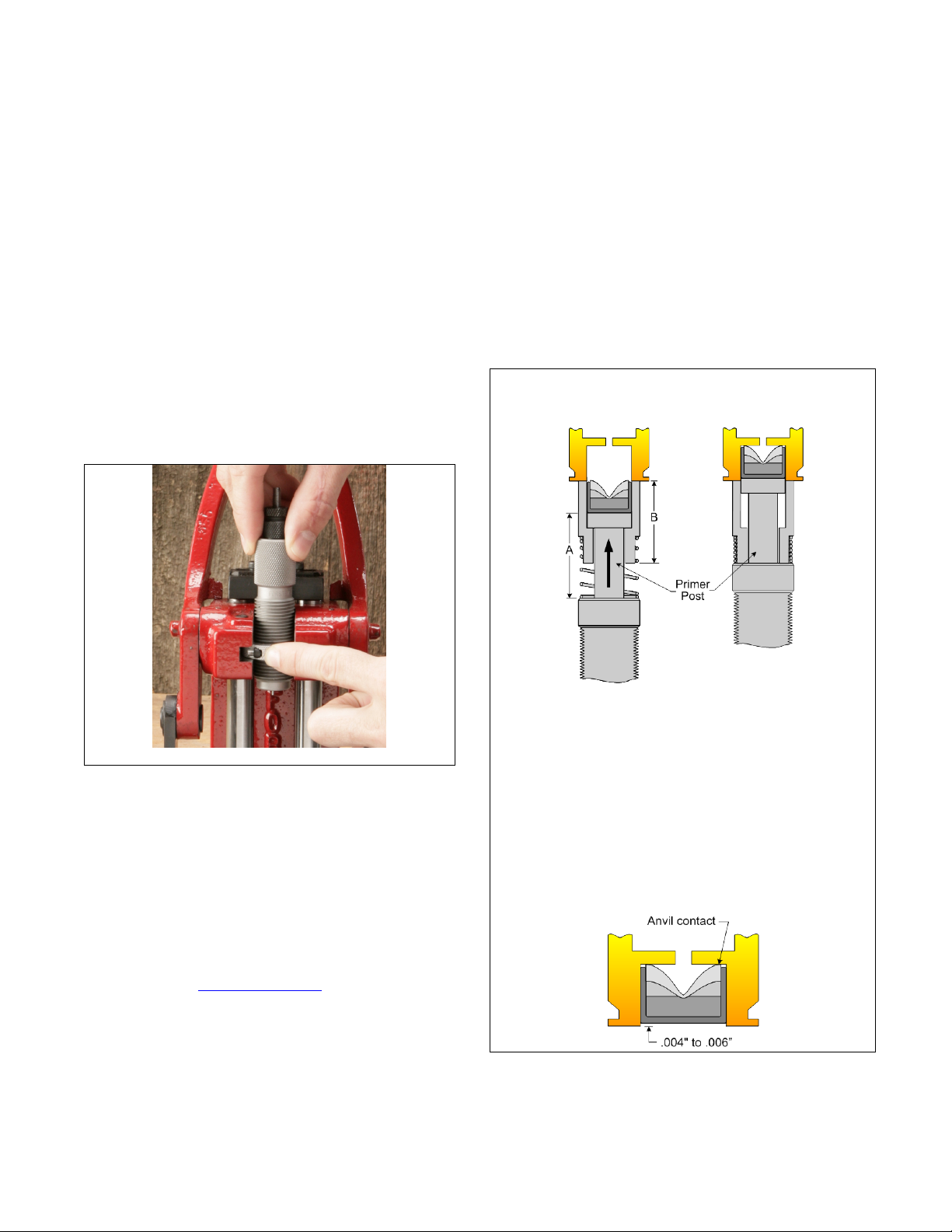

7.1 Primer Seating Overview (See Figure 6.)

Proper priming is one of the most critical operations in the

reloading process. In order for your ammunition to perform

efficiently, consistent ignition is absolutely mandatory. For

this reason, we paid special attention to the priming function

in the design of the Co-Ax Press.

The primer seater design is engineered with such precision

that no excessive tolerance or “slop” is required in any of the

mating parts. The primer post in the Primer Seater Assembly

(see Figure 6) moves freely in its channel with minimal

clearance. This extremely tight tolerance delivers remarkably

consistent seating depth, time after time.

Regardless of the variation in the dimension of the case rim

or the amount of force used in seating the primer, with the

Forster Products Co-Ax Press, it is impossible to crush a

primer or vary the seating depth.

Figure 6. Primer Seater Assembly Function

View A View B

View A: Dimension “A” is greater than dimension “B” by

.004" to .006".

View B: When force is applied to the guide block of the

press, the bottom of the primer cup stops against the base

of the primer post. The top of the primer cup stops against

the case head. Because the primer post is longer than the

cup by .004" to .006", the primer will always be seated

.004" to .006" below the case head as shown in View C.

View C

6

7.2 Adjust the Co-Ax Press

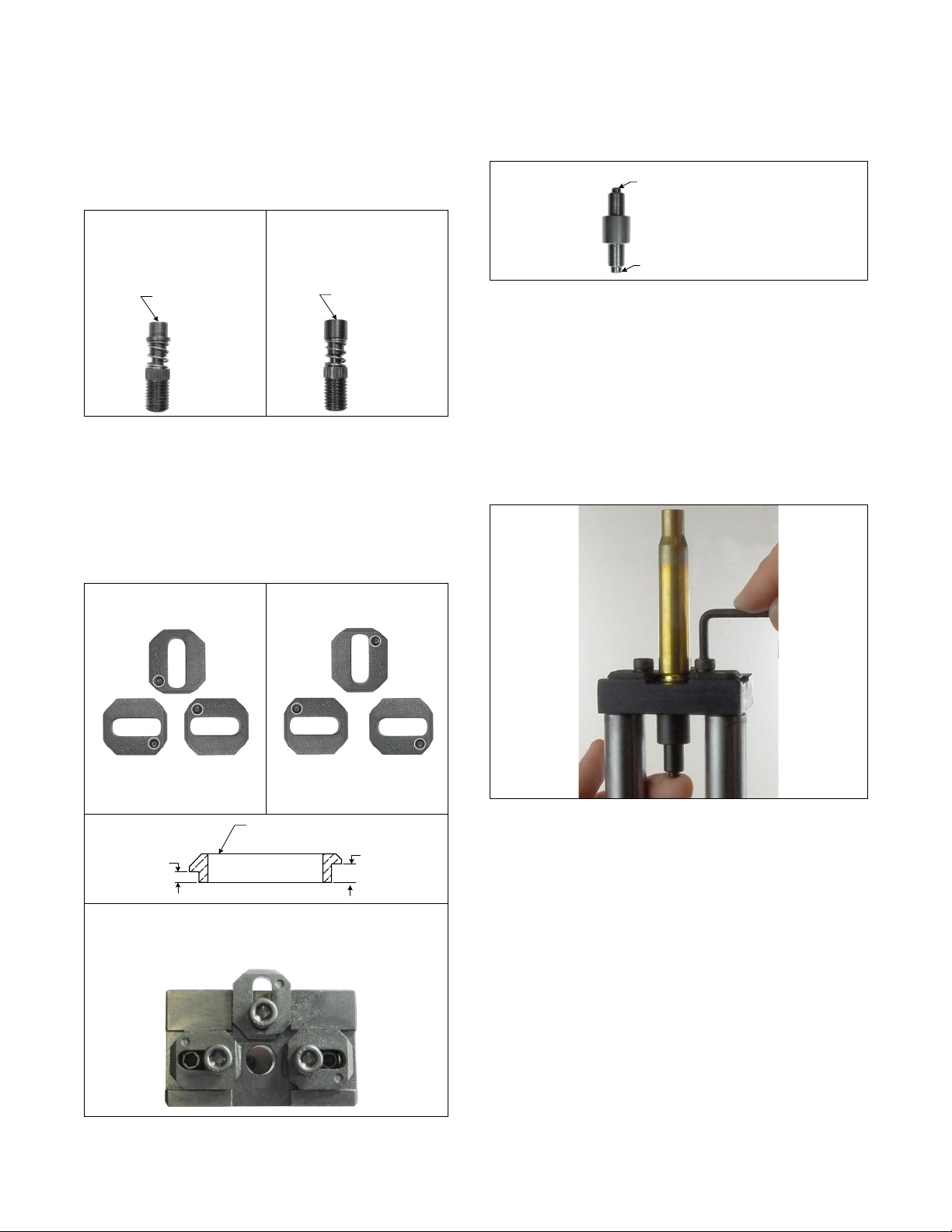

7.21 Primer Seater Assembly (See Figure 7.)

Based on the primer diameter being used, select either the

Small Primer Seater Assembly or the Large Primer Seater

Assembly (see Figure 7) and screw it into the Co-Ax Press.

Figure 7. Primer Seater Assembly Versions

Small Primer Seater

Assembly

(-101)

.175"

Diameter

Large Primer Seater

Assembly

(-102)

.210"

Diameter

7.22 Top Shell Holder Jaws (See Figure 8.)

Based on the thickness of the case rim being used, ensure

all three ends of the Top Shell Holder Jaws are matched and

aligned, and held loosely face down on the Shell Holder Jaw

Block (-017). Note the stamped circle that indicates which

ends are aligned.

Figure 8. Top Shell Holder Jaws (-016)

0.054” Ends

0.072” Ends

.054" .072"

Stamped

Circle

Top Shell Holder Jaws in Place and Ready to Be

Tightened

7.23 Locator

1. Match the Locator end to the primer diameter being

used. (See Figure 9.)

Figure 9. Locator (-018)

.175" Diameter

.210" Diameter

2. Lower the Co-Ax Press Handle until there is enough

room to insert the Locator up into the Top Shell Holder

Jaw Block (-017) from underneath.

3. Center an unprimed case on the Locator.

4. While holding the locator in place, adjust the three Top

Shell Holder Jaws inward onto the case rim and tighten

the three Socket Head Cap Screws (SCR10-

24X1/2SHEADCAP) around the case. Do not

overtighten. (See Figure 10.)

Figure 10. Locator in Use

5. Lower the Co-Ax Press handle and remove the Locator.

You are now ready to prime. If the case rim is either too

loose or too tight, try using the opposite end of the Top

Shell Holder Jaws.

7

7.3 Prime Your Cartridges

NOTICE

Wear thin medical gloves on the primer hand to improve

the grip and help keep the primer from contamination.

1. Insert the primer on the Primer Seater Assembly and

the case on the Top Shell Holder Jaws following the

instructions below.

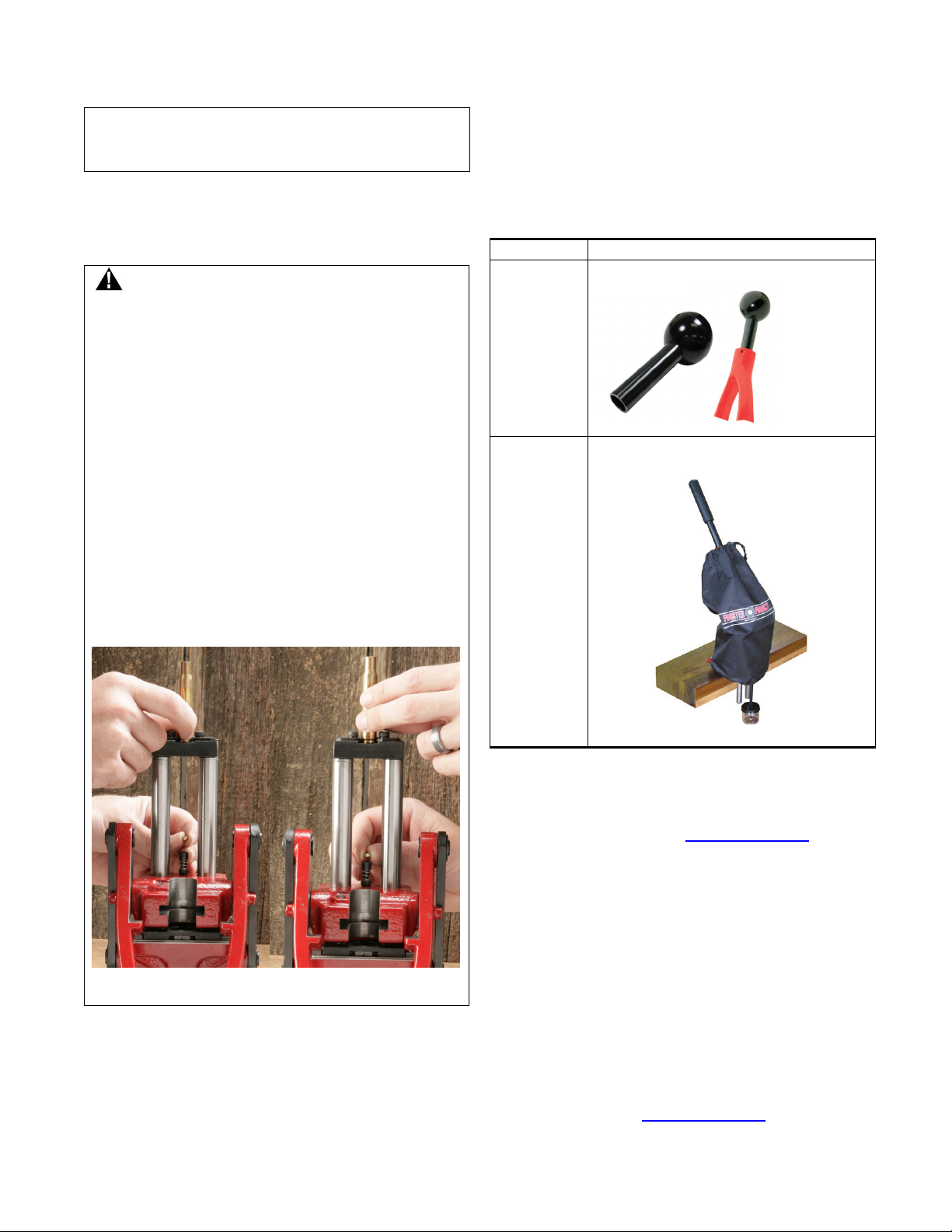

WARNING

PERSONAL INJURY

Ensure you use one of the two following positions for

inserting the primers on the Primer Seater Assembly and

the cases on the Top Shell Holder Jaws:

Right-handed users:

•Facing the press, take a position to the right of the

press.

•Lower the handle forward approximately 90 degrees.

•From the rear of the press, use your right hand to insert

the primer and the left hand to insert the case.

Left-handed users:

•Facing the press, take a position to the left of the press.

•Lower the handle forward approximately 90 degrees.

•From the rear of the press, use your left hand to insert

the primer and the right hand to insert the case.

Right-handed Left-handed

Failure to comply with these instructions could result

in death or serious injury.

2. Raise the Co-Ax Press handle to seat the primer. Only a

very small amount of force is needed.

8.0 MAINTENANCE

•Use a good quality gun oil to lubricate moving parts, wipe

all unpainted parts with oil to prevent rust.

•When not in use, keep a protective cover, such as our

028271-300 (see Table 2), over the Co-Ax Press.

9.0 ACCESSORIES

Table 2. Accessories

Order No.

Description

SH1000

Short Handle for Co-Ax Press

In use

028271-300

Protective Cover for Co-Ax Press (Press

not included)

10.0 REPLACEMENT PARTS

Every product component is available individually. A

complete list of component order numbers and prices is

available on our website. Go to forsterproducts.com, then

click on Components/Parts Price List.

11.0 VIDEO

Go to our Video Library (see Video Library link under

RESOURCES on our homepage) to see videos of the Co-Ax

Press.

12.0 DISTRIBUTORS/RESELLERS

We recommend using our Resellers when ordering our

products. Their experience and knowledge will help you

select the best products that meet your specific

requirements. In addition, they usually offer the best prices

and convenient delivery options.

To find a Reseller, go to forsterproducts.com, then click on

Locate a Distributor/Reseller. If your Distributor/Reseller

cannot supply you, please contact Forster Products directly.

WARRANTY

All Forster Products are warranted against defects in materials and workmanship for the life of the product. Parts which, by nature of their

function, are subject to normal wear (such as springs, pins, etc.) and parts which have been altered, abused or neglected, are excluded from

the warranty. If the product is deemed defective by workmanship or materials, it will be repaired, reconditioned or replaced (at Forster

Products’ option). This warranty supersedes all other warranties for Forster Products whether written or oral.

forsterproducts.com

028271-002 Issue 4, November 2013

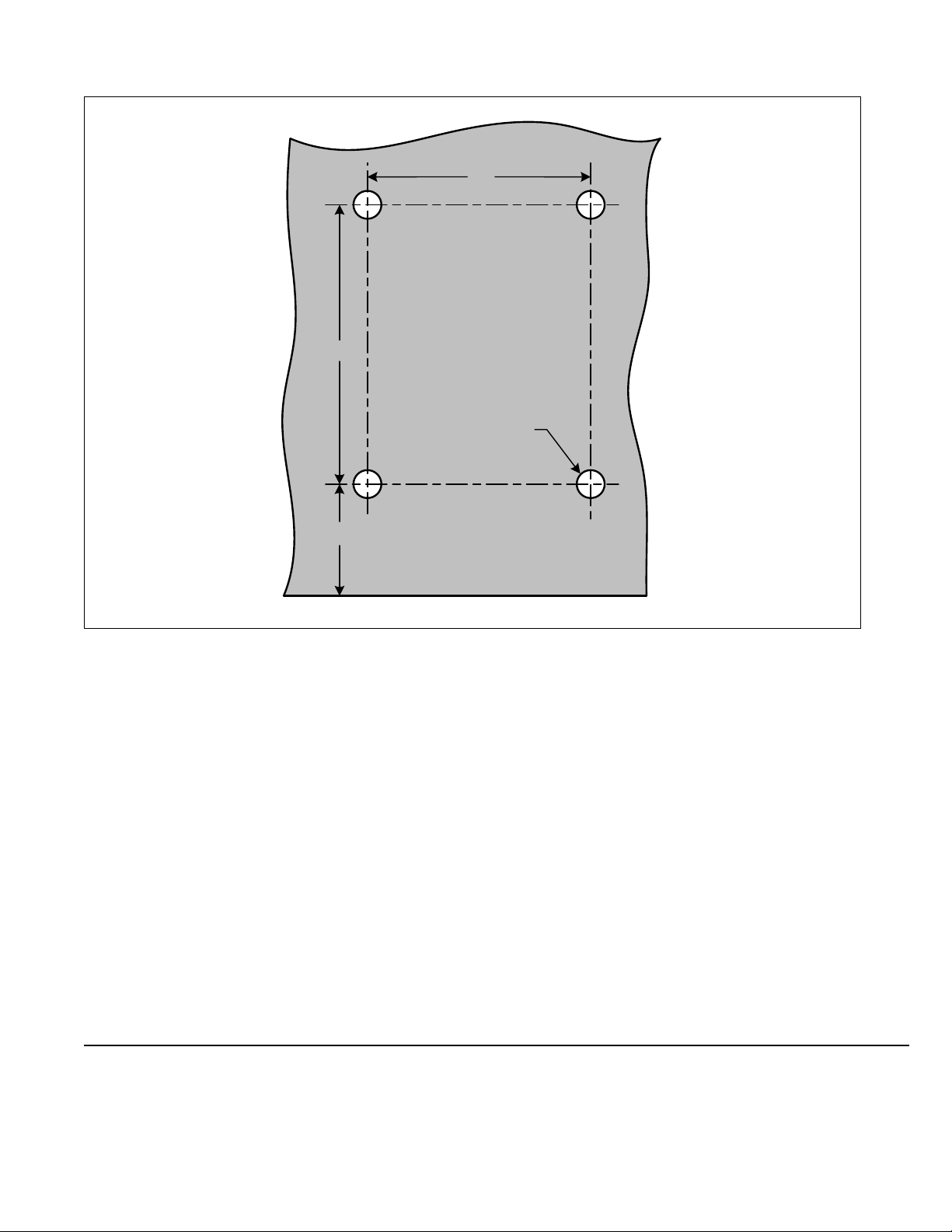

Figure 11. Scale Drilling Template

2"

2.5"

1"

Edge of Workbench

4X 0.25" Dia.

Mounting

Holes

Table of contents

Popular Power Tools manuals by other brands

Central Pneumatic

Central Pneumatic 167 Assembly and operating instructions

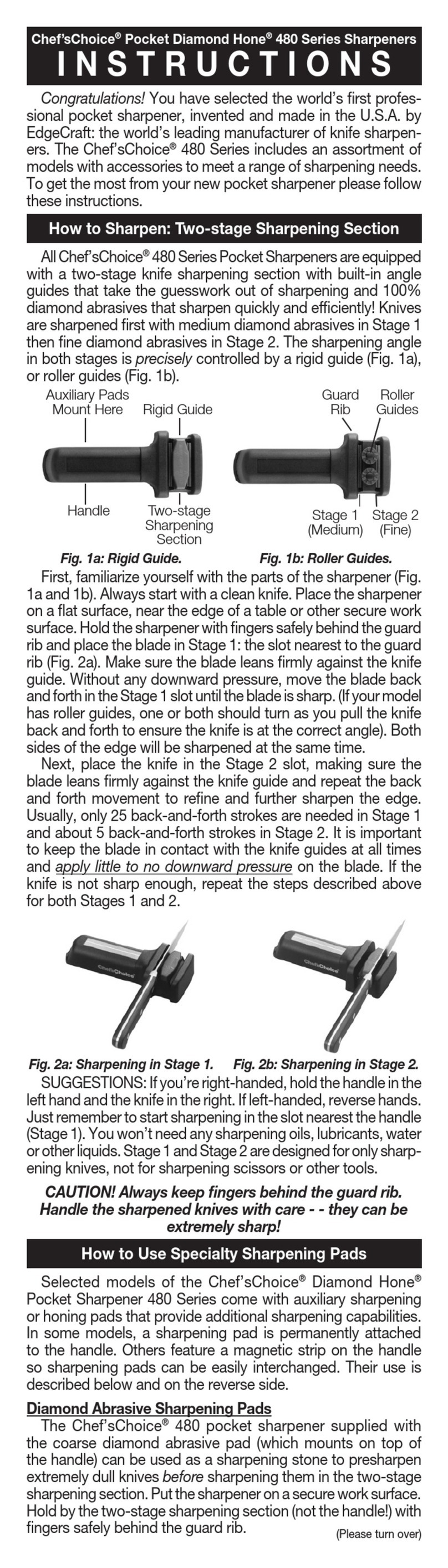

Chef's Choice

Chef's Choice Diamond Hone 480 Series instructions

protech

protech TS1610 user manual

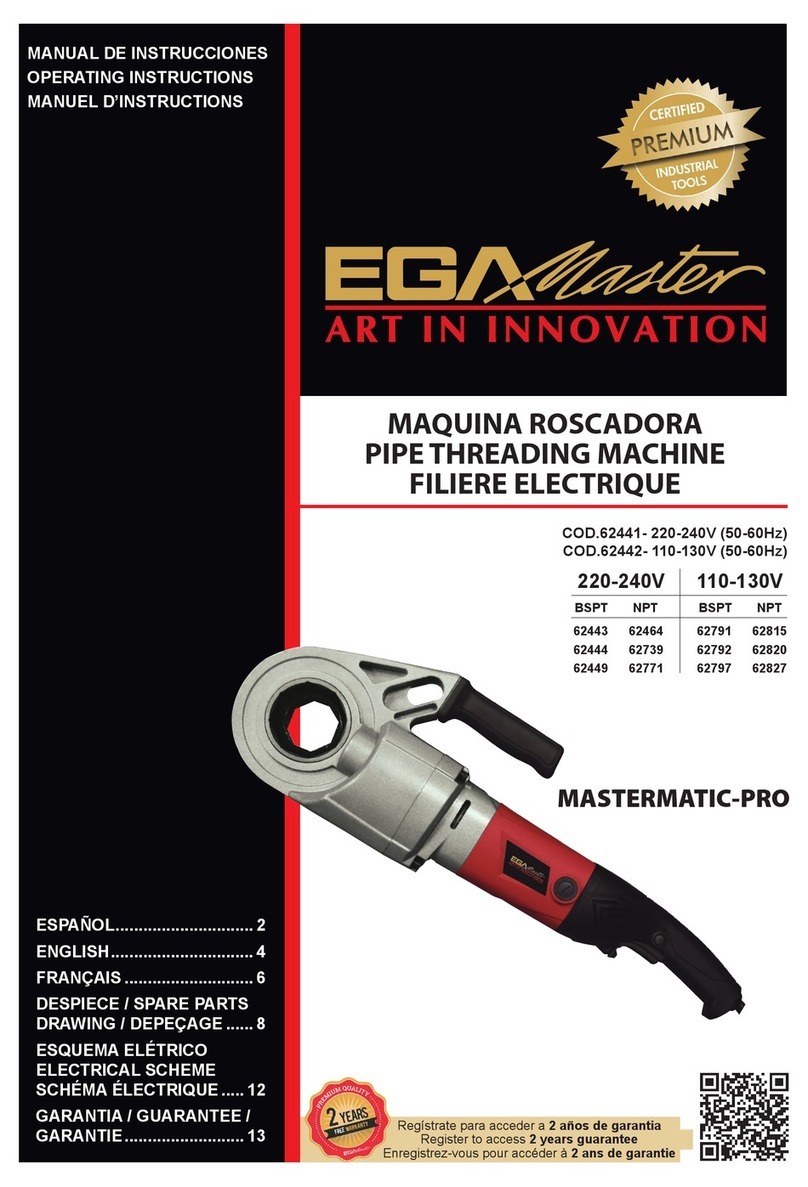

EGAmaster

EGAmaster MASTERMATIC-PRO operating instructions

Toolshop

Toolshop 241-9834 Operator's manual

NUTOOL

NUTOOL NHG2000 Original instructions