Toolshop 241-9834 User manual

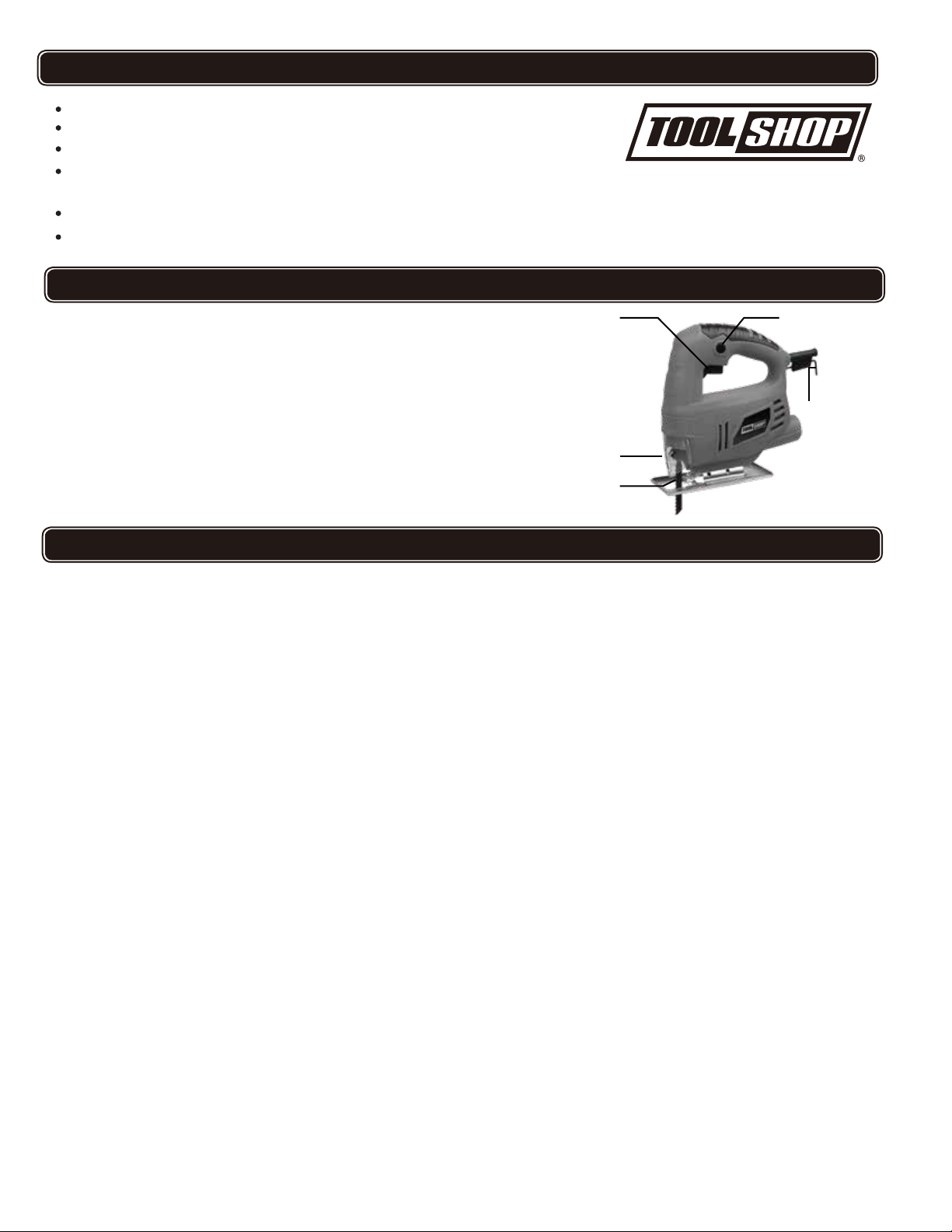

JIGSAW

SAVE THIS MANUAL

You will need this manual for safety instructions, operating procedures and warranty.

Put it and the original sales receipt in a safe dry place for future reference.

For questions about this product, Please call 1-866-915-8626

Operator’s Manual

241-9834

2

WARNING When using electric tools, machines or equipment, basic safety

precautions should always be followed to reduce the risk of fire, electric shock, and

personal injury. !

READ ALL INSTRUCTIONS BEFORE USING THIS TOOL

1. KEEP WORK AREA CLEAN. Cluttered areas can cause injuries.

2. CONSIDER WORK AREA ENVIRONMENT. Don’t use power tools in damp,

wet, or poorly lit locations. Don’t expose tools to the rain. Keep the work area

well lit. Don’t use tools in the presence of flammable gases or liquids.

3. KEEP CHILDREN AND BYSTANDERS AWAY. All children should be kept

away from the work area. Don’t let them handle machines, tools or extension

cords. Bystanders can be a distraction and can be injured.

4. GROUNDED TOOLS must be plugged into an outlet that is properly

installed and grounded. Grounding provides a low-resistance path to carry

electricity to the ground away from the operator, should the tool malfunction elec--

trically. Do not remove the grounding prong from the plug or alter the plug in

any way. If in doubt as to whether the outlet is properly grounded according

to code, check with a qualified electrician.

5. OBSERVE PROPER PRECAUTIONS REGARDING DOUBLE INSULA-

TION. This tool is double insulated. It is equipped with a polarized plug.

One blade is wider than the other, so it will fit into a polarized outlet only one

way. If you have difficulty inserting the plug, try reversing it. If it still doesn’t

fit , do not alter the plug; have a qualified electrician install a polarized outlet.

6. GUARD AGAINST ELECTRIC SHOCK. Prevent body contact with grounded

surfaces: pipes, radiators, ranges, and refrigerator enclosures. When your

body is grounded the risk of electric shock increases. When working wher-

ever “live” electrical wires may be encountered, try to ascertain whether

there is a danger of shock. DO NOT TOUCH ANY METAL PARTS

OF THE TOOL while using it. Hold the tool only by the plastic grip to prevent

electric shock if you contact a live wire.

7. DO NOT MISUSE THE CORD. Never carry your tools by the cord or pull on

the cord to unplug it. Protect the cord from potential sources of damage:

heat, oil & solvents, sharp edges, or moving parts. Replace damaged cords

immediately.

8. WHEN WORKING OUTDOORS, USE AN OUTDOOR-RATED EXTENSION

CORD. An extension cord rated for outdoor use must be marked “W-A” or

“W”.

9. DO NOT EXPOSE ELECTRICAL POWER TOOLS TO MOISTURE. Rain or

wet conditions can cause water to enter the tool and lead to electric shock.

10. ENSURE THE EXTENSION CORD YOU USE IS OF SUFFICIENT GAUGE

FOR ITS LENGTH.

11. STORE IDLE EQUIPMENT. Store equipment in a dry area to inhibit rust.

Equipment also should be in a high location or locked up to keep out of

reach of children.

12. DON’T FORCE THE TOOL. It will do the job better and more safely at the

rate for which it was intended.

13. USE THE RIGHT TOOL. Don’t force a small tool or attachment to do the

work of a larger industrial tool. Don’t use a tool for a purpose for which it was

not intended.

14. DRESS PROPERLY. Don’t wear loose clothing or jewelry; they can be

caught in moving parts. Protective, non-electrically conductive gloves, protective

eyewear and non-skid footwear are recommended. Wear protective hair

covering to contain long hair and keep yourself from harm.

Recommended Minimum Wire Gauge for Extension Cords

Amps

from

Tool Nameplate

25’ length 50’ length 75’ length 100’ length 150’ length 200’ length

0-5 amps 16 ga. 16 ga. 16 ga. 14 ga. 12 ga. 12 ga.

5.1-8 amps 16 ga. 16 ga. 14 ga. 12 ga. 10 ga. Do Not Use

8.1-12 amps 14 ga. 14 ga. 12 ga. 10 ga. Do Not Use Do Not Use

12.1-15 amps 12 ga. 12 ga. 10 ga. 10 ga. Do Not Use Do Not Use

15.1-20 amps 10 ga. 10 ga. 10 ga. Do Not Use Do Not Use Do Not Use

IMPORTANT SAFETY INSTRUCTIONS

3

•GUARD AGAINST ELECTRIC SHOCK. When cutting wherever “live” electrical

wires may be encountered, hold the tool only by the plastic handle to prevent

electric shock. DO NOT TOUCH ANY METAL PARTS OF THE TOOL. If you

contact a live wire, the exposed metal of the saw becomes live as well, and can

shock the operator.

•DO NOT START THE SAW WITH THE BLADE IN CONTACT WITH ANY

SURFACE. The reciprocating action will cause the saw to bounce violently and

could cause injury.

•LET THE SAW COME TO A STOP before putting it down. The reciprocating

action could cause the saw to jerk violently if it contacts anything with the

blade tip.

15. USE EYE PROTECTION. Use a full-face mask if the work you’re doing

produces metal filings, dust or wood chips. Goggles are acceptable in other

situations. Wear a clean dust mask if the work involves creating a lot of fine

or coarse dust.

16. SECURE WORK. Use clamps or a vise to hold the work, this frees both

hands to operate the tool.

17. DON’T OVERREACH. Keep proper footing and balance at all times. Do not

reach over or across machines that are running.

18. MAINTAIN TOOLS. Keep tools sharp and clean for better and safer

performance. Follow instructions for lubricating and changing accessories.

For safe performance. Keep handles dry, clean and free from oil and grease.

19. AVOID UNINTENTIONAL STARTING. Be sure the switch is in the OFF posi-

tion before plugging in.

20. ALWAYS CHECK AND MAKE SURE TO REMOVE ANY ADJUSTING KEYS

OR WRENCHES before turning the tool on. Left attached, these parts can fly

off a moving part and result in injury.

21. DO NOT USE THE TOOL IF IT CANNOT BE SWITCHED ON OR OFF.

Have your tool repaired before using it.

22. DISCONNNECT THE PLUG FROM THE POWER SOURCE BEFORE MAKING

ANY ADJUSTMENTS.

Changing attachments or accessories can be dangerous

if the tool could accidentally start.

23. STAY ALERT. Watch what you are doing & use common sense. Don’t operate

any tool when you are tired.

24. CHECK FOR DAMAGED PARTS. Before using this tool, any part that is

damaged should be carefully checked to determine that it will operate prop-

erly and perform its intended function. Check for alignment of moving parts,

binding of moving parts, breakage of parts, mountings, and other conditions

that may affect its operation. Inspect screws and tighten any ones that are

loose. Any part that is damaged should be properly repaired or replaced by

an authorized service center unless otherwise indicated elsewhere in the in-

struction manual. Have defective switches replaced by an authorized service

center. Don’t use the tool if switch does not turn it on and off properly.

25. REPLACEMENT PARTS. When servicing, use only identical replacement

parts.

26. SERVICE AND REPAIRS should be made by qualified repair technicians at

an authorized repair center. Improperly repaired tools could cause serious

shock or injury.

IMPORTANT SAFETY INSTRUCTIONS

SAFETY PRECAUTIONS FOR JIGSAW

D

E

C

A

B

4

1 wood cutting blade

Voltage:120V AC, 60Hz.

Current rating: 3.0 Amp

No load speed: 3,000 /min

Maximum depth of cut: 2-3/16” (Wood), 1/4” (Steel)

OPERATING PROCEDURES

Blades

Your jigsaw is designed to accept standard “T” and “U” shank jigsaw blades.

Check to ensure that any blades you use on this machine are designed for the task.

Installing a saw blade

1. Important: Unplug the saw.

2. Loosen the two hex screws on the saw blade clamp.

3. Insert the saw blade into the clamp and slide it in as deeply as it will go.

4. Be sure the blade is seated firmly in guide roller slot.

5. Tighten the hex screws to secure the blade.

6. Before you plug in the power cord, always pull on the blade sharply to ensure it

is firmly held in the blade clamp. Failure to do so may result in injury.

Adjusting the angle of cut

1. Loosen the two hex screws under the baseplate.

2. Slide the baseplate back about 5/16” (8mm)

3. Rotate the baseplate to the desired angle. The angles are clearly marked

on the baseplate.

4. Be sure the blade support roller, which is clamped in position by the same two

screws, is seated with its slot against the back of the blade.

5. Tighten the two screws.

To return to a vertical position

1. Loosen the screws under the baseplate.

2. Rotate the baseplate so that the ‘0’ line shows clear of the housing.

3. Slide the baseplate forward, which locks it in the vertical position.

4. Be sure the blade support roller, which is clamped in position by the same two

screws, is seated with its slot against the back of the blade.

5. Tighten the two screws.

Includes:

A. Blade clamp

B. Protective cover

C. On/Off trigger

Lock-on button

E.

D.

Hex key

SPECIFICATIONS

FUNCTIONAL DESCRIPTION

OPERATING PROCEDURES

1 hex key stored in the housing below the

cord sheath

5

Running the JigSaw

1. Plug in the tool.

Warning: Turn off your saw at once, unplug and inspect it for serious problems if:

Moving parts get stuck

Speed drops to an abnormally low level

The motor housing gets hot

Sparks or odours emit from the casing

General Cutting

Hold your saw firmly in front and away from you. Make sure the blade is clear of

any surface and that the power cord is out of the blade path. Be sure the material

to be cut is held firmly. Small pieces should be clamped in place to a workbench.

Mark the line of cut clearly. Depress the trigger switch. Allow the blade to cut the

material. hguoneylnoesU.tiecroftonoD pressure to keep the saw moving forward.

).yletarapesdlossiedalbgnittuclateM(gnittuClateM

Use a sharp blade especially designed to cut the material you are working on. It is

recommended you use a cutting fluid on the metal surface to avoid heat buildup.

Keep the tool housing clean, free of oil, and grease by using mild soap and a

damp (not wet) cloth. Do not let solvents like brake fluid, gasoline, petroleum-

based products, etc., contact plastic parts of the housing. Cleaning with these

substances can harm the plastic and compromise the integrity of the double

insulating system.

Inspect the mounting screws regularly. They should be properly tightened. If

any are found loose, tighten them immediately or serious injury could result.

Use care to see that the motor winding does not become damaged or wet with

oil or water.

Keep the vents clear of dust and debris. A shot of compressed air is ideal.

This will help prevent possible electrical shorts and ensure proper cooling.

esoldnatohemoceblliwtI.lootehtecroftonoD.wasruoygnidaolrevodiovA

efficiency. Running it free of load for a minute or two will allow it to cool itself to

normal temperature.

Inspect the cord regularly and have it replaced by an authorized repair facility if

it is damaged.

Lubrication for this tool is done at the factory and, except for the blade guide

roller, should not be necessary again under normal use. The blade guide roller

can use a drop of oil from time to time.

An authorized repair center should do any repairs, modification, or mainte-

nance that involves opening or disassembling the saw.

OPERATING PROCEDURES

OPERATING PROCEDURES

OPERATING PROCEDURES

OPERATING PROCEDURES

MAINTENANCE

Any damage to the tool should be corrected at an authorized repair center.

2.Hold the saw firmly. Make sure that saw blade travel is not obstructed. Depress

the trigger switch to turn the tool on. Engage the lock-on button and release the

trigger switch to maintain the tool operating itself.

3.Depress the trigger at the end then release it. The tool will stop.

ADJUSTMENTS

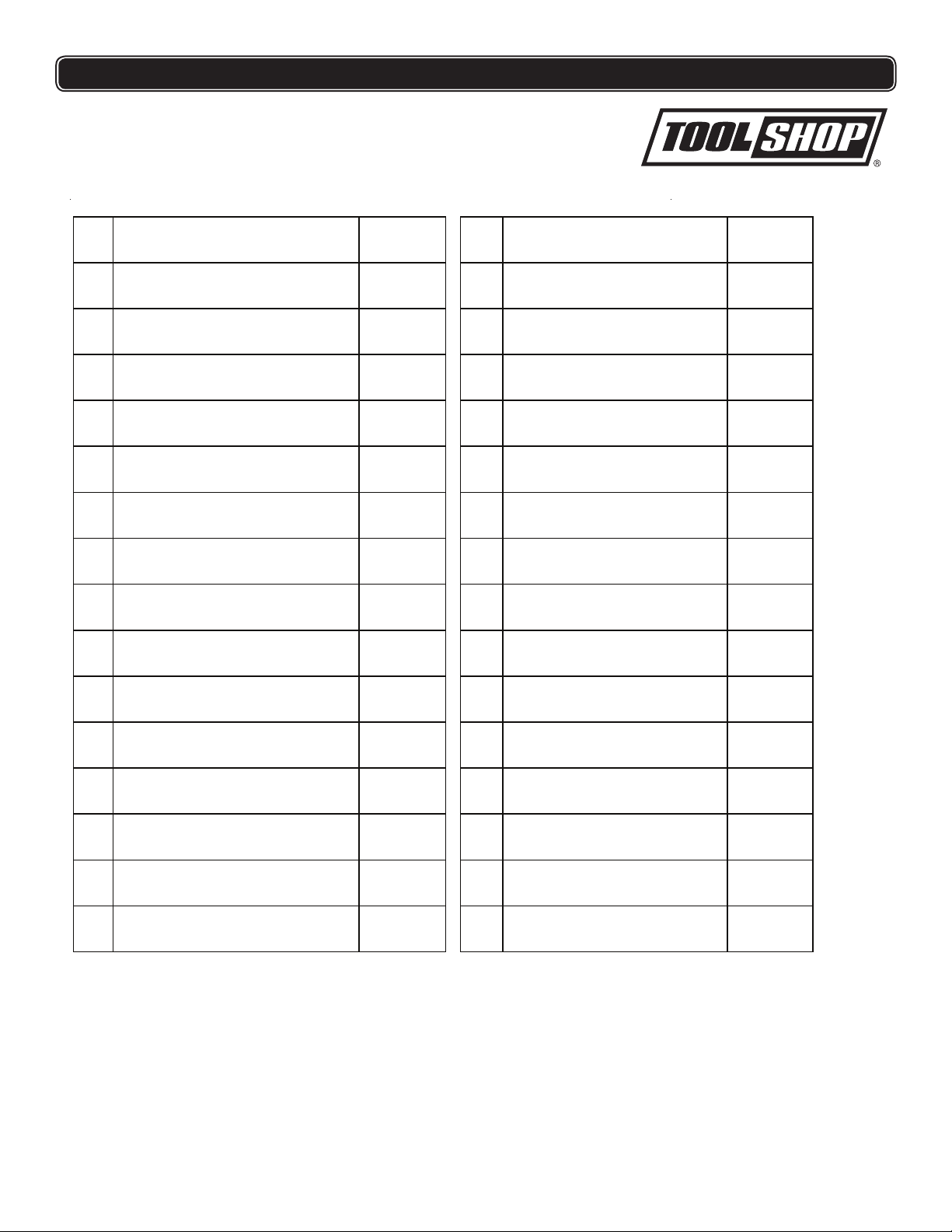

PARTS LIST

6

Please refer to the schematic drawing on page 7.

No Quantity No Quantity

Part Description Part Description

1 2 16 1

2 1 17 1

3 1 18 1

4 2 19 1

5 1 20 2

6 1 21 2

7 2 22 2

8 1 23 1

9 1 24 1

10 1 25 1

11 2 26 7

12 1 27 2

13 1 28 1

14 1 29 1

15 1 30 1

Screws MST4*14 Central support

Support roller Bearing 608ZZ

Sole Rotor

Square nut Wire holder

Left housing Screw ST4.2*12

Shield Brush-holder

Reciprocating lever support Carbon Brush

Baize components Bearing607ZZ

Reciprocating lever Stator

Blade-holder Right housing

Screws MST4*12 Screw ST4.2*16

Switch Screw ST4.2*20

housing soft cover Cable guard

Wheel Spanner S3

Cable

Gear

7

SCHEMATIC DRAWING

!WARNING: Repairs should be made by an authorized repair center. Do not open or

disassemble this power tool. Contact customer service at 1-866-915-8626 for

questions regarding this power tool.

8

TOOL SHOP®

1-YEAR LIMITED WARRANTY:

For questions / comments, technical assistance or repair parts –

Please call toll free at: 1-866-915-8626

(M-F 9am – 5pm EST)

SAVE YOUR RECEIPTS. THIS WARRANTY IS VOID WITHOUT THEM.

JIGSAW WARRANTY

This TOOL SHOP

®

brand power tool carries a 1-Year Limited Warranty to the

original purchaser. If, during normal use, this TOOL SHOP

®

tool fails due to a

defect in material or workmanship within one (1) year from the date of purchase,

simply bring this tool with your original sales receipt back to your nearest

MENARDS

®

retail store. At its discretion, TOOL SHOP

®

agrees to have the tool

replaced with the same or similar TOOL SHOP

®

product free of charge, within the

stated warranty period, when returned by the original purchaser with original sales

receipt. Notwithstanding the foregoing, this limited warranty does not cover any

damage that has resulted from abuse or misuse of the Merchandise. This warranty:

(1) excludes expendable parts including but not limited to blades, belts, bits, light

bulbs, and/or batteries; (2) shall be void if this tool is used for commercial and/or

rental purposes; and (3) does not cover any losses, injuries to persons/property or

costs. This warranty does give you specific legal rights and you may have other

rights, which vary from state to state. Be careful, tools are dangerous if improperly

used or maintained. Seller's employees are not qualified to advise you on the use of

this Merchandise. Any oral representation(s) made will not be binding on seller or

its employees. The rights under this limited warranty are to the original purchaser of

the Merchandise and may not be transferred to any subsequent owner. This limited

warranty is in lieu of all warranties, expressed or implied including warranties or

merchantability and fitness for a particular purpose. Seller shall not be liable for any

special, incidental, or consequential damages. The sole exclusive remedy against

the seller will be for the replacement of any defects as provided herein, as long as

the seller is willing or able to replace this product or is willing to refund the purchase

price as provided above. For insurance purposes, seller is not allowed to

demonstrate any of these power tools for you.

Table of contents

Other Toolshop Power Tools manuals

Toolshop

Toolshop 241-9970 User manual

Toolshop

Toolshop 240-2003 User manual

Toolshop

Toolshop 241-8502 User manual

Toolshop

Toolshop 241-9894 User manual

Toolshop

Toolshop 241-9023 User manual

Toolshop

Toolshop 241-9778 User manual

Toolshop

Toolshop 207-4825 User manual

Toolshop

Toolshop 241-9*780 User manual

Toolshop

Toolshop 241-9895 User manual