Foss Infratec 1241 User manual

Copyright 2011 / All rights reserved

FOSS Analytical A/S, Foss Allé 1, DK-3400 Hillerød, Denmark

Infratec™ 1241 Grain Analyzer

Service Manual

1001 5015 / Rev. 4

Infratec™ 1241 Grain Analyzer

Service Manual 1001 5015 / Rev. 4

Information may be changed or updated without notice. The latest version is found at www.foss.dk.

Rev. Date of Issue Revised Material

1 2011-03-18 First issue

2 2012-11-09 Service procedure updated

3 2015-05-18 General update

4 2016-09-26 Minor changes in section 1, 4 and 5

Infratec™ 1241 Grain Analyzer

Service Manual 1001 5015 / Rev. 4

Table of Contents

1 Important Instructions .............................. 1:1

1.1 General ........................................................................ 1:1

1.2 Service Documents ................................................... 1:1

1.3 Self-Service Support ................................................. 1:1

1.4 Contacting Customer Support ............................... 1:1

1.5 ESD Information ........................................................ 1:1

1.6 Precautions ................................................................. 1:2

2 Technical Description................................. 2:1

2.1 History ......................................................................... 2:1

2.2 Component Descriptions ......................................... 2:3

2.2.1 PC-Module ..................................................................... 2:4

2.2.2 Processor Board ............................................................ 2:5

2.2.3 DSP Board ...................................................................... 2:6

2.2.4 CompactFlash Disk ........................................................ 2:8

2.2.5 Monochromator ........................................................... 2:8

2.2.6 Lamp Module .............................................................. 2:10

2.2.7 Detector ...................................................................... 2:11

2.2.8 Power Supply .............................................................. 2:12

2.2.9 LCD Display ................................................................. 2:14

2.2.10 Display Interconnection Board .................................. 2:15

2.2.11 Electronic ID ................................................................ 2:15

2.2.12 TWM (Optional) .......................................................... 2:16

2.2.13 STM (Optional) ............................................................ 2:18

2.2.14 Remote I/O (Optional) ................................................ 2:19

2.3 Software Description ............................................. 2:22

3 Installation ................................................. 3:1

3.1 General ........................................................................ 3:1

3.2 Installation of Test Weight Module on

Infratec 1241 Generation 2 ..................................... 3:1

3.2.1 Preparation of the Infratec for assembly .................... 3:1

3.2.2 Preparation of the Test Weight Module for assembly 3:4

3.2.3 Final assembly of Infratec and Test Weight Module into a

complete assembly ....................................................... 3:6

3.3 Installation of Test Weight Module on

Infratec 1241 Generation 3 ................................... 3:10

3.4 Installation of Sample Transport Module ......... 3:21

Infratec™ 1241 Grain Analyzer

Service Manual 1001 5015 / Rev. 4

3.5 Mosaic Connection .................................................. 3:22

4 Diagnostics and Troubleshooting .............4:1

4.1 General ......................................................................... 4:1

4.1.1 Poor Results ................................................................... 4:2

4.1.2 User Problems ................................................................ 4:2

4.1.3 Poor Calibrations ........................................................... 4:2

4.1.4 Outliers .......................................................................... 4:2

4.1.5 Poor Reference Data ..................................................... 4:3

4.1.6 Instrument Problems ..................................................... 4:4

4.1.7 I2C Trouble Shooting .................................................... 4:4

4.2 Service Menu ............................................................ 4:10

4.3 Quality Control ......................................................... 4:12

4.3.1 Self-test ........................................................................ 4:12

4.3.2 Clean Measuring Unit ................................................. 4:19

4.3.3 Audit Log ..................................................................... 4:19

4.3.4 Software Error Log ...................................................... 4:19

4.3.5 Hardware Error Log .................................................... 4:20

4.3.6 Export Logs and Configuration .................................. 4:20

4.3.7 Wavelength Stability .................................................. 4:20

4.3.8 Lamp Check ................................................................. 4:20

4.4 Automatic Tests ....................................................... 4:21

4.4.1 Detector ....................................................................... 4:21

4.4.2 Monochromator .......................................................... 4:22

4.4.3 I/0 (Input/Output) ........................................................ 4:23

4.5 Manual Tests ............................................................. 4:25

4.5.1 Detector ....................................................................... 4:25

4.5.2 Monochromator .......................................................... 4:25

4.5.3 Measuring Unit ........................................................... 4:26

4.5.4 Display ......................................................................... 4:26

4.5.5 Scan .............................................................................. 4:26

4.5.6 Test Weight ................................................................. 4:27

4.5.7 Sample Transport Module .......................................... 4:27

4.6 Manual Analysis ....................................................... 4:28

4.6.1 Settings ........................................................................ 4:28

4.6.2 Fill Sample Cell ............................................................ 4:28

4.6.3 Scan .............................................................................. 4:28

4.6.4 Offset ........................................................................... 4:28

4.6.5 Empty Sample Cell ...................................................... 4:28

4.6.6 Flush Sample Cell ........................................................ 4:28

4.7 Instrument Info ........................................................ 4:29

4.7.1 Hardware ..................................................................... 4:29

Infratec™ 1241 Grain Analyzer

Service Manual 1001 5015 / Rev. 4

4.7.2 Software ...................................................................... 4:29

4.7.3 BIOS ............................................................................. 4:29

4.7.4 Monochromator Constants ........................................ 4:29

4.7.5 Operating Temperature ............................................. 4:29

4.7.6 Volume Information ................................................... 4:29

4.7.7 Voltage Information ................................................... 4:29

4.8 Clone Instrument .................................................... 4:29

4.9 Settings ..................................................................... 4:30

4.9.1 Default Settings .......................................................... 4:30

4.9.2 Scan Mode (Standard) ................................................ 4:30

4.10 Read Disk ................................................................... 4:30

4.11 Error Codes in Software Log (SL) and Hardware

Log (HL) ...................................................................... 4:31

4.11.1 Error 4, Grating Motor Error ...................................... 4:33

4.11.2 Error 22, MU/TWM Data Range Error ........................ 4:33

4.11.3 Error 32, Speckle Signal Blocked ................................ 4:33

4.11.4 Error 128, Path Length Error ...................................... 4:34

4.11.5 Error 512, Speckle Function Error .............................. 4:34

4.11.6 Error 16384, Strain Gauge Failure (Load Cell) ........... 4:34

4.11.7 Error 32768, Hardware Error ...................................... 4:34

4.11.8 Error 33292, Reference Scan too low ........................ 4:35

4.11.9 Error 33293, Too few valid Sub samples collected ... 4:35

4.11.10 Error 33294, Monochromator Shutter not able

to move ....................................................................... 4:35

4.12 Hardware Error Log (xxxxxxxx.HL) ..................... 4:36

4.12.1 Error Word .................................................................. 4:36

4.12.2 Commands .................................................................. 4:37

4.12.3 Status Word 1 ............................................................. 4:41

4.12.4 Status Word 2 ............................................................. 4:42

4.12.5 Error Word 1 ............................................................... 4:43

4.12.6 Error Word 2 ............................................................... 4:44

4.12.7 Error Word 3 ............................................................... 4:45

4.12.8 Error Word 4 bit encoding (0x0108) .......................... 4:45

4.12.9 DSP Version ................................................................. 4:45

4.13 Export Logs and Configuration ........................... 4:46

5 Service and Maintenance .......................... 5:1

5.1 Special Tools ............................................................... 5:1

5.2 Service Procedures .................................................... 5:1

5.2.1 Replacement of Display Kit .......................................... 5:1

5.2.2 Replacement of Keyboard Overlay .............................. 5:7

5.2.3 Replacement of Detector Unit Complete .................... 5:8

Infratec™ 1241 Grain Analyzer

Service Manual 1001 5015 / Rev. 4

5.2.4 Replacement of Monochromator Complete ............... 5:9

5.2.5 Replacement of Halogen Lamp for Monochromator 5:11

5.2.6 Use of the Aperture Kit (p/n 60023539) .................... 5:13

5.2.7 Replacement of Power Supply Board ........................ 5:16

5.2.8 Replacement of Interface Complete .......................... 5:18

5.2.9 Replacement of PC Module Complete w/o

Flash Disc ..................................................................... 5:23

5.2.10 Replacement of DSP Board ......................................... 5:29

5.2.11 Replacement of Compact Flash Disc .......................... 5:35

5.3 Measuring Unit ......................................................... 5:36

5.3.1 General ........................................................................ 5:36

5.3.2 Replacement of Measuring Unit Complete ............... 5:36

5.3.3 Replacement of Upper Solenoid ................................ 5:38

5.3.4 Replacement of Lower Solenoid ................................ 5:39

5.3.5 Replacement of Lower Linkage Shutter Assembly ... 5:40

5.3.6 Replacement of Upper Linkage Shutter Assembly ... 5:41

5.3.7 Replacement of Connection PCB Complete .............. 5:42

5.3.8 Replacement of Measuring Unit PCB ......................... 5:43

5.3.9 Replacement of Variable Motor ................................ 5:44

5.3.10 Replacement of Conveyor Motor ............................... 5:45

5.3.11 Replacement of Cell Wall Front with Speckle

Emitter PCB .................................................................. 5:46

5.3.12 Replacement of Cell Block Complete and Path Length

Encoder ........................................................................ 5:47

5.3.13 Replacement of Cell Cover Outer .............................. 5:48

5.3.14 Checking movement of the Variable Cell .................. 5:49

5.3.15 Drawer Sensor Cable, rerouting ................................. 5:50

5.4 Test Weight Module ................................................ 5:52

5.4.1 Replacement of Test Weight Balance Complete ....... 5:52

5.4.2 Replacement of Wiper Arm Complete ...................... 5:53

5.4.3 Replacement of TWM PCB .......................................... 5:56

5.4.4 Replacement of Wiper/Shutter Motor ....................... 5:58

5.4.5 Replacement of Locking Guide .................................. 5:61

5.4.6 Checking/Adjusting TWM Level Sensors .................... 5:63

5.5 Sample Transport Module ..................................... 5:65

5.5.1 Replacement of Cuvette Glass Kit .............................. 5:65

5.5.2 Replacement of STM Cuvette Cam Thread ................ 5:66

5.5.3 Checking STM Cuvette Cam Thread ........................... 5:69

5.6 Corrective Maintenance Procedures ................... 5:70

5.6.1 Cable Stalk Kit ............................................................. 5:70

5.6.2 Lamp Holder ................................................................ 5:70

5.6.3 DSP board .................................................................... 5:70

5.6.4 TWM PCB ..................................................................... 5:70

Infratec™ 1241 Grain Analyzer

Service Manual 1001 5015 / Rev. 4

5.7 Preventive Maintenance Procedures .................. 5:72

5.7.1 Measuring Unit Adjustment of Path Length ............ 5:72

5.7.2 TWM Balance Calibration .......................................... 5:74

5.7.3 TWM balance Control ................................................ 5:77

6 Technical Specifications............................. 6:1

7 Schematics .................................................. 7:1

8 Document References................................ 8:1

Infratec™ 1241 Grain Analyzer

Service Manual 1001 5015 / Rev. 4 1:1

1 Important Instructions

1.1 General

This Service Manual contains descriptions, installation instructions, maintenance

instructions, troubleshooting, specifications and schematics for the Infratec™ 1241

ISW 5.xx. Service of Infratec™ 1241 should only be done by authorized personnel.

NOTE: This manual covers the Infratec 1241 Generation 2 and 3

only. For reference to the Infratec 1241 Generation 1 and Infratec

1256 use Service Manual p/n 10012177.

1.2 Service Documents

This Service Manual is a part of the Service USB (if available) which contains the

complete support documentation for this product. The Service USB may contain

additional information in the form of animations for the purpose of illustrating and

explaining e.g. working principles, process flows and service and adjustment

procedures. See also section 8 Document References for an overview of User and

Service Documentation.

1.3 Self-Service Support

The Customer Support Toolbox (CST) on FOSS EXTRAnet (www.foss.dk) contains

all available support information. Please visit the CST at regular intervals for latest

updates of documents and software.

1.4 Contacting Customer Support

For support on this product, please contact the responsible Technical Support

engineer at FOSS or file a support request in the Global HelpDesk on FOSS

EXTRAnet.

1.5 ESD Information

Parts of this instrument, e.g. PCBs, are sensitive to Electro Static Discharge (ESD).

All sensitive parts should be handled using ESD protection.

Follow these rules for effective ESD protection:

• Handle all ESD sensitive parts with an ESD wrist band connected to earth.

• Transport all ESD sensitive parts in ESD protected bags or boxes.

• Check your ESD protection at regular intervals to secure its function and quality.

Infratec™ 1241 Grain Analyzer

1:2 Service Manual 1001 5015 / Rev. 4

The following ESD protection material is available from FOSS:

• 436220 Field-ESD service kit including wrist band

• 463238 Blue table mat with wrist strap and ground wire

• 436246 Coiled wire, 360 cm with stretch-wrist band

• 436261 Wrist-strap tester

Fig. 1:1 ESD equipment

1.6 Precautions

The layout of safety symbols used in this manual is described below. Symbols are

used whenever a safety related message is written to warn the reader of potential

hazards.

Safety Symbols

Explanation of safety symbols used in this manual:

Safety Terminology

Explanation of safety terms used in this manual.

Symbol Description

General hazard.

Electrical shock hazard.

Hot surface.

Heavy object.

Term Description

Warning Danger to human safety.

Caution Danger to product performance/operation.

Note Important supplementary information.

8000189a

Infratec™ 1241 Grain Analyzer

Service Manual 1001 5015 / Rev. 4 2:1

2 Technical Description

2.1 History

The Infratec 1241 was first launched in the year 2000. It was then equipped with a

black & white display and a diskette drive as means of importing and exporting data

to the instrument. These instruments are now referred to as Generation 1.

In 2007 the Infratec 1241 was hardware and software wise redesigned. It was then

equipped with a color display and USB ports for importing and exporting data. The

"Basic concept" was also introduced which made it possible to limit the amount of

calibrations on the instrument and thus reduce the selling price. These instruments

are now referred to as Generation 2.

In 2010 the exterior was redesigned to match the EyeFoss image analyzer design.

Few internal parts where altered. These instruments are now referred to as

Generation 3.

The Infratec 1256 is electronically and technology wise almost identical to the 1241.

Over the years different hardware and software features have been continuously

introduced, e.g. TCP/IP, calculated constituents. Many ofthese can be added to older

instruments. Upgrade of ISW is always free of charge.

The Basic Concept

Model Display Data ISW version

Generation 1 Black & white Diskette 3.xx

Generation 2 Color USB 5.xx

Generation 3 Color USB 5.xx

Model # of allowed AppM's # of allowed parameters

Full Many Many

Basic 1 One Three

Basic 2 Two Three per AppM

Basic 3 One Six

Basic 4 Two Four per AppM

Basic 5 Five Four per AppM

Basic 6 Six Four per AppM

Infratec™ 1241 Grain Analyzer

2:2 Service Manual 1001 5015 / Rev. 4

Related Information

Service personnel should be familiar with the following documentation:

• User Manual; for function descriptions, maintenance and operating instructions

• Spare Parts Manual; for spare part illustrations and spare part numbers

• Quick Guide; for a quick start instruction

Also see chapter 8 Document References.

Abbreviations

Explanation of abbreviations used in this manual.

ADC Analog to Digital Converter

DIB Display Interconnection Board

DSP Digital Signal Processing

EID Electronic ID

GA Grain Analyzer

I2C Standardised serial interface (Inter Integrated Communication)

I/O Input/Output

ISW Instrument Software

LIMS Laboratory Information and Management System

MU Measuring Unit

OS Operating System

PCB Printed Circuit Board

PSM Power Supply Module

RTOS Real Time Operating System

STM Sample Transport Module, optional

TWM Test Weight Module, optional

Infratec™ 1241 Grain Analyzer

Service Manual 1001 5015 / Rev. 4 2:3

2.2 Component Descriptions

Compatibility with previous version

System Overview

Fig. 2:1

Module Compatible Comments

PSU Yes All versions

Detector Yes All versions

Monochromator Yes All versions

MU Yes All versions

TWM Yes All versions (TN 1234)

STM Yes

LCD Display No See Spare Parts Manual

PC module

DSP

PC- board

Compact Flash

Floppy disk

No

No

No

No/Yes

No

Requires OS vers 5.01 or higher

Requires OS vers 5.01 or higher

Dependency. Requires ISW 5.xx

Disabled in BIOS, USB Floppy disk support

Cable Stalk No

Interface No USB

Chassis Yes

Infratec™ 1241 Grain Analyzer

2:4 Service Manual 1001 5015 / Rev. 4

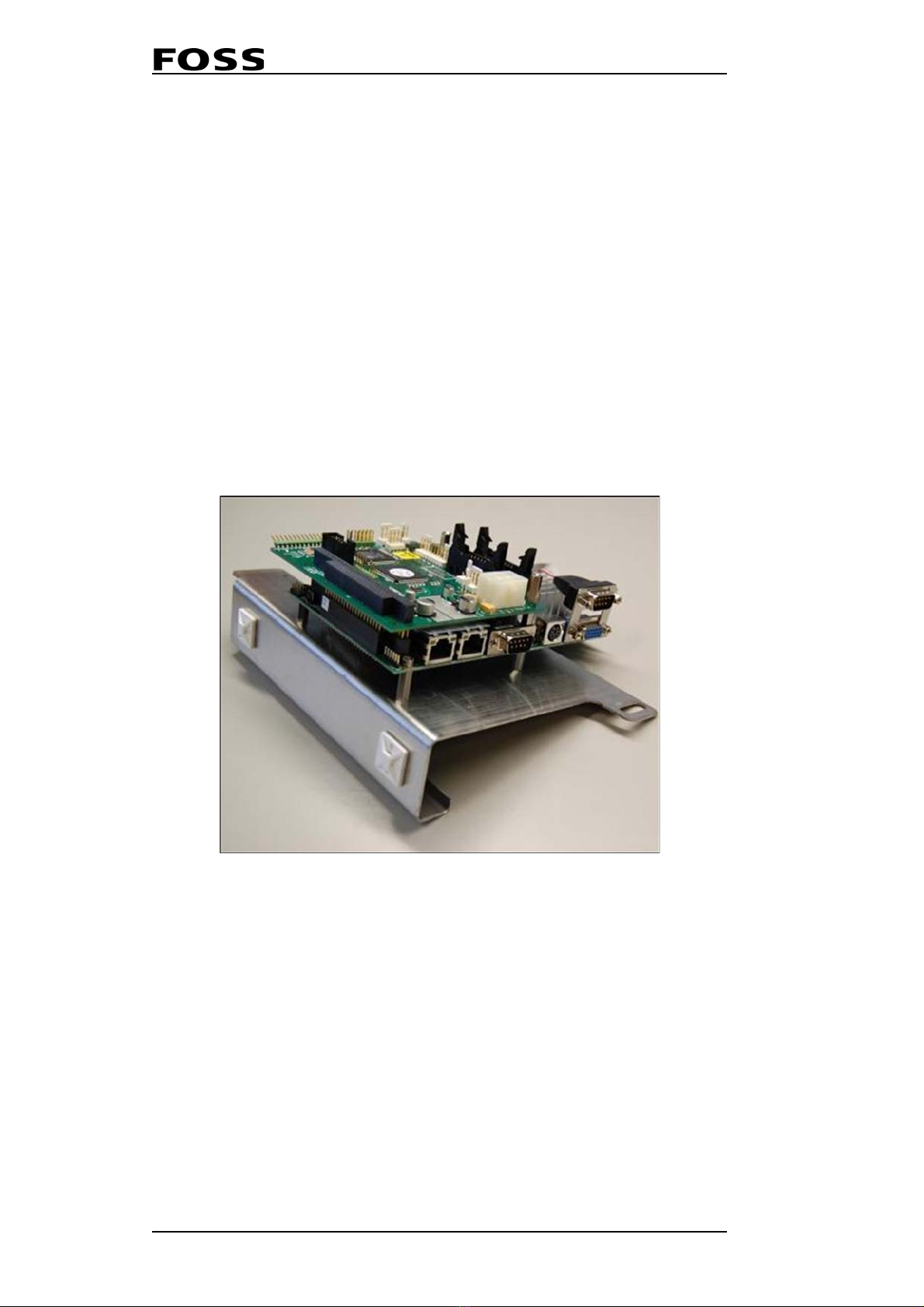

2.2.1 PC-Module

The PC-module is a PC104 embedded hardware platform with QNX real-time

operating system (RTOS). PC104 is a popular standardized form-factor for small

computing modules typically used in embedded system. A system composed of PC/

104 modules is often referred to as a "stack".

The PC module "stack" assembly consists of:

• Mounting plate

• Processor board, that acts as a controller for the peripheral components

• DSP board, that acts as an extension Processor board and is also used as an I/O

system

Communication between the PC-module and the instrument modules is routed via

the DSP board I2C bus, which is a simple standard 2-wire connection where the DSP

acts as the master device.

NOTE: Due to the QNX software platform, USB plug & play is not

supported. An USB-floppy drive solution may however work.

Fig. 2:2 PC-Module

Infratec™ 1241 Grain Analyzer

Service Manual 1001 5015 / Rev. 4 2:5

2.2.2 Processor Board

The processor board is a single board processor (SBC) with an onboard CPU

processor. Processor board acts as a controller for the peripheral components. The

processor board communicates with the DSP board via the PC/104 bus.

The processor board has three main interfaces:

• DSP board PC/104 bus

• TFT LCD display

• Connectors to chassis Interface panel, providing access to external keyboard,

USB, comm. ports, LAN etc

Fig. 2:3 Processor Board

CN3 Printer Interface (LPT1) CN15 LAN/Ethernet Interface

CN5 USB Interface (0&1) CN18 Keyboard/Bar code Interface

CN12 LCD Display CN19 COM1 Interface

CN13 COM2 Interface CN20 CRT Monitor Interface

Infratec™ 1241 Grain Analyzer

2:6 Service Manual 1001 5015 / Rev. 4

The Processor Board has replaceable external CMOS battery.

Fig. 2:4 Processor Board

2.2.3 DSP Board

The DSP module is accessed from the ISW via the PC/104 bus interface (P3) and acts

as slave under the ISW.

The DSP software acts as an extension of the ISW and is also used as an I/O system.

The PC-module makes it possible for the ISW to have control over the different HW

modules.

There is no ROM memory on the DSP Board. For this reason, the DSP software is

uploaded from the processor board by ISW during start-up. The ISW installation

package contains and installs the latest and matching DSP software version.

The DSP has an I2C bus interface, implemented as a SW driver in the DSP software

and is used for communication between devices inside the instrument. I2C is a two-

wire serial bus, as shown in Fig. 2:5.

Fig. 2:5

There are a number of on board LEDs on the DSP Board. These LEDs provide

information as to the status of the DSP Board.

LED Function Color

D3 Power On Green, constant

D4 DSP-ISW communication Red, flashing when active

D1 DSP running Red, constant after boot-up

D2 Monochromator motor

direction Red, blinking

Infratec™ 1241 Grain Analyzer

Service Manual 1001 5015 / Rev. 4 2:7

Fig. 2:6 DSP Board

P1 Keypad P13 Detector

P3 PC/104 Bus P14 I2C Bus

P6 Power Supply P15 I2C Bus

P7 Inverter Interface Board D1 DSP running (red LED)

P8 Monochromator D2 Monochromator (red LED)

P9 Monochromator D3 Power On (green LED)

P12 Monochromator D4 I2C communication (red LED)

DSP Board

From Designation To

P1 Keypad overlay

P3 PC/104 Bus Interface Processor Board

P6 Power Supply Power Supply Board (P7)

P7 Backlight Power Display Interconnection Board

P8 Encoder Connector Monochromator

P9 Grating Motor Connector Monochromator

P12 Shutter Board Connector Monochromator

P13 Detector Signal Detector

P14 I2C Bus Measuring Unit

Infratec™ 1241 Grain Analyzer

2:8 Service Manual 1001 5015 / Rev. 4

2.2.4 CompactFlash Disk

Type II CompactFlash™ Memory

The CompactFlash memory is preinstalled with latest OS version and ISW software.

As spare part it is available as Basic 1 configuration only.

The Flash Disk is an electronic memory mounted in a slot on the Processor Board.

Due to market conditions you may find different sizes in the instruments over the

years. There is no problem upgrading the Flash Disk to a larger size. The disk is

partitioned in three parts, 5 Mb for the operative system, 5 Mb for ISW. The

remaining space is for data.

The Basic Concept

2.2.5 Monochromator

The Monochromator is developed and manufactured by FOSS. It is to be considered

a closed, factory calibrated box. There is under no circumstance any reason to open

it for maintenance, inspection or other purpose. On the contrary an opened

monochromator will not be covered by warranty, neither will it be accepted in the

exchange part system. The monochromator is the only spare part in the Infratec that

is enrolled on the spare part exchange system.

In the Infratec the monochromation of the "white light" from the lamp is done before

the sample. This technology is called pre-dispersive monochromation. This is

optimal when using transmission of light through the sample, e.g. for grain analysis.

A disadvantage of this technology is that the system becomes very sensitive to stray

light from the environment, e.g. sunlight and fluorescent light from the ceiling.

In the Infratec the light from the light source (the instrument lamp) is transported in

an optic fiber bundle into the heart of the monochromator. This fiber bundle consists

of thousands of randomized fibers. A lamp change will therefore not affect the output

of the fiber bundle and thus makes it un-necessary to linearize after the lamp is

change. The fibre optic cables are sensitive to sharp bends and should be treated with

care.

Inside the monochromator the lamp light is split up (monochromated) in a diffraction

grating. The grating is turned by a motor so that only one wavelength is exiting the

monochromator at any given time. The grating is producing a spectrum covering the

wavelength range from 570 to 1100 nm. The bandwidth is 7 nm.

At the out put there is a second fiber bundle to transport the monochrome light over

to the right side of the instrument where the sample cell is located.

P15 I2C Bus Power Supply Board

Model # of allowed AppM's # of allowed parameters

Full Many Many

Basic 1 One Three

Basic 2 Two Three per AppM

Basic 3 One Six

Basic 4 Two Four per AppM

Basic 5 Five Four per AppM

Basic 6 Six Four per AppM

Infratec™ 1241 Grain Analyzer

Service Manual 1001 5015 / Rev. 4 2:9

Before the monochromator output there is a shutter with 3 positions, Open, Closed

and Filter. The closed position is used to block the light during the offset

measurement which is done prior to scanning the sample. Open position is used

during the sample scanning and Filter position is used during performance tests to

determine the wavelength accuracy compared to the factory status.

The monochromator is supplied with an EEPROM which stores the O- and P-

constants. These constants are obtained from the factory calibration and cannot be

altered or re-calibrated in the field. The EEPROM resides on a PCB underneath the

monochromator base plate. This PCB is therefore a unique part dedicated for each

monochromator and cannot be changed.

NOTE: The Monochromator is sealed and it is absolutely

forbidden to open it by other than FOSS personnel.

Fig. 2:7

1Lamp fiber 4Output fiber

2Grating 5Motor/Encoder

3Shutter 6PCB with EEPROM

Infratec™ 1241 Grain Analyzer

2:10 Service Manual 1001 5015 / Rev. 4

2.2.6 Lamp Module

The Infratec 1241 light source solution is accommodated in a heat sink aluminium

housing. It has no internal electronics other than the power supply cable and light

bulb. The module includes:

• Aluminium housing as heat sink

•LampHolder

•Lamp

• Aperture (if applicable)

• Optic Fibre connection

Lamp holder

Three versions of lamp holders have been manufactured for Infratec 1241. The latest

version, introduced 2008-10-17, has socket screw terminals to secure firm contact.

See picture below. Previous versions are exposed to oxidation coating causing bad

contact between lamp and terminals. It is recommended to replace the previous

versions with P/N 10013351 which is the latest version (see picture below).

Infratec 1241, InfraXact and FoodScan analysers all have the same lamp holder.

Fig. 2:8 Lamp Holder

Lamp source

The halogen lamp is FOSS custom manufactured and can not be substituted with

regular lamps. Use P/N 60023564 to order.

Aperture

Exchangeable apertures are used to adjust the amount of light admitted to the

monochromator inlet fibre. Monochromator replacement requires that light intensity

is checked due to dispersion variation in the Monochromator Optical Fiber.

Exchangeable apertures are available in fixed openingsof 5, 5.5,6, 6.5, 7and 7.5mm

diameter. An Aperture Kit (P/N 60023539) with a full range of apertures is supplied

with replacement monochromators. Please refer to TN1355 for replacement

instructions.

Other manuals for Infratec 1241

1

Table of contents

Other Foss Measuring Instrument manuals