Fortress Technologies AI13 User manual

1

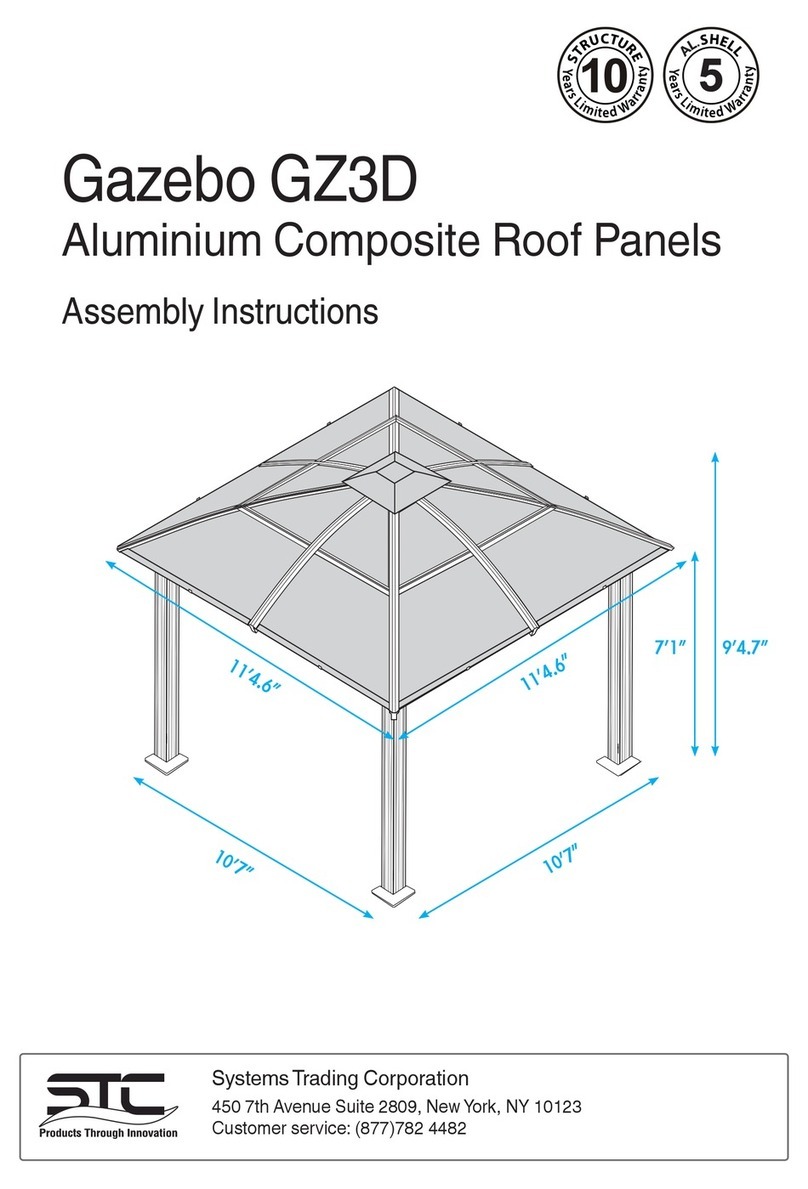

AL13 HOME TRADITIONAL PANEL INSTALLATION

INSTALLATION INSTRUCTIONS

INSTRUCTIONS D’INSTALLATION

INSTRUCCIONES DE INSTALACIÓN

TRADITIONAL ALUMINUM RAILING

RAMPE TRADITIONNELLE EN ALUMINIUM

BARANDAS DE ALUMINIO TRADITIONAL

2

AL13 HOME TRADITIONAL PANEL INSTALLATION

TABLE OF CONTENTS

English

Introduction...................................................................................3

Installation.....................................................................................5

OTP & Proud Post Installation.........................................5

Over The Top (OTP) Installation.....................................9

Proud Post Installation...................................................17

Angle Bracket Installation............................................22

Care & Maintenance.................................................................34

Warranty.....................................................................................35

Français

Introduction.................................................................................39

Installation...................................................................................41

Installation sur poteau et Proud Posts..........................41

Installation sur poteau..................................................45

Installation de Proud Posts...........................................53

Installation de ferrures à angle....................................58

Entretien......................................................................................70

Garatie........................................................................................71

Español

Introducción................................................................................75

Instalación..................................................................................77

Instalación OTP y postes salientes..............................77

Instalación sobre la parte superior (OTP)...................81

Instalación de postes salientes....................................89

Instalación de soporte en ángulo................................94

Cuidado y mantenimiento.......................................................106

Garantía....................................................................................107

3

AL13 HOME TRADITIONAL PANEL INSTALLATION

INTRODUCTION

READ INSTRUCTIONS COMPLETELY BEFORE

STARTING INSTALLATION

It is the responsibility of the installer to meet all code and

safety requirements, and to obtain all required building

permits. The deck and railing installer should determine and

implement appropriate installation techniques for each

installation situation. Fortress Railing Products and its

distributors shall not be held liable for improper or unsafe

installations.

Fortress AL13 HOME posts must always be secured to the deck

framing and should never be attached to only the deck

boards.

Note

When cutting Fortress railing, it is very important to complete

the following at cut points:

• Remove all metal shavings from the cut area.

• File any sharp edges left by cutting. Thoroughly wipe and

remove any filings, grime or dirt from the railing.

• Apply two coats of Fortress zinc based touch-up paint to the

cut area. If touch up is at rail ends, allow paint to dry before

connecting bracket to post.

• Be sure to remove any metal shavings from the surface of

deck, patio or balcony to prevent stains on the deck surface.

Torx Safety Tips

• Always use the lowest speed setting on drill.

• To reduce chance of bit breakage, start tightening with drill on

low torque setting and work up until screw is secured.

Tip: Pre-drill holes with 3/16” [4.5mm] drill bit.

4

AL13 HOME TRADITIONAL PANEL INSTALLATION

Required Tools

Goggles

Drill

Tape

Measurer

Level

Tool

Speed

Square

Touch-Up

Paint

Miter Saw

T-25

Driver Bit

#2 Phillips

Head Bit

Crescent

Wrench

Bit

Extender

5/16” [8mm]

Nut Driver Bit

Drill Bits:1/16”,

3/16”, 3/8”, 5/8” [1.5mm,

4.5mm,9.5mm, 16mm]

Al13 HOME Traditional Installation Options

Over The Post (OTP)

Socket

Set

Pencil

Rubber

Mallet

Hex

Wrench

Flat ATR

Line Splice

Round ATR

Line Splice

Flat Accent Top Rail

Round Accent Top Rail

Post

Pre-attached

Straight Brackets

2” [51mm]

Post

Post

Pre-attached

Straight Brackets

Post Base Cover

Flat ATR

End Splice

Round ATR

End Splice

I-Support

Al13 HOME Panels

69.5” [1763mm] or 93.5” [2375mm]

Spring

Punch

5

AL13 HOME TRADITIONAL PANEL INSTALLATION

Proud Post

Step 1: Install Wood Blocks

1. Install Wood Block level with top of joist. As shown in Fig.1(A)

2. Secure Wood Block to blocking on all four sides with #10 X

3-1/2” [89mm] deck screws.

• Wood Block must be constructed with treated dimensional

lumber with a minimum thickness of 1 1/2” [38mm].

OTP & PROUD POST: POST MOUNTING

Step 2: Position Base Plate

1. Position the edge of AL13 HOME base plate a minimum of ½”

[12.5mm] from the inside edge of rim joist. As shown in Fig. 1.

*If using Fortress Evolution Framing, contact Fortress for instructions.

Fig. 1

#10 x 3-1/3”

[84.5mm]

(A)

(A)

Joist

Blocking

Flat Accent Top Rail

Round Accent Top Rail

Post Cap

Post

Pre-attached

Straight Brackets

3” [76mm]

Post

Post Base Cover

Post

Pre-attached

Straight Brackets

I-Support

Al13 HOME Panels

69.5” [1763mm] or 93.5” [2375mm]

6

AL13 HOME TRADITIONAL PANEL INSTALLATION

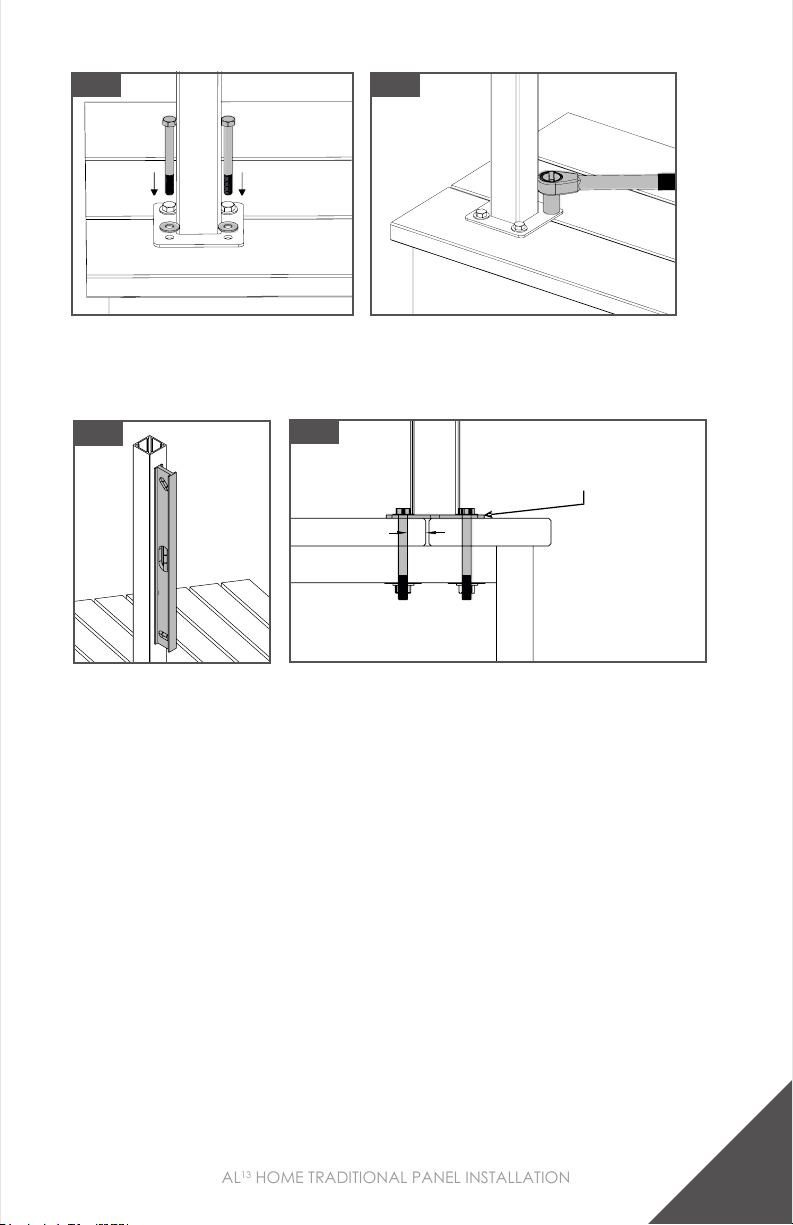

Step 4: Mount Posts

1. Mark mounting hole locations and pre-drill a 3/8” [9.5mm]

hole.

2. Insert 3/8” x 3-1/2” [9.5mm x 89mm]Hex Head galvanized

bolts through 3/8” [9.5mm] galvanized washer and post

base plate.

Note:

• Post Base Plate holes MUST be positioned a minimum ½”

[12.5mm] from edge of deck board.

• Use only 3/8” [9.5mm] Hex Head Galvanized Bolts. Lag

Screws should NOT be used. Secure each post with four bolts.

Fig. 1

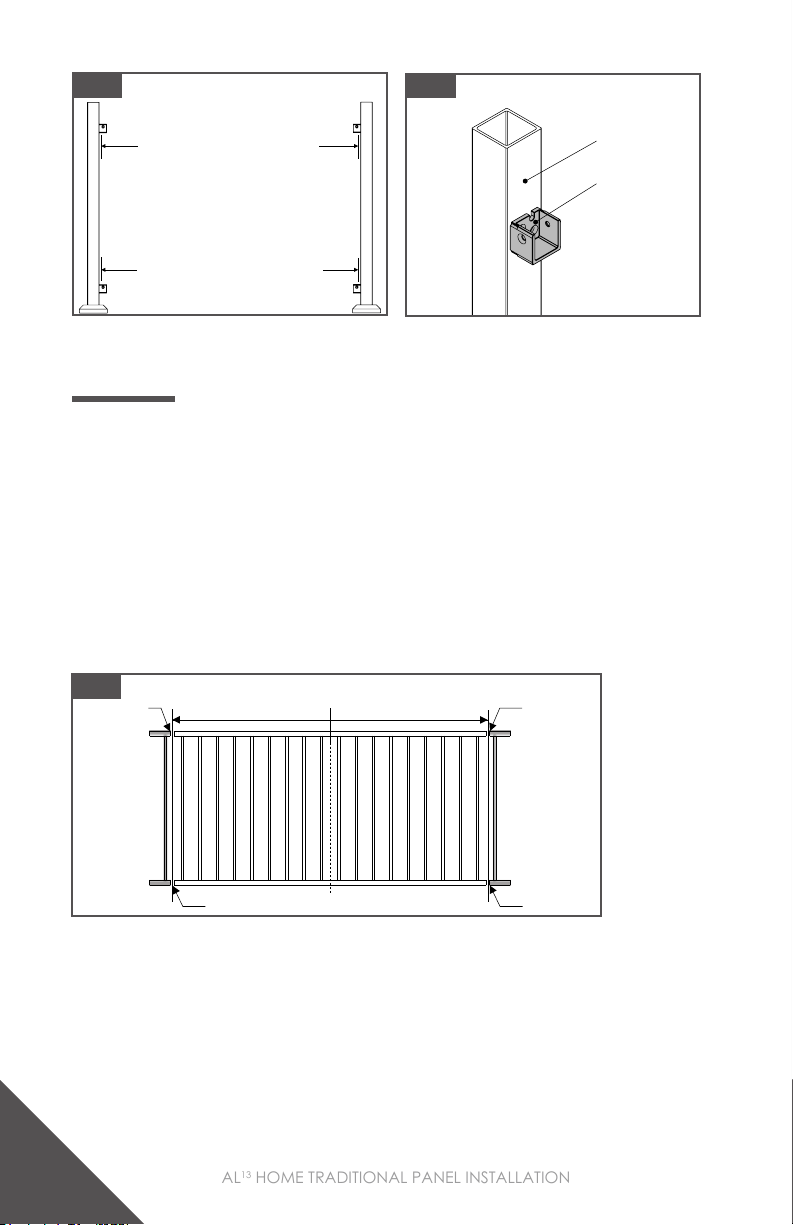

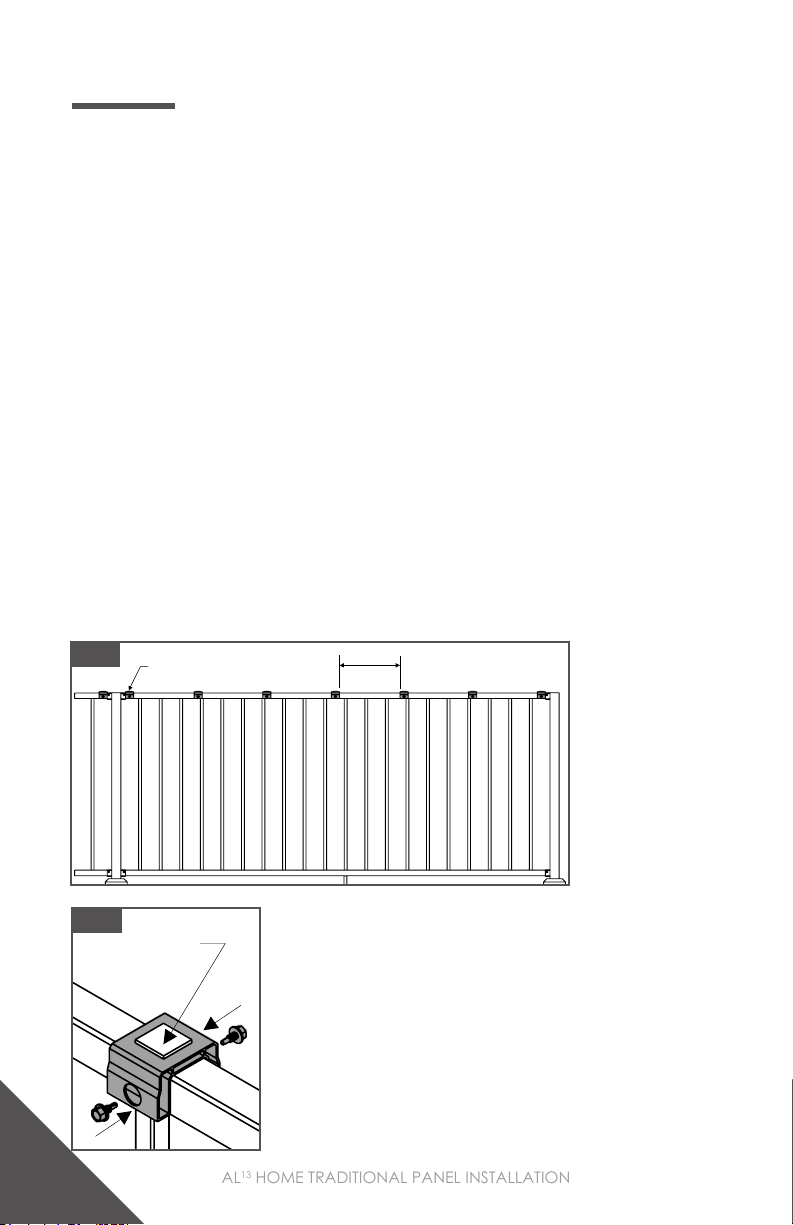

Step 3: Max Post Spacing

• 8’ panel maximum post spacing is 93-3/4” [2381mm].

• 6’ panel maximum post spacing is 69-3/4” [1771.5mm].

Note:

• Do not exceed the maximum post spacing.

Fig. 1

1/2” [12.5mm]

1/2”

[12.5mm]

8’ panel maximum post spacing is 93-3/4”

[2381mm]

6’ panel maximum post spacing is 69-3/4”

[1771.5mm]

7

AL13 HOME TRADITIONAL PANEL INSTALLATION

Step 5: Check Mounted Posts

1. Shim post as needed to ensure post is level.

Fig. 1

Fig. 1 Fig. 2

Step 6: Measure The Panel Opening Length

1. Measure the distance of the panel opening. As shown in Fig. 1.

2. Confirm that the measurements for the top brackets are the

same as the bottom brackets.

Note:

• Measure from the back wall of the bracket to the

back wall of the bracket on other post. As shown in

Fig. 2.

OTP and Proud Post: Max Post Spacing

• 8’ panel maximum post spacing is 93-7/8”.

• 6’ panel maximum post spacing is 69-7/8”.

Note: Do not exceed the maximum post spacing.

8’ Panel max post spacing 93-7/8”

6’ Panel max post spacing 69-7/8”

OTP and Proud Post: Measuring The Panel Opening Length

• Measure the distance of the panel opening.

• Measure from the back wall of the bracket to the back wall of the bracket on other post.

• Confirm that the measurements for the top brackets are the same as the bottom brackets.

Measure the panel opening

Not here

Measure from

back of bracket

Check measurement with top

3/12

OTP and Proud Post: Max Post Spacing

• 8’ panel maximum post spacing is 93-7/8”.

• 6’ panel maximum post spacing is 69-7/8”.

Note: Do not exceed the maximum post spacing.

8’ Panel max post spacing 93-7/8”

6’ Panel max post spacing 69-7/8”

OTP and Proud Post: Measuring The Panel Opening Length

• Measure the distance of the panel opening.

• Measure from the back wall of the bracket to the back wall of the bracket on other post.

• Confirm that the measurements for the top brackets are the same as the bottom brackets.

Measure the panel opening

Not here

Measure from

back of bracket

Check measurement with top

3/12

Fig. 2

Shim post as needed to

ensure post is level

Deck Board

Rim Joist

Joist / Blocking

Wood Block 1/2”

[12.5mm]

8

AL13 HOME TRADITIONAL PANEL INSTALLATION

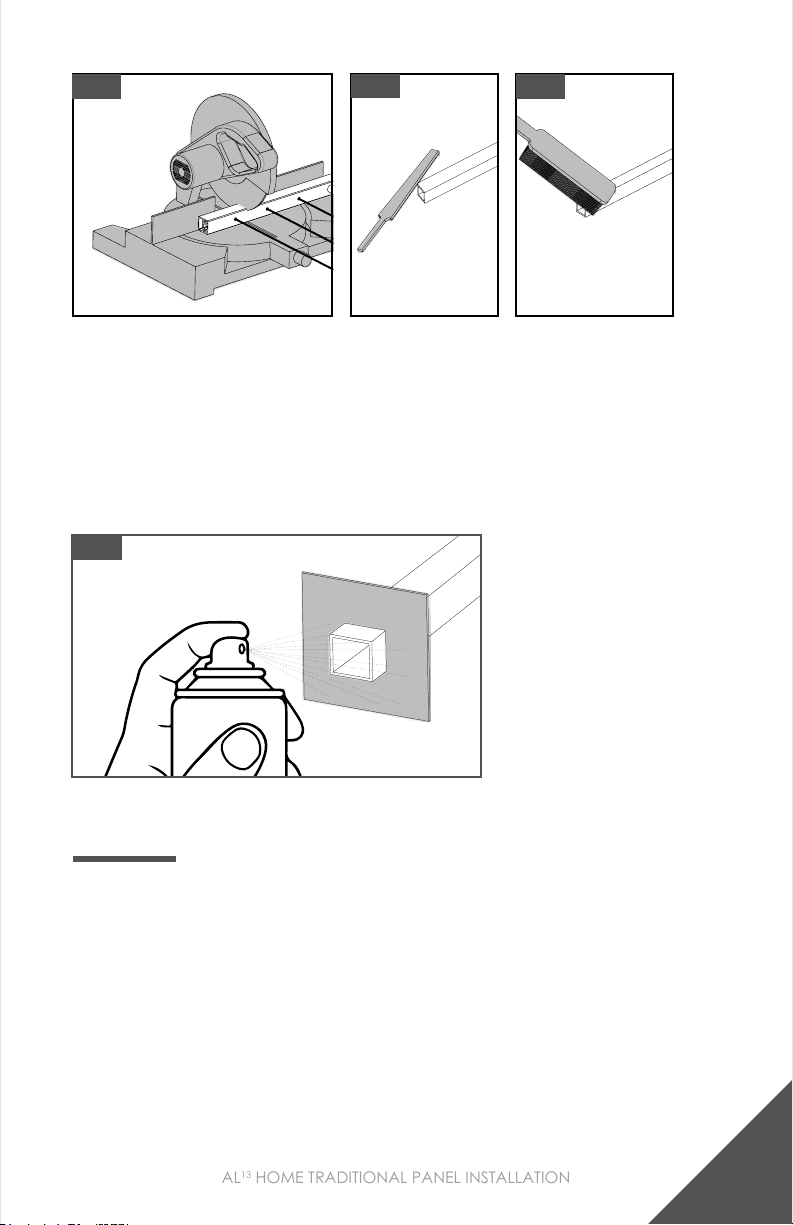

OTP & PROUD POST: CUTTING DOWN PANELS

Step 1: Measure & Mark Panels Where Cuts Will Be Made

1. To ensure panel is symmetrical, take the measurement found

on page 7 step 6 and divide it in half. Then cut equal lengths

from both ends.

2. Find the center of the panel and measure out half of the length

each direction.

3. Mark these locations with a pencil on the top and bottom rail.

Fig. 1

Step 2: Cut & Clean Panel

1. Cut rails using a saw with a fine tooth carbide cutting blade.

2. Use file to smooth cut edges.

3. Remove any metal shavings and dust with a brush or rag.

4. Make sure surfaces to be painted are clean.

Fig. 1 Fig. 2

Measure the panel opening

Check measurement with top

Do not measure

from post

Measure

from back

of bracket

Mark Here

Mark Here

Mark Here Mark Here

Half of Panel Length

Center of Panel

9

AL13 HOME TRADITIONAL PANEL INSTALLATION

Fig. 1 Fig. 2 Fig. 3

Step 3: Apply Spray Paint To Cut Areas

1. Using a piece of cardboard as a mask, apply the 1st coat of

Fortress zinc based touch-up paint.

2. Allow to dry before applying second coat.

3. Apply the 2nd coat of Fortress zinc based touch-up paint.

4. Allow to dry and install.

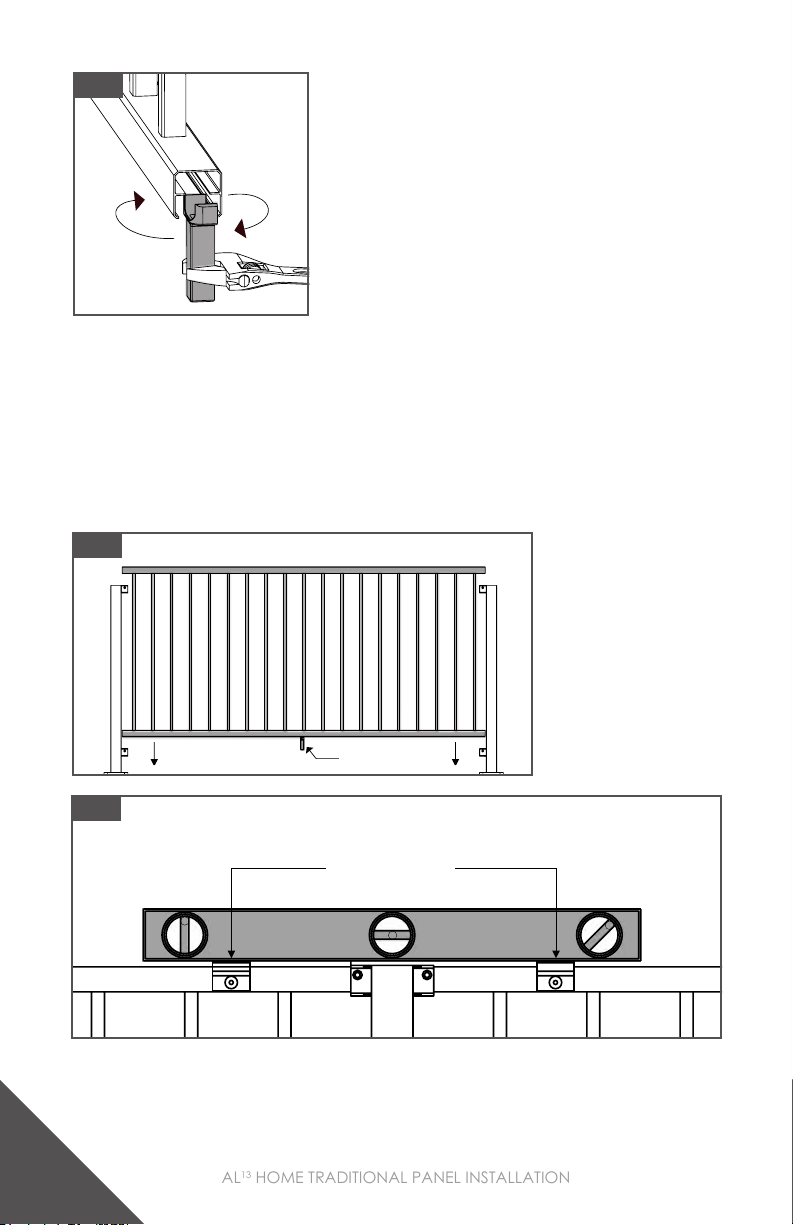

OTP INSTALLATION

Fig. 1

2X

Step 1: Install I-Support On Panel

1. Install the panel I-support by twisting it into the center of the

bottom rail directly under a baluster. As shown in Fig. 1.

2. Position the I-support so the attachment screw can be easily

installed on the deck.

10

AL13 HOME TRADITIONAL PANEL INSTALLATION

Step 2: Install Panel

1. Insert cut panel to ensure proper fit.

2. Use level to ensure that all panels are at the same height

before attaching them to the post. As shown in Fig. 2.

• The use of an ATR spacer or block might be needed to

measure over a post.

Fig. 1

Fig. 1

OTP and Proud Post: Max Post Spacing

• 8’ panel maximum post spacing is 93-7/8”.

• 6’ panel maximum post spacing is 69-7/8”.

Note: Do not exceed the maximum post spacing.

8’ Panel max post spacing 93-7/8”

6’ Panel max post spacing 69-7/8”

OTP and Proud Post: Measuring The Panel Opening Length

• Measure the distance of the panel opening.

• Measure from the back wall of the bracket to the back wall of the bracket on other post.

• Confirm that the measurements for the top brackets are the same as the bottom brackets.

Measure the panel opening

Not here

Measure from

back of bracket

Check measurement with top

3/12

OTP and Proud Post: Max Post Spacing

• 8’ panel maximum post spacing is 93-7/8”.

• 6’ panel maximum post spacing is 69-7/8”.

Note: Do not exceed the maximum post spacing.

8’ Panel max post spacing 93-7/8”

6’ Panel max post spacing 69-7/8”

OTP and Proud Post: Measuring The Panel Opening Length

• Measure the distance of the panel opening.

• Measure from the back wall of the bracket to the back wall of the bracket on other post.

• Confirm that the measurements for the top brackets are the same as the bottom brackets.

Measure the panel opening

Not here

Measure from

back of bracket

Check measurement with top

3/12

I-Support

Fig. 2

ATR Spacers

11

AL13 HOME TRADITIONAL PANEL INSTALLATION

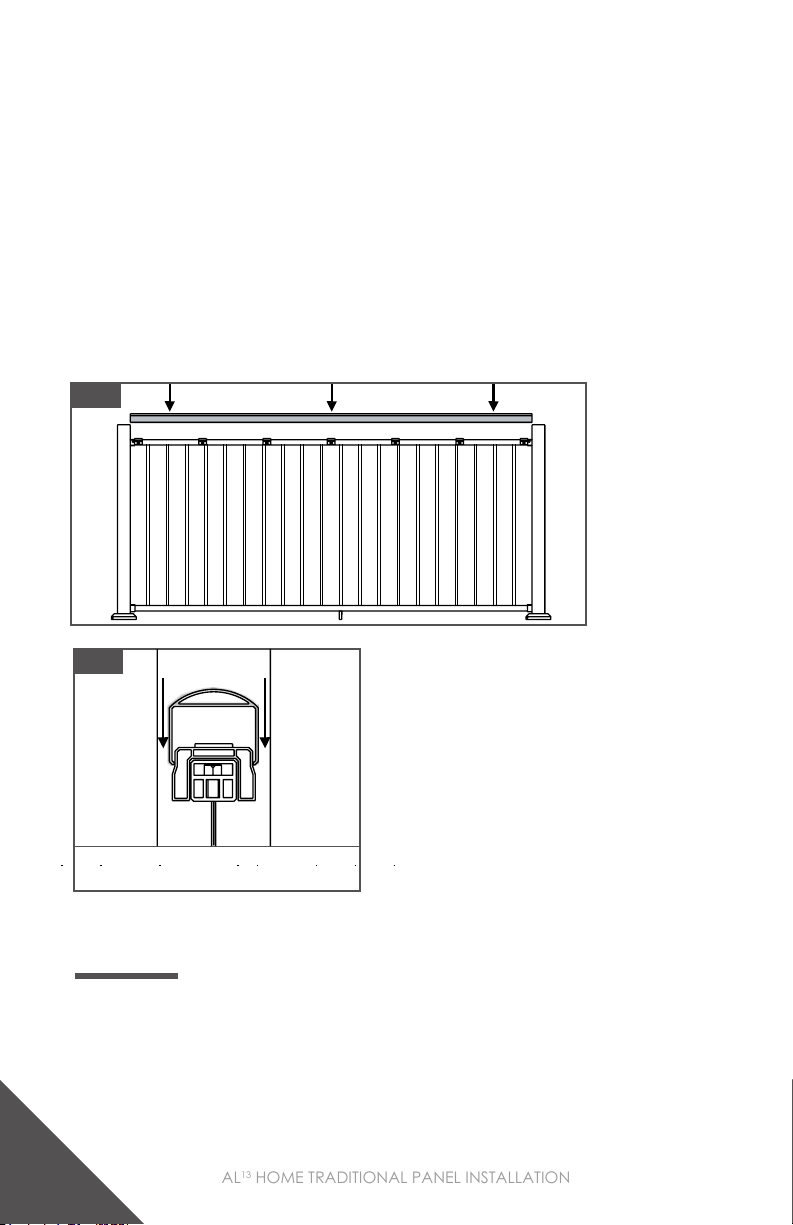

Step 3: Apply Screws

1. Attach the panel to each of the 4 brackets using the provided

self-drilling screw with a T-25 Bit.

Tip: Pre-drill with a 3/16” [4.5mm] drill bit.

Note:

• It is recommended that all panels are attached with

provided screws on the same side of the bracket

when using a line post. As shown in Fig.1.

• Only one screw is needed to secure the bracket to

the panel.

Fig. 1

Fig. 1

Step 4: Attach I-Support To Deck

1. Fasten I-Support to Deck Surface with the supplied Phillips

Head Wood Screw.

Tip: Pre-drill with a 1/16” [1.5mm] drill bit.

12

AL13 HOME TRADITIONAL PANEL INSTALLATION

OTP: ROUND ACCENT TOP RAIL (ATR)

Step 1: Round ATR Spacers

1. Attach spacers using provided self-drilling screws with a

5/16” [8mm] nut driver, two screws per spacer. As shown in

Fig. 2.

• The Accent Top Rail Kit comes with 7 spacers in the 93.89”

[2385mm] kit, 6 spacers in the 69.89” [1775mm] kit and 14

spacers in the 190” [4826mm] kit.

• The spacers should be equally spaced along the length of the

rail, with no more then 14” [279.5mm] spacing between them.

As shown in Fig. 1.

• The end spacers should be placed as close to the end brackets

as possible.

Note:

• DO NOT REMOVE BACKING OF DOUBLE SIDED TAPE

UNTIL YOU ARE READY TO PERMANENTLY ATTACH

THE ATR.

Double Sided Tape

Fig. 1

Fig. 2

Spacer Attached

Next To Bracket 14” [279.5mm]

Max

13

AL13 HOME TRADITIONAL PANEL INSTALLATION

Step 2: Round ATR Line and End Posts

1. Measure the distance from the inside edge of the 2 posts.

2. Cut the ATR to measured length.

3. The ATR cannot block the inside edge of the post. As shown in

Fig. 2.

4. When test fitting the ATR, place on top of the spacers. Do not

press the ATR down over the spacers. Removing the ATR from

the spacers can damage the ATR and spacers. As shown in

Fig. 3.

5. Remove the backing of all of the double-sided tape on the ATR

spacers.

6. A Rubber Mallet might need to be used to install. If using a

rubber mallet, use a cloth to protect the ATR from damage.

Fig. 1

Fig. 2 Fig. 3

ATR Cannot Go

Past This Line

ATR Should Go Past This

Point When Test Fitting

14

AL13 HOME TRADITIONAL PANEL INSTALLATION

Step 3: Round ATR Corner

1. When installing ATR on corners with a 2” [51mm] post, the ATR

must be 5/16” [8mm] away from the post. As shown in Fig. 1.

2. If installing a corner with a 3” [76mm] proud post, install the

ATR at full length from the inside edge of the post to the inside

edge of the post.

Fig. 1 Fig. 2

Step 4: Round ATR Splice

1. To install an ATR splice: Center the splice over the post and

with force press down over the ATR. As shown in Fig. 1,2,3.

2. A Rubber Mallet might need to be used to install. If using a

Rubber Mallet, use a cloth to protect the splice from damage.

• ATR splices reference the inside of the post and snap down

around the ATR.

• ATR splices allow up to 1/2” [12.5mm] of length variation

from the edge of the post. As shown in Fig. 4,5,6.

Fig. 1 Fig. 2 Fig. 3

CORNER LINE END

ATR With 3” [76mm] Proud Post

Over The Post

3” Post

[76mm]

ATR

ATR

ATR With 2” [51mm] Proud Post

Over The Post

2” Post

[51mm]

5/16’ [8mm]

Minimum

5/16’ [8mm]

Minimum

15

AL13 HOME TRADITIONAL PANEL INSTALLATION

Fig. 4 Fig. 5 Fig. 6

CORNER LINE END

OTP: FLAT ACCENT TOP RAIL (ATR)

Step 1: Flat ATR Spacers

1. Measure distance between brackets and cut ATR spacer to

length. The spacer can be 1/4” [6.5mm] shorter than the

distance between brackets.

2. If one of the screw holes was cut off during the sizing of the

ATR spacer, use a 5/8” [16mm] drill bit to add another hole

1” from the end of the ATR spacer.

3. Attach the ATR spacer using the provided self-drilling screws

with a 5/16” [8mm] nut driver.

4. All screw holes must have a screw installed.

Note:

• Flat ATR uses a full length ATR spacer.

• DO NOT REMOVE BACKING OF DOUBLE SIDED TAPE

UNTIL YOU ARE READY TO PERMANENTLY ATTACH

THE ATR.

1/2”

[12.5mm]

1/2”

[12.5mm]

1/2”

[12.5mm]

1/2”

[12.5mm] 1/2”

[12.5mm]

Fig. 1

16

AL13 HOME TRADITIONAL PANEL INSTALLATION

Step 2: Flat ATR Line and End

• Reference OTP Round ATR Line and End instructions on page 13.

Step 3: Flat ATR Corner

• Reference OTP Round ATR Corner instructions on page 14.

Step 4: Flat ATR Splice

• Reference OTP Round ATR Splice instructions on page 14.

OTP: CAP RAIL CLIPS & POST BASE COVER

Step 1: Cap Rail Clips

1. Install top rail bracket covers that come with the Cap Rail Clips.

As shown in Fig. 2.

2. Use Cap Rail Clips when installing a drink rail.

Note:

• Cap Rail Clips should be equally spaced over the panel length.

• It is recommended to pre-drill the screw holes.

Fig. 1 Cap Rail Clip

Double Sided

Tape

Fig. 2

17

AL13 HOME TRADITIONAL PANEL INSTALLATION

Fig. 2 Fig. 3

Step 2: Bracket Cap and Post Base Cover

1. Bracket Caps snap down over Bracket Cups.

2. Dis-assemble post base cover and install on post.

3. Use a broom or compressor to remove debris from railing and

deck surface.

Fig. 1 Fig. 2

Top Cap Installation When

Installing A Drink Rail

PROUD POST INSTALLATION

Step 1: Install I-Support On Panel

• Reference OTP I-Support Installation instructions on page 9.

Step 2: Install Panel

• Reference OTP Panel Installation instructions on page 10.

18

AL13 HOME TRADITIONAL PANEL INSTALLATION

1. Attach the panel to each of the 4 brackets using the provided

self-drilling screw with a T-25 Bit.

Tip: Pre-drill with a 3/16” [4.5mm] drill bit.

NOTE:

• Only one screw is needed to secure the bracket to

the panel.

Step 3: Apply Screws

Fig. 1

Step 5: Install Bracket Caps

1. Bracket Caps snap down over Bracket Cups.

• If you are installing a drink rail using the Cap Rail Clips, the

cap is installed under the bracket. See page16 for details.

• The top bracket cap can be installed when using an ATR but is

not required to be installed.

Fig. 2Fig. 1

Step 4: Attach I-Support To Deck

• Reference OTP I-Support Attachment instructions on page 11.

19

AL13 HOME TRADITIONAL PANEL INSTALLATION

PROUD POST: ROUND ACCENT TOP RAIL (ATR)

Step 1: Round ATR Spacers

1. Attach Spacers using provided self-drilling screws with a

5/16” [8mm] nut driver, two screws per spacer. As shown in

Fig. 2.

• The Accent Top Rail Kit comes with 7 spacers in the 93.89”

[2385mm] kit, 6 spacers in the 69.89” [1775mm] kit and 14

spacers in the 190” [4826mm] kit.

• The spacers should be equally spaced along the length of the

rail, with no more then 14” [279.5mm] spacing between them.

As shown in Fig. 1.

• The end spacers should be placed as close to the end brackets

as possible.

Note:

• DO NOT REMOVE BACKING OF DOUBLE SIDED TAPE

UNTIL YOU ARE READY TO PERMANENTLY ATTACH

THE ATR.

Fig. 1 Spacer Attached

Next To Bracket 14” [279.5mm]

Max

Double Sided Tape

Fig. 2

20

AL13 HOME TRADITIONAL PANEL INSTALLATION

Step 2: Round ATR

1. Measure the distance from the inside edge of the 2 posts.

2. Cut the ATR to measured length.

3. When test fitting the ATR, place it on top of the spacers. Do not

press the ATR down over the spacers. Removing the ATR from the

spacers can damage the ATR and spacers. As shown in Fig. 2.

4. Remove the backing of all of the double-sided tape on the

ATR spacers.

5. A Rubber Mallet might need to be used to install. If using a

Rubber Mallet, use a cloth to protect the ATR from damage.

Fig. 1

Fig. 2

ATR Should Go Past This

Point When Test Fitting

PROUD POST: FLAT ACCENT TOP RAIL (ATR)

Step 1: Flat ATR Spacers

1. Measure distance between brackets and cut ATR Spacer to

length. The Spacer can be 1/4” [6.5mm] shorter than the

distance between brackets.

Table of contents

Languages:

Other Fortress Technologies Outdoor Furnishing manuals

Popular Outdoor Furnishing manuals by other brands

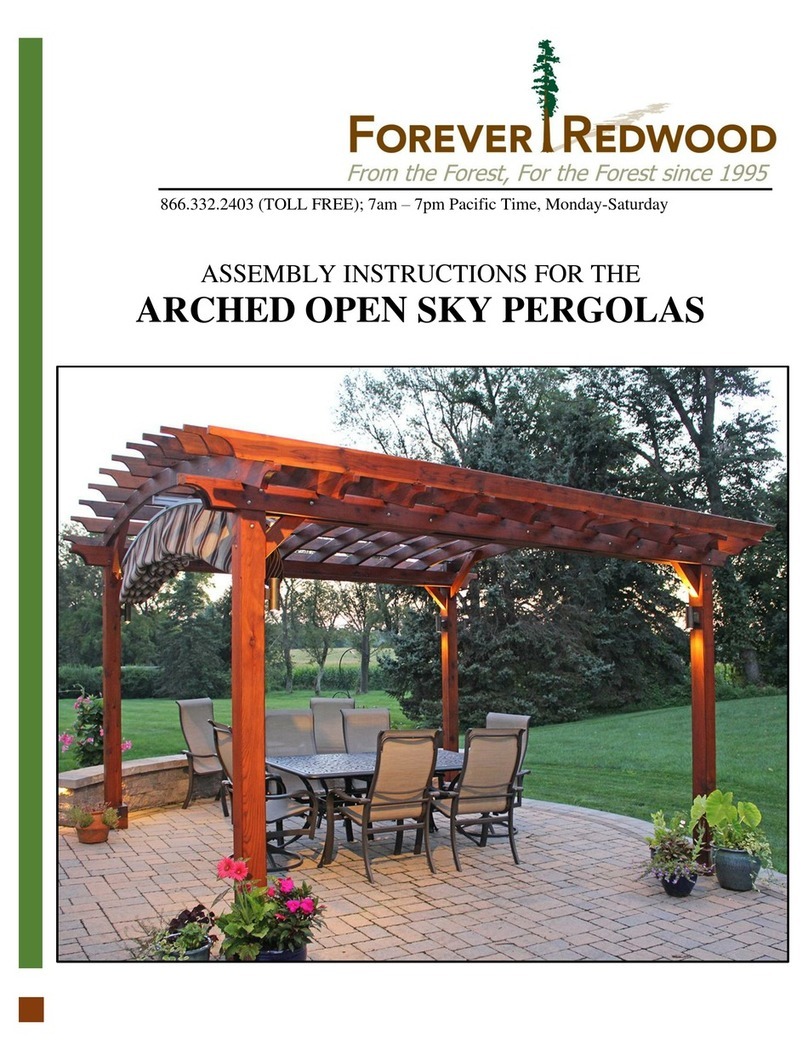

Thomasville

Thomasville Richwood 203074431 Assembly instructions

Gutta

Gutta BS 160 Assembly instructions

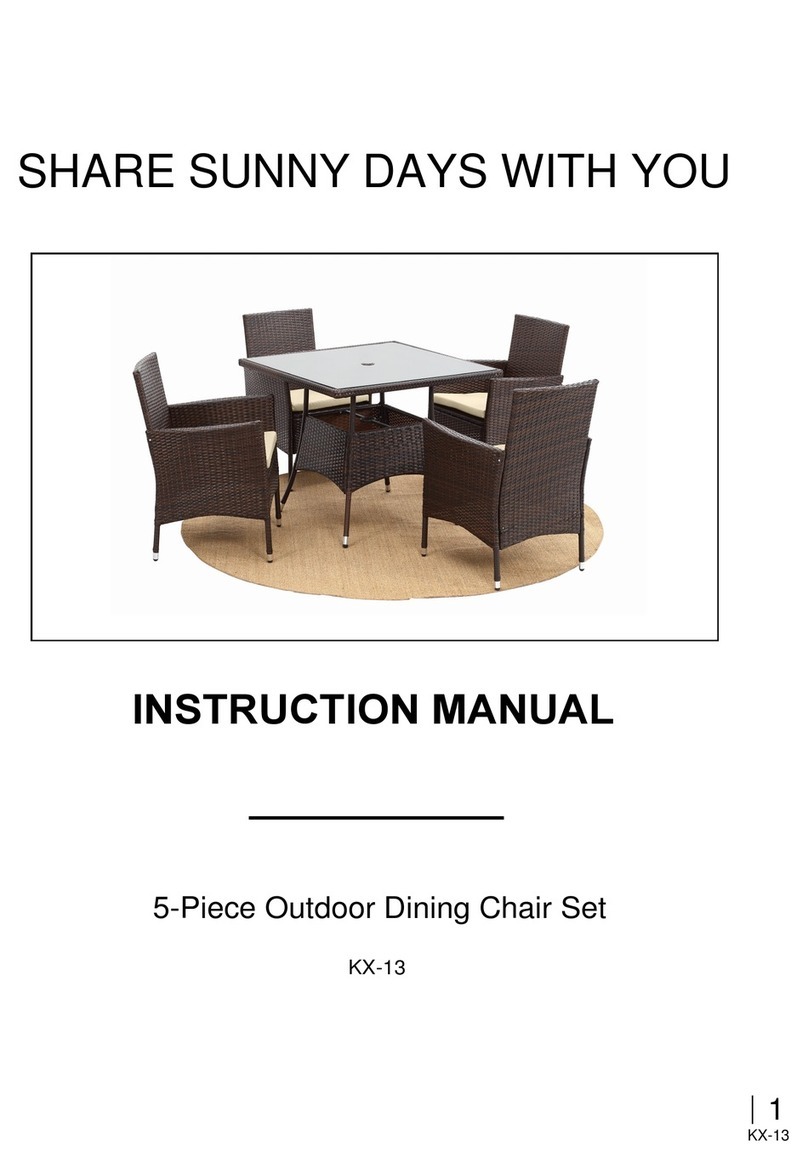

Wisteria Lane

Wisteria Lane KX-13 instruction manual

Kettler

Kettler CUBIC 0111925-9000 Assembly & operating instructions

Canvas

Canvas SHERBROOKE 088-0095-6 Assembly instructions

Walker Edison

Walker Edison OW48PEALS Assembly instructions