FOS Technologies Tower 400 User manual

FOS TECHNOLOGIES V07.19

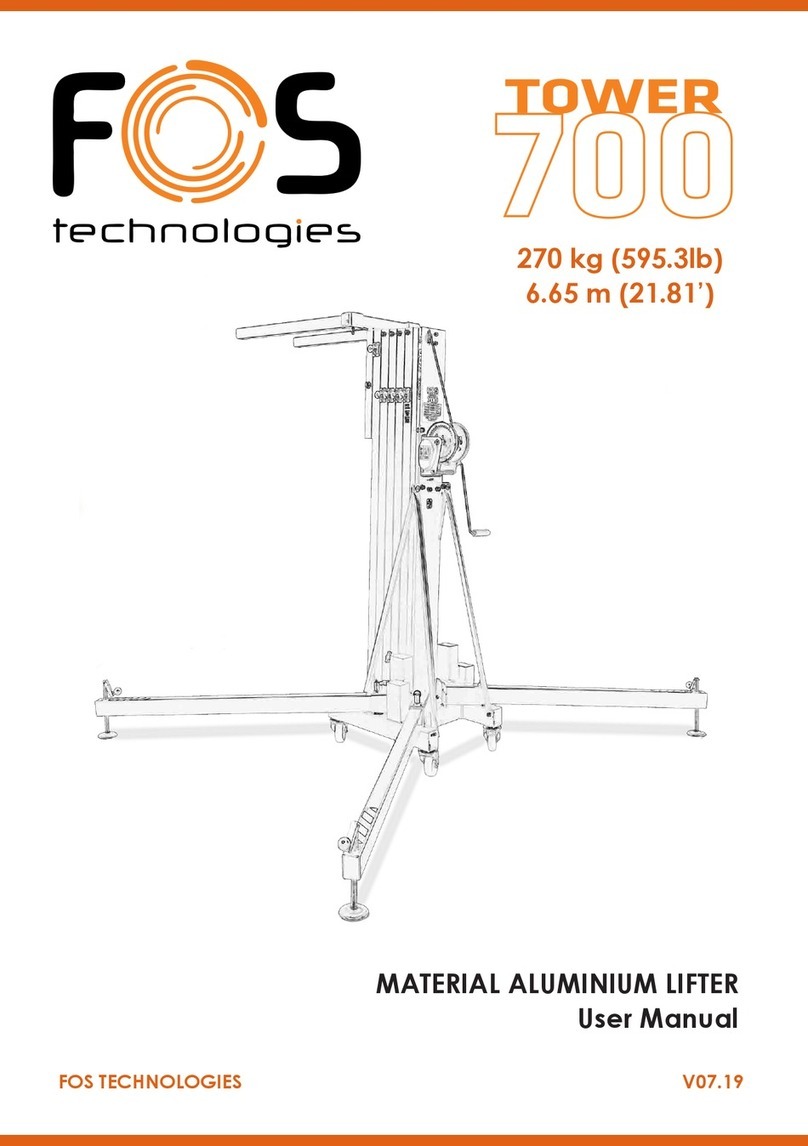

MATERIAL TELESCOPIC LIFTER

User Manual

125 kg (275.6lb)

3.8 m (12.5’)

2

FOS 400

F1302K

F1301K

F1303K

F4001K

F1201K

F2102K

F2103K

F1001K

F7001K

Screw

Nut

F2104K

Strap cap

Section 1

Section 2

Section 3

A

B

C

Leg

Strap

Leg cap

Winch

3

FOS 400

F1007K

F1007K

F1007K F8002K

F8002K

F8002K F1102K

F2002K

F1008K

F1103K

F2110K

F2182K

A.1

F1012K

F1006K

A.1

F8003K

F7002K

A.1

Lock

Screw

Screw

Bracket

A

4

FOS 400

F2105K

F2109K

F2107K

F2101K

F1002NK

F7001K

Tornillo / Screw

Tuerca / Nut

F2106K

F1004NK

F3001K

F2001K

F1010K

F1101K

F1004NK

F1004NK

Soporte jo tirantes /

Fixed strap support

Tapón superior pata/

Leg upper cap

Pomo soporte patas /

Leg support knob

Soporte patas /

Leg support

Gatillo / Lock

F7001K

Tuerca / Nut

F1001K

Tornillo / Screw

C

B

C.1 - Lower pulleys set Section 2 (Ref.1302)

5

FOS 400

F9001K

F2111K

F4001K

F1003K

F8001K

Screw

Washer

F7001K Nut

F1009K

F2003K

F7002K F8004K

F8003K

F9001K

D.1

D

F2131K

F1006K

Screw

Extension bar

Cable clamp

Steel cable

Cable

Winch

D.1

6

FOS 400

Code/Código Description/Descripción

F1001K M8x55 hexagonal screw

F1002NK M8x25 hexagonal screw

F1003K Allen screw M8x16

F1004NK Conic allen screw M5x12

F1006K Allen screw M10x25

F1007K Allen screw M6x20

F1008K Special M10 screw

F1009K Hexagonal screw M10x40

F1010K Conic screw M4x35

F1012K Allen screw M6x10

F1101K 10mm axis plate

F1102K Pletina portapolea

F1103K FOS 400 threaded pulley cover plate

F1201K FOS 400 Leg

F1301K Section 3 FOS 400

F1302K Section 2 FOS 400

F1303K Section 1 (Base) FOS 400

F2001K Pulley Ø 50

F2002K Pulley Ø 40 (Upper pulley support FOS-400)

F2003K Pulley Ø 40 (Cable entry)

F2101K Upper leg tap

F2102K Ground leg tap

F2103K Leg strap

F2104K Strap tap

F2105K Sliding leg support

F2106K Fixed strap support

F2107K Short lock for sliding leg bracket

F2109K Knob for sliding leg bracket

F2110K 35x35 mm Bracket

F2111K Cable clamp screw Ø4 mm

F2131K FOS 400 extension bar

F2182K FOS 400 Lock

F3001K 10x50 steel axis

F4001K 450 kg winch

F7001K Auto-block nut M8

F7002K Auto-block nut M8

F8001K Flat M8 washer

F8002K M6 washer

F8003K Flat M10 washer

F8004K M12 washer

F9001K Cable FOS 400 (Ø4mm)

LISTA DE REPUESTOS / SPARE PARTS LIST

7

FOS 400

Operating Instructions

1 - INTRODUCTION.

Dear user. Thank you purchasing your FOS 400 lifter. We hope you will be very satised

with it.

This manual has been written so that you can understand how to effectively use the lift

and most importantly, so that you can use it safely.

It is important that you fully read the manual and follow the instructions carefully before

using your lift. All FOS lifts undergo a very strict quality control process during their

manufacture. So that your lift always works properly please only purchase original FOS

parts from an authorized distributor or dealer. The user waives all warranty rights if using

parts other than FOS or if the product is manipulated in any way by an unauthorized third

party. When requesting parts, please refer to the diagrams in the back of this manual and

quote the serial number and year of manufacture located on your lifter.

2.- TECHNICAL SPECIFICATIONS.

The FOS 400 lifter has been designed for vertically lifting lighting, trussing and other

materials in the professional light and sound sector.There is various supports or acces-

sories available, please refer to our website or catalogue.

2.1 - Max. load: 125 kg (275.6 lb).

2.2 - Min. load: 25 kg (55 lb).

2.3 - Max. height: 3.2 m (10,5’) (with extension bar 3.8m (12,5’)

2.4 - Folded. height: 1.26 m (4,1’)

2.5 - Transport surface: 1,27x0.27x0.36m (4.17’x0.89’x1.18’).

2.6 - Shipping dimension: 1,28x0.29x0.18m (4.20’x0.95’x0.59’). (Handle removed)

2.7 - Work surface: 1.50 x 1.50 m (4,90’ x 4,90’)

2.8 - Weight: 21 kg (46 lb)

2.9- Winch: 450 kg certied.

2.10 - Cable: Steel DIN 3060. Tensile strength 180 kg/mm2. Anti-torsion & anti-corrosion

4 mm cable diameter.

2.11 - Construction material: Steel proles EN 10305.

2.12 - Three-prole telescopic system operated by steel cable driven by pulleys with

metal protected bearing pads. Adaptor Ø35 mm.

2.13 - Antirust protection priming paint bathed black steel, covered with cured polyester

dust.

8

FOS 400

Operating Instructions

3 - SAFETY GUIDELINE.

3.1.- Situate the tower on a solid and at surface.

3.2.- Check that the support system is xed by the security trigger and that the tower is

in a upright position.

3.3.- Check that the tower is locked in its working position with the safety lock.

3.4.- When used outdoors, place the tower on a hard surface and if necessary secure it

against excess wind force via cable braces.

3.5.- Do not use ladders nor lean them against the lifter.

3.6.- Be careful with any cables, prominent objects etc. placed above the tower.

3.7.- Do not stand underneath the load.

3.8.- Do not move the tower when it is elevated or loaded.

3.9.- Before using the tower, check the condition of the cable. This must be free of cuts

and frays. Never use damaged cables.

3.10.- Never dismount the winch handle or any element of the winch under any circum-

stance.

3.11.- Once the tower is set-up in its working position we recommended the winch handle

is locked to avoid anyone interfering with it.

3.12.- The minimum load for a safe operation of the brake is 25 kg. The brake will not

function without this minimum load.

3.13.- Do not grease or lubricate the brake mechanism of the winch.

3.14.- This lift cannot lift human beings.

3.15.- For transportation it is necessary to retract all proles and lock them with the co-

rresponding safety lock.

4.- OPERATION.

4.1.- Place the tower on a at and solid surface where it is going to be used.

4.2.- Unlock the safety lock from the legs support system. Slide the support system

downwards until the lock has reached the required position.

4.3.- Attach the load to the tower using the desired support (the support varies upon the

application), and ensure it is only used to lift loads vertically. The minimum load is 25 kg.

4.4.- Elevation: Extend the tower by turning the winch handle clockwise, lifting the load

to the desired height.

9

FOS 400

Operating Instructions

4.5.- Hold: Release the winch handle, it will remain in position by the action of the

winch’s automatic brake. Ensure the FOS lock has introduced in to the prole by turning

the handle slightly anti-clockwise.

4.6.- Continue elevating: Turn the winch handle again clockwise and lift the load until

the second prole is fully extended. Release the handle which will remain xed by the

winch’s automatic brake and proceed to ensure that the FOS lock has introduced into the

second prole by turning the handle again anti-clockwise. The tower can be stopped in

any desired intermediate position. Simply release the winch handle and secure the tower

by inserting the corresponding FOS lock into the hole which is closest to the required

position.

4.7.- Descent: Descending the load follows the same procedure but in reverse. Firstly

unlock the FOS lock and turn the winch handle anti-clockwise, until the rst prole is

completely folded down. Now unlock the next FOS lock and retract the second prole.

Just as when lifting the load, the lift may be stopped at any intermediate position.

4.8.- Transport: When transporting / carrying the lift it is necessary to fold the tower by

retracting all the proles completely. Then close the sliding support piece and x it with

the safety lock and tightening the knob.

5.- MAINTENANCE.

5.1.- All cables must be checked regularly. Faulty cables must be replaced immediately.

Do not use the lifter with faulty cables as it is potentially very dangerous. Only use DIN

3060 cables, supplied from an authorised dealer.

5.2.- The lifter is delivered ex factory completely greased. Depending on its mechanical

use though, we recommend that the crown wheel of the winch, the pads & bushings of

the drive shaft, the handle thread and the proles of the lift are periodically greased.

ATTENTION:

Do not apply oil or grease to the brake mechanism.

The brake discs have been pre-greased with a special heat and pressure resistant grea-

se. To avoid malfunction to the winch brake, no other products must be used except the

original provided by the company. It is not necessary to grease the brake discs.

10

FOS 400

Operating Instructions

5.3.- Your lifter should be inspected at least once a year by a specialized / authorized

service centre.

5.4.- Only original FOS spare parts must be used to guarantee the reliability and opera-

tional safety of your lifter. The user shall lose all warranty claims if he uses anything other

than original spare parts or modies this product in any way.

5.5.- In case a spare part is required please indicate the reference number which can be

found in the spare parts list at the back of this manual.

6.- WARRANTY.

All FOS TECHNOLOGIES lifts come with 2 years warranty. This warranty period is from

the date of purchase. FOS will repair any defect product caused by either faulty materials

or poor workmanship free of charge within this period as long as the parts are tted by

an authorized dealer.

If the product have been manipulated in any way or a repair attempted by an unauthori-

zed dealer the warranty will be invalid. This warranty does not cover damage occurred

by improper use.

7.- CERTIFICATIONS.

FOS reserves the right to make any modication/alteration to the lift without prior notice.

Any modication/alteration would be an innovation, intended to improve the product.

FOS Technologies LTD

Bulevard Iliensko Shose 8

Sladova Baza ZMM, Soa, BG

www.fos-lighting.eu

Call Center : +30 2102811700

Table of contents

Other FOS Technologies Lifting System manuals

Popular Lifting System manuals by other brands

smv

smv MULTI-LIFT SYSTEM instruction manual

Clarke

Clarke Strong-Arm CPL30S Operating & maintenance instructions

Rotary

Rotary SGL35 Operating and maintenance manual

LGMG

LGMG A45JE Service manual

Custom Equipment

Custom Equipment HB-P830 Maintenance and troubleshooting manual

Nußbaum Hebetechnik

Nußbaum Hebetechnik 2.30 SL E Operating Instruction and Documentation

AL-KO

AL-KO B 400-2,0 Original instructions for use

AMGO

AMGO Hydraulics PRO-12ASX Installation and service manual

Liko

Liko Likorall 242 S Instruction guide

rav

rav KPH-40ECGA Operation and maintenance manual

Lippert

Lippert Titan Leveling Systems installation manual

AMGO Hydraulics

AMGO Hydraulics MR06 Installation and service manual