FOS Technologies Tower 650 User manual

FOS TECHNOLOGIES V07.19

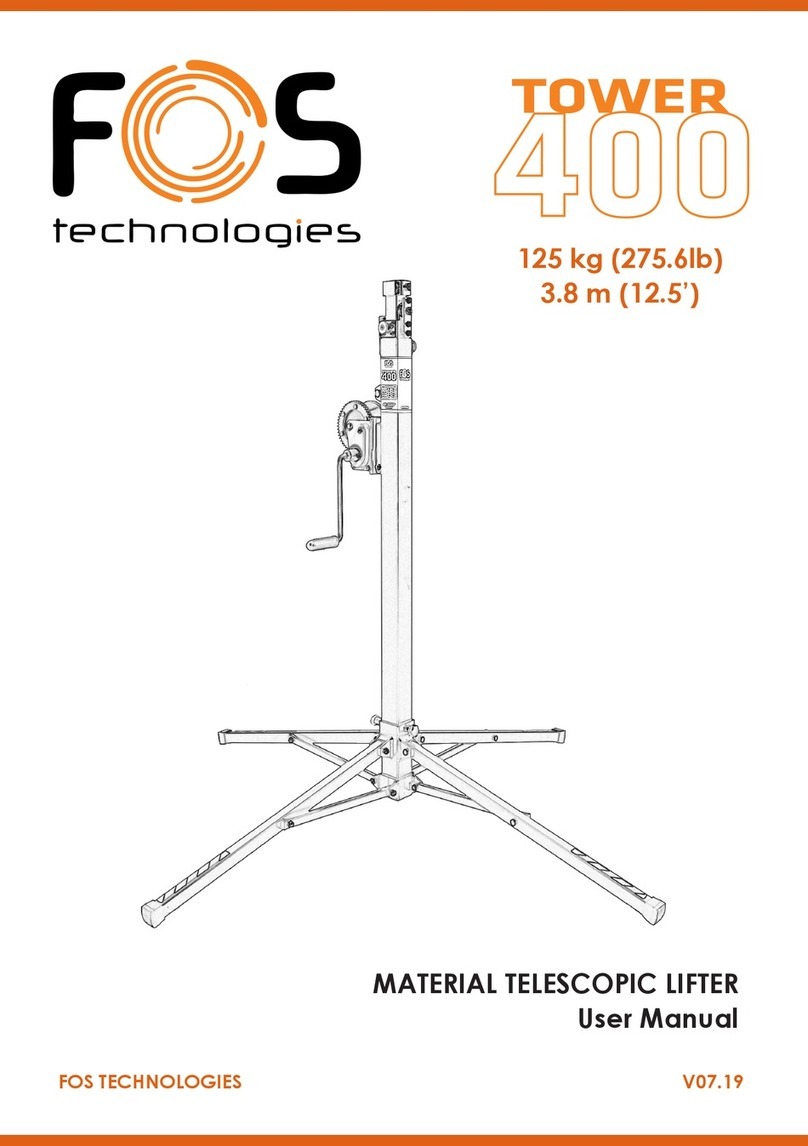

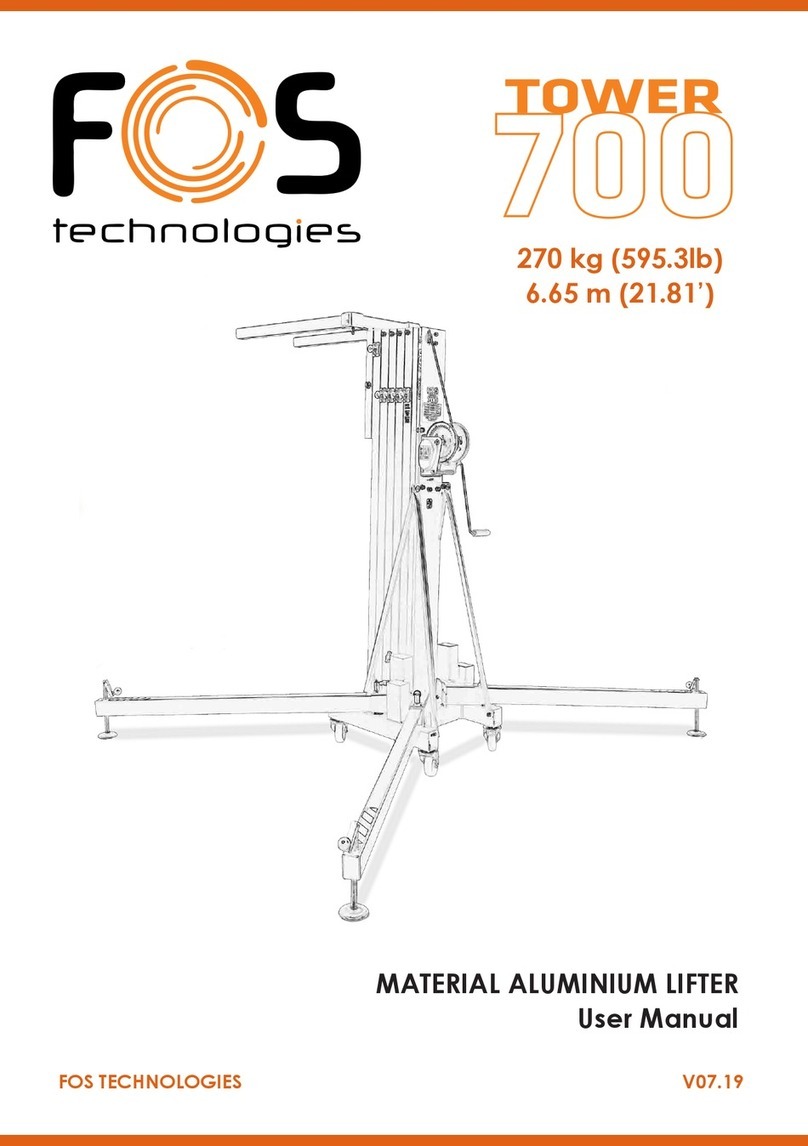

MATERIAL TELESCOPIC LIFTER

User Manual

220 kg (485lb)

6.5 m (21.3’)

2

FOS 650

F1313K

F1316K

F1314K

Section 1 (Base)

Section 2

Section 4

F4003K

Winch

A

B

C

F2121K

Leg

F1207K

Leg cap

F1312K

Section 3

F1315K

Section 5

3

FOS 650

A

A.5

A.6

F2183K

FOS Lock

A.1

A.1

Left Right

A.7

F2184K

A.2

A.3

F1015K

Screw

A.1 A.2 A.3

LOCK F2183K F2183K F2184K

Left

F1061K F7005K F2124K F1061K F7005K F2124K F1062K F7005K F2124K

(x2) (x2) (x2) (x2) (x2) (x2)

Right

F1061K F7005K F2124K F1012K F1012K

(x2) (x2) (x2) (x2)

F2126K

F2125NK F1020K F8001K

F1020K F8001K

F1116K

A.4

A.4

4

FOS 650

A.7

F2004K

F8004K

F1019K

F7006K

F2125K

F1104K

F2126K

F1105K

F1018K

A.5

F2006K

F8004K F1019K

F7006K

F2125K

F1106K

F2126K

F1105K

F1020K

F1018K

F8001K

A.6

F1020K

F1020K

F8001K

F8001K

F2007K

F8004K F1019K

F7006K

F2125K

F1109K

F2130K

F1110K

F1020K

F1018K

F8001K

F1020K F8001K

F1020K F8001K

5

FOS 650

BF7010K Nut

F1014K

Screw

F5005K

B.1

B.2

F1024K

F3004K

F2006K

F1023K

F1108K

F1005K

F1005K

F1024K

F3005K

F2008K

F1023K

F1111K

F1005K

F1005K

B.3

F1024K

F1023K

F1107K

F1005K

F1005K

F2004K

F3003K

Wheel

6

FOS 650

F4003K

Winch

F1021K

F8003K

Screw

Washer

F7006K

F8004K

D.1

F9005K

Steel cable F2127K

Cable clamp

F1022K

F2004K F8009K

F2119K

Spirit level

D

D.1

C

F2115K

F7003K

F2116K

F1006K F8004K

F2117K

F8005K

F1012K

F2129K

F1011K

F7004K

F2128K

Complete stabilizer kit

7

FOS 650

Code/Código Description/Descripción

F1005K Conic screw M6x16 / Tornillo avellanado M6x16

F1006K Allen screw M10x25/ Tornillo allen M10x25

F1011K Allen screw M5x25 / Tornillo allen M5x25

F1012K Allen screw M6x10 / Tornillo allen M6x10

F1014K Hexagonal taptite screw / Tornillo hexagonal taptite

F1015K Allen screw M12x25 / Tornillo allen M12x25

F1018K Allen screw M6x25 / Tornillo allen M6x25

F1019K Special M12 screw / Tornillo especial M12

F1020K Allen screw M8x25 / Tornillo allen M8x25

F1021K Allen screw M10x20 / Tornillo allen M10x20

F1022K Hexagonal screw M12x40 / Tornillo hexagonal M12x40

F1023K Conic screw M6x35 / Tornillo cónico M6x35

F1024K Conic screw M6x35 / Tornillo cónico M6x35

F1061K Headless allen screw M6x25 / Tornillo allen sin cabeza M6x25

F1062K Headless allen screw M6x20 / Tornillo allen sin cabeza M6x20

F1104K Pulley support plate Ø 60 / Pletina portapoleas Ø 60

F1105K Interior plate / Pletina interior

F1106K Pulley support plate Ø 80 / Pletina portapoleas Ø 80

F1107K Axel plate 60 / Pletina eje 60

F1108K Axel plate 80 / Pletina eje 80

F1109K Pulley support plate Ø 55 / Pletina portapoleas Ø 55

F1110K Interior plate / Pletina interior

F1111K Axel plate 100 / Pletina eje 100

F1116k Interior steel piece / Pletina interior roscada de acero

F1207K Legprole/Perlpata

F1312K Section 3 K-6 / Tramo 3 K-6

F1313K Section 2 K-6 / Tramo 2 K-6

F1314K Section 1 (Base) K-6 / Tramo 1 (Base) K-6

F1315K Section 5 K-6 / Tramo 5 K-6

F1316K Section 4 K-6 / Tramo 4 K-6

F2004K Pulley Ø 60 / Polea Ø 60

F2006K Pulley Ø 80 / Polea Ø 80

LISTA DE REPUESTOS / SPARE PARTS LIST

8

FOS 650

F2007K Pulley Ø 55 / Polea Ø 55

F2008K Pulley Ø 90 / Polea Ø 90

F2115K Stabilizer ball / Bola del estabilizador

F2116K Stabilizer handle / Manivela estabilizador

F2117K Stabilizer plate Ø 80 / Plato estabilizador Ø 80

F2119K Spirit level indicator / Nivel de burbuja

F2121K 50x50 leg tap / Tapón pata 50x50

F2124K Lock runner / Patín de gatillo

F2125K M10x35 knob / Palomilla LARGA Kuzar

F2125NK M10x20 knob / Palomilla CORTA Kuzar

F2126K Nylon rest / Taco de nylon

F2127K Cable clamp screw Ø6 mm / Prisionero cable Ø6 mm

F2128K Complete stabilizer / Estabilizador completo

F2129K Threaded bolt M16 / Esparrago M16

F2130K Nylon rest / Taco nylon

F2183K KAT Lock K-6 / Gatillo KAT K-6

F3003K 12x60 Axel / Eje 12x60

F3004K 12x80 Axel / Eje 12x80

F3005K 12x100 Axel / Eje 12x100

F4003K 450 Kg Winch with long handle / Cabrestante 450 Kg manivela larga

F5005K Ø100 blue wheel with 4 screws plate / Rueda Ø100 plato 4 taladros

F7003K Nut M10 / Tuerca M10

F7004K Auto-block nut M5 / Tuerca autoblocante M5

F7005K Nut M6 / Tuerca M6

F7006K Auto-block nut M12 / Tuerca autoblocante M12

F7010K Auto-block nut M6 / Tuerca autoblocante M6

F8001K Flat M8 washer / Arandela plana M8

F8003K Flat M10 washer / Arandela plana M10

F8004K M12 washer / Arandela M12

F8005K Wide M6 washer / Arandela M6 ancha

F8009K Flat M14 washer / Arandela M14 plana

F9005K Cable K-6 (Ø6 mm) / Cable K-6 (Ø6 mm)

LISTA DE REPUESTOS / SPARE PARTS LIST

9

FOS 650

Operating Instructions

1 - INTRODUCTION.

Dearuser.ThankyoupurchasingyourFOS650lifter.Wehopeyouwillbeverysatised

with it.

This manual has been written so that you can understand how to effectively use the lift

and most importantly, so that you can use it safely.

It is important that you fully read the manual and follow the instructions carefully before

using your lift. All FOS lifts undergo a very strict quality control process during their

manufacture. So that your lift always works properly please only purchase original FOS

parts from an authorized distributor or dealer. The user waives all warranty rights if using

parts other than FOS or if the product is manipulated in any way by an unauthorized third

party. When requesting parts, please refer to the diagrams in the back of this manual and

quote the serial number and year of manufacture located on your lifter.

2.- TECHNICAL SPECIFICATIONS.

The FOS 650 has been designed for vertically lifting lighting, trussing etc in the Profes-

sional sound and light sector. There is various supports or accessories available, please

refer to our website or catalogue.

2.1 - Max. load: 220 kg (485 lb)

2.2 - Min. load: 25 kg (55 lb)

2.3 - Max. height: 6.5 m (21.32’)

2.4 - Folded height: 1.82 m (5.97’)

2.5 - Work surface: 2.56 x 2.56 m (8.4’ x 8.4’)

2.6 - Folded base area: 47 cm x 47 cm (1.5’ x 1.5’)

2.7 - Weight: 90 Kg (198.4 lb)

2.8-Winch:450kgcertied(LongHandle)

2.9 - Cable: Steel DIN 3060. Tensile strength 180 kg/mm2. Anti-torsion & anti-corrosion

6 mm cable diameter.

2.10-Constructionmaterial:SteelprolesEN10305.

2.11 - Antirust protection priming paint bathed black steel, covered with cured polyester

dust.

2.12-Five-proletelescopicsystemoperatedbysteelcabledrivenbypulleyswithmetal

protected bearing pads. Adaptor Ø35 mm.

10

FOS 650

Operating Instructions

2.13 - FOS Locks on each section which automatically slots in to the sections during

elevation, locking them in place.

2.14 - Anchor of the legs by safety catches.

2.15 - Adjustable stabilizer plates in the legs with nonslip rubber base support.

2.16 - Spirit level for vertical alignment.

2.17 - Swivel wheels for transporting the lifter to its working position.

3. - SAFETY GUIDELINE.

3.1.-Situatethetoweronasolidandatsurface.

3.2.- Check that the legs are fully inserted and secured in to their housing with the safety

locks.

3.3.- Ensure that the lifter is in a vertical position and use the spirit level located on the

baseproletocheck.Ifnecessary,adjustitsalignmentwiththeplatesbyturningthe

handle in the appropriate direction.

3.4.- Check that the tower is locked in its working position with the safety lock.

3.5.- When used outdoors, place the tower on a hard surface and if necessary secure it

against excess wind force via cable braces.

3.6.- Do not use ladders nor lean them against the lifter.

3.7.- Be careful with any cables, prominent objects etc. placed above the tower.

3.8.- Do not stand underneath the load.

3.9.- Do not move the tower when it is elevated or loaded.

3.10.- Before using the tower, check the condition of the cable. This must be free of cuts

and frays. Never use damaged cables.

3.11.- Never dismount the winch handle or any element of the winch under any

circumstance.

3.12.- Once the tower is set-up in its working position we recommended the

winch handle is locked to avoid anyone interfering with it.

3.13.- The minimum load for a safe operation of the brake is 25 kg. The brake will not

function without this minimum load.

3.14.- Do not grease or lubricate the brake mechanism of the winch.

3.15.- This lift cannot lift human beings,

11

FOS 650

Operating Instructions

3.16.-Fortransportationitisnecessarytoretractallprolesandlockthemwiththe

corresponding safety lock.

4. - OPERATION.

4.1.-Placethetoweronaatandsolidsurfacewhereitisgoingtobeused.

4.2.- Remove the legs from their support brackets and insert them in their working

position.Checkthattheyarefullyinsertedandxedwiththesafetylock.

4.3.- Ensure that the lifter is in a vertical position and use the spirit level located on the

baseproletocheckthebubbleiscentred.Ifnecessary,adjustitsalignmentwiththe

stabiliser plates by turning the handle in the appropriate direction.

4.4.- Attach the load to the tower using the desired support (the support varies upon the

application), and ensure it is only used to lift loads vertically. The minimum load is 25 kg.

4.5.- Elevation: Extend the tower by turning the winch handle clockwise, lifting the load

to the desired height.

4.6.- Hold: Release the winch handle, it will remain in position by the action of the

winch’sautomaticbrake.EnsuretheFOSlockhasintroducedintotheprolebyturning

the handle slightly anti-clockwise.

4.7.- Continue elevating: Turn the winch handle again clockwise and lift the load until

the next prole is fully extended. Release the handle which will remain xed by the

winch’s automatic brake and ensure again the FOS lock has introduced into the second

prolebyturningthehandleagainanti-clockwise.Thetowercanbestoppedinanydesi-

red intermediate position. Simply release the winch handle and secure the tower by in-

serting the corresponding FOS lock into the hole which is closest to the required position.

4.8.- Descent: Firstly unlock the safety lock and turn the winch handle anti-clockwise

untiltheintermediateproleiscompletelyfoldeddown.NowunlockthenextFOSlock

andretractthefollowingprole.Justaswhenliftingtheload,theliftmaybestoppedat

any intermediate position.

4.9.- Transport: Four swivel wheels are located at the base for transporting the lifter. Be-

foretransportitisnecessarytofolddownthetowerbyretractingitsprolescompletely.

Dismount the legs by releasing the safety locks and place them back in their transport

compartments.

12

FOS 650

Operating Instructions

5.- MAINTENANCE.

5.1.- All cables must be checked regularly. Faulty cables must be replaced immediately.

Do not use the lifter with faulty cables as it is potentially very dangerous. Only use DIN

3060 cables, supplied from an authorised dealer.

5.2.- The lifter is delivered ex factory completely greased. Depending on its mechanical

Use though, we recommend that the crown wheel of the winch, the pads & bushings

ofthedriveshaft,thehandlethreadandtheprolesoftheliftareperiodicallygreased.

ATTENTION:

Do not apply oil or grease to the brake mechanism. The brake discs have been pre-grea-

sed with a special heat and pressure resistant grease. To avoid malfunction to the winch

brake, no other products must be used except the original provided by the company. It

is not necessary to grease the brake discs.

5.3.- Your lifter should be inspected at least once a year by a specialized / authorized

service centre.

5.4.- Only original FOS spare parts must be used to guarantee the reliability and opera-

tional safety of your lifter. The user shall lose all warranty claims if he uses anything other

thanoriginalsparepartsormodiesthisproductinanyway.

5.5.- In case a spare part is required please indicate the reference number which can be

found in the spare parts list at the back of this manual.

6.- WARRANTY.

All FOS lifts come with 2 years warranty. This warranty period is from the date of pur-

chase. FOS will repair any defect product caused by either faulty materials or poor work-

manshipfreeofchargewithinthisperiodaslongasthepartsarettedbyanauthorized

FOS dealer. Should the product have been manipulated in any way or a repair attempted

by an unauthorized dealer the warranty will be invalid. This warranty does not cover da-

mage occurred by improper use.

7.- CERTIFICATIONS

FOSreservestherighttomakeanymodication/alterationtotheliftwithoutpriornotice.

Anymodication/alterationwouldbeaninnovation,intendedtoimprovetheproduct.

13

FOS 650

14

FOS 650

15

FOS 650

FOS Technologies LTD

Bulevard Iliensko Shose 8

SladovaBazaZMM,Soa,BG

www.fos-lighting.eu

Call Center : +30 2102811700

This manual suits for next models

1

Table of contents

Other FOS Technologies Lifting System manuals

Popular Lifting System manuals by other brands

JLG

JLG 3507 Supplemental repair manual

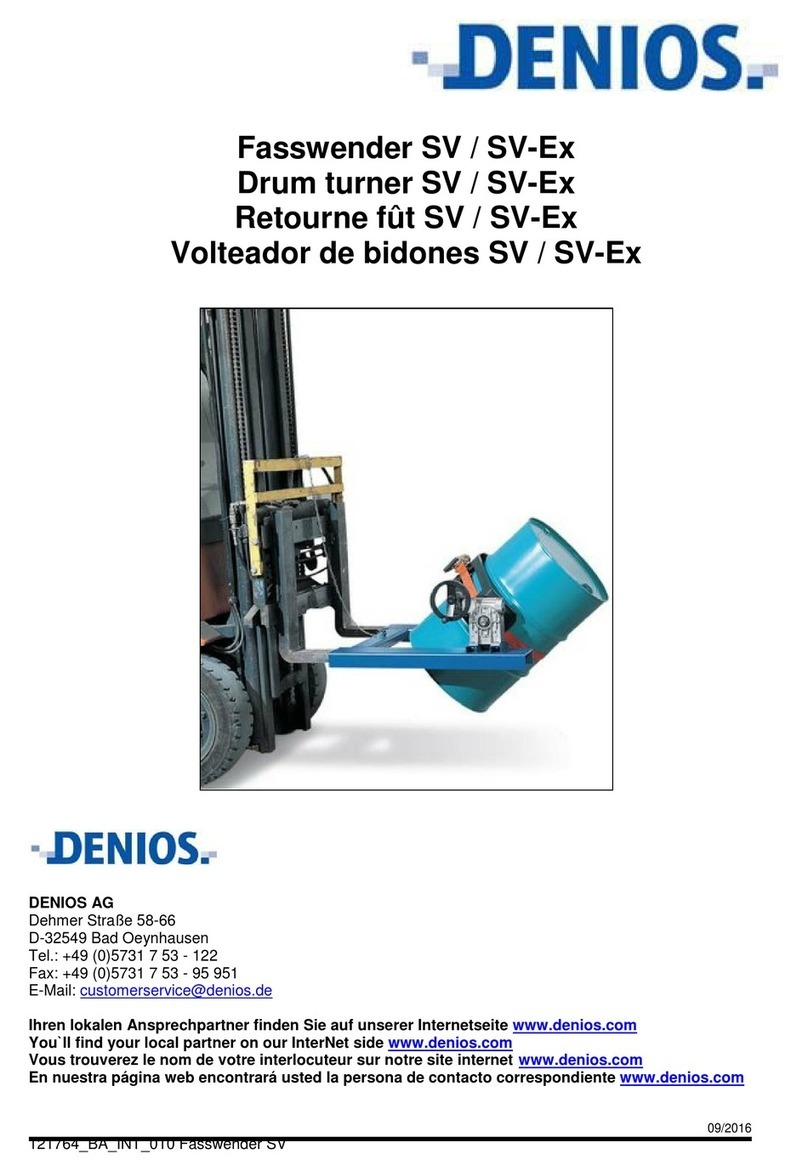

Denios

Denios SV manual

AMF-BRUNS

AMF-BRUNS HUBMATIK K90 operating instructions

HSS Hire

HSS Hire 69313 Operating & safety guide

WERTHER INTERNATIONAL

WERTHER INTERNATIONAL PRM50 manual

Custom Equipment

Custom Equipment HY-BRID LIFTS HB-P3.6 MAINTENANCE & TROUBLESHOOTING MANUAL

EZ-ACCESS

EZ-ACCESS PASSPORT user manual

Dino lift

Dino lift DINO 125T Operation & instruction manual

JLG

JLG E600 Service and maintenance manual

Launch

Launch TLT235SC user manual

ShoulderDolly

ShoulderDolly HandyLifter instruction manual

AAQ

AAQ AutoLift AL-1132-220 Installation manual & operation instructions