fos4X RD 110 V User manual

INSTRUCTIONS FOR USE

Application Tool

RD 110 V

Product Type Accessory

Product Number 1295

Product Version 1.2.x

Document Version 2.0

Issue Date 2019-0 -01

Language en-us

Follow these instructions for safe and proper use.

Keep instructions for future use.

INSTRUCTIONS FOR USE

Application Tool

RD 110 V

Product Type Accessory

Product Number 1295

Product Version 1.2.x

Document Version 2.0

Issue Date 2019-0 -01

Language en-us

Follow these instructions for safe and proper use.

Keep instructions for future use.

Imprint

Imprint

fos4X GmbH

Thalkirchner Str. 210

81371 Munich

Germany

Phone: + 9 89 9995 2-00

Fax: + 9 89 9995 2-01

www.fos X.de

WEEE-Reg.-Nr. DE: 703901 8

©2019 fos X®

Distribution and reproduction of this document, exploitation and

communication of its contents are prohibited unless expressly

permitted. Violations will result in the liability for damages. All rights

reserved in the event of patent, utility model or design registration.

All rights reserved.

fos X is a trademark of fos X GmbH.

Brand names and protected trademarks are the property of their

respective owners. The naming of brand names and protected

trademarks has only descriptive character. Named trademarks are

not part of any partnership or cooperation with fos X.

1295_1.2.x_ -10-2.0-en-us © fos X 2019 2 / 28

Table of Contents

Table of Contents

1 About this Document.................................................................................................... 5

1.1 Target Audience................................................................................................................................5

1.2 Objective of these Operating Instructions.............................................................................. 5

1.3 Identification of Information....................................................................................................... 5

1.3.1 Safety-relevant Information............................................................................................5

1.3.2 Non-safety-related Information.................................................................................... 6

1. Abbreviations.....................................................................................................................................6

2 Safety...................................................................................................................................7

2.1 Conformity..........................................................................................................................................7

2.2 Qualification of Personnel............................................................................................................ 7

2.3 Intended Use..................................................................................................................................... 8

2. Residual Risks....................................................................................................................................8

2. .1 Explosion Protection.......................................................................................................... 8

2. .2 Working Environment Wind Turbine.............................................................................8

2. .3 Working Environment Blade Manufacturing Facility..............................................8

2. . Adhesives............................................................................................................................... 9

2. .5 Risk of Burns.........................................................................................................................9

2. .6 Mechanical Risks............................................................................................................... 10

2. .7 Vacuum.................................................................................................................................. 11

2.5 Personal Protective Equipment................................................................................................. 11

3 Product Description...................................................................................................... 12

3.1 Functional Description..................................................................................................................12

3.2 Technical Data.................................................................................................................................13

3.2.1 Mechanical Data................................................................................................................13

3.2.2 Electrical Data.....................................................................................................................1

3.2.3 Environmental Conditions.............................................................................................. 1

3.2. Specification of the Vacuum Supply.......................................................................... 1

3.2.5 Product Specific Data...................................................................................................... 15

3.3 Markings on the Product............................................................................................................ 15

3.3.1 Type Plate.............................................................................................................................15

3.3.2 Warning Labels...................................................................................................................16

3. Display and Control Elements................................................................................................... 16

1295_1.2.x_ -10-2.0-en-us © fos X 2019 3 / 28

Table of Contents

Packaging and Transport...........................................................................................18

.1 Scope of Delivery...........................................................................................................................18

.2 Packaging......................................................................................................................................... 18

.3 Unpacking.........................................................................................................................................18

. Packing.............................................................................................................................................. 18

.5 Transport...........................................................................................................................................19

.6 Storage...............................................................................................................................................19

5 Installation.......................................................................................................................20

6 Commissioning............................................................................................................... 21

7 Operation......................................................................................................................... 22

8 Troubleshooting............................................................................................................ 2

9 Maintenance...................................................................................................................26

9.1 Preventive Maintenance............................................................................................................. 26

9.1.1 Maintenance Table........................................................................................................... 26

9.1.2 Cleaning the Application Tool.......................................................................................26

9.2 Corrective Maintenance.............................................................................................................. 27

9.3 fos X Support................................................................................................................................. 27

10 Taking out of Service and Disposal........................................................................28

10.1 Taking out of Service................................................................................................................... 28

10.2 Disassembly.................................................................................................................................... 28

10.3 Disposal.............................................................................................................................................28

1295_1.2.x_ -10-2.0-en-us © fos X 2019 / 28

1. About this Document

1 Abo t this Doc ment

1.1 Target A dience

These operating instructions are intended for trained technicians and

service technicians.

1.2 Objective of these Operating Instr ctions

These operating instructions describe all activities for the intended

use of the Application Tool.

1.3 Identification of Information

1.3.1 Safety-relevant Information

These operating instructions contain the following safety

information:

■Safety information in the Safety chapter applies to the entire use

of the product. See Safety, page 7.

■Safety notes at the beginning of a section apply to the entire

section.

■Safety notes before a step apply to the entire following section.

Presentation Safety notes are shown in the operating instructions as follows:

DANGE Nature and cause of risk

Consequences

uMeasures to avoid the risk.

Meaning The safety notes with the signal words Danger, Warning, Caution and

Notice have the following meanings:

DANGE Risk which, if not avoided, will result in death or serious injury.

WA NING Risk which, if not avoided, could result in death or serious injury.

CAUTION Risk which, if not avoided, could result in minor injury.

NOTICE Risk which, if not avoided, will result in damage to property.

1295_1.2.x_ -10-2.0-en-us © fos X 2019 5 / 28

1. About this Document

1.3.2 Non-safety-related Information

TIP Advice on the optimal use of the product.

Symbols and Meaning Table 1: Representation of the information in the operating instructions

Symbol Meaning

Task:

1. First step

2. Second step

Instruction with task and several steps

Task:

uStep

Instruction with a single step

PResult Result of an instruction

List:

■Point 1

■Point 2

Enumeration with title

Identification of

Information, page 5 Cross reference

Bold Text Highlighting of particularly important

information

CONTROL ELEMENT Designation of a control element of the

product

1.4 Abbreviations

AC Alternating Current

GTIN Global Trade Item Number

Max Maximum

PE Protective Earth

1295_1.2.x_ -10-2.0-en-us © fos X 2019 6 / 28

2. Safety

2 Safety

2.1 Conformity

The product is in conformity with the relevant Union harmonisation

legislation.

The EU Declaration of Conformity is available on request. Contact

details see fos X Support, page 27.

2.2 Q alification of Personnel

Definitions ■Instructed personnel: Personnel instructed in the tasks assigned to

them.

■Trained personnel: Personnel trained in the operation and safe

use of the product.

■Qualified personnel: Personnel who, based on their specialist

training, knowledge and experience and knowledge of the relevant

regulations, are able to assess the work assigned to them and

identify possible hazards.

Assignment of tasks Tasks within the scope of use may only be carried out by the

personnel defined below.

Table 2: Tasks

Task Personnel

Packaging and transport

Installation

Commissioning

Operation

Troubleshooting

Maintenance

Taking out of service

Qualified personnel

Disassembly

Disposal

fos X or specialized

disposal company

1295_1.2.x_ -10-2.0-en-us © fos X 2019 7 / 28

2. Safety

2.3 Intended Use

Intended Use The Application Tool is used exclusively for the installation of

fos Strain expert sensors in rotor blades of wind turbines with the

adhesive UHU PLUS BLACK. The installation of the sensors can

take place during the production of the rotor blades in the blade

manufacturing facility or in retrofit on a wind turbine.

The Application Tool may only be used in a commercial/industrial

environment.

Any use other than described in these operating instructions is

considered improper use.

Predictable Mis se Do not use the Application Tool for the installation of other sensors

and adhesives.

2.4 Resid al Risks

2.4.1 Explosion Protection

The product is not suitable for use in potentially explosive

environments.

2.4.2 Working Environment Wind T rbine

The use of the Application Tool on wind turbines requires special

measures to avoid risks.

Measures for risk prevention on wind turbines:

uObtain and observe safety and work regulations:

– Qualification and training of personnel

– Personal protective equipment

– Required permits

uEnsure that the use of the Application Tool on the wind turbine is

permitted.

2.4.3 Working Environment Blade Man fact ring Facility

The use of the Application Tool in a blade manufacturing facility

requires special measures to avoid risks.

Measures for risk prevention in blade manufacturing facilities:

uObtain and observe safety and work regulations:

1295_1.2.x_ -10-2.0-en-us © fos X 2019 8 / 28

2. Safety

– Qualification and training of personnel

– Personal protective equipment

– Required permits

uMake sure that the use of the Application Tool allowed in the blade

manufacturing facility.

2.4.4 Adhesives

Adhesives can cause severe irritation and allergic skin reactions.

uAvoid skin contact.

uObserve the safety data sheet of the adhesive.

uUse personal protective equipment according to the safety

data sheet of the adhesive. See Personal Protective Equipment,

page 11.

Fumes from adhesives can cause damage to health and allergic

reactions.

uDo not inhale fumes.

uObserve the safety data sheet of the adhesive.

uUse adhesives only in sufficiently ventilated rooms.

Adhesives can cause severe environmental damage.

uObserve the safety data sheet of the adhesive.

uDispose of adhesives and adhesive packaging in accordance with

applicable environmental regulations.

2.4.5 Risk of B rns

The heating plate of the heating element of the Application Tool is

hot during operation (>100 °C).

Burns caused by touching the hot heating plate.

uDo not touch the heating plate and adjacent parts.

uSwitch off the Application Tool when not in use.

uWhen not in use, place the Application Tool with the heating plate

on the supplied temperature-resistant underlay.

uAllow the Application Tool to cool down for at least 15 minutes

after switching off.

uWear protective gloves (protection against contact heat

performance level 2 according to DIN EN 07).

1295_1.2.x_ -10-2.0-en-us © fos X 2019 9 / 28

2. Safety

Material damage caused by placing the hot heating plate on

surfaces that are not temperature-resistant.

uEnsure that the material of the rotor blade is suitable for use with

the Application Tool.

uKeep a distance of at least 10 cm between hot parts of the

Application Tool and parts that are not temperature-resistant.

uWhen not in use, place the Application Tool with the heating plate

on the supplied cork underlay.

– A temperature-resistant underlay is included in the scope of

delivery.

– The transport case has an integrated temperature-resistant

underlay.

uSwitch off the Application Tool when not in use.

uAllow the Application Tool to cool down for at least 15 minutes

after switching off.

2.4.6 Mechanical Risks

Injuries caused by dropping the Application Tool.

uDo not use the Application Tool on surfaces with an inclination

angle of more than 90°.

Figure 1: Maximum angle for using the Application Tool

uDo not stay under the suctioned Application Tool.

uSecure the Application Tool against falling down before switching

off the vacuum supply.

uUse the transport case to transport the Application Tool.

1295_1.2.x_ -10-2.0-en-us © fos X 2019 10 / 28

2. Safety

2.4.7 Vac m

isk of suffocation due to suction of ambient air.

uUse the Application Tool with vacuum pump only in rooms with

adequate ventilation and air volume.

2.5 Personal Protective Eq ipment

Protective Gloves For all activities in which the Application Tool is switched

on or was recently switched on:

uWear protective gloves with the following

characteristics:

– General requirements according to DIN EN 20

– Contact heat resistance: performance level 2

according to DIN EN 07

For all tasks with adhesives:

uWear protective gloves according to EN ISO 37 -1

(nitrile, min. 0. mm).

Safety Goggles For all tasks with adhesives:

uWear safety goggles with side protection according to

DIN EN 166.

Protective Clothing For all tasks:

uWear protective clothing (long-sleeved work clothing).

1295_1.2.x_ -10-2.0-en-us © fos X 2019 11 / 28

3. Product Description

3 Prod ct Description

3.1 F nctional Description

F nction The Application Tool is a tool for attaching fos Strain sensors into the

rotor blades of wind turbines. The Application Tool is used for faster

thermal curing of UHU PLUS BLACK adhesive.

Overview

Figure 2: Overview

1Temperature knob

2On/Off switch

3Power cable

4Temperature display

5Heating element

6Ball valve

7DN 7,2 coupling

8Frame

Figure 3: Bottom

9Suction cups 10 Heating plate

The Application Tool consists of the following components:

■Temperature knob: Adjusts the temperature of the heating plate.

■On/Off switch: Turns the Application Tool on and off.

1295_1.2.x_ -10-2.0-en-us © fos X 2019 12 / 28

3. Product Description

■Power cable: Cable with Protective contact plug to power the

Application Tool.

■Temperature display: Displays the current temperature of the

heating plate in °C.

■Heating element: The heating element is connected to the frame

by springs. The springs pull the heating element downwards

with a defined force. The frame of the heating element has

6 M threaded holes for height adjustment. The threaded

holes can be used with M screws and lock nuts for height

compensation for plane-parallel mounting of the heating surface.

■Ball valve: Connects and disconnects the frame and suction cups

with the compressed air hose to the vacuum pump.

■DN 7.2 coupling: Coupling for connecting the vacuum supply. The

coupling has a non-return valve. The non-return valve prevents

the Application Tool from falling down immediately if the vacuum

supply fails.

■Frame: Base frame of the Application Tool. The frame is connected

to the compressed air coupling and the suction cups. The frame

distributes the vacuum of the vacuum pump to the suction cups.

■Suction cups: When the ball valve is open, the suction cups hold

the Application Tool by the vacuum of the vacuum pump on the

ground.

■Heating plate: Heats the sensor and accelerates the curing of the

adhesive.

Operation The Application Tool is connected to the power supply (110 V AC,

60 Hz) and a vacuum pump.

After opening the ball valve, the Application Tool is held on the

ground by the vacuum with the suction cups. The springs press the

heating element onto the sensor with a defined force (100 ±10 N).

The adhesive is then cured. Temperature and duration depend on the

sensor type. See operating instructions of the sensor.

3.2 Technical Data

3.2.1 Mechanical Data

Table 3: Mechanical Data

Property Value Unit

Length 31 .0 mm

Height 133.2 mm

1295_1.2.x_ -10-2.0-en-us © fos X 2019 13 / 28

3. Product Description

Property Value Unit

Width 302.3 mm

Total weight*3.8 kg

* Application Tool without packaging

3.2.2 Electrical Data

Table : Electrical Data

Property Value Unit

Power supply 110 V AC

Power frequency 60 Hz

Power consumption 1200 W

Electrical connector Protective contact plug

3.2.3 Environmental Conditions

Table 5: Environmental Conditions

Property Value Unit

Maximum operating altitude 3000 m

Permitted temperature

(Transport and storage) -10 … +60 °C

Permitted relative humidity

(Transport and storage) 5 ... 80 %

Permitted temperature

(Operation) -10 … + 0 °C

Permitted relative humidity

(Operation) 5 ... 80 %

3.2.4 Specication of the Vac m S pply

TIP The vacuum pump for the vacuum supply is not part of the product.

1295_1.2.x_ -10-2.0-en-us © fos X 2019 1 / 28

3. Product Description

Table 6: Specification of the Vacuum Supply

Property Value Unit

Negative pressure 0, bar

Pumping capacity (typical)*50 l/min

Connection type DN 7,2

* Max. external air 10 l/min

3.2.5 Prod ct Specific Data

Table 7: Product Specific Data

Property Value Unit

Temperature range of heating

plate 90 … 160 (+10)*°C

Length of power cable: 3 m

* The temperature of the heating plate can be up to 10 °C above the set temperature.

3.3 Markings on the Prod ct

3.3.1 Type Plate

Figure : type plate

(exemplary contents)

Contents of the type plate (example data from graphic)

■fos X-Logo

■Product name: Application Tool RD

■Product category and number: ABC123

■Produkt version: v1.2.3

■Serial number: S/N: 123 -5678

■QR-code of the serial number

■CE marking

■RoHS-marking

■Power supply: 230V

■Power consumption: 1200W

■GTIN: P/N: 2511123 5678

1295_1.2.x_ -10-2.0-en-us © fos X 2019 15 / 28

3. Product Description

3.3.2 Warning Labels

Warning symbol: Hot s rfaces

The warning symbol indicates surfaces that become hot when the

Application Tool is used. Touching hot surfaces may cause burns.

uDo not touch marked surfaces and components.

uObserve the safety instructions. See Safety, page 7.

3.4 Display and Control Elements

Display Elements Table 8: Display elements

Display element Description/function

Green light: The Application Tool is

turned on.

ON/OFF SWITCH

Off: The Application Tool is turned off.

Temperature display

LCD-display

Displays the current temperature of the

heating plate in °C.

When the TEMPERATURE KNOB is turned:

Displays the target temperature of the

heating plate in °C.

Operating Elements Table 9: Operating elements

Operating element Description/function

ON/OFF SWITCH Pushbutton

Turns the Application Tool on and off.

BALL VALVE

Ball valve

Connects and disconnects the frame

and suction cups with the compressed

air hose to the vacuum pump.

Positions:

1295_1.2.x_ -10-2.0-en-us © fos X 2019 16 / 28

3. Product Description

Operating element Description/function

Figure 5: Opening the

ball valve

Figure 6: Closing the

ball valve

TEMPERATURE KNOB

Rotary control

Adjusts the temperature of the heating

plate.

1295_1.2.x_ -10-2.0-en-us © fos X 2019 17 / 28

. Packaging and Transport

4 Packaging and Transport

4.1 Scope of Delivery

The Application Tool is delivered with the following scope of delivery:

■1x Application Tool RD 110 V

■1x Transport case with integrated temperature-resistant underlay

■1x Temperature-resistant underlay

■1x Operating instructions

4.2 Packaging

TIP uKeep the transport packaging.

In the original packaging, the product is best protected for transport.

4.3 Unpacking

Unpacking the Application Tool:

1. Open the packaging.

2. Remove the transport case with the Application Tool from its

packaging.

3. Open the transport case.

. Remove the Application Tool from the transport case.

5. Check the scope of delivery. See Scope of Delivery, page 18.

6. If parts of the scope of delivery are missing: Contact fos X

Support. See fos X Support, page 27.

4.4 Packing

Packing the Application Tool:

1. If the Application Tool was switched on:

a) Place the Application Tool on a temperature-resistant surface.

b) Switch off the Application Tool.

c) Disconnect the power cable from the power supply.

d) Disconnect the vacuum hose from the Application Tool.

e) Let the Application Tool cool for 15 minutes.

2. Wind the power cable and place it on the Application Tool.

1295_1.2.x_ -10-2.0-en-us © fos X 2019 18 / 28

. Packaging and Transport

3. Disconnect the vacuum hose from the DN 7.2 coupling.

. Place the Application Tool and accessories in the transport case.

5. Close the transport case.

PThe Application Tool is ready for transport.

6. If the Application Tool is to be shipped:

a) Place the transport case with the Application Tool in the

packaging (shipping box). If necessary, use padding material.

b) Close the packaging.

PThe Application Tool is ready for shipping.

4.5 Transport

Transporting the Application Tool:

uHandle the Application Tool with care during transport. Observe

the transport conditions. See Environmental Conditions, page 1 .

uTransport the Application Tool in the transport case. See Packing,

page 18.

uShip the Application Tool in the transport case and packaging. See

Packing, page 18.

4.6 Storage

Storing the Application Tool:

uStore the Application Tool in a dry and clean place.

uStore the Application Tool in a transport packaging. See Packing,

page 18.

uObserve the environmental conditions. See Environmental

Conditions, page 1 .

1295_1.2.x_ -10-2.0-en-us © fos X 2019 19 / 28

5. Installation

5 Installation

uObserve the safety instructions. See Safety, page 7.

Connecting the power supply and vacuum pump:

1. Transport the Application Tool to the installation site.

2. Remove the Application Tool from the transport case.

3. Place the Application Tool on a temperature-resistant underlay.

WA NING Electric shock caused by touching a damaged cable.

Serious injury or death.

uBefore connecting the Application Tool to the power supply, check

all cables for damage. If cables are damaged: Do not use the

Application Tool.

uOperate the Application Tool only on a power supply with PE,

suitable fuse and residual current circuit breaker.

. Check all cables of the Application Tool for damage.

5. If cables are damaged: Do not use the Application Tool and

contact support. See fos X Support, page 27.

6. Connect the Application Tool to the power supply.

7. Make sure the Application Tool is switched off.

8. If necessary, press the ON/OFF-SWITCH to switch off the

Application Tool.

Figure 7: Closing the ball

valve

9. Make sure that the BALL VALVE is closed.

10. Connect the vacuum pump to the DN 7.2 coupling using a vacuum

hose. Avoid kinks in the vacuum hose.

Specification of the vacuum pump see Specification of the

Vacuum Supply, page 1 .

11. Install the vacuum pump. See operating instructions of the

vacuum pump.

PApplication Tool is ready for operation.

1295_1.2.x_ -10-2.0-en-us © fos X 2019 20 / 28

Table of contents

Popular Tools manuals by other brands

Kubota

Kubota AP-SA20 Operator's manual

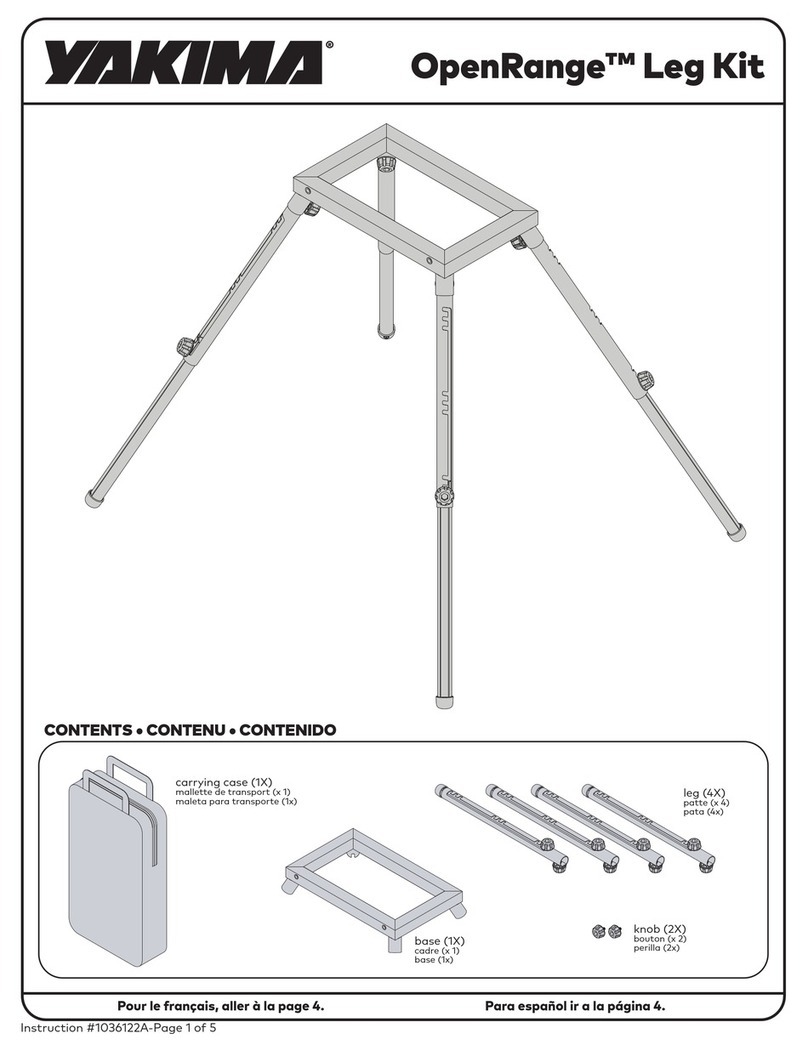

Yakima

Yakima OpenRange Leg Kit instruction manual

Beechcfaft

Beechcfaft Bonanza D35 1994 Pilot's operating handbook and faa approved airplane flight manual

resideo

resideo Braukmann EA122A quick start guide

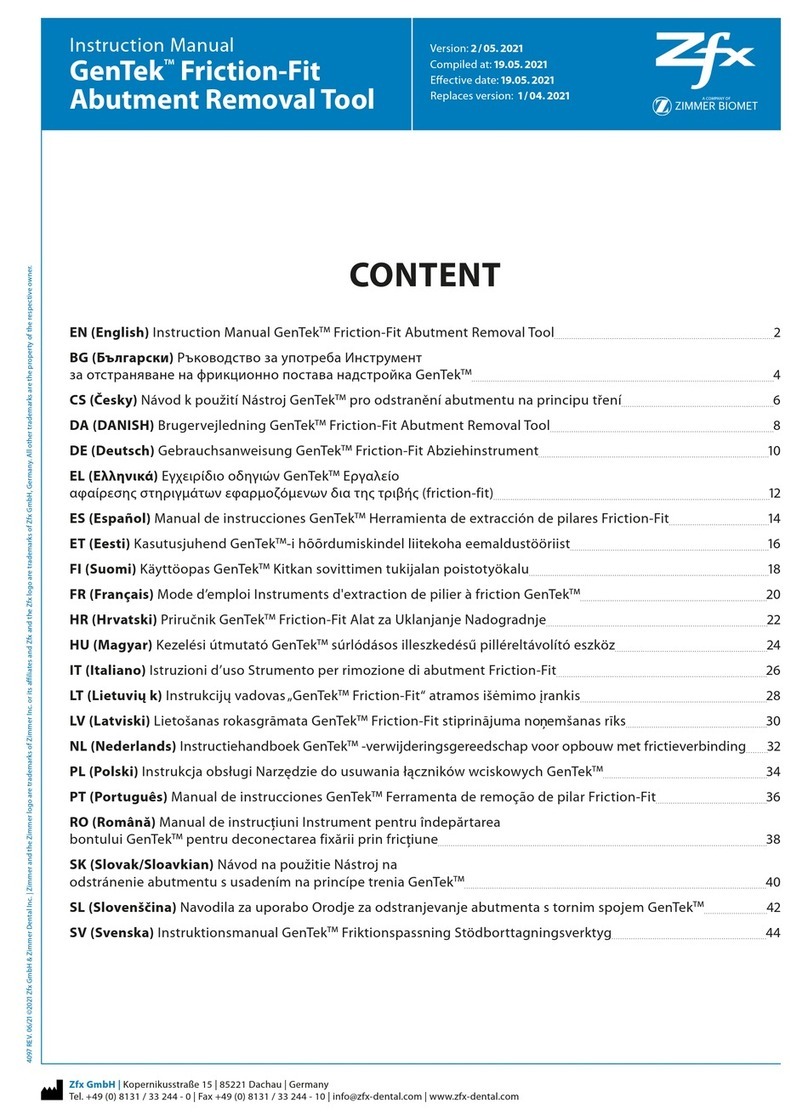

Zfx

Zfx GenTek instruction manual

Makita

Makita HR007G instruction manual