Foss XDS OptiProbe User manual

NIRS

XDS Interactance OptiProbe

Analyzer

Manual

8.921.8006EN

Metrohm AG

CH-9100 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

NIRS

XDS Interactance OptiProbe

Analyzer

Manual

8.921.8006EN 03.2013 fpe

Teachware

Metrohm AG

CH-9100 Herisau

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been checked with great care, errors

cannot be entirely excluded. Should you notice any mistakes please send us your comments using the

address given above.

▪▪▪▪▪▪▪

3

Change Control

Change Control (initiated with version 1.01):

Version Date Summary of Changes

1.01 November 16,

2006

Address changes to reflect move to 7703 Montpelier Road, Laurel, MD

20723. This was applied on the cover page and on page 66.

1.02 August 24,

2009

Updated headers and Table of Contents to current style.

Updated Network Connection to current recommendations.

Replaced photos showing XC-1200 Standard on probe, clarified

Reference Standardization explanation.

Updated various menus to current XDS style.

Moved Wavelength Linearization before Reference Standardization.

Replaced section on XDS Instrument Connection with an updated,

more current version. This also includes basic connection

troubleshooting. The sections on Windows 95, 98, and NT 4.0 were

dropped.

Updated explanations for Instrument Calibration and Wavelength

Certification.

Added photos to some procedures to clarify required probe positions.

Added note that USP dropped “Photometric Linearity Test” as of 12-

2008.

Added notes about possible failure of Photometric Test, and corrective

action.

Corrected wrong instruction in Gain Test. Reflectance probe is normally

used in Gain.

Changed photo in Lamp Replacement, now showing arrow on lamp.

Corrected reference to Lamp Replacement in Troubleshooting to

section 8.3.

Updated Vision “opening screen”, removed copyright date for

publication.

Updated Configure, Options screen and discussion to current version.

Added note to Troubleshooting, Instrument Calibration, that Reference

Standardization must be performed.

Added note about wavelength drift due to temperature change with

the WSR standard. This is on the page immediately following

Instrument Calibration.

Added note about 21 CFR Part 11 Verification document to Validation

section.

Added note to avoid scratching sample probe window to maintenance

section.

Added troubleshooting items which may be symptomatic of network

connection issues.

Added note on page in section on Interactance Reflectance, to avoid

carrying dirt or sample material from the OptiProbe barrel to the

instrument reference.

1.03 February 21,

2012

Corrected photo and description of taking reference during

Wavelength Linearization.

4

▪▪▪▪▪▪▪

Table of contents

1Introduction................................................................................................................... 6

2Site Readiness................................................................................................................ 8

2.1 Temperature and Humidity .......................................................................... 8

2.2 General Environment.................................................................................... 8

2.3 Electrical Power ........................................................................................... 8

2.4 Vibration ...................................................................................................... 8

2.5 Instrument Communication.......................................................................... 8

2.6 Instrument Dimensions and Weight ............................................................. 9

3Instrument Connection ................................................................................................ 10

3.1 Network Connection, connected to an active network port as shown ....... 10

3.2 Direction Connection, free-standing manner with no network connection 11

3.2.1 Overview of XDS Instrument Communication ....................................................... 11

3.2.2 Microsoft Windows Firewalls ................................................................................ 12

3.2.3 Network Evolution Issues...................................................................................... 13

3.2.4 Quick Glossary of Terms: ...................................................................................... 13

3.2.5 Connection in Vision............................................................................................. 14

3.2.6 Troubleshooting Connection Problems.................................................................. 15

3.2.7 Network Troubleshooting Overview...................................................................... 16

3.2.8 Direct Connection Troubleshooting Overview ....................................................... 19

4Assembly of the Instrument......................................................................................... 21

5OptiProbe Module ....................................................................................................... 26

5.1 Interactance Reflectance Configuration ..................................................... 27

5.2 Interactance Immersion Configuration ....................................................... 29

5.2.1 Cleaning the Probe End ........................................................................................ 32

5.3 Cleaning of internal reflectance reference.................................................. 32

6Vision Software: Connection to the Instrument ........................................................... 37

7Instrument Diagnostics................................................................................................ 42

7.1 Setup Diagnostics....................................................................................... 42

7.1.1 Wavelength Linearization ..................................................................................... 43

7.1.2 Reference Standardization .................................................................................... 46

7.1.3 Instrument Calibration .......................................................................................... 49

7.1.4 IPV Setup (Instrument Performance Verification) ................................................... 53

7.2 Evaluation Diagnostics ............................................................................... 55

7.2.1 Performance Test ................................................................................................. 56

7.2.2 Wavelength Certification ...................................................................................... 58

7.2.3 Photometric Test .................................................................................................. 62

7.2.4 Gain Test.............................................................................................................. 66

7.2.5 Low Flux Test ....................................................................................................... 67

8Instrument Maintenance.............................................................................................. 70

8.1 Overview.................................................................................................... 70

8.2 Fan Filter Replacement............................................................................... 70

▪▪▪▪▪▪▪

5

8.3 Lamp Replacement .....................................................................................72

8.4 Fuse Replacement.......................................................................................77

8.5 Maintenance Log ........................................................................................79

9Validation Tools ...........................................................................................................81

9.1 Hardware Validation Tools .........................................................................81

9.1.1 Factory Instrument Test Guide and Results ............................................................81

9.1.2 Installation and Operating Qualification Documents.............................................. 82

9.1.3 NIRStandards® for Instrument Performance Verification .......................................82

9.1.4 Instrument Performance Certification....................................................................82

9.1.5 Metrohm Master Instrument Program...................................................................83

9.2 Software Validation Tools ..........................................................................83

9.2.1 Installation and Operating Qualification Documents.............................................. 83

9.2.2 Vision Certificate of Validation ..............................................................................83

9.2.3 Vision Validation Document Package ....................................................................83

9.2.4 21 CFR Part 11 Compliance...................................................................................84

10 Safety and Electrical Certification ...............................................................86

11 Troubleshooting .........................................................................................87

12 Lifting and transporting the Metrohm instrument......................................92

13 Index ..........................................................................................................93

6

▪▪▪▪▪▪▪

1Introduction

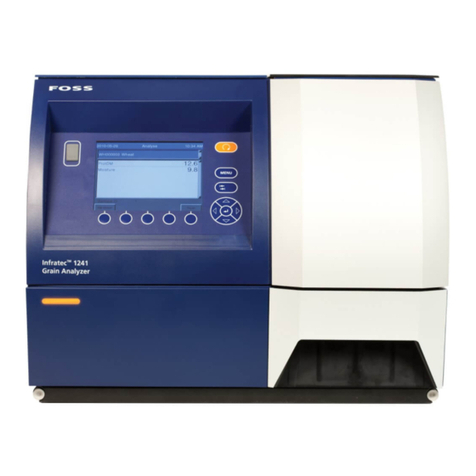

Thank you for selecting the XDS™ OptiProbe

Analyzer, manufactured by FOSS. This instrument is

the third generation in a series of instruments

designed for precision NIR measurement,

characterization of organic materials, and

qualification of known materials to quality

parameters.

The XDS™ is designed for stable operation in harsh

environments, while still providing the precision and

accuracy users have come to expect of FOSS

instruments.

Standard fiber bundle lengths are 2-meter and 3-

meter. The 2-meter fiber bundle is shown here.

The XDS OptiProbe Analyzer uses a proven monochromator design, employing a digitally-controlled

dispersive grating, along with sensitive detection devices and state-of-the-art circuitry to enhance

signal output and minimize any extraneous noise that might influence performance. The XDS™ uses

various patented algorithms to provide superior accuracy and transferability between like

instruments.

This instrument uses near-infrared (NIR) spectral energy to illuminate the sample. By measuring the

energy reflected off (or passing through) the sample, chemical information and composition may be

determined. This information may be used for quantification of constituents, or for comparison to a

library of known materials, providing identification and qualification of materials.

The OptiProbe Analyzer has been a versatile, proven design for NIR sampling for many years. As an

XDS™ instrument, the OptiProbe benefits from the improvements in wavelength accuracy, precision,

low noise, speed, and overall performance.

A panel of 6 LED indicators provides information to the user on these functions:

Icon

Status

Green when power is ON

Amber when connected to network or direct

connection

Green when instrument lamp is ON

Red when scanning reference or sample

▪▪▪▪▪▪▪

7

Green when stable operating temperature is reached

Green when module is properly attached

Vision Software™ offers an easy user interface, using the familiar interface provided with previous

generations of NIR instrumentation. All functions required to perform identification, qualification, and

quantitation are provided, with easy tools for interpretation of results. Vision offers full instrument

diagnostics, with built-in acceptance specification tables for all tests. Vision stores all results in a

diagnostic database for later lookup, with control chart views of results tracked over time.

The menu-driven, validated Vision Software package meets all requirements of CFR 21 Part 11,

covering Electronic Records and Signatures. Vision comes with a full manual for operation and theory

of operation, with complete instructions for analytical development.

The XDS Analyzer provides 0.5nm data points, and uses several innovative methods to assure

wavelength accuracy and repeatability. Wavelength positions are traceable to NIST SRM-1920a.

Because SRM-1920a does not have certified wavelengths above 2000 nm, an additional wavelength

absorber is included in the calibration standard, to provide stable wavelengths beyond 2000 nm.

These additional wavelengths have been independently measured on calibrated instrumentation to

ascertain the wavelength positions used.

Instrument communication is through RJ-45 network connections, which eliminates issues involved

with long runs of RS-232 cable. An Internet Protocol (IP) address is dynamically requested upon

connection. This address may be permanently installed, if required for network purposes. The RJ-45

connection also permits remote interrogation and diagnostics checks of the instrument, if necessary

and authorized.

The instrument enclosure is completely sealed to prevent contamination by dust or other substances.

The cooling fans operate outside the main enclosure, and are thermally linked to internal fans that

maintain a constant temperature inside the instrument enclosure. There is no airflow drawn into the

optics chamber instrument. An external fan-cooling loop is provided in the side chassis, with thermal

conduction from the inside of the optics chamber. This avoids contamination of the instrument in

dusty environments. An air filter is built into the door of this chamber. For cool environments, heaters

are embedded in the thermal transfer block to raise temperature when required.

Lamp changes are performed through a single panel on the rear surface of the instrument. The lamp

is easy to remove and replace, and requires no special tools or expertise.

8

▪▪▪▪▪▪▪

2Site Readiness

Like most precision instruments, the OptiProbe Analyzer is sensitive to environmental conditions that

can affect its performance and useful life. Observe the following guidelines when selecting a site and

installing the instrument:

2.1 Temperature and Humidity

The XDS Analyzer is designed to work in ambient air temperatures from 40-95°F (4.5-35°C).

Use the XDS Analyzer only in 10-90% relative humidity levels, non-condensing. Rapid changes in

humidity can cause interferences by adding trace moisture absorptions to the spectra. In general,

lower humidity levels are preferred.

The Performance Test (a comprehensive instrument diagnostic test in Vision software) is somewhat

sensitive to changes in ambient humidity, and the Performance Test may fail under conditions of

extreme humidity, or rapidly varying humidity.

2.2 General Environment

Minimize exposure of the monochromator to dust.

Inspect the fan filter at least monthly. If an accumulation of lint, dust, or other matter has

accumulated, pull open the right-hand panel from the instrument. Replace the filter. If dust has

accumulated on the fans, carefully wipe them clean with a moist soft cloth. Do not distort or damage

the fan blades or fins, as this will impede cooling.

Do not place the instrument directly near any HVAC duct. The direct flow of heating or cooling air

will cause the instrument to exhibit high noise during the Performance Test.

2.3 Electrical Power

Power should be a single, separate, stable, transient-free filtered AC circuit. The circuit should have

surge protection.

Operating voltage for the instrument is 100-240VAC, 50/60Hz. The power supply is self-switching

and will provide the correct operating voltage to the instrument.

Maximum power consumption is 750W.

2.4 Vibration

Install the XDS Analyzer where it will not be affected by bench vibration from grinders, blenders,

stirrers, or mixers.

Never permit hammering or other physical impact on the bench top supporting the XDS Analyzer or

its computer.

2.5 Instrument Communication

The XDS OptiProbe Analyzer can communicate directly with the computer by use of a UTP Crossover

Cable, such as CDW #243786, supplied with unit. (gray cable)

Alternatively, the instrument may be accessed directly through a network connection. This uses a

standard RJ-45 type cable, such as CDW #074092, available from CDW Computer Centers, Inc. The

▪▪▪▪▪▪▪

9

instrument detects network capability and optimizes communication speed.

The computer that operates the instrument must have clear access through the network, and be

configured to communicate properly. This communication is the responsibility of your on-site

network personnel.

Full instructions are given in section 3.0.

2.6 Instrument Dimensions and Weight

XDS™ OptiProbe Analyzer dimensions are:

•Width: 18.0” (457 mm)

(Leave about 6” (152mm) on the right side for access to standards door)

•Height: 15.0” (381 mm)

Height with Probe: 17.5” (445mm)

•Depth: 22.5” (572 mm) front to back

Depth with Probe: 32” (812mm)

Leave a minimum of 3” (76mm) around the back and left side for airflow and access space. Leave at

least 6” (152mm) on the right side, and in front for fiber bundle space.

•Weight: 67.2 pounds (30.6 kg)

Follow lifting instructions (on last page) when moving the instrument. Avoid injury.

10

▪▪▪▪▪▪▪

3Instrument Connection

The XDS instrument may be connected to the host computer in one of two ways: If the XDS

Instrument will be used as part of a network, use the Network Connection method shown

immediately below. If there are not enough active network ports near the XDS instrument, a hub or

router may be used.

This section assumes use of Windows® 2000, XP, or later versions of Windows Operating Systems.

For computers using Windows 95, 98, or NT 4.0, we recommend upgrade of the computer and

operating system to current specifications.

CAUTION: Metrohm NIRSystems does not recommend the use of two network cards under any

circumstances. Do not use Direct Connection to the instrument along with a network connection to

the company network. The use of two network cards -- on one data bus in the computer – may

result in lost commands, lost data, and unsatisfactory software operation. Metrohm cannot be

responsible for software and instrument problems resulting from the use of two network cards in the

host computer.

This information is correct as of the time of original publication. Changes to computers, operating

systems, and network protocols may require revision of this information without notice.

3.1 Network Connection, connected to an active network port as

shown

This is the preferred method of instrument communication when a connection to the company Local

Area Network (LAN) is necessary. Specific information about this method follows:

•The XDS instrument should be connected -- with a “patch” cable – to the network port.

•Upon power-up, the XDS instrument will request a dynamic IP address from the network

server. This is normally assigned in 5 to 10 seconds.

•The XDS instrument uses a proprietary, encrypted command language. It cannot be activated

by any program except Vision, or Metrohm programs designed to operate the instrument.

Therefore, the instrument maintains “Closed System” status under 21 CFR Part 11 rules. No

hacking or support of viruses is possible with XDS instruments.

▪▪▪▪▪▪▪

11

•The XDS instrument appears just like a network printer (or other peripheral device) on the

LAN system. It generates no signals, and only responds when commanded by an authorized

user, logged into Vision software.

•This is the easiest connection method for XDS instruments.

3.2 Direction Connection, free-standing manner with no network

connection

This method allows users to connect to the instrument when there is no network present. In such

cases, a “crossover cable” (provided) is used. The XDS instrument, upon power-up, requests a

dynamic IP address. When none is supplied within 45 seconds, the XDS instrument concludes that no

DHCP server is available. It then defaults to an internal IP address which the computer may use for

“direct communication”.

This method of hookup should not be used when the computer is also connected to a network. Such

connection may result in lost commands, lost data, and unsatisfactory software operation. Metrohm

cannot be responsible for software and instrument problems resulting from the use of two network

cards in the host computer.

For IT personnel, it may be helpful to understand the sequence of events used by the XDS instrument

and Vision software when establishing an electronic connection. These are explained.

3.2.1 Overview of XDS Instrument Communication

The XDS instrument may be connected to LAN systems in the same manner as any printer or other

peripheral Ethernet-enabled device. These key items will help understand the communication

methods. See the flowchart diagram on next page.

1. The XDS instrument maintains “Closed System Status” under 21 CFR Part 11 guidelines. It

uses a proprietary, encrypted command language. It is not susceptible to hacking or virus

attacks.

2. The XDS system may only be addressed using proprietary software (usually “Vision”) which

can only be entered by an authorized user, using the “two-token” method of entry. (Unique

User ID and password)

12

▪▪▪▪▪▪▪

3. Upon being powered up on a LAN, the XDS instrument requests a “dynamic” IP address from

the DHCP server which controls the LAN. This IP address is normally granted promptly

(typically in 5-10 seconds) so the instrument can function on the LAN. Most DHCP servers

track the XDS instrument by the “MAC” (Machine Access Code) to later re-assign that same IP

address whenever the XDS instrument is on the LAN.

4. If there is no DHCP server available to assign an IP address (a free-standing router may serve

the same DHCP function), the XDS instrument will “time out” in 45 seconds --and it will know

that it is not attached to an active LAN. It will then default to an internally-stored default IP

address. This address, 169.254.0.2, is used for local, free-standing communication only. In

such cases, a crossover cable, or a hub with two patch cables, should be used to connect the

computer and the XDS instrument.

5. Upon the next power-down and subsequent power-up of the XDS instrument, it will again

request an IP address of the DHCP server. It will go through the same cycle, eventually

reverting to the stored default IP address. This is intentional.

6. A dynamic IP address is the preferred method of XDS instrument connection. The default IP

address is only used when no DHCP server is available to assign a dynamic IP address.

A short glossary of terms follows. See the flowchart diagram for XDS instrument communication

which visually outlines the items explained above.

Flowchart Diagram of XDS communication protocol

3.2.2 Microsoft Windows Firewalls

The Microsoft Windows® Firewall on the PC may interfere with Vision communication. To assure

communication, follow these steps:

▪▪▪▪▪▪▪

13

•Enter Control Panel, Security Center.

•On the “General” Tab, be sure that “exceptions” are allowed. (Un-click “Don’t allow

exceptions”.)

•On the “Exceptions” Tab, click “Add Program”.

•Select Vision from the list of programs – click on it. (Vision must be installed to appear on the

list.)

•Click on “OK” at each window to exit Control Panel.

3.2.3 Network Evolution Issues

This document is as correct as possible at the time or writing. However, network management is an

evolving discipline, and conditions will change. Some of the drivers for change include network

security, authentication, and data integrity. Technology changes factor into all of these issues.

Because the network communication environment is complex and ever-changing, we have tried to

provide the basic information needed for connection of the XDS instrument. 95% of users will have

no connection problems, if these instructions are followed.

In the rest of the cases, there may be network issues, corporate restrictions, or other issues which

inhibit easy connection. The troubleshooting section covers some of the most common problems.

In all cases, we recommend minimal tampering with computer settings. This can cause instability, and

may be prohibited by company policies.

At this time, we recommend Microsoft Windows® XP as the easiest operating system by which to

establish network communication. We strongly recommend that Windows 95, 98, and NT 4.0 be

avoided, as they require considerable expertise in network configuration.

3.2.4 Quick Glossary of Terms:

DHCP:

The Dynamic Host Configuration Protocol (DHCP) is an Internet protocol for automating the

configuration of computers that use TCP/IP.

DNS Server:

A Domain Name Server. DNS Servers run special-purpose software, as part of the Domain Name

System, for managing enterprise networks.

IP:

An Internet Protocol (IP) address is a numerical identification and logical address that is assigned to

devices participating in a computer network utilizing the Internet Protocol for communication

between its nodes.

IPv4:

IPv4 refers to “Internet Protocol version 4” which is the fourth revision in the development of the

Internet Protocol (IP) and it is the first version of the protocol to be widely deployed. Together with

IPv6, it is at the core of standards-based internetworking methods of the Internet and is still by far

the most widely deployed Internet Layer protocol. XDS Instruments use IPv4.

14

▪▪▪▪▪▪▪

LAN:

A local area network (LAN) is a computer network covering a small physical area, like a home, office,

or small group of buildings, such as a corporate site, a university, or an airport. These are often called

“enterprises”.

Subnet Mask:

“Subnetting” is used to break a large network into smaller sections. This can enhance efficiency, raise

speeds, and reduce “packet collisions” within the network. To accomplish subnetting, “Subnet

Masks” may be applied to separate one section of the network from another. A subnet mask typically

takes the form “255.255.255.0” or something similar. This scheme is becoming obsolete, as new

network management methods are being implemented.

TCP/IP:

(Transmission Control Protocol/Internet Protocol) is the basic communication language or protocol of

the Internet.

3.2.5 Connection in Vision

1.

Log into Vision with your User ID and Password.

Click on Configure, Input as shown.

▪▪▪▪▪▪▪

15

2. Highlight “NIRSystems XDS-series

Instrument Driver” as shown, then

click on “Configure”.

Information:

At this point, Vision requests any

XDS instrument on the local area

network (LAN) to report connection

status. This may take a few

moments.

If the instrument is not on a LAN,

and instead is connected with a

crossover cable, this will take a

minute or more. Vision first

requests a dynamic IP address, If no

server or router is available to

assign an IP address, Vision waits

45 seconds, then searches for the

default instrument IP address, in the

event of Direct Connection using a

crossover cable.

3. When Vision “finds” the

instrument on the LAN, it will

be shown. The dynamic IP

address (assigned by the

server) is shown, along with

the XDS Serial number. The

instrument is shown as

“Available” on port 2083.

Highlight the instrument and

click “OK”.

4. If the IP Address field is empty, the user should consult “Troubleshooting Connection

Problems”.

3.2.6 Troubleshooting Connection Problems

Many connection problems are easily solved, especially with Windows® XP operating systems.

Windows XP is currently the preferred operating system, and has enhanced connectivity over other

operating systems. Vista is good also, but may impose user security restrictions. Windows 2000 is

almost as simple, but may require an extra step or two, as discussed.

If your computer uses Windows 95, 98, or NT 4.0 for the operating system, we strongly recommend

upgrade to Windows XP for easiest connectivity. This may require a full computer upgrade, as older

computers may not have the processor speed, memory, or connectivity required to run Windows XP

with full Ethernet compatibility.

16

▪▪▪▪▪▪▪

1. Vision cannot see any

instrument on the

connection path.

Click on the “down

arrow” at the right side

of the empty field to see

if instrument(s) are

shown.

Solution: By expanding

the field, Vision can

display the instruments

shown.

Note that only the top

instrument, Serial #3010-

0878, is “Available”.

Highlight it and click

“OK”.

2. Vision still sees no

instrument(s) after

expanding the field.

This indicates connection

or network issues.

Verify Cable Type:

Verify correct cable type for hookup. Most networks use “patch” cables. Free-standing systems use a

“crossover cable”. Power down the XDS instrument, then power it back up. Wait 120 seconds for the

XDS instrument to fully reset its communication. If an instrument is shown, proceed to “Acquire”,

“Connect” in Vision.

If this does not resolve the problem, continue to the next section.

3.2.7 Network Troubleshooting Overview

If no XDS instrument shows as “available”, there may be a setting which should be changed. It may

be necessary to contact your IT department for assistance with these issues.

First, verify that the network has a DHCP Server. If no DHCP server is available, the instrument must

be connected by Direct connection, using a crossover cable. If this is the case, proceed to the section

entitled “Direct Connection Troubleshooting Overview”.

Network Solution 1:

Check Internet Protocol (TCP/IP) Properties. (You may need to contact your IT department to follow

these steps.)

▪▪▪▪▪▪▪

17

•Click on Start, then Control Panel

•Double-click on Network Connections

•Double-click on Local Area Connection

•Click on Local Area Connection Properties

•Click on Internet Protocol (TCP/IP)

•Click on Properties

The full path, from Network Properties forward to Internet Protocol (TCP/IP) Properties, is shown:

Verify these settings:

•Obtain an IP address automatically

•Obtain DNS server address

automatically

When finished, click “OK”. Close all other

boxes opened for this verification.

If the settings were not set properly, it may

be necessary to exit Windows XP, then re-

enter XP, to have the correct settings take

effect. If in doubt, do this and try XDS

instrument communications again after this

takes effect.

18

▪▪▪▪▪▪▪

Network Solution 2:

Returning to the Local Area

Connection Status dialog box, note

these items for the computer:

•Address Type:

(should be “assigned by

DHCP”)

•IP Address:

Write this address down for

the next step

•Subnet Mask:

Write this down for the next

step

If connection cannot be achieved, it

may be necessary to verify that the

XDS instrument is installed “within

the IP address range” of the

computer.

Network Solution 3:

Verify network has full IPv4

compatibility.

Some networks have moved to Ipv6

(Internet Protocol version 6) which

uses different address formats.

The IT department at your company can verify if the

network offers full Ipv4 compatibility. If the network has

migrated to Ipv6 operation, a “compatibility pack” may

need to be loaded to support Ipv4-enabled devices.

Table of contents

Other Foss Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Thorne & Derrick

Thorne & Derrick Kamstrup ULTRAFLOW 54 Installation

Drello

Drello Drelloscop 1020 operating instructions

LaserLiner

LaserLiner EvolutionCross-Laser 8P PowerBright operating instructions

Tektronix

Tektronix 491 product modification

Extech Instruments

Extech Instruments MO290 user guide

Johnson

Johnson 40-6535 instruction manual