FOS Technologies TOWER 700 User manual

FOS TECHNOLOGIES V07.19

MATERIAL ALUMINIUM LIFTER

User Manual

270 kg (595.3lb)

6.65 m (21.81’)

2

FOS 700

C

D

F1349K

F1350K

F1351K

F1352K

F1353K

Section 2

Section 3

Section 4

Section 5

Section 1

Base

F2159K

Forks

F2195K

Forks support

F1223K

FOS 700 Long leg F1222K

FOS 700 Short leg

B

A

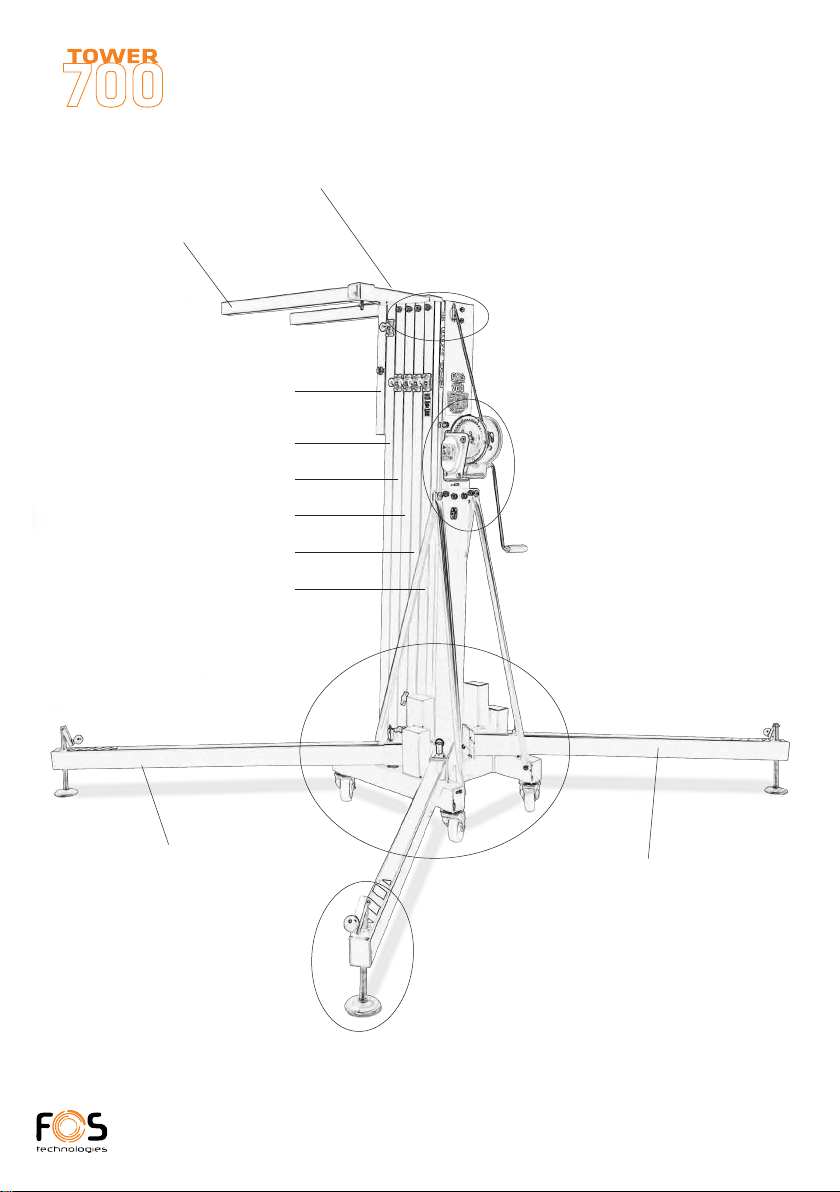

A - Pulleys sets

B - Winch set

C - Base set

D - Stabilizer set

F1354K

Section 6

3

FOS 700

F2185K

FOS Lock

F1029K

Screw

F8001K

Washer F2138K

Lock rest

Prisionero nal de cable / Cable grip

F1038K

F2154K

F1038K

F1038K

F2156K

F2157K

LIFT

BLOCK

F1038K

F1038K

F1038K

4

FOS 700

A.1

A.1

A.1

A.1

A.1

A

A.2

F1026KF3008K

F2007K

F1027KF8001K

F1027KF8001K

F1027K

F1027K

F1005K

F2162K

F1033K

F2141K

F1031K

F1030K F1030K

F1113K

F1032K

F2006K

F8004K

Top view

A.4

F2132K

A.1

5

FOS 700

A.5

A.6

A.7

F2146K

F2144K

F1026K

F1004K

F2145K

F2143K F2142K

F1030K

F1030K

A.3

F1040NK

F8009K

F8009K

F7007K

F1033K

F2141K

F8003K

F7002K

A.4

F1030K F1030K

F1113K

F1026K

F2155K

F1026K

6

FOS 700

B

F1028K

Screw

F8003K

Washer

F7002K

Nut

F2161NK

Winch support plate

F1036K

Screw

F8006K

Washer

F7001K

Nut

F2192K

Strut support plate F4004K

Winch

F1036K Screw

F8001K Washer

F7001K Nut

F9040K

Steel cable

7

FOS 700

C

F2119K

Tornillo / Screw

Spirit level

F5004K Rueda /Wheel K-40

Arandela / Washer

F1022K

F8004K

F2187K

Base FOS 700

F2190K

Transport security knob

Security leg lock

F2189K

F1028K Screw

F8003K Washer

F7002K Nut

F1020K Screw

F8001K Washer

F7001K Nut

F2137K

Long right strut

F2136K

Long left strut

F2136K

Long left strut

(front position)

Tuerca / Nut

F7006K

8

FOS 700

D

F2115K

F7003K

F2116K

F1006K F8004K

F2117K

F8005K

F1012K

F2134K

F1011K

F7004K F2133K

Complete stabilizer kit

9

FOS 700

Code/Código Description/Descripción

F1004K Conic screw M5 x 12

F1005K Conic allen screw M6 x 16

F1006K Allen screw M10 x 25

F1011K Allen screw M5 x 25

F1012K Allen screw M6 x 10

F1020K Allen screw M8 x 25

F1022K Allen screw M12 x 40

F1026K Conic screw M8 x 20

F1027K Special screw M8 x 16

F1028K Allen screw M10 x 30

F1029K Allen screw M8 x 35

F1030K Conic screw M8 x 25

F1031K Allen screw M5x20

F1032K SpecialatM12screw

F1033K Nylon runner screw

F1036K Allen screw M8 x 30

F1038K Headless allen screw M8 x 10

F1040NK Allen screw M14 x 180

F1113K Alluminiumstoppiece

F1222K ShortlegFOS700

F1223K LonglegFOS700

F1349K FOS700Section1(Base)

F1351K FOS700Section2

F1352K FOS700Section3

F1353K FOS700Section4

F1354K FOS700Liftingcarriagesection5

F2006K Pulley Ø80

F2007K Pulley Ø55

F2115K StabilizerballM10

F2116K Stabilizerhandle

F2117K Stabilizerplateº80

F2119K Spiritlevelindicator

F2132K Axelrest

F2133K Completestabilizer

F2134K ThreadedBoltM18

F2136K Longleftstrut

F2137K Longrightstrut

LISTA DE REPUESTOS / SPARE PARTS LIST

10

FOS 700

LISTA DE REPUESTOS / SPARE PARTS LIST

F2138K Lockrest

F2140K Smalllowerpulleyrestº55

F2141K Nylon runner

F2142K SectionTop

F2143K Sectionscrewtop

F2144K Brakeramp

F2145K Spring

F2146K Carriagebreak

F2154K Cableclamp

F2155K Basesectionrest

F2156K Pin

F2157K “R” Shape clip

F2159K Liftingfork

F2161NK ShortwinchplateFOS700

F2162K PulleyrestØ80

F2185K FOS700Lock

F2187K FOS700Base

F2189K Securityleglock

F2190K Transportsecurityknobforlegs

F2192K FOS700strutsupportplate

F2195K FOS700Forksupport

F3008K 12 x 92 Axel

F4004K 900kgWinchLonghandle

F5004K WheelØ100(white)

F7001K Auto-blocknutM8

F7002K Auto-blocknutM10

F7003K NutM10

F7004K Auto-blocknutM5

F7006K Auto-blocknutM12

F7007K Butterynut

F8001K M8 washer

F8003K M10 washer

F8004K M12 washer

F8005K WideM6washer

F8006K WideM8washer

F8009K M14 washer

F9040K FOS700CableØ6mm

Code/Código Description/Descripción

11

FOS 700

OperatingInstructions

1 - INTRODUCTION.

Dearuser.ThankyoupurchasingyourFOS700lifter.Wehopeyouwillbeverysatised

withit.

Thismanualhasbeenwrittensothatyoucanunderstandhowtoeffectivelyusethelift

andmostimportantly,sothatyoucanuseitsafely.Itisimportantthatyoufullyreadthe

manualandfollowtheinstructionscarefullybeforeusingyourlift.AllFOSliftsundergoa

verystrictqualitycontrolprocessduringtheirmanufacture.

SothatyourliftalwaysworksproperlypleaseonlypurchaseoriginalFOSpartsfroman

authorizeddistributorordealer.Theuserwaivesallwarrantyrightsifusingpartsother

thanFOSoriftheproductismanipulatedinanywaybyanunauthorizedthirdparty.

When requesting parts, please refer to the diagrams of this manual and quote the

serial number and year of manufacture located on your lifter.

2 - TECHNICAL SPECIFICATIONS.

FOSlifter,modelK-40hasbeendesignedforverticallyliftinglighting,trussingetcinthe

Professionalsoundandlightsector.Thereisvarioussupportsoraccessoriesavailable,

pleaserefertoourwebsiteorcatalogue.

2.1-Max.load:270kg(595.25lb)

2.2-Min.load:25kg(55lb)

2.3-Max.height:6.65m(21.81’)

2.4-Foldedheight:1.78m(5.84’)

2.5-Worksurface:1.88x2.15m(6.17’x7.05’)

2.6-Foldedbasearea: 46cmx60cm(1.51’x1.97’)

2.7-Weight:144kg(317.47lb)

2.8-Winch:900kgcertied

2.9-Cable:SteelDIN3060.Tensilestrength180kg/mm2.Anti-torsion&anti-corrosion

Ø6mmcablediameter.

2.10-Constructionmaterial:Alluminiumproles6082T6.

2.11-Antirustprotectionprimingpaintbathedblacksteel,coveredwithcuredpolyester

dust.

12

FOS 700

OperatingInstructions

2.12-FOSLocksoneachsectionwhichautomaticallyslotsintothesectionsduring

elevation,lockingtheminplace.

2.13-Anchorofthelegsbysafetycatches.

2.14-Adjustablestabilizerplatesinthelegswithnonsliprubberbasesupport.

2.15-Spiritlevelforverticalalignment.

2.16-Swivelwheelsfortransportingtheliftertoitsworkingposition.

3 - SAFETY GUIDELINE.

3.1-Situatethetoweronasolidandatsurface.

3.2-Checkthatthelegsarefullyinsertedandsecuredintotheirhousingwiththesafety

locks.

3.3-Ensurethatthelifterisinaverticalpositionandusethespiritlevellocatedonthe

baseproletocheck.Ifnecessary,adjustitsalignmentwiththeplatesby turning the

handleintheappropriatedirection.

3.4-Checkthatthetowerislockedinitsworkingpositionwiththesafetylock.

3.5-Whenusedoutdoors,placethetoweronahardsurfaceandifnecessarysecureit

againstexcesswindforceviacablebraces.

3.6-Donotuseladdersnorleanthemagainstthelifter.

3.7-Becarefulwithanycables,prominentobjectsetc.placedabovethetower.

3.8-Donotstandunderneaththeload.

3.9-Donotmovethetowerwhenitiselevatedorloaded.

3.10-Beforeusingthetower,checktheconditionofthecable.Thismustbefreeofcuts

andfrays.Neverusedamagedcables.

3.11-Neverdismountthewinchhandleoranyelementofthewinchunderanycircum-

stance.

3.12-Oncethetowerisset-upinitsworkingpositionwerecommendedthewinchhan-

dleislockedtoavoidanyoneinterferingwithit.

3.13-Theminimumloadforasafeoperationofthebrakeis25kg.Thebrakewillnot

functionwithoutthisminimumload.

3.14-Donotgreaseorlubricatethebrakemechanismofthewinch.

3.15-Thisliftcannotlifthumanbeings.

3.16-Fortransportationitisnecessarytoretractallprolesandlockthemwiththe

correspondingsafetylock.

13

FOS 700

OperatingInstructions

4 - OPERATION.

4.1-Placethetoweronaatandsolidsurfacewhereitisgoingtobeused.

4.2-Removethelegsfromtheirtransportsupportsandinsertthemintheirworkingpo-

sition.Checkthattheyarefullyinsertedandxedwiththeirsafetylock.

4.3-Ensurethatthelifterisinaverticalpositionandusethespiritlevellocatedonthe

baseproletocheckthebubbleiscentred.Ifnecessary,adjustitsalignmentwiththe

stabilizerplatesbyturningthehandleintheappropriatedirection.

4.4-Changetheforkstotheirhorizontalworkingpositionandxthemwiththefastener

pins,placetheloadontheforksusingaFOSAccessoryifnecessary,andensurethat

thetowerisonlyusedtoliftloadsvertically.Theminimumloadis25kg.

NEVERRAISETHETOWERSECTIONSWITHOUTLOAD.

1

2 3 4 5

4.5 - Elevation:

4.5.1-EnsurethatalltheFOSlocksareinthe

BLOCKposition.

4.5.2-Changethenº1 FOSlocktotheLIFTposition.

4.5.3-Turnthehandleclockwisetoraisethelifting

carriageofthetower.

4.5.4-Whenyouhavereachedthedesiredheight,

xthe nº1 FOSlockinbyturningthehandleanti-

clockwise.Changethenº1 FOSlocktotheBLOCK

position.

4.5.5-Changethenº2 FOSlocktotheLIFTposition.

4.5.6-Turnthehandleclockwisetorisethenextsectionofthetower.

4.5.7-Whenyouhavereachedthedesiredheight,xthenº2 FOSlockinby

turningthehandleanti-clockwise.

Checkthatthenº2 FOS lockhasintroducedintoitscorrespondinghole.

Andchangethenº2 FOS locktotheBLOCKposition.

4.5.8-Repeatthesestepstoraiseallthesectionsofthetower,changingall.

theFOSlocksleftorderlytotheLIFTpositionandturningthehandleclockwise.

14

FOS 700

OperatingInstructions

WARNING: The tower can be left in any intermediate height if necessary. Just make

sure that the FOS locks are always xed and introduced. In the unlikely event of cable

breaking the FOS locks will ensure that the tower stays UP and SECURE.

Your security is our main concern.

4.6 - Descent:

4.6.1-Tofoldthetowerdown,rst,turnthehandleofthewinchclockwiseto

tightenthesteelcable.

4.6.2-Oncethecableistense,pulloutthenº5 FOSlock,mantainitalwaysin

LIFTpositionbutkeepitout.

4.6.3-WhileyoukeeptheFOSlockout,turnthehandleanti-clockwisetobring

downthecorrespondingsectionofthetower.

4.6.4-Oncethesectionhasbeenbroughtdown,releasethenº5 FOSlock,

andpulloutthenº4 FOSlock.

4.6.5-WhileyoukeepthenextFOSlockout,turnthehandleanti-clockwise

tobringdownthenextsection.

4.6.6-Keeprepeatingthesesteps,pullingoutalltheFOSlocksleftinorder

whileyouturnthehandleanti-clockwise.

4.6.7-Oncethetowerhasbeenfoldeddown,placealltheFOSlocksinthe

BLOCKposition.

4.7 - Transport:

Turnthehandleofthestabilizerstoreleasetensiononthelegsinordertopullthemout.

Then,placethelegsintheirtransportcompartmentslocatedatthebaseofthetower.

Pullouttheforksandplacetheminverticalposition.Thetowerwillbereadyfortransport.

5 - MAINTENANCE.

5.1-Allcablesmustbecheckedregularly.Faultycablesmustbereplacedimmediately.

Donotusethelifterwithfaultycablesasitispotentiallyverydangerous.OnlyuseDIN

3060cables,suppliedfromanauthoriseddealer.

5.2-Thelifterisdeliveredexfactorycompletelygreased.Dependingonitsmechanical

Usethough,werecommendthatthecrownwheelofthewinch,thepads&bushings

ofthedriveshaft,thehandlethreadandtheprolesoftheliftareperiodicallygreased.

15

FOS 700

ATTENTION:

Do not apply oil or grease to the brake mechanism. The brake discs have been pre-grea-

sed with a special heat and pressure resistant grease. To avoid malfunction to the winch

brake, no other products must be used except the original provided by the company. It

is not necessary to grease the brake discs.

5.3-Yourliftershouldbeinspectedatleastonceayearbyaspecialized/authorized

servicecentre.

5.4-OnlyoriginalFOSsparepartsmustbeusedtoguaranteethereliabilityandopera-

tionalsafetyofyourlifter.Theusershallloseallwarrantyclaimsifheusesanythingother

thanoriginalsparepartsormodiesthisproductinanyway.

5.5-Incaseasparepartisrequiredpleaseindicatethereferencenumberwhichcanbe

foundinthesparepartslistatthebackofthismanual.

6 - WARRANTY.

AllFOSliftscomewith2yearswarranty.Thiswarrantyperiodisfromthedateofpur-

chase.FOSwillrepairanydefectproductcausedbyeitherfaultymaterialsorpoorwork-

manshipfreeofchargewithinthisperiodaslongasthepartsarettedbyanauthorized

FOSdealer.Shouldtheproducthavebeenmanipulatedinanywayorarepairattempted

byanunauthorizeddealerthewarrantywillbeinvalid.Thiswarrantydoesnotcoverda-

mageoccurredbyimproperuse.

7 - CERTIFICATIONS

FOSreservestherighttomakeanymodication/alterationtotheliftwithoutpriornotice.

Anymodication/alterationwouldbeaninnovation,intendedtoimprovetheproduct.

16

FOS 700

17

FOS 700

FOS Technologies LTD

BulevardIlienskoShose8

SladovaBazaZMM,Soa,BG

www.fos-lighting.eu

Call Center : +30 2102811700

Table of contents

Other FOS Technologies Lifting System manuals

Popular Lifting System manuals by other brands

Alpinespas

Alpinespas VX3 Easy installation guide

Bend-Pak

Bend-Pak HD-12LS Installation and operation manual

Bend-Pak

Bend-Pak XPR-10S-168 Service manual

Screen Int

Screen Int SCREEN WINCH SYSTEM installation manual

Wesco

Wesco HWLFX-4 instruction manual

Bend-Pak

Bend-Pak HDS-18E Installation and operation manual

MarineTech

MarineTech Panther 55-0045 Installation and operating instruction

Bend-Pak

Bend-Pak HDSO-14AX Installation and operation manual

Ravaglioli

Ravaglioli KP153 manual

Dhollandia

Dhollandia DH-R Series Operation manual

smv

smv MULTI-LIFT SYSTEM instruction manual

Sumake

Sumake SA-22900 instruction manual