1. Safety instructions

During any operation (manipulation) do not

leave the handler position, particularly when

the machine is in operation.

Climbing to the farm equipment during work

or transport is not permitted.

If there is clogging of the tiller (equipment),

shut down the engine and clean the tiller

(equipment) with the appropriate tools.

If there is a damage to motor hoes or

equipment, immediately turn off the engine

and repair.

If there are problems with steering, stop

immediately and turn off the motor

hoes. Repair immediately.

To prevent slipping of the motor hoes on

slopes, you need an assistant who will, by

using a rope or rod, hold the machine. This

person must be at the higher place than the

machine and at a safe distance from the

operating elements.

If possible, always work horizontally to the

slope.

End of work

Never leave the motor hoes unsecured with

the engine running.

Before leaving the machine, turn off the

engine and then turn off the fuel tap.

Secure the motor hoes against unauthorized

use - remove the spark plug cable.

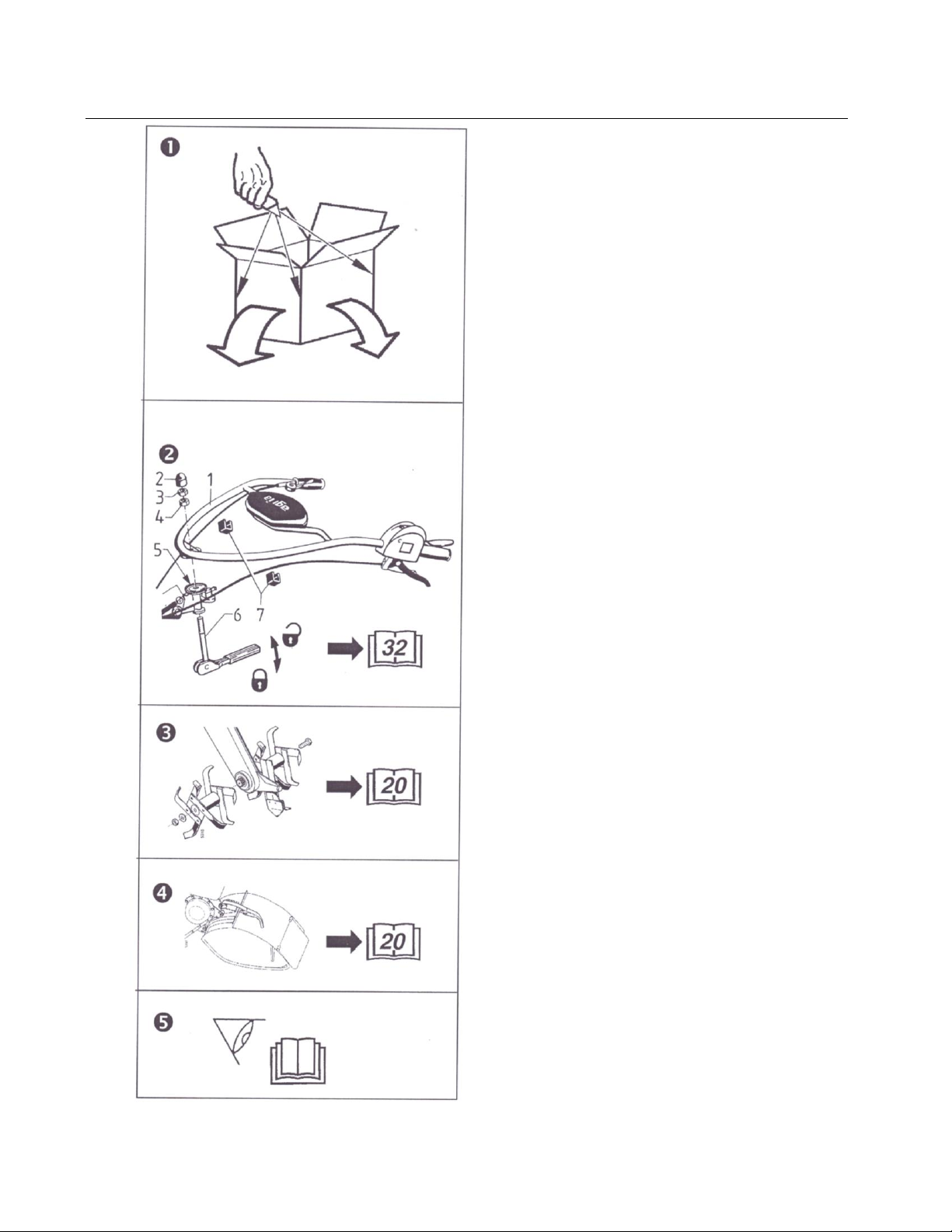

Additional equipment

Mount additional equipment only when

the engine and the drive are off. Always

use appropriate tools and protective

gloves when changing equipment or

parts.

For assembly and disassembly, use the

support devices to bring the motor hoes in

a convenient and stable position.

Secure the motor hoes and equipment

against rolling (use the supporters).

Beware of injuries when mounting

equipment, be very careful.

Mount the equipment as specified in the

instructions and connect them with the

motor hoes only at the designated points.

Secure the motor hoes and equipment

from unauthorized use and rolling when

you leave the machine.

Additional equipment –tiller

Set the tiller hood so that only those parts

(hoes) tilling the soil are not covered.

When tilling (cultivating), make sure that

the slider is set up correctly.