~WARRiANTY AID REGISTRATION

Thank You...

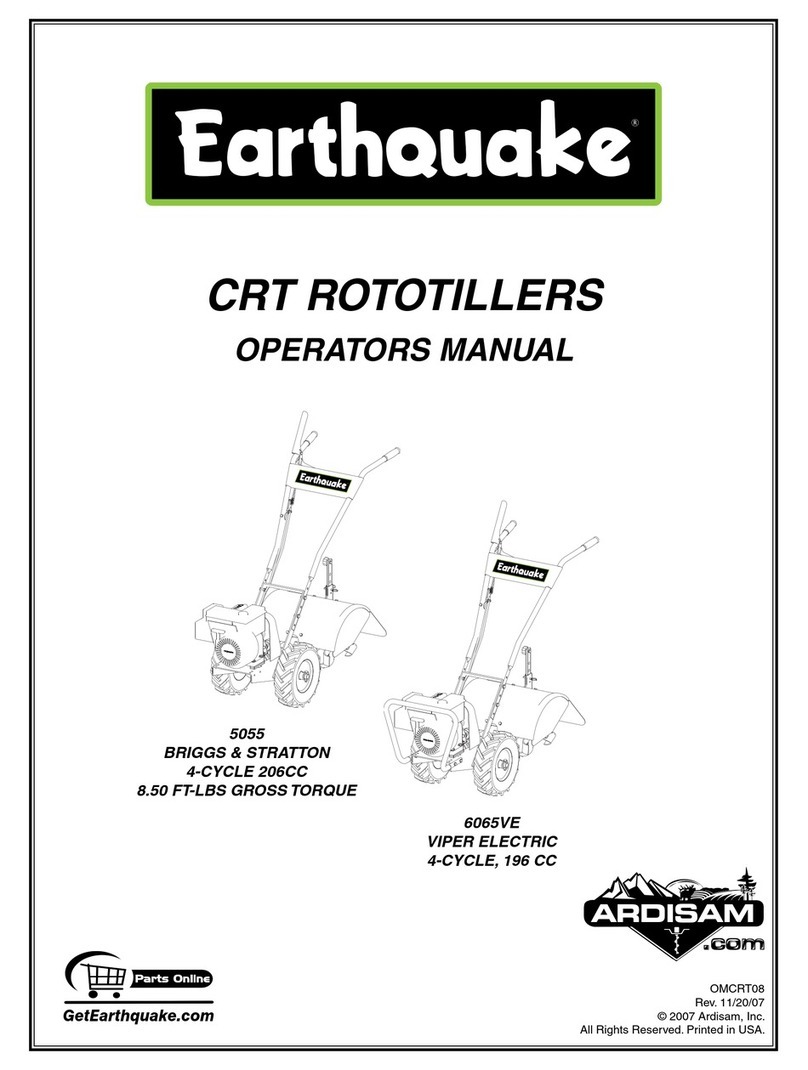

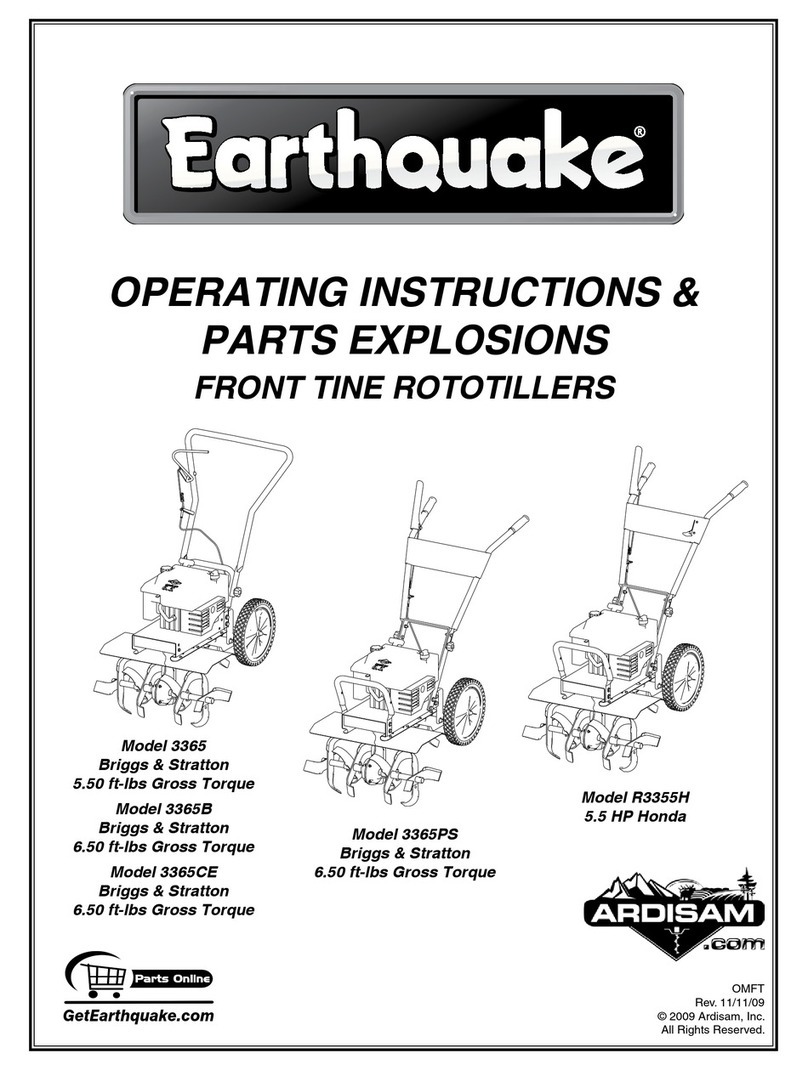

for purchasing an Ardisam front tine rototiller. We guarantee that this front tine rototiller conforms to

applicable North American safety standards, and have worked to ensure that it will meet your exacting

standards for usability and durability. With proper care, your rototiller will provide many years of service.

Please take time to read this manual carefully to learn how to operate and service your ro~otiller

correctly. Failure to do so could result in personal injury or equipment damage. This manual should be

considered apermanent part of your rototiller. Congratulations on your investment in quality.

ONE YEAR

LIMITED WARRANTY

The Ardisam, Inc., Manufacturing Company warrants this

rototiller to befreefrom defects in material or workmanship.

Conditions of this warranty include:

What is covered under warranty:

For the first year from the date of purchase, Ardisam will

furnish100%parts and labor tocorrect any defect caused

by faulty material or workmanship. During the second year

of ownership, Ardisam will furnish 100% of the parts to

correct any defect caused by faulty material or

workmanship. All repairs made under warranty must have

prior approval from Ardisam, Inc. Items subject to normal

wear and tear, such as belts, batteries, tines, shear bolts

and tires, due tothe nature of their function are not covered

under this warranty. Any unit used in a commercial

application is covered for a period of 90 days after

purchase. The engine is covered under a separate

warranty issued by the engine manufacturer as stated in

the engine manual.

What is not covered under warranty:

This warranty applies only to products which have not been

repaired or altered outside our factory. It covers only

defects resulting from normal use, and does not cover

defects arising from misuse, alteration, negligence, or

accident. This warranty applies only to the original

purchaser, and is not transferrable.

This warranty supersedes al/ other warranties either

expressed or implied and a/l other obligations or

liabilities on our part. Ardisam, Inc., does not assume,

and does not authorize any other person to assume for

us, any liability in connection with the sale of our

products. This guarantee is void unless the warranty

card is properly filled out and returned to Ardisam, Inc.,

Cumberland, Wisconsin, within two weeks of the

purchase date. ARDISAM,INC.

"-" AiI2IIS* leaSHanIIs * Ronmuss

TlBS-* c- s.-* EoGss

136D 1sc Avenue; P.O. Sax 666

CumlMtrland,Wisconsin54829

(715) 822-2415 Fu (715) 822-4180

1-800.3456-007

u_~

ACAUTION

Youmust read, understand and comply with all safety

and operating instructions in this manual before

attemptingto setup and operatethis equipment.

Failure to comply with all safety and operating

instructionscan resultin lossof machinecontrol,serious

personal injury to you and/or bystanders, and risk of

equipment and property damage.The triangle in the

textsignifiesimportantcautionsorwarningswhichmust

befollowed.

ACAUTION

Engineexhaust from this product contains chemicals

known, in certain quantities, to cause cancer, birth

defects,or other reproductive harm.

For easy reference, please record the

information on the chart below.

The RototillerReference Data can befound onthe

identificationtag located on the unit'sleft enginemount.

(Refer to theengine manual for location of engine infor-

mationand serial number.)

llp.:. :lRbTOTILLERREF~RENCEbATA' .'

Model DescriptionlNumber

MIN (Manufacturer's Number) SIN (Serial Number)

Dealer Name Date Purchased

2