Foss NIRS DA1650 User manual

Copyright 2020 / All rights reserved

FOSS Analytical A/S, Nils Foss Allé 1, DK-3400 Hillerød, Denmark

NIRS™ DA1650

User Manual

6008 1286 / Rev. 8

NIRS™ DA1650

User Manual

NOTE: Please note that all information is liable to change without prior

notice.

Information may be changed or updated without notice. The latest version is found at www.foss.dk.

Rev. Date of Issue Revised Material

1 2011-05-10 First edition

2 2013-03-25 General update to reflect ISIscan Nova software version 5.2

3 2013-09-13 General update to reflect ISIscan Nova software version 6.0

4 2015-10-21 FOSS address updated

5 2017-06-15 Safety sections moved to seperate manual. General update to reflect Plug and

Play installation.

6 2019-04-23 Name change

7 2019-11-12 Small Updates

8 2020-12-17 Detailed steps how to install Mosaic Solo on external win 10 PC

NIRS™ DA1650

User Manual 6008 1286 / Rev. 8

Table of Contents

1 Safety.......................................................... 1:1

1.1 General ................................................................... 1:1

1.2 Personal Safety ..................................................... 1:1

1.3 Product Safety ....................................................... 1:2

1.4 Disposal Instructions ............................................ 1:3

1.5 Legal Data .............................................................. 1:3

1.5.1 RF Exposure ................................................................... 1:3

1.5.2 Class B Digital Device .................................................... 1:3

1.6 Warranty Policy ..................................................... 1:3

1.7 Copyright of Embedded Software ....................... 1:4

1.8 Trademarks ............................................................ 1:4

2 Introduction................................................ 2:1

2.1 General ................................................................... 2:1

2.2 Principle of Operation .......................................... 2:3

2.3 Sample Cups .......................................................... 2:3

2.3.1 General .......................................................................... 2:3

2.3.2 Radio Frequency Identification System ....................... 2:4

2.3.3 Other Cups and Accessories ......................................... 2:5

2.4 NIRS DA1650 Software ......................................... 2:7

2.4.1 ISIscan Nova .................................................................. 2:7

2.4.2 local configuration ....................................................... 2:7

2.4.3 Routine Operation Software ....................................... 2:9

3 Installation ................................................. 3:1

3.1 Site Preparation .................................................... 3:1

3.2 Unpacking and Checking ...................................... 3:1

3.3 Lifting and Placement of the Instrument ........... 3:1

3.4 Software Installation and Initial Configuration . 3:1

3.5 PC connection for Mosaic Solo ............................. 3:2

3.5.1 Installation of Mosaic Solo on external PC ................. 3:2

3.5.2 Via Local Area Network ............................................... 3:9

3.5.3 Via switch / network hub ............................................. 3:9

3.6 Printer .................................................................... 3:9

4 Operating Instructions............................... 4:1

4.1 Routine Start-up .................................................... 4:1

NIRS™ DA1650

User Manual 6008 1286 / Rev. 8

4.2 Analysis Procedure ................................................ 4:2

4.2.1 Sample Preparation ...................................................... 4:2

4.2.2 Analysing the Sample ................................................... 4:3

4.2.3 Multi-cup Analysis ........................................................ 4:6

4.2.4 Turning off the Analyser .............................................. 4:6

4.3 Care Menu .............................................................. 4:7

4.3.1 FossManager Synchronisation ..................................... 4:8

4.3.2 Instrument Diagnostics ................................................. 4:9

4.3.3 Clean Screen .................................................................. 4:9

4.3.4 Instrument Calibration ............................................... 4:10

4.3.5 Maintenance ............................................................... 4:13

4.3.6 Shut Down .................................................................. 4:16

4.3.7 Upgrade ...................................................................... 4:17

4.3.8 Instrument Information ............................................. 4:18

4.3.9 Remote Support .......................................................... 4:18

4.3.10 Export Logs ................................................................. 4:19

4.3.11 Configuration ............................................................. 4:20

4.4 Check Samples ..................................................... 4:22

4.4.1 Check Sample .............................................................. 4:22

4.4.2 FOSS Check Sample ..................................................... 4:27

5 Maintenance............................................... 5:1

5.1 Cleaning the Instrument ...................................... 5:1

5.2 Cleaning the Touch Screen ................................... 5:1

5.3 Cleaning the Sample Cups .................................... 5:1

5.4 Replacement of Lamp ........................................... 5:2

5.5 FOSS Preventive Maintenance Agreement ......... 5:3

6 Troubleshooting......................................... 6:1

6.1 General ................................................................... 6:1

6.2 Recommended Actions ......................................... 6:2

6.3 Error Messages ...................................................... 6:3

7 Parts, Accessories and

Consumables7:1

8 Technical Specifications............................. 8:1

8.1 Technical Data ....................................................... 8:1

8.2 Installation Requirements .................................... 8:1

8.3 Prformance Data ................................................... 8:2

NIRS™ DA1650

User Manual 6008 1286 / Rev. 8 1:1

1 Safety

1.1 General

Please read the user manual carefully and use the instrument as advised. Follow all

safety precautions as instructed.

Safety Symbols

Explanation of safety symbols used in this manual.

Safety Terminology

Explanation of safety terms used in this manual.

1.2 Personal Safety

Warning

The instrument is NOT to be operated in atmospheres which could

constitute an explosion risk.

Warning

The marking labels must be visible to the user and shall not be

removed from the instrument or made unreadable in any way.

Warning (label placed on lamp module)

The lamp module can be very warm if the operating temperature

is high. Cotton gloves must be used when replacing the lamp to

avoid burn injuries.

Symbol Description

General hazard.

Hot surface.

Term Description

Warning Danger to human safety.

Caution Danger to product performance/operation.

Note Important supplementary information.

NIRS™ DA1650

1:2 User Manual 6008 1286 / Rev. 8

1.3 Product Safety

Caution

The instrument is designed and tested for European (CE)

compliance. To ensure that this compliance is maintained,

connect only CE approved equipment. Connecting equipment

that is not CE approved may cause EMC incompatibility and

thereby affect the function of the instrument and other

equipment.

Caution

When nothing is connected the sealing caps should be mounted

to maintain dust protection.

Caution

The air circulation around the lamp cooling flange must not be

inhibited. Leave uncovered with sufficient space for air

circulation at all times.

Caution

Do not touch the lamp glass or reflector or let any rough surface

come into contact with the lamp glass. A microscopic scratch in

the glass might cause a lamp explosion later.

Caution

The lamp can be damaged by fingerprints and oily residues.

Cotton gloves must be used when replacing the lamp to avoid

any damages.

NIRS™ DA1650

User Manual 6008 1286 / Rev. 8 1:3

1.4 Disposal Instructions

Do not dispose of this electrical device with unsorted household

waste. Improper disposal may be harmful to environment and

human health. Please refer to your local waste authority for

information on return and collection systems in your area.

1.5 Legal Data

The equipment is CE labelled and complies with the following directives:

• EMC (ElectroMagnetic Compatibility) Directive 2014/30/EU

• LVD (Low Voltage Directive) 2014/35/EU

• Packing and Waste Directive 94/62/EC

• RoHS Directive 2002/95/EC

• WEEE Directive 2012/19/EU

• REACH Directive 1907/2006/EC

• FCC ID: 2AZ6M-DA1650

•DA1650 is only compliant if no changes or modifications are made on the

device.

1.5.1 RF Exposure

DA1650 is compliant with the requirement for RF exposure in US with <50 mm

separation distance between the user and/or bystander of the device.

1.5.2 Class B Digital Device

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications.

However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following

measures.

1.6 Warranty Policy

Warranty conditions are either specified on the order confirmation of the purchase

order together with the invoice, or in the contract with the FOSS representative and

only apply if:

• the Customer/User has followed all written instructions and documentation from

FOSS regarding the product

• the product has been installed, maintained, adjusted and calibrated according to

all descriptions and recommendations in the documentation

• the product has not been used for purposes other than those reasonably

contemplated by FOSS

• the product has not been altered or repaired with non-original FOSS parts or by

personnel not authorised by FOSS

• only original FOSS consumables and accessories or equivalents recommended

by FOSS have been used

NIRS™ DA1650

1:4 User Manual 6008 1286 / Rev. 8

• the product has not in any other ways been handled contrary to ordinary practice

• only software authorised by FOSS has been installed on any product PC

• any external product PC has complied with the recommendations of the FOSS

representative

• computer games have not been played on the PC, including any games

preinstalled together with the operating system.

• the instrument has been properly maintained, as recommended by FOSS

Your instrument may contain parts that, due to wear during use of the instrument, are

expected to have a shorter lifetime than the instrument in general. These parts are

listed in the User Manual and/or in the FOSS product software and in the Owner's

Guide.

The liability for worn down parts subject to wear is limited to cases with

extraordinary wear due to defective material or production errors.

1.7 Copyright of Embedded Software

Copyright (c) 2001, 2002 Swedish Institute of Computer Science.

All rights reserved.

Redistribution and use in source and binary forms, with or without modification, are

permitted provided that the following conditions are met:

1. Redistributions of source code must retain the above copyright notice, this list

of conditions and the following disclaimer.

2. Redistributions in binary form must reproduce the above copyright notice, this

list of conditions and the following disclaimer in the documentation and/or other

materials provided with the distribution.

3. The name of the author may not be used to endorse or promote products derived

from this software without specific prior written permission.

This software is provided by the author “as is” and any express or implied warranties,

including, but not limited to, the implied warranties of merchantability and fitness for

a particular purpose are disclaimed. In no event shall the author be liable for any

direct, indirect, incidental, special, exemplary, or consequential damages (including,

but not limited to, procurement of substitute goods or services; loss of use, data, or

profits; or business interruption) however caused and on theory of liability, whether

in contract, strict liability, or tort (including neglience or otherwise) arising in any

way out of the use of this software, even if advised of possibility of such damage.

1.8 Trademarks

NIRS™ DA1650 is a registered trademark of FOSS Analytical A/S. Windows® is a

registered trademark of Microsoft Corporation.

NIRS™ DA1650

User Manual 6008 1286 / Rev. 8 2:1

2 Introduction

2.1 General

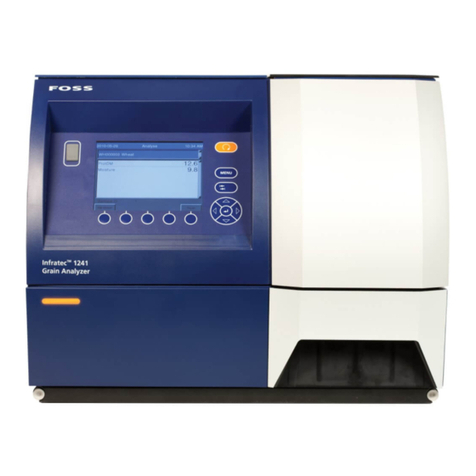

NIRS™ DA1650 is a robust, simple-to-use and accurate near-infrared analyzer that

is based on diode array technology. NIRS DA1650 is a robust instrument that can be

used in a laboratory or at-line environments. The user interface is designed for simple

daily routine operation.

Measurements are simple to perform and results are delivered in minutes. The

analyzer is easy to move around and can be placed close to the production line. The

sample handling is easy, making high quality analysis a matter of routine. The NIRS

DA1650 is ready to use with a range of FOSS calibrations.

Instrument communication is through ethernet network connections. An Internet

Protocol (IP) address is dynamically requested upon connection. This address may

be permanently installed, if required for network purposes.

Connection through a FossManager networking system allows for remote

surveillance and diagnostic checks of the instrument, if necessary and authorized.

The instrument enclosure is completely sealed to prevent contamination by dust or

other substances. The cooling fans operate inside the main enclosure, and are

thermally linked to an external heat sink at the rear of the instrument that maintains

a constant temperature inside the instrument enclosure. There is no airflow drawn

into the optics chamber instrument.

Lamp changes are performed through a single panel on the rear surface of the

instrument. The lamp is easy to remove and replace, and requires no special tools or

expertise.

Fig. 2:1Front view of NIRS DA1650

1Touch screen display 2Lid

NIRS™ DA1650

User Manual 6008 1286 / Rev. 8 2:3

2.2 Principle of Operation

A sample, ground or unground, is placed in a sample cup which is placed in the

instrument. By means of a motor, the cup is turned so that multiple parts of the

sample is scanned. This multipoint reflectance measurement allows for an accurate

analysis of the sample. For inhomogeneous samples like pellets it is crucial with a

multipoint measurement.

Fig. 2:3Sample cup in instrument

2.3 Sample Cups

2.3.1 General

All sample cups used with NIRS DA1650 fulfill the requirements of ISO 12099

requiring a quartz window to eliminate drying effects of the interacting sample

surface layer.

Analysis can be done with a range of different sample cups. The most commonly

used are the Small cup and the Large cup. Other cup types are shown in section 2.3.3.

The small cup is intended for fine samples in granular or powder form and products

that are easy to compress. When placing the small cup in the sample presentation unit

the holder must be used. (The holder is shown between the sample cups in the

illustration below.)

The large cup is intended for unground or coarse samples like whole grains, pellets

or cut silage. The bottom and upper part of the Large sample cup are screwed

together and can be taken apart for e.g. cleaning or for replacing the glass if needed.

The bottom part also fit with the "Large cup extension".

Note: When filling the cup it is important that the bottom of the

sample cup is completely covered so that no light leaks through.

If you are not sure of which cup to use for your application, please contact your local

FOSS product specialist.

NIRS™ DA1650

2:4 User Manual 6008 1286 / Rev. 8

Fig. 2:4Sample cups

2.3.2 Radio Frequency Identification System

Radio Frequency Identification (RFID) is a method used by the NIRS DA1650 for

identifying each individual sample cup. There is a small RFID chip in each cup with

CupType information and a unique CupID.

The CupType information can be used to ensure that the correct Cup Type is used for

each measurement. The analysis is aborted and a automatic warning is displayed if

analysis is started with a different cup type than what is specified in the application

setup.

The unique Cup ID is stored with each measurement so it afterwards can be traced

which cup that was used for the individual analyses.

RFID settings can be enabled/disabled in the FossManager software.

ASmall cup CLarge cup

BSmall cup holder

NIRS™ DA1650

2:6 User Manual 6008 1286 / Rev. 8

Large Cup Extension

The "large cup extension" fits on the bottom part of the Large sample cup. It can be

used when a larger sample volume is required in order to scan a representative

portion of the sample.

Slurry Cup

The best choice for samples that tends to stick to the cup. Also the preferred choice

for samples warmer than 50 °C. Should only be used for homogenous samples.

Petri Dish Holders

For wet, sticky or otherwise unpleasant samples. Can be used with plastic or glass

petri dishes. The absorbance spectrum of the petri dish has to be taken into account

while developing calibrations.

Gold Reflector

The gold reflector is suitable for homogenous, fairly transparent liquid samples.

Liquid samples should preferably be analysed at a well defined temperature since

temperature have a large influence on the shape of the moisture spectrum. When the

sample is placed in the cup, the gold reflector is placed over the sample. The sample

will quickly heat up or cool down to the temperature of the cup and gold reflector.

Keeping the cup and reflector at the same temperature thus ensures consistent results.

Depending on the product analysed, the required path length may vary. For NIRS

DA1650 there are gold reflectors giving a path length of 0.1, 0.2, 0.5and 6 mm gold

reflectors. To get optimal performance the maximum absorbance level should be

below 2 AU. If needed, you can ask your FOSS representative for recommendations.

Fig. 2:6Gold reflector

NIRS Ring Cup

A holder that allows for use of the NIRS ring cup is available. This permits scanning

of an ISI ring cup on the NIRS DA1650. Primary use is for cross-standardization

purposes between NIR platforms.

Fig. 2:7NIRS ring cup

AGold reflector

NIRS™ DA1650

User Manual 6008 1286 / Rev. 8 2:7

2.4 NIRS DA1650 Software

NIRS DA1650 is operated by two separate software programs:

• ISIscan Nova

• Mosaic Solo

This User Manual describes the main features and work flows for routine operation

in ISIscan Nova software and some of the FossManager software which is used for

configurations and setup.

In both softwares there are built-in help files which can give further information on

specific details.

2.4.1 ISIscan Nova

ISIscan Nova is the operating software for the NIRS DA1650. It contains all

necessary functionalities for the normal analysis routines:

• Select product and start analysis

• Enter Sample ID and other sample related information fields

• Present results on screen, printer and/or transfer results to predefined network

location

• Generate result and diagnostic reports

• Perform diagnostics and instrument calibration

• Create backup of database

• Configuration for reporting, data transfer and backup paths

• Configuration and commands for communication with FossConnect server

• Initiate remote support session via Internet

2.4.2 local configuration

FossManager is used for configuration of the User Interface of ISIscan Nova

determining what is available for the routine analysis operations:

• Active Products / Calibrations

• Operation profiles (e.g. which cup type to use for different products and

calibrations)

• Calculated parameters

• Icons, Parameter names and Units

• Mandatory and/or Optional Sample information fields

• Report templates

• Slope/Intercept and Moisture Compensation settings

FossManager can also be used for networking one or several instruments with

communication to/from a FossConnect server. The FossConnect server then also has

the function as a backup of all data, results and configurations.

Connecting instruments to a FossConnect server enables remote management of all

configurations above as well as remote surveillance and troubleshooting.

An instrument can be connected to a FossConnect server and at the same time run

local calibration models which are not administrated via the network.

NIRS™ DA1650

2:8 User Manual 6008 1286 / Rev. 8

The two scenarios are shown below.

Fig. 2:8FossManager - Solo setup

• Instrument configurations managed locally from an external PC running

FossManager software.

• Routine Operator operates NIRS DA1650 via ISIscan Nova software via the

built-in touch screen.

Fig. 2:9FossManager - Network setup

• Instrument configurations managed remotely by the Network manager using

FossManager software.

• Routine Operator operates the NIRS DA1650 via ISIscan Nova software via the

built-in touch screen.

• FossConnect server is used for backup of data and configuration settings. The

FossConnect server can either be FOSS hosted or Customer hosted. Please

contact your local FOSS representative for more details.

• Network can consist of one or several FOSS instruments of different types.

• Wide Area Network can also be a Local Area Network (LAN).

NIRS™ DA1650

User Manual 6008 1286 / Rev. 8 2:9

2.4.3 Routine Operation Software

The NIRS DA1650 analyzer is supplied with software to support all the necessary

functions and features to operate the system on a daily basis.

Touch Screen Display

Fig. 2:10Overview

Product and sample information

Information on the last sample analysed or the last historical sample inspected using

toggle arrows.

Go to previous sample

Press to display information about the previous sample.

Go to next sample

Press to display information about the next sample.

1Care Menu 7Current product

2Product and sample information 8Select Product

3Go to previous sample 9Task indicator

4Go to next sample 10 Event indicator

5Sample registration values

(User Defined Fields) 11 Print result

6Start/Stop analysis 12 Result

NIRS™ DA1650

2:10 User Manual 6008 1286 / Rev. 8

Sample registration values

These can be lists or free text fields. Lists are indicated with an arrow and free

text fields with a keyboard . A star will indicate if the field is mandatory and has

to be filled out. Once the sample is synchronised to the FossConnect server it can no

longer be edited, which is indicated with a small padlock icon .

Start/Stop analysis

Press to start analysis. Once analysis has been initiated the button turns into a stop

button. Press to abort analysis and open the lid.

Current product

Name of the product currently selected.

Select product

This will open up the Product list.

Task indicator

This indicator lights up when there is a error or a warning that has to be handled

by the operator. Press the task icon to access the task list.

Event indicator

If something happened during analysis, like an unexpected error or if the lid was

opened, this will be shown with a colour indication. Errors are indicated with red

and warnings with yellow . Press the event icon to access the event log. Once the

event has been read, press RESET to remove and upload the event.

Print result

Pressing the print button will print the sample displayed to the Windows default

printer. If no printer is configured, a save dialog for the print file will appear.

Result

In the case that product limits are used, a result exceeding a warning or action limit

will be displayed with either a yellow (warning) or red (action) background. Pressing

on the coloured box will open up a dialog with information of the exceeded limits.

For more inforation about ISIscan Nova, see chapter 4 and the on-line helpfiles

available in the software.

NIRS™ DA1650

User Manual 6008 1286 / Rev. 8 2:11

Care Menu

The Care View Menu contains features not related to routine analysis. They are

described in chapter 4 and you need to go through some of them during installation

to ensure your instrument is configured correctly. This is also the view you use for

some regular or ad hoc activities (e.g. database backup, instrument diagnostics,

FossManager synchronisations for Networked instruments).

Fig. 2:11

Fig. 2:12

Table of contents

Other Foss Measuring Instrument manuals