FORTEZA TRIBO-M User manual

TRIBOELECTRICGUARDALARM

FORPERIMETERAREAS

“FORTEZATRIBO‐M”

Operationmanual

2010

JSC“Forteza”“FortezaTribo‐M”operationmanual

2

Tableofcontents

1.Generalinformation........................................................................................................................................4

1.1.Purpose....................................................................................................................................................4

1.2.Operatingconditions...............................................................................................................................4

1.3.Technicalcharacteristics..........................................................................................................................6

1.4.Standardequipment................................................................................................................................6

2.DESIGNANDPRINCIPLEOFOPERATION.........................................................................................................7

2.1.PrincipleofOperation.............................................................................................................................7

2.1.1.Sensor..................................................................................................................................................7

2.1.2.Signal‐ProcessingUnit.........................................................................................................................7

2.1.3.AdapterandCoupling..........................................................................................................................7

2.1.4.TerminalUnit.......................................................................................................................................7

3.APPLICATION...................................................................................................................................................8

3.1.VersionsofFenceEquipping...................................................................................................................8

3.1.1.FlexibleFence(Fig.1)......................................................................................................................8

3.1.2.Wire‐NettingFence(Fig.1а)............................................................................................................8

3.1.3.“Rabitsa”Wire‐NettingFence(Figs1band1c)...............................................................................8

3.1.4.Barbed‐WireFence(Fig.1d)............................................................................................................9

3.1.5.FenceMadeofFlat(Round)ReinforcedBarbedTape“АКЛ”(Fig.1e)...........................................9

3.1.6.Rigid(Continuous)Fences(Fig.2)...................................................................................................9

3.1.7.Gate(Wicket)(Fig.3).......................................................................................................................9

4.Serviceabilitycheck.......................................................................................................................................10

4.1.SafetyPrecautions.................................................................................................................................10

4.2.ServiceabilityCheck...............................................................................................................................10

5.Installationandpreparationforuse..............................................................................................................11

5.1.General..................................................................................................................................................11

5.2.SPUInstallation......................................................................................................................................11

5.3.SensorLaying.........................................................................................................................................12

5.4.SplicingtheEndsoftheTribocableandConnectingCable...................................................................12

5.5.CablesTerminationinAdapter(Fig.8)..................................................................................................13

5.5.1.Toterminatethecablesintheadapter,proceedasfollows(Fig.8a):..........................................13

5.5.2.Toterminatethecablesintheextendedadapterinequippinggatesandwickets(Fig.8b),

proceedaccordingtoItem5.5.1butbesurefirsttosliparequired‐lengthspiralwraphoseovercableРК.

Thenslipasealoverthespiralwraphoseend.Completingthecableterminationbesuretoputthespiral

wraphoseendtogetherwiththesealintothecaseandtightenitwiththethirdadditionalclamp...........13

JSC“Forteza”“FortezaTribo‐M”operationmanual

3

5.6.CablesTerminationinCoupling.............................................................................................................14

5.7.CableTerminationinTerminalUnit(Fig.9)..........................................................................................14

5.8.InstallationofAdapterandCoupling.....................................................................................................14

5.9.TerminalUnitInstallation......................................................................................................................14

6.Controls.........................................................................................................................................................15

7.Maintenance..................................................................................................................................................16

7.1.InmaintenancebesuretoobservethesafetyprecautionsspecifiedinSection4...............................16

7.2.Typesofmaintenanceservices:.............................................................................................................16

7.3.Forthescopeofmaintenanceservices,refertoTable7.1...................................................................16

8.Storageandtransportation...........................................................................................................................18

8.1.WhenpackedinManufacturer’sshippingboxes,guardalarmsmaybecarriedbyanyclosed

transportmeans(boxcars,coveredtrucks,pressurizedheatedcargobays,holds,etc)including:..................18

8.2.GuardalarmsinManufacturer’stransitpackingshouldbestoredinheatedandventilated

storehouseswithairconditioninglocatedinanymacroclimaticareasatanambienttemperaturefrom+5°С

to+40°Сandrelativeairhumidityupto80%at25°С.......................................................................................18

8.3.Thestorehouseroomsshouldbefreeofdustandvapourofcorrodingagents...................................18

8.4.Guardalarmsmaybetransportedatanambienttemperaturefromminus40°Сto+50°Сandrelative

airhumidityupto100%at25°С.Intransportation,besuretoprotectthemagainstdirectexposureto

precipitationanddust.......................................................................................................................................18

8.5.Guardalarmsinstandardpackingarestoredoneyear,maximum.Ontheexpiryofthisperiodopen

thepacking,inspecttheguardalarmvisually,removerevealeddefectsandpacktheguardalarminstandard

packing...............................................................................................................................................................18

9.Repairandutilization.....................................................................................................................................19

9.1.Alltypesofthesignal‐processingunitrepairaretobeperformedbytheManufacturer....................19

9.2.Utilizationofthesignal‐processingunitsthatarenotrepairableistobeperformedatenterpriseJSC

“Forteza“............................................................................................................................................................19

10.Metrologicalsupport.................................................................................................................................20

10.1.ToensurethecheckoftheparametersspecifiedinthepresentOperationManualuseshouldbe

madeofthefollowingcalibratedmeasuringinstruments:...............................................................................20

Contacts.................................................................................................................................................................21

JSC“Forteza”“FortezaTribo‐M”operationmanual

4

1. Generalinformation

Theoperationmanualcontainsinformationabouttheconstruction,technicalfeatures,operation

andapplicationofthe“FortezaTribo‐M”securitydetectorsystem.Themanualalsocontains

information,necessaryfortheproperinstallationanduseofthedevice.

1.1. Purpose

“FortezaTribo‐M”issingle‐positiontriboelectric,passiveandunmaskedguardalarmsystemwith

surfacedetectionzone,whichisdesignedforextendedperimeterareasandisusedasastationary

unit.

Theguardalarmsystemforperimeterfencesismeanttogeneratealarmsignalsonthelocal

deformationofthefenceandthesensorfastenedtoitinunauthorizedpenetrationbygettingover

thefence,nofacilitiesbeingused,andasaresultofdamagetothefence,thesensor,andits

fasteners.

Theguardalarmsystemensuresthemonitoringofthesensorintegrity(thecableoftriboelectric

effect),theconnectingcablebeingcheckedaswell.Ontheirdamage(short‐circuitorbrokencable)

theguardalarmsystemgeneratesanalarmsignalonthefault.

1.2. Operatingconditions

Theguardalarmsystemisintendedforcontinuousround‐the‐clockoperation.Its

performanceismaintainedwithinthesetnormalvalues.Theguardalarmdoesnotgeneratethefalse

“Alarm”signalsonandafterexposuretotheoutdoorenvironmentalfactors(OEF)giveninTable1.1.

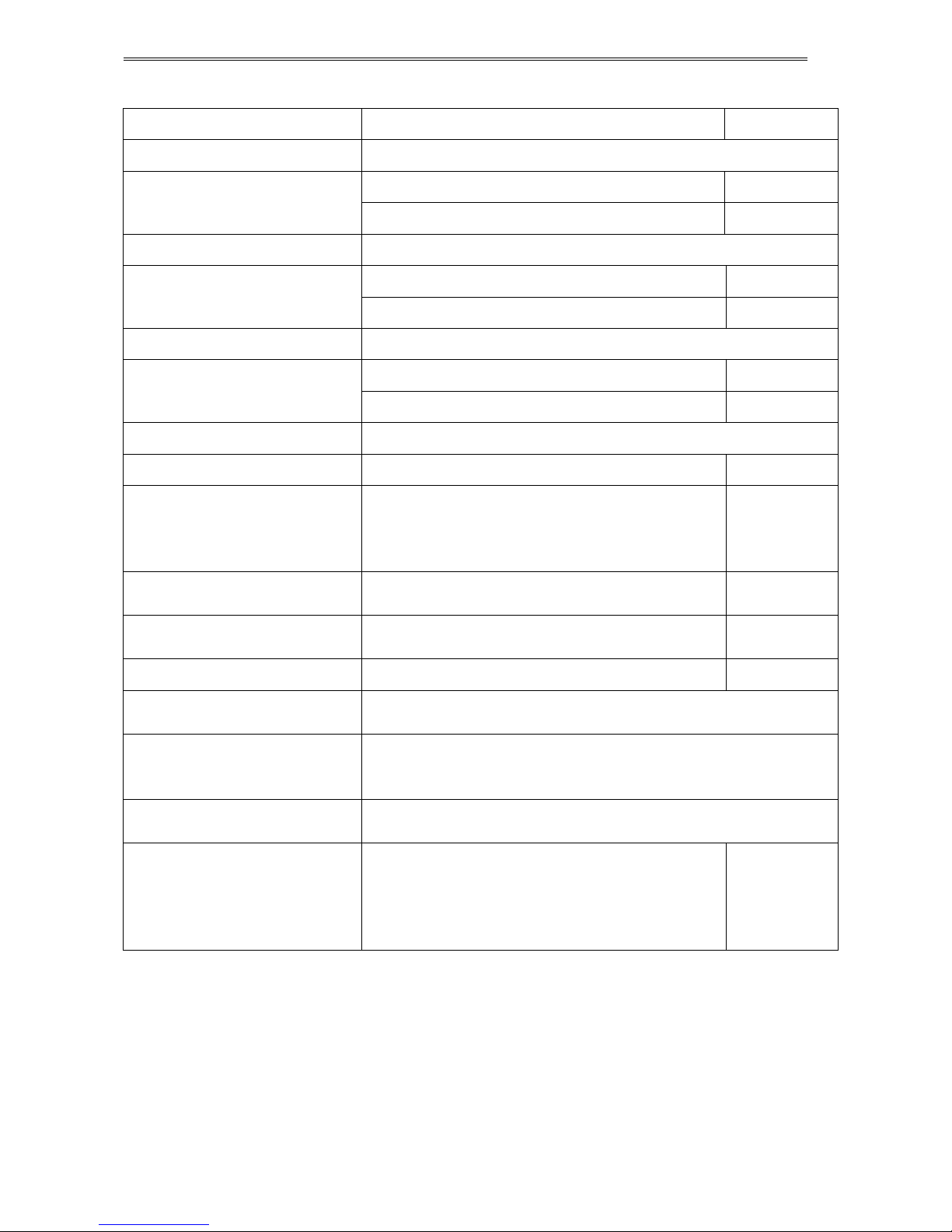

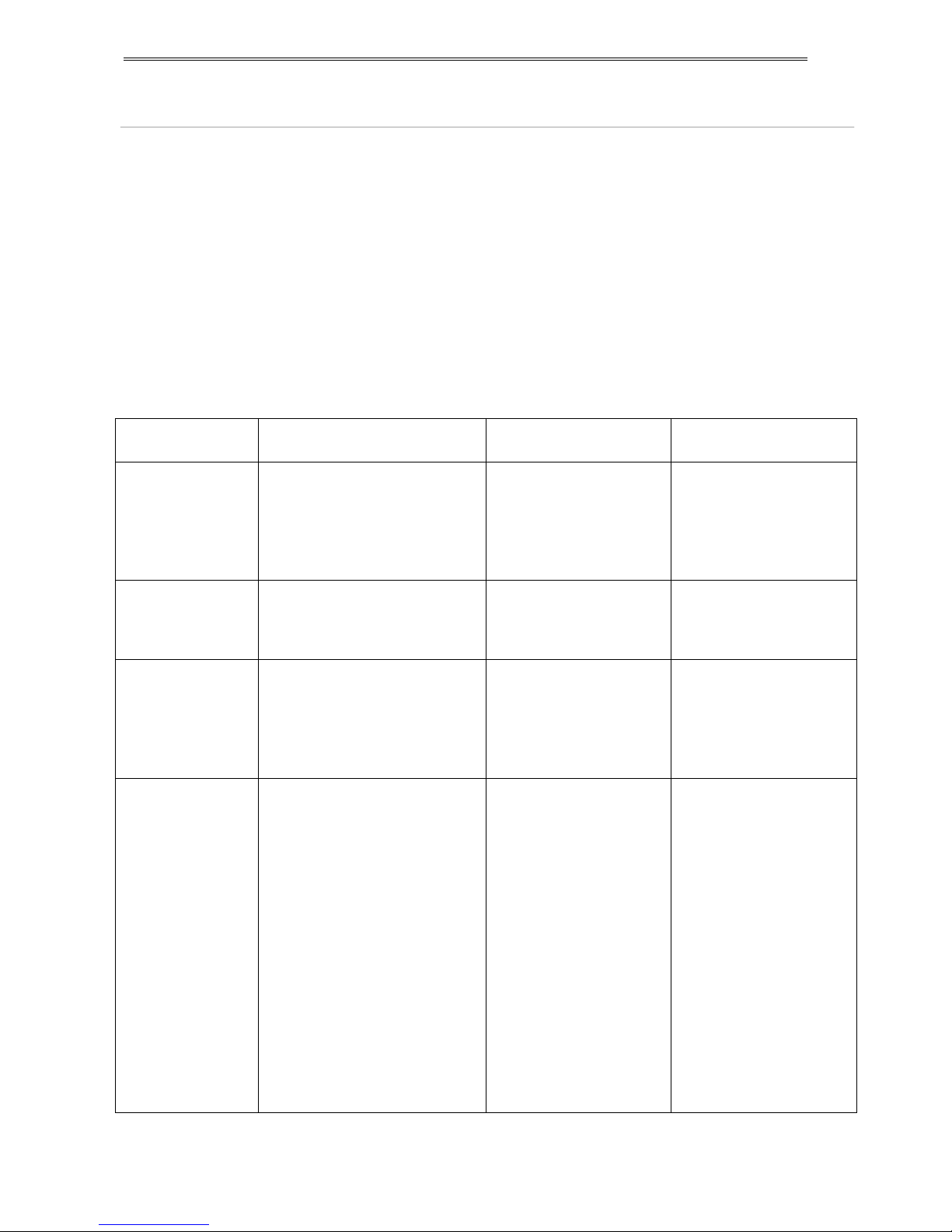

Table1.1

OEFDescriptionValue

AcousticnoiseIsnotregulated

ElevatedambienttemperatureElevatedoperatingtemperature+50oC

LowambienttemperatureLowoperatingtemperature‐40oC

Elevatedhumidity

Upto98%atatemperatureof+35oC

Isnotregulatedwithasignal‐processingunit(SPU)installedinthemetal

alarmcabinet

LowhumidityIsnotregulated

RainIsnotregulated

Hoar‐frostandice‐crusted

groundThickness(atwindspeed)2mm

(10m/s)

DewIsnotregulated

BlanketofsnowIsnotregulated

FogOfanyintensity

JSC“Forteza”“FortezaTribo‐M”operationmanual

5

Table1.1continued

OEFDescriptionValue

Saline(sea)fogOfanyintensity

Dust(sand)

Particlescirculationspeed10m/s

Dust(sand)flowdensity5kg/m2/s

Ultra‐violetsolarradiationIsnotregulated

Wind

Meanwindspeed20m/s

Maximumwindspeedvalue30m/s

Blizzardsandsand‐stormsOfanyintensity

Ground

Maximumsubgradeslopeforthefence 30deg.

Terrainirregularitiesalongthefenceaxis±0,30

HerbageIsnotregulated

FloodForfence‐depth0.3m

One‐manmovement,

movementofseveralpeople

(from3to5men)andbig

animals

Distancetotheguardedzone0.5m

Drivingofwheeled,full‐track

andelectric‐batteryvehiclesDistancetotheguardedzone1.5m

Railwayfreightandpassenger

transportDistancetotheguardedzone15m

Powerlines(upto500kV)Distancetotheguardedzone5m

Exposuretotheradar

electromagneticfield

Isnotregulated(withasignal‐processingunitinstalledinthe

metalalarmcabinet)

Exposuretotheultra‐short

pulsesoftheelectromagnetic

field

Isnotregulated(withasignal‐processingunitinstalledinthe

metalalarmcabinet)

Exposuretothemomentum

neutronfluxIsnotregulated

Influenceofbirdsandsmall

animalsoverthefence

components:

‐birds

‐smallanimals

Weight

1(5)kg

upto20kg

JSC“Forteza”“FortezaTribo‐M”operationmanual

6

1.3. Technicalcharacteristics

•TheguardalarmisenergizedfromanuninterruptedDCpowersourcewithsupplyvoltages

from9to36V;

•Withvoltagedropbelow5Vtheguardalarmgoesintothe“Alarm”mod;

•Minimallengthofthesensortobeconnected(tribocable)comesto1.2m.

•Maximallengthofthetribocabletobeconnecteddoesnotexceed1000m.(4zoneseach

250m);

•Maximalareaofdetectionzone(enclosedarea)dependsonthefencetypeandthewayofthe

sensorlaying.

1.4. Standardequipment

Thefollowingequipmentisincludedintheguardalarmdeliveryset:

‐signal‐processingunit;

‐adapter;

‐terminalunit;

‐USB/RS485cable

‐Software

JSC“Forteza”“FortezaTribo‐M”operationmanual

7

2. DESIGNANDPRINCIPLEOFOPERATION

2.1. PrincipleofOperation

Thebasisfortheguardalarmoperationisgenerationofelectricalsignalsinthesensorandatits

stresscenters(pointsofthesensorrigidfasteningtothefence)undermechanicalactiononthefence

componentsandtheirsubsequentdetectionbythesignal‐processingunit.

2.1.1. Sensor

Thesensormountedonthefenceismeantforelectricalsignalgenerationunderunauthorized

mechanicalactionsonthefence.

Itisagoodpracticetousetribocableasasensor.

Thesensorlengthdependsontheguardedzonelength,thefenceheight,numberofsupports,

andtheselectedwayofthesensormountingonthefence.

2.1.2. SignalProcessingUnit

Thesignal‐processingunit(SPU)isusedforthesensorsignalsdetectionandthealarmsignal

generation.

SPUisdesignedinthemetalcase.Locatedinsidethecaseisanelectronicboardarrangedaround

whicharein‐circuitelementsofthesignal‐processingunit,RS485connection,terminalsforthe

externalcircuitsconnection,andtheguardalarmcontrols.

ProvidedontheSPUcasearefastenersmeantforitsinstallation.

2.1.3. AdapterandCoupling

Theadapterismeantforconnectingthesensortogetherwithitsconnectingcabletothesignal

processingunitandfortheconnectionpointshieldingandsealing.

Inequippinggatesandwicketsuseshouldbemadeofanextendedadapterpermittingtofixa

spiralwraphosefortheconnectingcableprotection.

Thecouplingisusedwhenneededtoconnecttwoseparateportionsofthesensorandforthe

connectionpointshieldingandsealing.

Thecouplingisequippedwithnylontiesneededforitsfasteningtothefence.

2.1.4. TerminalUnit

TheterminalunitprovidesacontinuousmonitoringofthesensorandtheSPUconnectingcable

integrity.Itisalsomeantforthesensorendpointshieldingandsealing.

JSC“Forteza”“FortezaTribo‐M”operationmanual

8

3. APPLICATION

Toensuretherequireddetectability(unauthorizedactionsdetection),highnoiseimmunity(actually

anutterabsenceoffalseresponses)andspecifiedsabotageresistance

THEFOLLOWINGSHOULDBEPROVIDED:

•properfencemounting(flexiblefencesshouldbestretcheduniformlywithspecifiedtension

force);

•combinationofdifferent‐typefencesandoftribocablelayingandfasteningschemes;

•fenceuniformity,i.e.thefenceshouldbemadeofthesamematerialasdifferent‐material

sectionsgeneratesignalsofdifferentstrengthwhensubjectedtoanunauthorizedaction;

•tribocableproperinstallationandtightness;

•SPUsensitivitysettingwithspecifieddetectability.

3.1. VersionsofFenceEquipping

Possiblearethefollowingversionsoftheguardalarminstallation:

‐flexiblefencemadeofreinforcedbarbedtape,wirenetting,wirenetting“Rabitsa”,barbed

wire,etc.(Fig.1);

‐rigid(continuous)fencemadeofmetalelements(forgedandweldedgratings,solidmetal

plates,corrugatedplates,etc.),concrete,bricks,wood,etc.(Fig.2);

‐gates,wickets,etc.(Fig.3).

3.1.1. FlexibleFence(Fig.1)

Flexiblefenceisactuallyafencemadeofmetalwirenettingaccording,barbedwire,wireof

rust‐resistantsteel,bimetallicwire,reinforcedbarbedtape,etc.

Thesensorismounteddirectlyonthefenceflexibleelements.Thesupportsenablinga

violatortogetoverthefencewithouttouchingitsflexibleelementsbeingavailable,thesensoris

mountedonthesupportsaswell.

The“Alarm”signalisgeneratedontheflexiblefenceunderlocaldeformationofthefenceand

thesensorfastenedtoitincaseofunauthorizedpenetrationbygettingoverthefence,nofacilities

beingused,andasaresultofdamagetothefence,thesensor,anditsfasteners.

Toobtaintherequirednoiseimmunity,besuretolimittheflexiblefencemobilityunderwind

asmuchaspossible.

3.1.2. WireNettingFence(Fig.1а)

Thewire‐nettingfenceshouldmeetthefollowingrequirements:makesurethenettingis

stretcheduniformlybetweenthefencesupportsinahorizontalplanewithaforceof100kg,

minimum.

3.1.3. “Rabitsa”Wire‐NettingFence(Figs1band1c)

The“Rabitsa”wire‐nettingfenceshouldmeetthefollowingrequirements:

•makesurethenettingisstretcheduniformlybetweenthefencesupportsinahorizontalplane

andfastenedtotheupperandlowerwireropes(Fig.1b);

•aframemadeofanglesectionsbeingused,makesurethenettingisstretcheduniformlyand

fastenedtotheallsidesoftheframe.Inadditionbesuretolaythesensoralongtheupper

anglesectionoftheframeandthefencesupports(Fig.1c).

JSC“Forteza”“FortezaTribo‐M”operationmanual

9

3.1.4. BarbedWireFence(Fig.1d)

Thebarbed‐wirefenceisactuallybarbedwirestretchedinseverallevellinesbetweenrigid

supports.Stretcheddiagonallyisalsobarbedwirefastenedtoeachlevelwireline,which,initsturn,

shouldberigidlyfastenedtoeachfencesupport.

Thebarbed‐wirefenceshouldmeetthefollowingrequirements:makesurebarbedwireis

stretchedinahorizontalplanewithaforceof200kg,minimum.8

3.1.5. FenceMadeofFlat(Round)ReinforcedBarbedTape“АКЛ”(Fig.1e)

The“АКЛ”tapefenceshouldmeetthefollowingrequirements:makesurethereinforced

barbedtapeisfastenedtothewireropesstretchedbetweenthefencesupportswithaforceof200

kg,minimum,ontwosides.

3.1.6. Rigid(Continuous)Fences(Fig.2)

Rigidfenceisafencemadeofmetalelements(forgedandweldedgratings,solidmetalplates,

corrugatedplates,etc.),woodenmaterials,reinforcedconcretepanels,concreteblocks,brickworkor

masonry.

Thesensorismounteddirectlyontherigidfenceelements.Thesupportsenablingaviolator

togetoverthefencewithouttouchingitsrigidelementsbeingavailable,thesensorismountedon

thesupportsaswell.

Toequiprigidfenceofforgedandweldedgratingsbesuretolaythesensoraccordingtothe

diagramwithstresscentersoneverybar(Fig.2а);

Toequiprigidfenceofwoodenmaterials,solidmetalplatesandcorrugatedplates,besureto

laythesensoraccordingtothediagram,stresscentersbeingmadewithclamps(Figs2band2c).

Note.Thestiffenerbeingavailableatthetopofthefence,besuretolaythesensoralongthis

stiffeneraswell.

Toequiprigidsolidfenceofreinforcedconcretepanels,concreteblocks,brickworkor

masonry,besuretolaythesensoralongthefenceuppercrownunderthevisormadeofdeformable

material,forexample,plate(Fig.2d).

Anextraflexiblefencebeingavailableovertherigidsolidone,besuretolaythesensoralong

theflexiblefence(Fig.2e).

3.1.7. Gate(Wicket)(Fig.3)

Thegate(wicket)isactuallyaframemadeofmetalanglesectionsortubes,theinnerspace

beingfilledwithbarsornettingweldedtotheframe.Theinter‐barclearanceshouldnotexceed0.15

m.

Theaforesaidrequirementscovergates(wickets)aswell.

Thefenceandthegatebeingofthesamematerial,justonesensorcanbeused.

Ifsothesensorislaidonsupportsbetweenthefenceandthegatethroughspecialstretch‐out

boxes,extendedadaptersandaspiralwraphose.

Besuretolaythesensorfromonegateleaftoanotherinametalbypasspipeburiedata

depthof0.3m,minimum.

Thefenceandthegatebeingofdifferentmaterials,besuretoequipthemwithseparateguard

alarms.

JSC“Forteza”“FortezaTribo‐M”operationmanual

10

4. Serviceabilitycheck

4.1. SafetyPrecautions

Onlyaskilledelectrician,atleastofthefifthrate,familiarwiththepresentManualisentitledto

performtheguardalarminstallation,operationandmaintenance.

Besuretoobservetheinstructionsfortheelectrictoolsuseandworkingataheightintheguard

alarminstallationandmaintenance.

MakesurethemeasuringinstrumentsswitchedintotheACcircuitarereliablygrounded.

4.2. ServiceabilityCheck

TheguardalarmistobeinspectedforexternaldefectsonitsreceiptfromtheManufacturer.

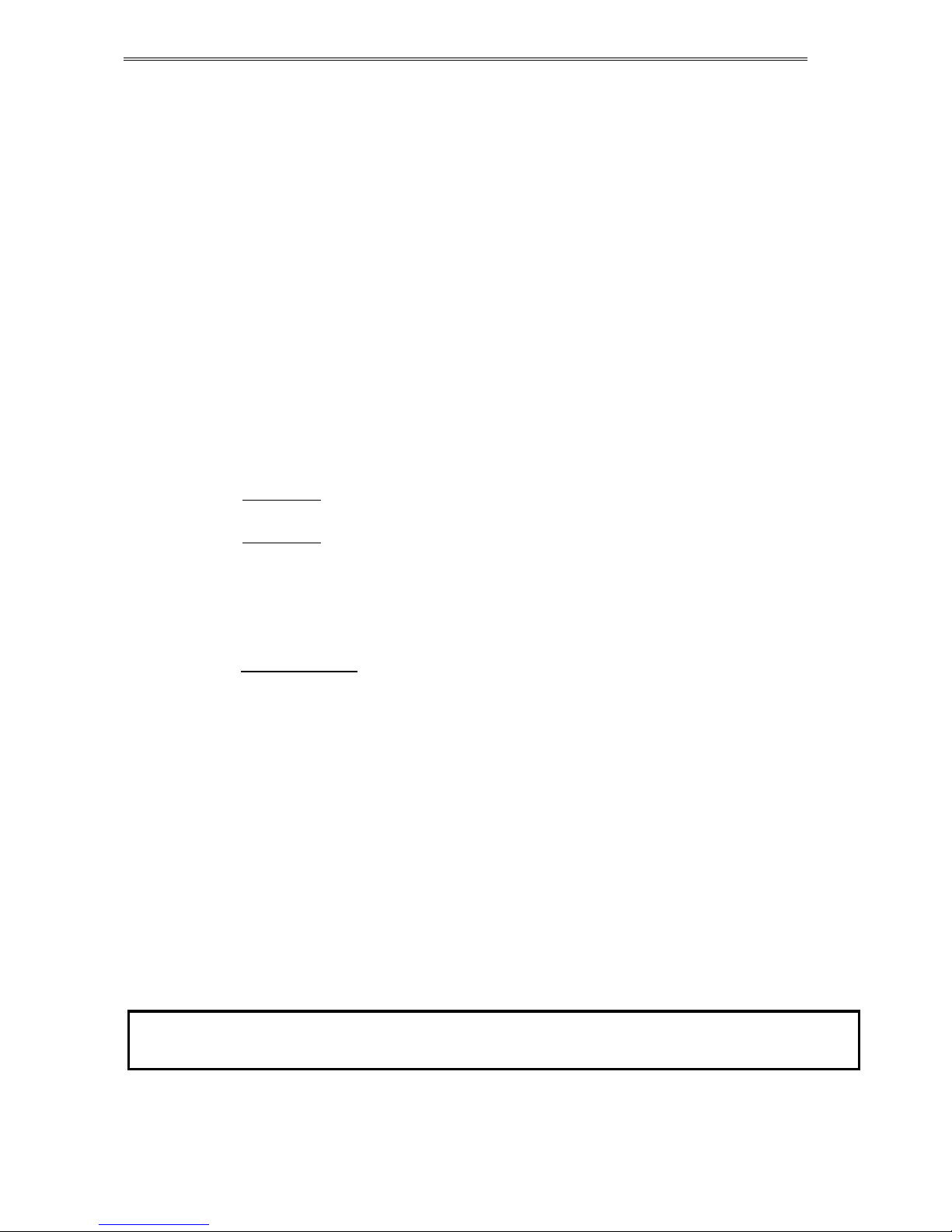

ChecktheguardalarmforserviceabilityincompliancewithTable4.1.

Table4.1

DescriptionandprocedureofcheckTechnicalrequirements

CheckofcompletenessCorrespondencewiththecertificateandcontract

Checkforappearance

Visualinspection

Absenceofmechanicaldamagesandcorrosion.

AvailabilityofintactManufacturersealonthe

coveroftheSPUcase

JSC“Forteza”“FortezaTribo‐M”operationmanual

11

5. Installationandpreparationforuse

5.1. General

Besuretoobserveallnormsandregulationsforassemblingandwiringworkintheguardalarm

installation.

Theguardalarmbeingpoweredfromtheremotepowersource,selectthetypeofwireandthe

conductorcross‐sectionsothatthevoltageacrosstheSPUterminalsisfrom9to36Vwiththe

outputpowersupplyvoltagechangingwithinpermissiblelimits.

IMPORTANT.Toensuretheguardalarmtrouble‐freeoperationprovisionshouldbemadeforthe

standbyDCpowersupply

Usenon‐sensitivecabletoconnectthesensortothesignal‐processingunit.

Makesurenon‐sensitivecableishiddenandthepossibilityofitsdamageiseliminatedwhen

layingthecablefromthesignal‐processingunittothesensorend.

5.2. SPUInstallation

Inequippingtheperimeterfencesitisagoodpracticetoinstallthesignal‐processingunitinthe

metalsplash‐proofcabinettoimprovetheguardalarmsabotageresistanceandtoallowforthe

additionalequipmentlocation(analarmbutton,anetworkcontrollerofthedataacquisitionand

processingsystem,etc).Besuretolocatethecabinetandthesignal‐processingunitinitsothatthe

connectingcablesofthesensor,alarmstub,remote‐monitoringstubandpowerleadsare

convenientlyconnectedandthepossibilityofSPUperiodicinspectionandadjustmentisprovided.

PriortotheSPUinstallation,doholeslayoutworkfortheSPUfasteningandfastenitwithscrews

andscrewnails.

Thefollowingequipmentistobeconnectedtothesignal‐processingunit:

•groundbus(uninsulatedcopperwireofcross‐section1.0mm2,minimum);

•sensorconnectedbymeansofconnectingcable;

•alarmstub;

•remote‐monitoringstub;

•supplyline.

CAUTION.

Be sure to ground the guard alarm only at one point - by a fastener on the SPU case.

In mounting the connecting cable, sensor and terminal unit, be sure to eliminate the possibility of

grounding at other points of electric circuit.

In connecting alarm and remote-monitoring stubs, MAKE SURE they are de-energized.

Check the conductors’ polarity in connecting the supply line.

JSC“Forteza”“FortezaTribo‐M”operationmanual

12

5.3. SensorLaying

Priortolaying,proceedasfollows:

•checkthesensorinsulationresistance(makesuretheinsulationresistancebetweenallthe

conductorsandthebraidedshieldisatleast1MOhm);

•first,arrangethesensoralongthefenceinsidewithoutbights;makesureitisfreeof

mechanicaldamagesandthesensorendsareprotectedfrommoistureingress.

Tolaythesensor,proceedasfollows:

•proceedaccordingtothedesigndocuments;

•makesuretheambienttemperatureisnotlessthanminus10

о

С;

•inlayingthesensoralongthefencemakesuretheradiusofitsbendis120mm,minimum;

•thestresscentersshouldbemadewithsteelgalvanizedwireatleast1.6mmindiameteror

withrigidsteelclamps;

CAUTION. The cable fastening should be rigid enough to prevent its ANY lengthwise movement

relative to the attaching point and the fastener movement relative to the fence.

To create “stress centers” at attaching points BE SURE to provide for the tribocable sheath

visible deformation without its integrity breaking.

Sensorcuttingsbeingusedinterconnectthemwithacoupling.

5.4. SplicingtheEndsoftheTribocableandConnectingCable

Splicetheendsofthetribocableandconnectingnon‐sensitivecable.

Topreparethetribocable,proceed:

•slipasealoverthetribocable;

•removetheexternalinsulationofthetribocableforadistanceof35to40mm;

•cutthebraidedshieldoffexceptfor9to11mmleftattheexternalinsulationedge;

•cutthecontactwireoffexceptfor9to11mmleftattheexternalinsulationedge;

•bendthebraidedshieldwiththecontactwiretowardstheexternalinsulation;

•cutthetapeoffforadistanceof2to3mmfromtheexternalinsulationedge;

•cutoffallcentralconductorsforadistanceof30to32mmfromtheexternalinsulationedge;

•skinallcentralconductors;

•cuttheconductorsoffbringingtheirnumbertosixandtwistalltheconductorstogether;

•applyplasticstrapsservingtothefoldedbraidedshieldexceptfor35to40‐mmwireendleft

uncovered;

•shapethetwistingofcentralconductorsincompliance.Besuretogetatotallengthof28mm;

•makesurethelengthofthesix‐conductortailis6mm,minimum.

JSC“Forteza”“FortezaTribo‐M”operationmanual

13

Topreparecablenon‐sensitive,proceedasfollows:

•slipasealfornon‐sensitivecableoverthecable;

•slipanebonitebushoverthecable;

•removetheexternalinsulationfromnon‐sensitivecableforadistanceof42to44mm;

•dividethebraidedshieldintostrands;

•applythebraidedshieldstrandstotheebonitebush;

•applytinned‐wireservingexceptfor35to40‐mmwireendleftuncovered;

•removethecentralconductorinsulationexceptfor18to20mmleftattheexternalinsulation

edge;

•foldtheskinnedcentralconductorintwolayersandtwistitsothatthelengthoftheskinned

endcomesto12mm;

•shapethecentralconductorincompliance.Besuretogetatotallengthof28mm;

•makesurethetaillengthis6mm,minimum.

5.5. CablesTerminationinAdapter(Fig.8)

5.5.1. Toterminatethecablesintheadapter,proceedasfollows(Fig.8a):

•pullthesplicedendsofthetribocableandnon‐sensitivecablethroughthebraidedshieldand

adaptercaseholes;

•connectthesplicedendsofthetribocableandnon‐sensitivecabletothecorresponding

contactsoftheterminalblock.Besuretoinsulatebareportionsofthetribocableandnon‐

sensitivecablecentralconductorsfromaccidentalcontactwiththebraidedshield;

•slipthebraidedshieldoverthecableconnectorandthebushsothattheedgesofthebraided

shieldandthebushcoincide.Insodoing,makesurethetinned‐wireleadsarearranged

throughthecentreofthebraidedshieldcontact;

•crimpthebraidedshieldcontactstogetherwiththetinnedwire.Makesurethediameteris

notinexcessof16mm;

•sliptheadapteroverthebraidedshield;

•putgasketsintotheadaptercase;

•tightenthescrewsoftwoclampssothattheadaptercasefitstightlyagainstthecables(make

surethelocationsofclampsandgasketscoincide).

Topreventmoistureingressintotheadapteruseshouldbemadeofneutralsealantappliedatthe

pointsoftheadaptercaseandgasketscontact.

5.5.2. Toterminatethecablesintheextendedadapterinequippinggatesandwickets(Fig.

8b),proceedaccordingtoItem5.5.1butbesurefirsttosliparequired‐lengthspiral

wraphoseovercableРК.Thenslipasealoverthespiralwraphoseend.Completingthe

cableterminationbesuretoputthespiralwraphoseendtogetherwiththesealintothe

caseandtightenitwiththethirdadditionalclamp.

Besuretotightenonlynon‐sensitivecableseal,notthespiralwraphoseone.

JSC“Forteza”“FortezaTribo‐M”operationmanual

14

5.6. CablesTerminationinCoupling

Toterminatethecablesinthecoupling,proceedaccordingtoItem5.5.1exceptthatthesecond

cuttingofthetribocableisconnectedtotheterminalblockinsteadofnon‐sensitivecable.

Topreventmoistureingressintothecouplinguseshouldbemadeofneutralsealant.

5.7. CableTerminationinTerminalUnit(Fig.9)

SplicethetribocableendincompliancewithItem5.4.

Toterminatethetribocableintheterminalunit,proceedasfollows:

•pullthesplicedendofthetrobocablethroughtheholesofthebraidedshieldandtheterminal

unitcase;

•usetheterminalblocktoconnectthesplicedendofthetribocabletotheprintedcircuitboard

andtightenthefasteningscrews;

•besuretoinsulatethebareportionsofthetribocablecentralconductorsfromaccidental

contactwiththebraidedshield;

•slipthebraidedshieldoverthecableconnectorandthebushsothattheedgesofthebraided

shieldandthebushcoincide.Insodoing,makesurethetinned‐wireleadsarearranged

throughthecenterofthebraidedshieldcontact;

•crimpthebraidedshieldcontactstogetherwiththetinnedwire.Makesurethediameteris

notinexcessof16mm;

•sliptheterminalunitcaseoverthebraidedshield;

•putsealandaplugintotheterminalunitcase;

•tightentheclampscrewssothattheterminalunitcasefitstightlyagainstthecable.Make

surethelocationsofclampsandgasketscoincide.

•Topreventmoistureingressintotheterminalunituseshouldbemadeofneutralsealant.

5.8. InstallationofAdapterandCoupling

Theadaptershouldbeinstalledonthefenceatthetribocableandconnectingcablejoint.

Thecouplingshouldbeinstalledonthefenceatthetribocablecuttingsjoint.

To ensure against moisture running down from the cable towards the coupling, be sure to install the

coupling horizontally over the cable.

Withallelectricalconnectionscompletedaccordingtotheschematicdiagram,usenylonties

beingapartofthecouplingdeliverysettofastenedittothefence.

5.9. TerminalUnitInstallation

To ensure against moisture running down from the cable towards the terminal unit, be sure to install the

terminal unit horizontally over the tribocable.

Withallelectricalconnectionscompletedaccordingtotheconnectiondiagram,usenylonties

beingapartoftheterminalunitdeliverysettofastenedittothefence.

JSC“Forteza”“FortezaTribo‐M”operationmanual

15

6. Controls

AllcontrolsandconfigurationscanbedoneusingPCprogram.

ConnectSPUtoPCviaUSBtoRS485connector(Providedinstandardequipmentpackage).

InstallprovidedSoftware.

FordetailedconfigurationseeAppendix1.

JSC“Forteza”“FortezaTribo‐M”operationmanual

16

7. Maintenance

7.1. Inmaintenancebesuretoobservethesafetyprecautionsspecifiedin

Section4.

7.2. Typesofmaintenanceservices:

•MonthlymaintenanceNo.1;

•Seasonalmaintenanceisperformedintheguardalarmpreparationforuseatautumn‐winter

andspring‐summerperiods;

•AnnualmaintenanceNo.2.

7.3. Forthescopeofmaintenanceservices,refertoTable7.1.

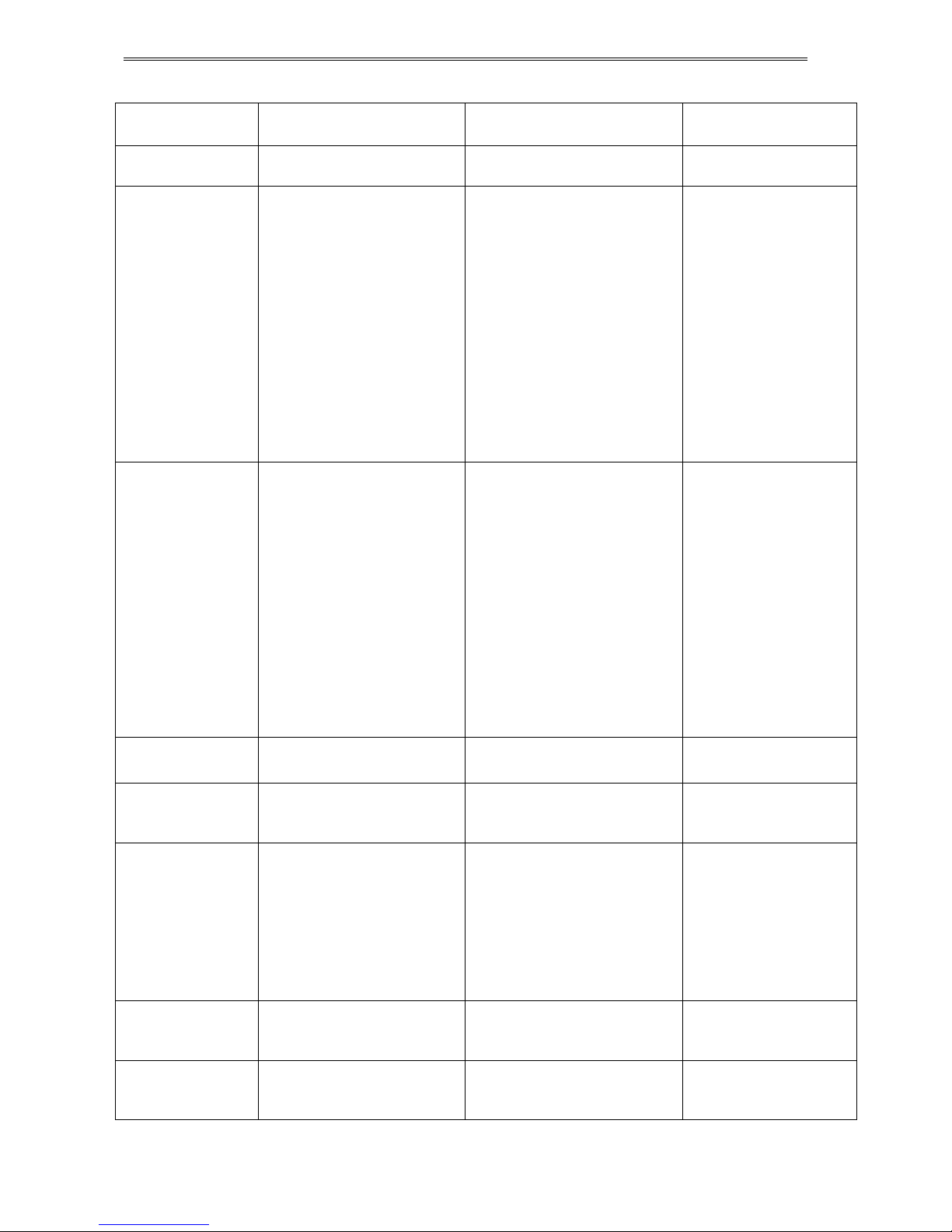

Table7.1

Typeof

maintenanceOperationsperformedProcedureNorms

1. MaintanceNo1

(mothly)

1.1. SPUvisualinspectionand

cleaningwithoutopening

it

CleantheSPUsurfaceof

dust,dirtandmoisture.

Makesurethecaseis

freeofmechanical

damages.Checktheseal

foravailability

TheSPUsurfaceshould

befreeofdust,moisture

andpronounced

mechanicaldamages.

Thesealshouldbeintact

1.2. SPUcheckforreliable

grounding

Inspectthepointsof

groundconnection

visually.Tightenthe

screwsup

Screwjointsshouldbe

tightenedsafely

1.3. Visualinspectionofthe

sensor,adapter,coupling,

andterminalunit

Thesensor,adapter,

coupling,andterminal

unitshouldbefreeof

damages.Thefastening

tothefenceshouldbe

intact

1.4. Guardalarmcheckfor

serviceabilitywiththeremote

monitoringfunction

Applya0.1to0.5‐s

supplyvoltagepulseto

the«ДК»inputofthe

signal‐processingunit.

Withthetest‐receiving

equipmentattheusing

activitynotpermitting

theuseoftheremote

monitoringfunction,

subjectthefence

componentsatits

differentportionstothe

checkactionwithaforce

of8kg,minimum,for

flexiblefencesand20kg,

minimum,forrigidones

Insodoingtheguard

alarmshouldgointothe

“Alarm”modeandthen

againintothe“Guard”

one.

Theguardalarmshould

gointothe“Alarm”mode

andthenagainintothe

“Guard”oneuponevery

checkaction

JSC“Forteza”“FortezaTribo‐M”operationmanual

17

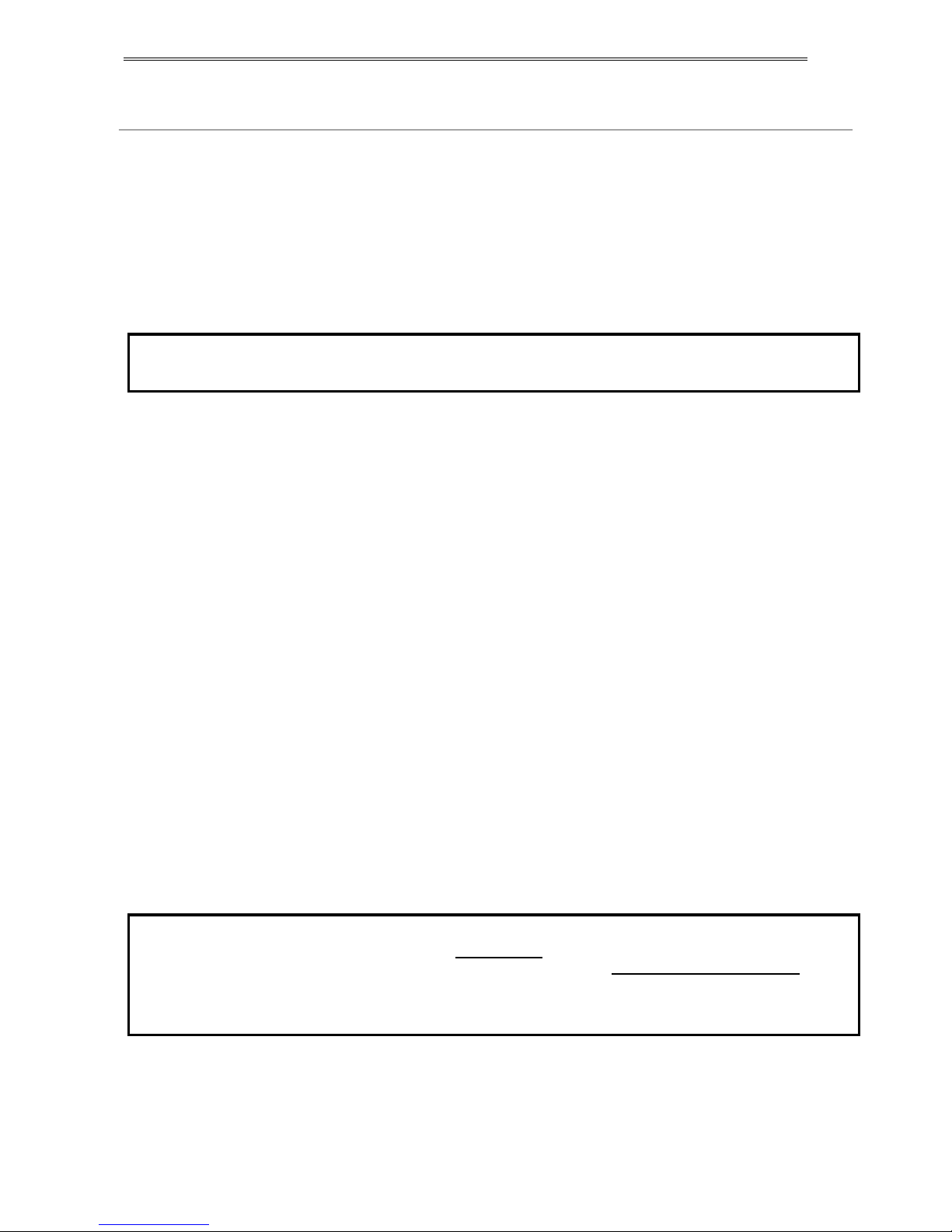

Table7.1,continued

Typeof

maintenanceOperationsperformedProcedureNorms

2. Seasonal

maintenance

2.1. Proceedto

maintenanceNo.1

2.2. CheckfordelectabilitySimulateanattempted

penetrationoverthefence

(mechanicalactiononthe

fencewithaforceof8kg,

minimum,forflexiblefences

and20kg,minimum,forrigid

ones).

Withnoalarmsignal,strivefor

thesteadyalarmsignal

generationunderattempted

penetrationoverthefence.To

thisendusethesensitivity

controllertoincreasethe

guardalarmsensitivity

Theguardalarmshould

gointothe“Alarm”

modeandthenagain

intothe“Guard”one

uponeverycheck

action

2.3. Checkfornoise

immunity

Subjectthefencetoanaction

withaforceof4kg,

maximum,forflexiblefences

and10kg,maximum,forrigid

ones.

Lessthan1‐sfencestrokewith

awoodenstick(branchstroke

simulation).

Theguardalarmbeing

switchedtothe“Alarm”

mode,usethesensitivity

controllertoreducetheguard

alarmsensitivityandproceed

accordingtoItems.2.2and2.3

Theguardalarmshould

notgointothe“Alarm”

modeuponeverycheck

action

2.4. Groundingresistance

measurement

Useanohmmetertomeasure

thegroundingresistance

RGRshouldnotexceed

10ohm

3. Maintenance

No.2(annual)

3.1. Proceedaccordingto

Items1.1to1.3ofthe

monthlymaintenance

3.2. Checktheexternal

circuitsandSPU

terminalblocksfor

reliableconnection

RemovetheSPUcover.Make

surethewiresarereliably

connectedtotheterminal

blocks.Withloose

attachment,tightenthe

screwsoftheterminals.Place

theSPUcoverintoposition

andsealit

Externalcircuitwires

shouldbereliably

connectedtothe

terminalblocksin

compliancewiththe

connectiondiagram

3.3. Proceedaccordingto

Item1.4ofthemonthly

maintenance

3.4. Proceedaccordingto

Items2.2to2.4ofthe

seasonalmaintenance

JSC“Forteza”“FortezaTribo‐M”operationmanual

18

8. Storageandtransportation

8.1. WhenpackedinManufacturer’sshippingboxes,guardalarmsmaybe

carriedbyanyclosedtransportmeans(boxcars,coveredtrucks,

pressurizedheatedcargobays,holds,etc)including:

•roadtransportrunningalongtheroadswithunimprovedpavementorwithoutitwithaspeed

upto50kmanhour,whilealongsomesectionswithaspeedupto20kmanhour,fora

distanceof500kmprovidedtheshippingboxesarerigidlysecuredonthetruckbed;

•roadtransportrunningalongtheroadswithimprovedpavementprovidedtheshippingboxes

arerigidlysecuredonthetruckbed;

•airtransportexceptfornon‐heatedcargobays;railwayandwatertransport,distance

unlimited,providedtheshippingboxesaresecuredaccordingtotheregulationsappliedto

thegiventransportmeans.

8.2. GuardalarmsinManufacturer’stransitpackingshouldbestoredin

heatedandventilatedstorehouseswithairconditioninglocatedinany

macroclimaticareasatanambienttemperaturefrom+5°Сto+40°Сand

relativeairhumidityupto80%at25°С.

8.3. Thestorehouseroomsshouldbefreeofdustandvapourofcorroding

agents.

8.4. Guardalarmsmaybetransportedatanambienttemperaturefrom

minus40°Сto+50°Сandrelativeairhumidityupto100%at25°С.In

transportation,besuretoprotectthemagainstdirectexposureto

precipitationanddust.

8.5. Guardalarmsinstandardpackingarestoredoneyear,maximum.On

theexpiryofthisperiodopenthepacking,inspecttheguardalarm

visually,removerevealeddefectsandpacktheguardalarminstandard

packing.

JSC“Forteza”“FortezaTribo‐M”operationmanual

19

9.Repairandutilization

9.1. Alltypesofthesignalprocessingunitrepairaretobeperformedby

theManufacturer.

9.2. Utilizationofthesignalprocessingunitsthatarenotrepairableisto

beperformedatenterpriseJSC“Forteza“.

JSC“Forteza”“FortezaTribo‐M”operationmanual

20

10. Metrologicalsupport

10.1. Toensurethecheckoftheparametersspecifiedinthepresent

OperationManualuseshouldbemadeofthefollowingcalibrated

measuringinstruments:

•multimeter,accuracyclass2.5;

•megohmmeter,accuracyclass1.5;

•dynamometer,accuracyclass2.

Note.Usemaybemadeofsimilarmeasuringinstrumentswithaccuracyclassnotlessthanthe

aforesaidones.

Other manuals for TRIBO-M

1

Table of contents

Other FORTEZA Security System manuals

Popular Security System manuals by other brands

Stardom

Stardom ST7610-4S-S2 Quick installation guide

Intellinet

Intellinet Network Camera & Video Server user manual

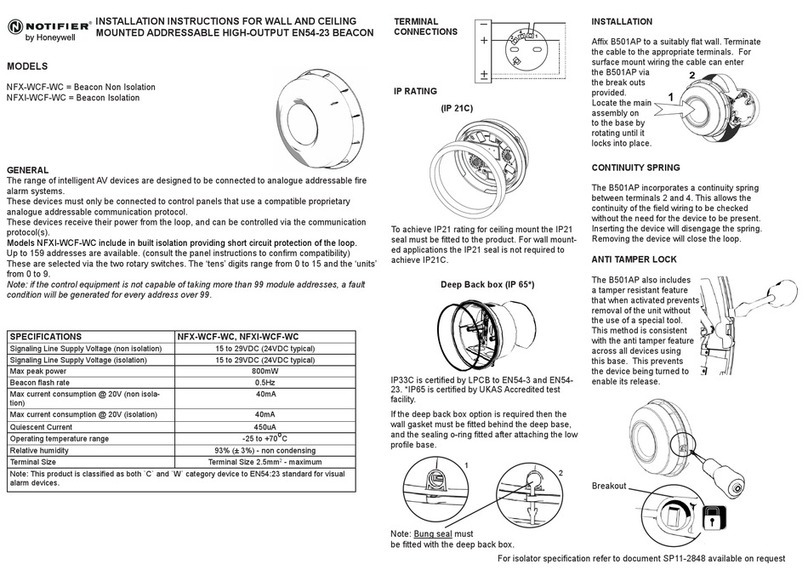

Notifier

Notifier NFX-WCF-WC installation instructions

Moore Industries

Moore Industries SPA TPRG quick start guide

ADT

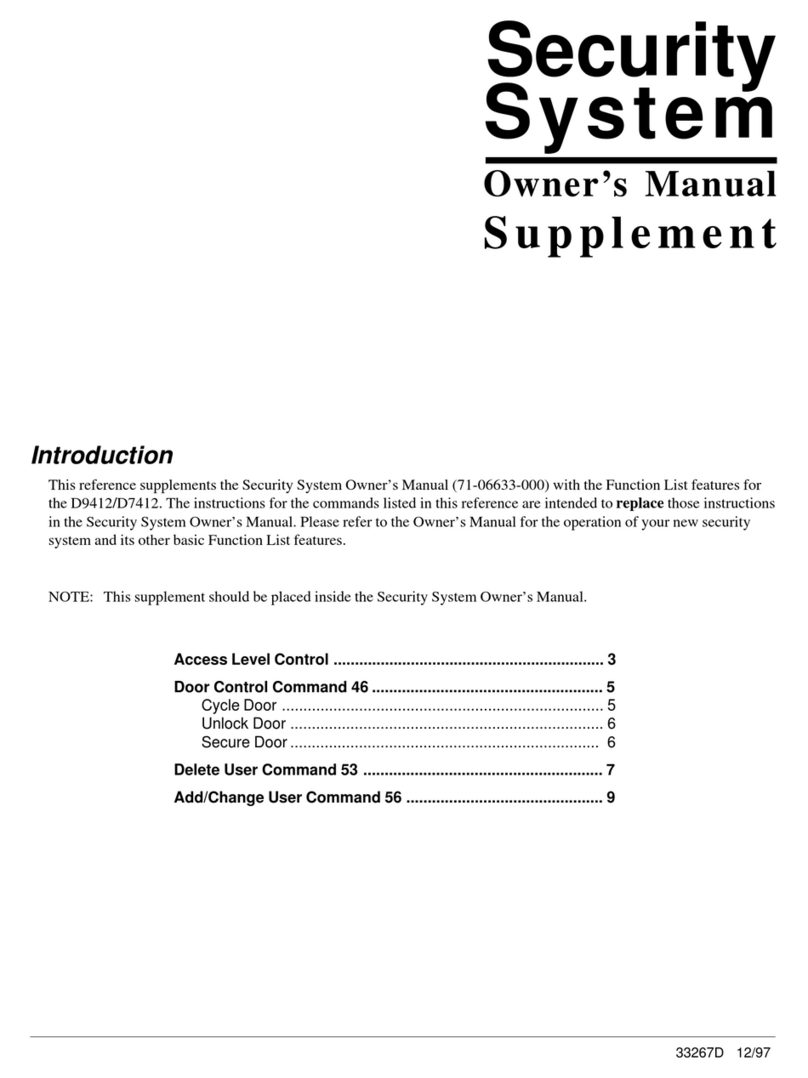

ADT Security System D7412 Supplement owner's manual

CBC

CBC MP3 user manual