3

The purpose of this manual is to provide the necessary information for the proper

installation, use and maintenance of SC/1-TA. The user should read this manual before

operating the unit. Improper use may cause damage to the machine and lead to the

forfeiture of the warranty coverage. Always specify the model identification code and the

construction number when requesting technical information or spare parts from our Sales

and Service department. The instruction and warnings given below concern the standard

version; refer to the sale contract documentation for modifications and special version

characteristics. For instructions, situations and events not considered in this manual or in

the sale documents, please contact our customer service.

Our units must be installed in sheltered, well-ventilated, non-hazardous environments and

must be used at a maximum temperature of +40°C and minimum of -5°C.

DANGER

WARNING

The panel must be handled with care, as falls and knocks can cause damage without any

visible external signs.

If for any reason the unit is not installed and starter immediately after it has reached its

destination it must be stored properly. The external packaging and the separately packed

accessories must remain intact, and the whole must be protected from the weather,

especially from freezing temperatures, and from any knocks or falls.

PRELIMINARY INSPECTION: after you have removed the external packaging, visually

inspect the control panel to make sure it has suffered no damage during shipping.

If any damage is visible, inform a FOURGROUP dealer as soon as possible, no later then

five days from the delivery date.

FOURGROUP S.r.l. shall not be liable for any damage caused or suffered by the

unit as a result of its unauthorised or improper use.

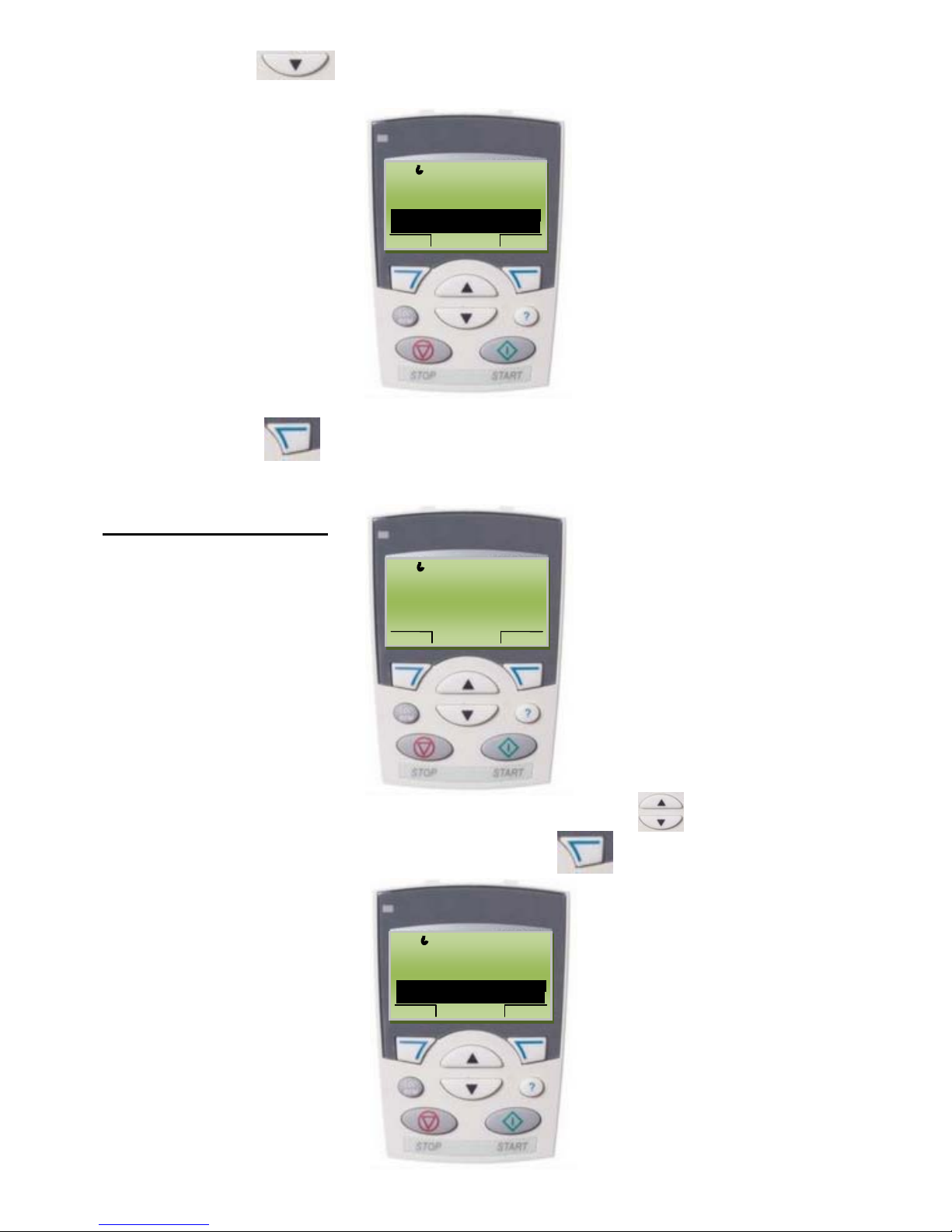

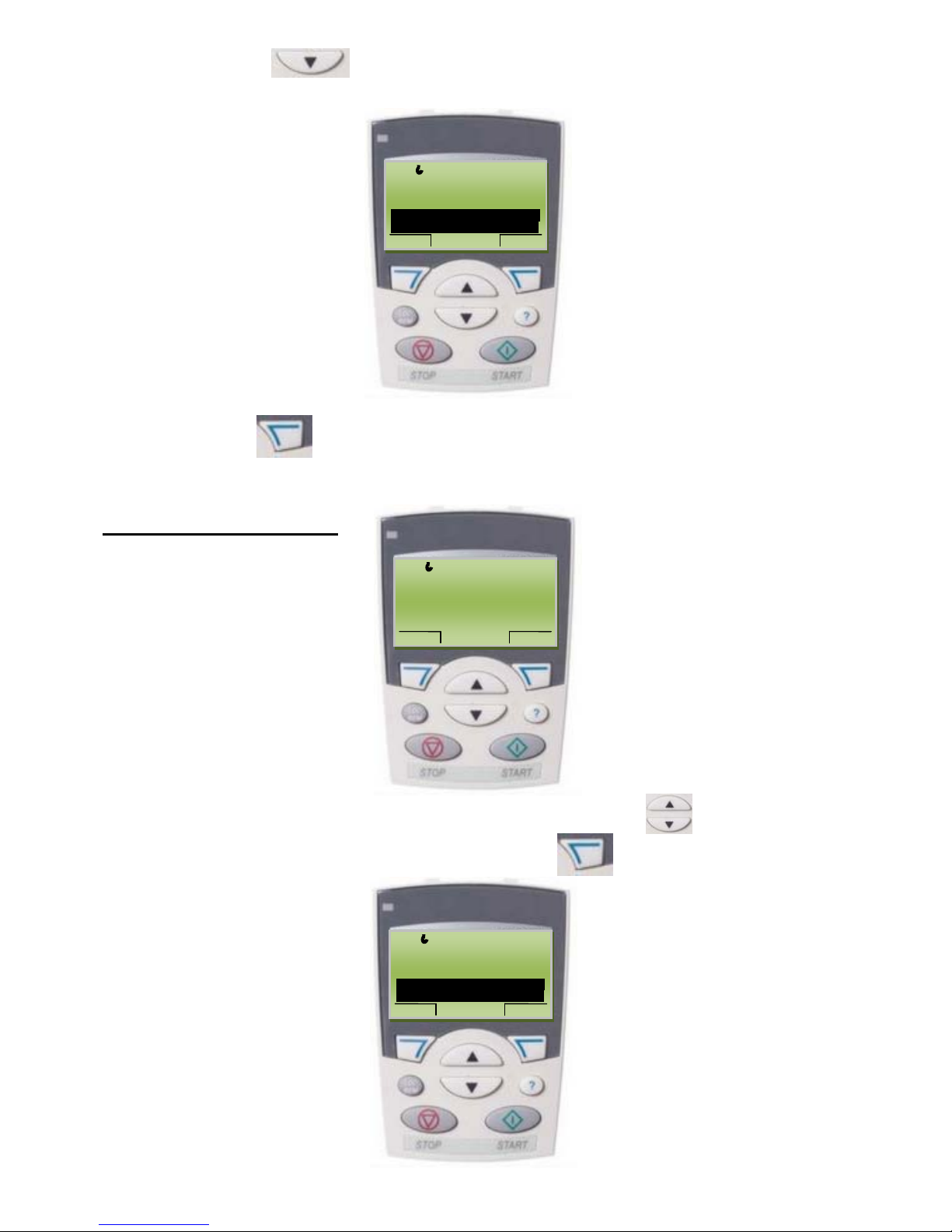

2. OVERVIEW

3. HANDLING