Toro Soil Cultivator User manual

FormNo.3431-447RevA

SoilCultivator

CompactToolCarrier

ModelNo.23102—SerialNo.319000001andUp

Registeratwww.Toro.com.

OriginalInstructions(EN)*3431-447*A

ThisproductcomplieswithallrelevantEuropean

directives.Fordetails,pleaseseetheDeclarationof

Incorporation(DOI)atthebackofthispublication.

WARNING

CALIFORNIA

Proposition65Warning

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

ThissoilcultivatorisintendedtobeusedonaToro

compacttoolcarrier.Itisdesignedprimarilyfor

buryingstones,soilclods,debris,andgrass,which

createstheperfectgerminationenvironmentforfresh

seedsorsodonresidentialorcommercialproperties.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

Visitwww.Toro.comforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpnding

adealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,or

additionalinformation,contactanAuthorizedService

DealerorT oroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

g285760

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2098—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Contents

Safety.......................................................................3

GeneralSafety...................................................3

SlopeSafety.......................................................4

SoilCultivatorSafety..........................................4

MaintenanceandStorageSafety........................4

SafetyandInstructionalDecals..........................5

Setup........................................................................6

InstallingtheRoller.............................................6

ProductOverview.....................................................6

Specications....................................................6

Operation..................................................................7

InstallingandRemovingtheAttachment.............7

RemovingtheRoller...........................................7

SettingtheDiggingDepth...................................8

AdjustingtheGraderBlade.................................8

ChangingtheHorizontalPositionofthe

Roller..............................................................9

OperatingtheCultivator......................................9

TransportPosition..............................................9

OperatingTips.................................................10

Maintenance............................................................11

RecommendedMaintenanceSchedule(s)............11

GreasingtheCultivator......................................11

ChangingtheDrive-ChainOil............................11

AdjustingtheDrive-ChainTension....................12

ReplacingTines................................................13

Storage...................................................................14

Troubleshooting......................................................15

Safety

DANGER

Theremaybeburiedutilitylinesinthework

area.Diggingintothemmaycauseashock

oranexplosion.

Havethepropertyorworkareamarkedfor

buriedlinesanddonotdiginmarkedareas.

Contactyourlocalmarkingserviceorutility

companytohavethepropertymarked(for

example,intheUS,call811orinAustralia,

call1100forthenationwidemarkingservice).

GeneralSafety

Alwaysfollowallsafetyinstructionstoavoidserious

injuryordeath.

•Donottransportanattachmentwiththearms

raised.Alwaystransporttheattachmentcloseto

theground;refertoTransportPosition(page9).

•Havethepropertyorworkareamarkedforburied

linesandotherobjects,anddonotdiginmarked

areas.

•ReadandunderstandthecontentofthisOperator’s

Manualbeforestartingtheengine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Neverallowchildrenoruntrainedpeopleto

operatethemachine.

•Keepyourhandsandfeetawayfromthemoving

componentsandattachments.

•Donotoperatethemachinewithouttheguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepbystandersandpetsawayfromthemachine.

•Stopthemachine,shutofftheengine,andremove

thekeybeforeservicing,fueling,orunclogging

themachine.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

3

SlopeSafety

•Operatethemachineupanddownslopeswith

theheavyendofthemachineuphill.Weight

distributionchangeswithattachments.This

attachmentmakesthefrontofmachinetheheavy

end.

•Keeptheattachmentintheloweredposition

whenonslopes.Raisingtheattachmentona

slopeaffectsthestabilityofthemachine.

•Slopesareamajorfactorrelatedtolossofcontrol

andtip-overaccidents,whichcanresultinsevere

injuryordeath.Operatingthemachineonany

slopeoruneventerrainrequiresextracaution.

•Establishyourownproceduresandrulesfor

operatingonslopes.Theseproceduresmust

includesurveyingthesitetodeterminewhich

slopesaresafeformachineoperation.Always

usecommonsenseandgoodjudgmentwhen

performingthissurvey.

•Slowdownanduseextracareonhillsides.Ground

conditionscanaffectthestabilityofthemachine.

•Avoidstartingorstoppingonaslope.Ifthe

machinelosestraction,proceedslowly,straight

downtheslope.

•Avoidturningonslopes.Ifyoumustturn,turn

slowlyandkeeptheheavyendofthemachine

uphill.

•Keepallmovementsonslopesslowandgradual.

Donotmakesuddenchangesinspeedor

direction.

•Ifyoufeeluneasyoperatingthemachineona

slope,donotdoit.

•Watchforholes,ruts,orbumps,asuneventerrain

couldoverturnthemachine.Tallgrasscanhide

obstacles.

•Usecautionwhenoperatingonwetsurfaces.

Reducedtractioncouldcausesliding.

•Evaluatetheareatoensurethatthegroundis

stableenoughtosupportthemachine.

•Usecautionwhenoperatingthemachinenearthe

following:

–Drop-offs

–Ditches

–Embankments

–Bodiesofwater

Themachinecouldsuddenlyrolloverifatrack

goesovertheedgeortheedgecavesin.Maintain

asafedistancebetweenthemachineandany

hazard.

•Donotremoveoraddattachmentsonaslope.

•Donotparkthemachineonahillsideorslope.

SoilCultivatorSafety

•Forwheeledtractionunits,usethecounterweight

onthetractionunitwhenusingtheattachment.

•Alwayslowertheattachmenteachtimeyoushut

offthemachineorleavetheoperatingposition.

MaintenanceandStorage

Safety

•Checkfastenersatfrequentintervalsforproper

tightnesstoensurethattheequipmentisinsafe

operatingcondition.

•RefertotheOperator’sManualforimportant

detailsifyoustoretheattachmentforanextended

periodoftime

•Maintainorreplacesafetyandinstructionlabels,

asnecessary.

4

SafetyandInstructional

Decals

Safetydecalsandinstructionsare

easilyvisibletotheoperatorandare

locatednearanyareaofpotential

danger.Replaceanydecalthatis

damagedormissing.

decal93-7321

93-7321

1.Cutting/dismembermenthazardofhandsandfeet,rotating

knives/blades—stayawayfrommovingparts.

decal100-4708

100-4708

1.Thrownobjecthazard—keepbystandersaway.

decal108-1287

108-1287

1.Crushinghazard,hand—stayawayfrommovingparts.

decal133-8061

133-8061

5

Setup

InstallingtheRoller

1.Removetherollerfromtheshippingstand.

2.Installthecultivatoronthetractionunitand

removeitfromtheshippingstand.

Note:RefertoyourtractionunitOperator’s

Manualformoreinformationoninstalling

attachmentsonyourtractionunit.

3.Lowerthecultivatortotheground.

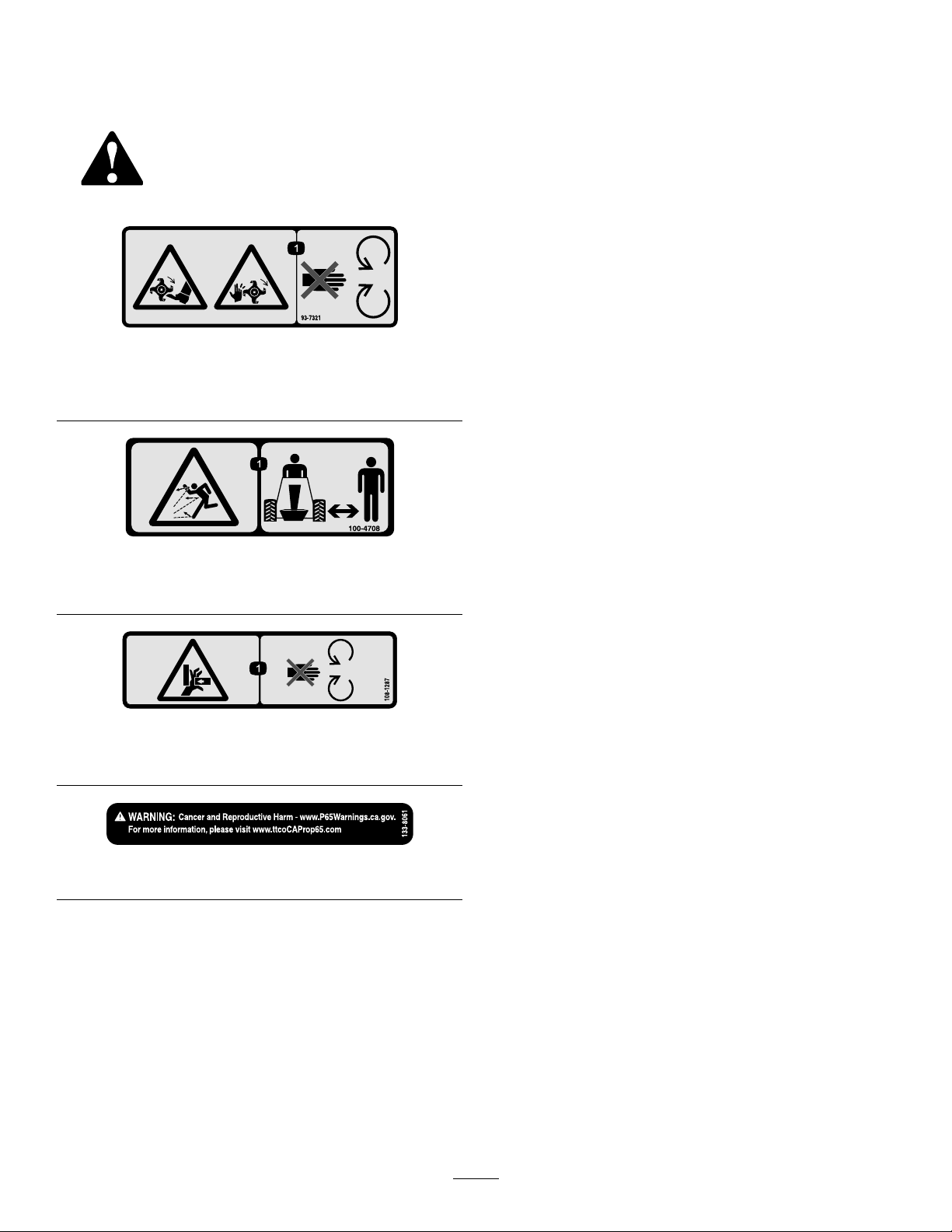

4.Removethesnap-ringclevispinsfromthedrift

pins(Figure3).

5.Removethedriftpinsfromthearmsofthe

cultivator(Figure3).

g030947

Figure3

1.Driftpin3.Cultivatorarm

2.Snap-ringclevispin4.Rollerarm

6.Slidethearmsontherollerintothearmsonthe

cultivatorandconnectthemwiththedriftpins

(Figure3).

7.Securethedriftpinswiththeattachedsnap-ring

clevispins.

ProductOverview

g008177

Figure4

1.Drive-chainhousing4.Graderblade

2.Hydraulichoses5.Roller

3.Diggingtinesandtine

guard

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

Width130cm(51inches)

Length130cm(51inches)

Height53cm(21inches)

Weight250kg(550lb)

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

6

Operation

Determinetheleftandrightsidesofthemachinefrom

thenormaloperatingposition.

InstallingandRemoving

theAttachment

RefertotheOperator’sManualforthetractionunitfor

theinstallationandremovalprocedure.

Important:Beforeinstallingtheattachment,

positionthemachineonalevelsurface,ensure

thatthemountplatesarefreeofanydirtordebris,

andensurethatthepinsrotatefreely.Ifthepins

donotrotatefreely,greasethem.

Note:Alwaysusethetractionunittoliftandmove

theattachment.

WARNING

Ifyoudonotfullyseatthequick-attach

pinsthroughtheattachmentmountplate,

theattachmentcouldfalloffthemachine,

crushingyouorbystanders.

Ensurethatthequick-attachpinsarefully

seatedintheattachmentmountplate.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjected

intotheskinmustbesurgicallyremoved

withinafewhoursbyadoctorfamiliarwith

thisformofinjury;otherwise,gangrenemay

result.

•Ensurethatallhydraulic-uidhoses

andlinesareingoodconditionandall

hydraulicconnectionsandttingsaretight

beforeapplyingpressuretothehydraulic

system.

•Keepyourbodyandhandsawayfrom

pinholeleaksornozzlesthateject

high-pressurehydraulicuid.

•Usecardboardorpapertondhydraulic

leaks;neveruseyourhands.

CAUTION

Hydrauliccouplers,hydrauliclines/valves,

andhydraulicuidmaybehot.Ifyoucontact

hotcomponents,youmaybeburned.

•Weargloveswhenoperatingthehydraulic

couplers.

•Allowthemachinetocoolbeforetouching

hydrauliccomponents.

•Donottouchhydraulicuidspills.

RemovingtheRoller

Tousethecultivatorasatillerwithoutthegrader

orroller,ortoperformvariousadjustmentsand

maintenanceprocedures,removetherollerand

graderasfollows:

1.Parkthemachineonalevelsurface,lowerthe

attachment,tilttheattachmenttoraisetheroller

offoftheground,andengagetheparkingbrake

(ifequipped).

2.Shutofftheengineandremovethekey

3.Removethedriftpinsfromthearmsofthe

cultivator(Figure5).

g030948

Figure5

1.Driftpin3.Cultivatorarm

2.Snap-ringclevispin4.Rollerarm

4.Pulltherolleroffthecultivator(Figure5).

5.Storethepinsinthearmsoftherollerforfuture

use.

Note:Toinstalltheroller,refertoInstallingtheRoller

(page6).

7

SettingtheDiggingDepth

Setthedigdepthofthecultivatoraccordingtothe

workyouareperformingupto13.9cm(5-1/2inches).

Thedepthofcutisdeterminedbythepositionof

theroller.Youcanmovetherollerupanddownby

changingthemountinglocationofthearmsonthe

cultivatorasfollows:

1.Removetherollerfromthecultivator;referto

RemovingtheRoller(page7).

2.Removetheboltssecuringthearmstothe

cultivator(Figure6).

g008181

Figure6

3.Movethearmstothesetofholescorresponding

tothedesireddepth(Figure6).

•Movethearmsuptosetthediggingdepth

deeper

•Movethearmsdowntosetthediggingdepth

shallower.

4.Securethearmsusingtheboltsandnuts

removedpreviously.

5.Installtheroller.

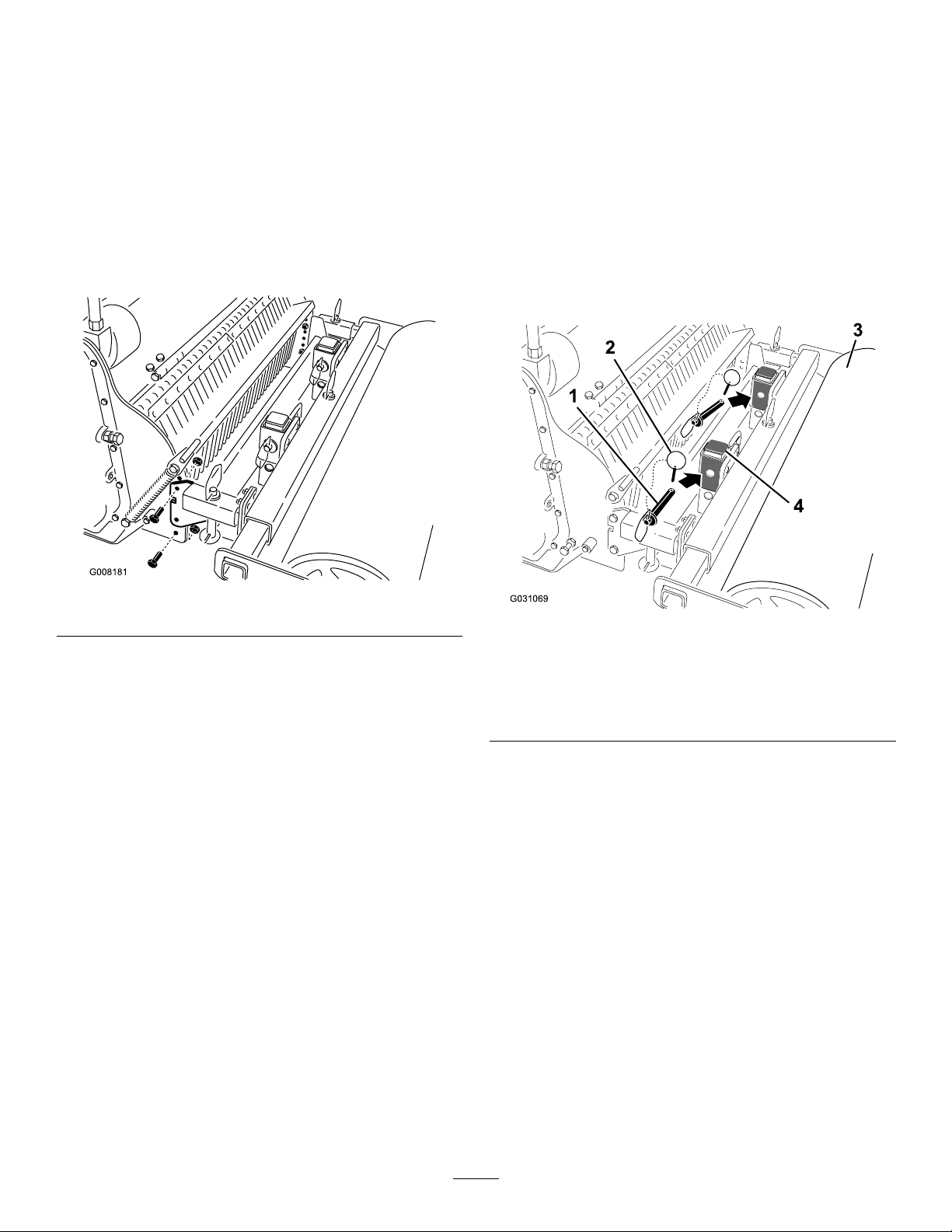

AdjustingtheGraderBlade

Youcanadjustthegraderbladethatsitsjustbehind

therollertogivethedesirednish.Typically,you

shouldadjustitsothattheedgeofthebladeisjust

slightlyhigherthanthebottomoftheroller.

1.Parkthemachineonalevelsurface,lowerthe

attachment,tilttheattachmenttoraisetheroller

offoftheground,andengagetheparkingbrake

(ifequipped).

2.Shutofftheengineandremovethekey

3.Removethedriftpinsfromthegrader-blade

mountingposts(Figure7).

g031069

Figure7

1.Driftpin3.Roller

2.Snap-ringclevispin4.Grader-blademounting

post

4.Slidethegraderbladeupordowntothedesired

holeposition.

5.Placethedriftpinsintomountingposts.

6.Placetheattachedsnap-ringclevispinsintothe

2driftpins.

7.Swingthesnapringsdownovertheendsofthe

pintosecurethegraderblade.

8.Lowertherollertotheground.

8

ChangingtheHorizontal

PositionoftheRoller

Therollerhas3horizontalpositions.Tocultivatealong

theedgeoftheworkarea,aligntheedgesoftheroller

withtheedgesofthecultivator.Tocultivateandarea

withnomessyedgesbetweencultivationpasses,

offsettherollertoeithersidesothatabout15cm(6

inches)oftherolleroverlapsthelastcultivatingpass.

1.Parkthemachineonalevelsurface,lowerthe

attachment,andengagetheparkingbrake(if

equipped).

2.Shutofftheengineandremovethekey

3.Removethedriftpin(Figure8).

g030866

Figure8

1.Snap-ringclevispin3.Roller-supportbar

2.Driftpin

4.Slidetherollertothedesiredposition(Figure8).

5.Insertthedriftpinthroughtheroller-supportbar.

6.Inserttheattachedsnap-ringclevispinthrough

thedriftpintosecuretheroller.

OperatingtheCultivator

1.Lowerthecultivatortothegroundandensure

thatthechaincaseisperpendiculartothe

ground(Figure9).

g008183

Figure9

2.Pulltheauxiliary-hydraulicslevertotheoperator

griptostartthecultivator.

3.Slowlylowerthecultivatoruntilthebladesdig

intothesoilandtherollertouchestheground.

4.Slowlymoverearward.

5.Whenthepassisnished,stopthehydraulics

andraisethecultivator.

Important:Donotdrivethemachineacross

pavementorotherhardsurfaceswithoutrst

raisingthecultivator.Crossinghardsurfaces

withthetineslowereddamagesthetinesandthe

property.

TransportPosition

Whentransportingtheattachment,keepitasclose

tothegroundaspossible,nomorethan15cm(6

inches)abovetheground.Tiltitrearward.

g286182

Figure10

1.Nomorethan15cm(6

inches)abovetheground

2.Tilttheattachment

rearward.

9

OperatingTips

•Inspecttheareawherethecultivatoristobe

usedandremoveallobjectssuchaslargerocks,

trash,andbranchesbeforecultivatingtoprevent

equipmentdamage.

•Alwaysbegincultivatingwiththeslowestground

speedpossible.Increasethespeedifconditions

permit.

•Alwaysusefullthrottle(maximumenginespeed).

•Cultivateinlong,straightpasses.Turningwith

thetinesloweredcausesequipmentandproperty

damage.

•Ifarockorotherobstructiongoesintothetines,

disengagethehydraulicsanddrivethetraction

unitforwarduntiltheobstructionisdislodged.

•Ifyouareusingatractionunitwithaowdivider

(somewheeledunitshaveowdividers;referto

yourtractionunitOperator’sManual),youcanuse

theowdividertoachievetheoptimalrotorand

groundspeedforyoursoilconditionsasfollows:

1.Settheowdividertothe9o’clockposition

andthespeedselectortotheturtleposition.

2.Pulltheauxiliaryhydraulicslevertothe

operatorgriptostartthecultivator.

3.Movetheowdividerleverwhilemovingthe

tractionunitrearwarduntilthecultivation

resultsareideal.

10

Maintenance

Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

CAUTION

Ifyouleavethekeyintheswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheswitchbeforeyouperformanymaintenance.

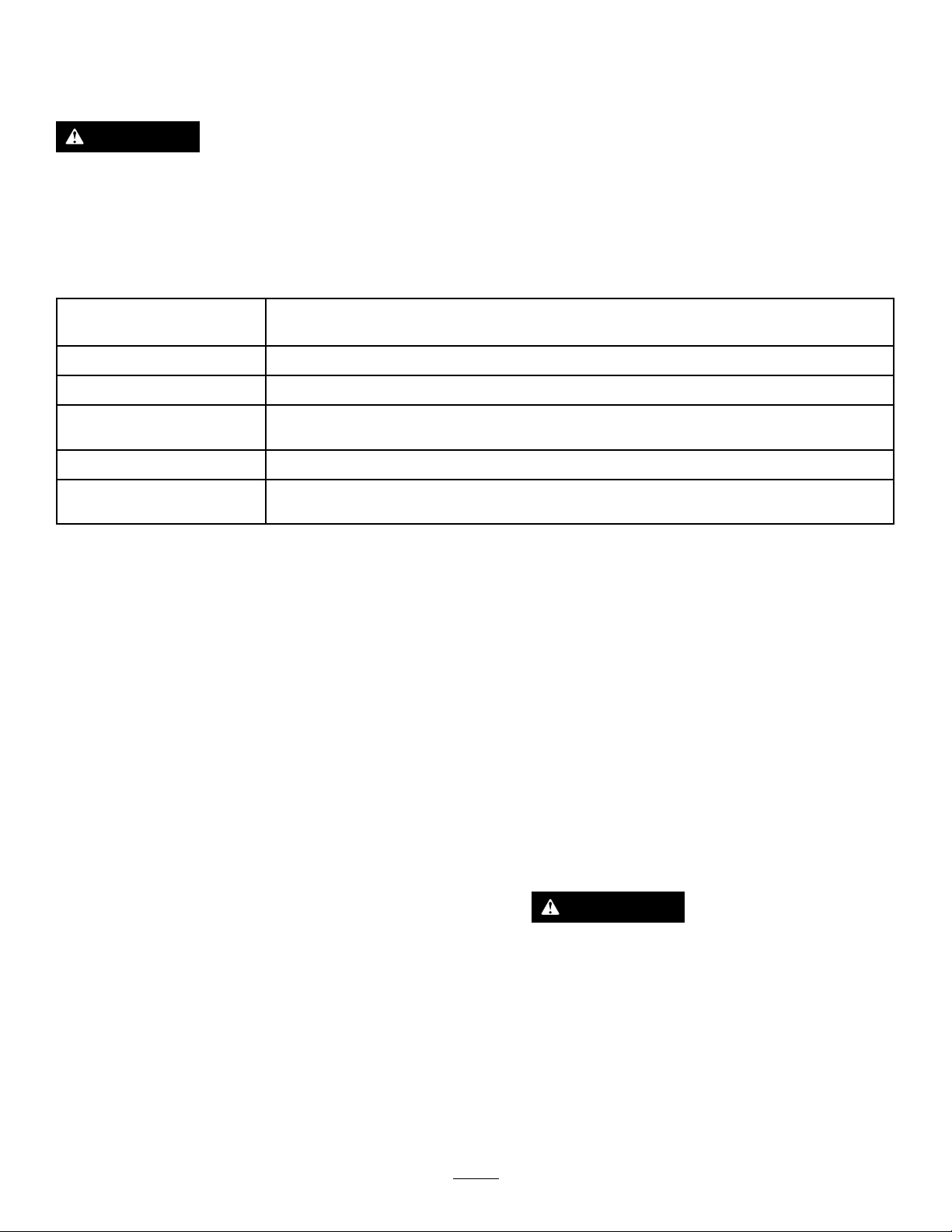

RecommendedMaintenanceSchedule(s)

MaintenanceService

IntervalMaintenanceProcedure

Aftertherst5hours•Adjustthedrive-chaintension.

Aftereachuse•Cleandebrisfromtheattachment.

Every25hours•Greasethecultivator.

•Adjustthedrive-chaintension.

Every200hours•Changethedrive-chainoil.

Beforestorage•Greasethecultivator.

•Paintchippedsurfaces.

GreasingtheCultivator

ServiceInterval:Every25hours

Beforestorage

Greasethe2ttingsontheendsoftherollerand1

ttingonthe4-boltangeontheleftsideofthemain

housing.

GreaseType:General-purposegrease

Important:Greaseimmediatelyafterevery

washing

1.Parkthemachineonalevelsurface,lowerthe

attachment,andengagetheparkingbrake(if

equipped).

2.Shutofftheengineandremovethekey

3.Cleanthegreasettingswitharag.

4.Connectagreaseguntoeachtting.

5.Pumpgreaseintothettingsuntilgreasebegins

tooozeoutofthebearings.

6.Wipeupanyexcessgrease.

ChangingtheDrive-Chain

Oil

ServiceInterval:Every200hours

Checkthegearlubricationoillevelinthegearcase

every25operatinghoursandchangeitevery200

operatinghoursoronceayear,whichevercomesrst.

OilType:85W140

1.Parkthemachineonalevelsurface,engagethe

parkingbrake(ifequipped),andensurethatthe

drive-chaincoverisperpendiculartotheground.

2.Raisetheattachmenthighenoughtoplacea

panunderthedrive-chaincaseandsupportthe

attachmentwithjackstands.

WARNING

Mechanicalorhydraulicjacksorthelift

armsmayfailtosupportthecultivator

andcauseaseriousinjury;usejack

standstosupportthecultivator.

Donotusetheliftarmsaloneorhydraulic

jacks.

3.Shutofftheengineandremovethekey

4.Opentheoil-llholeontopofthedrive-chain

case(Figure11).

11

g008186

Figure11

1.Oil-llhole3.Sideplug

2.Drainplug

5.Placealargedrippanunderthedrive-chain

case.

6.Removethedrainplug(Figure11).

7.Whenalloftheoilhasdrainedfromthecase,

replaceandtightenthedrainplug.

8.Removethesideplug(Figure11).

9.Pouroilintothellholeslowlyuntiloilrunsout

theside-plughole.

10.Replacethesideplugandoil-llholeplugand

tightenthem.

11.Wipeupanyspilledoil.

AdjustingtheDrive-Chain

Tension

ServiceInterval:Aftertherst5hours

Every25hours

1.Parkthemachineonalevelsurface,lowerthe

attachment,andengagetheparkingbrake(if

equipped).

2.Shutofftheengineandremovethekey

3.Loosenthejamnutonthechain-adjustingscrew

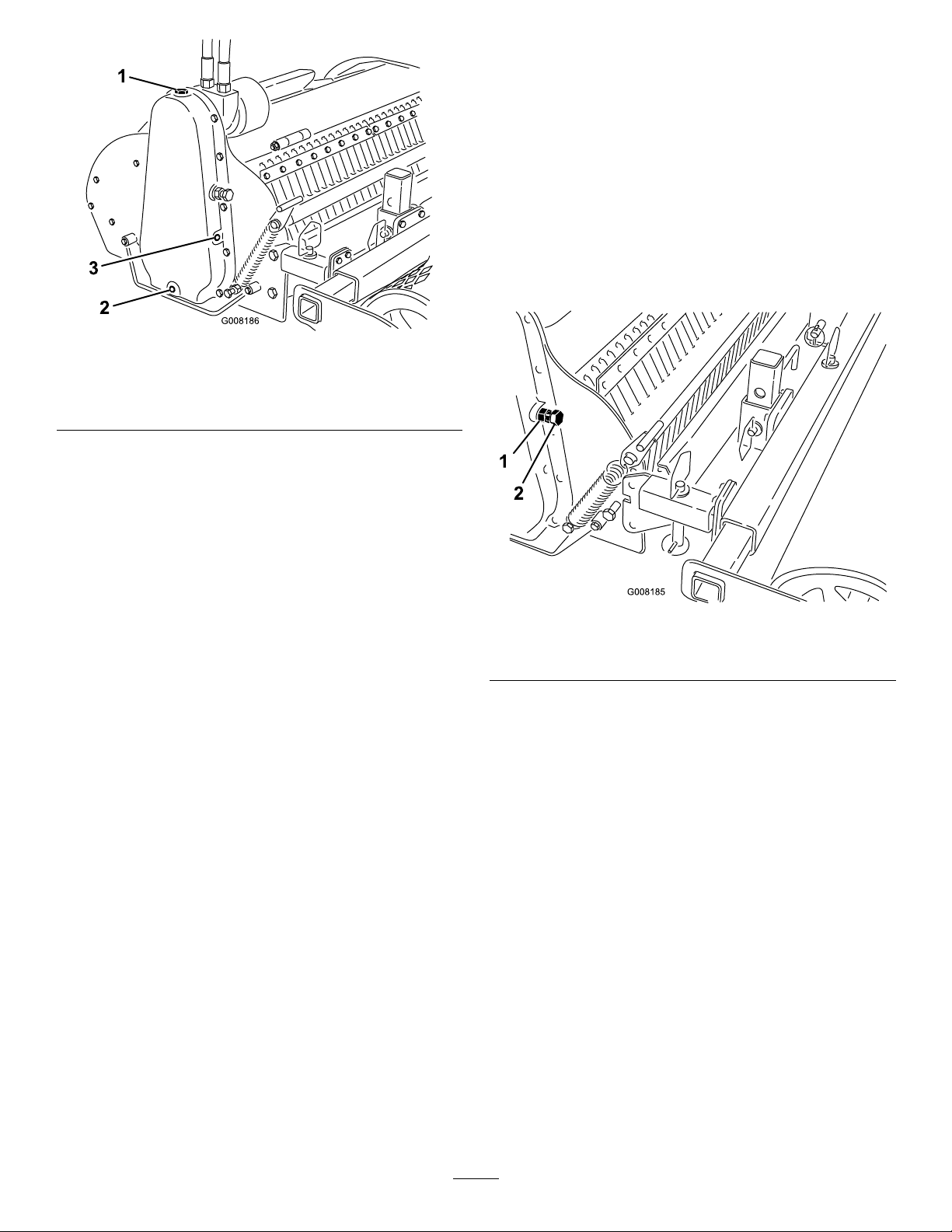

(Figure12).

g008185

Figure12

1.Jamnut2.Chain-adjustingscrew

4.Turnthescrewbyhanduntilyoufeelresistance

(Figure12).

5.Markthescrewwithapencilandthenunscrew

it1turn.

6.Tightenthejamnut.

12

ReplacingTines

Checkandreplacetineswhentheybecomeworn

ordull.Wornordulltinesdegradetheperformance

ofthecultivator

1.Parkthemachineonalevelsurface,lowerthe

attachment,andengagetheparkingbrake(if

equipped).

2.Shutofftheengineandremovethekey

3.Removetherollerassemblyfromthecultivator.

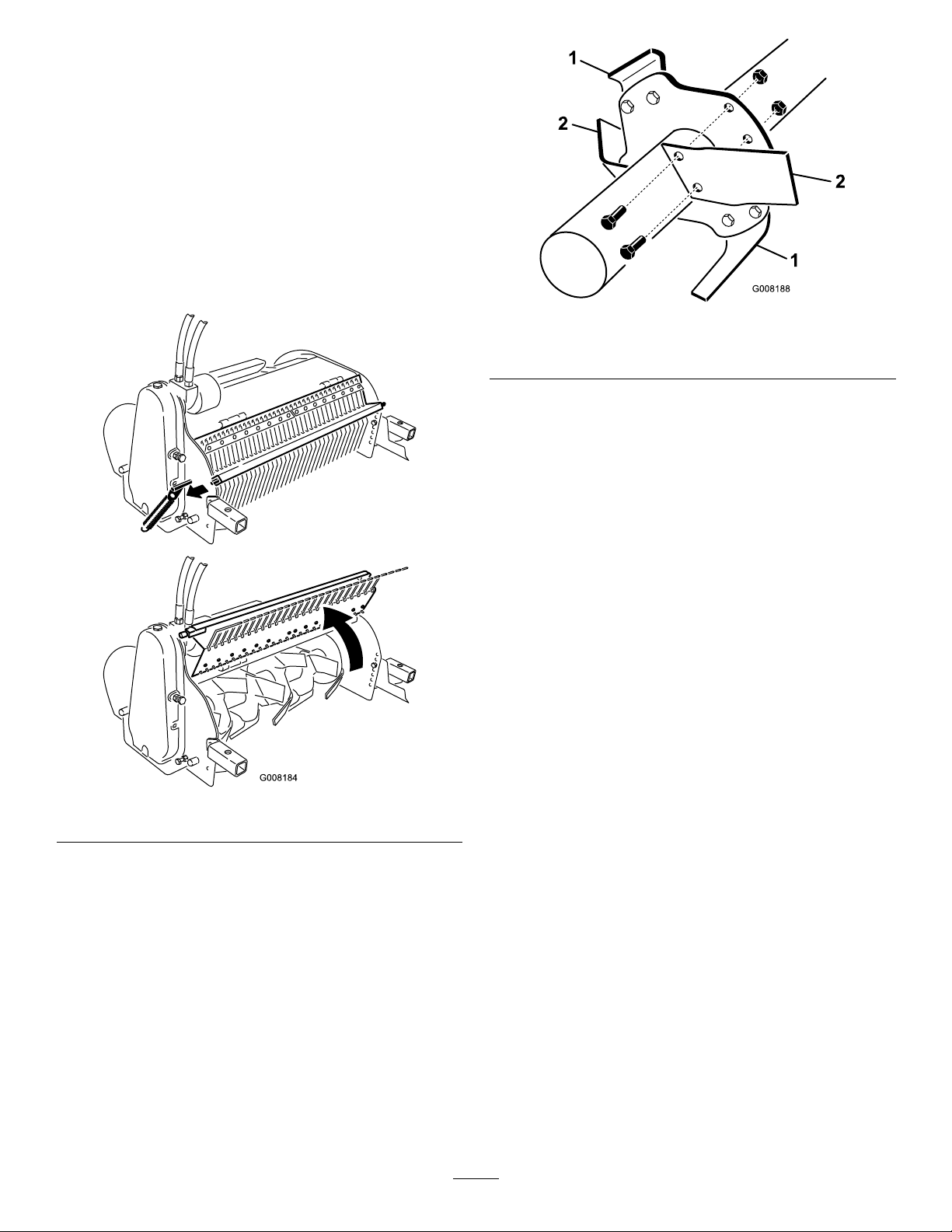

4.Liftupandreleasethespringcatchontheside

ofthecultivator(Figure13).

g008184

Figure13

5.Openthetinecover(Figure13).

6.Removeoldtines,1atatime,andinstallthe

newtines(Figure14).

Note:Eachcenterhubhas4tines(2right-hand

and2left-hand).Theleftandrighttinesare

alternatedonthehub.Ensurethatyoureplace

eachtinewiththesametypeoftinethatwas

installedpreviously.

g008188

Figure14

1.Lefttine2.Righttine

7.Torquethetine-mountingboltsto86to104N∙m

(63to77ft-lb).

8.Closethetinecoverandsecureitwiththespring

latch.

9.Installtherollerassembly.

13

Storage

1.Beforelong-termstorage,washtheattachment

withmilddetergentandwatertoremovedirtand

grime.

2.Greaseallttings.

3.Checkandadjustthetensionofthedrivechain.

4.Checkandtightenallhardware.Repairor

replaceanydamagedorwornpart.

5.Ensurethatallhydrauliccouplersareconnected

togethertopreventcontaminationofthe

hydraulicsystem.

6.Paintallscratchedorbaremetalsurfaces.Paint

isavailablefromyourAuthorizedServiceDealer.

7.Storetheattachmentinaclean,drygarageor

storagearea.Coverittoprotectitandkeepit

clean.

14

Troubleshooting

ProblemPossibleCauseCorrectiveAction

1.Ahydrauliccouplerisnotcompletely

connected.

1.Checkandtightenallcouplers.

2.Ahydrauliccouplerisdamaged.2.Checkthecouplersandreplaceany

thataredamaged.

3.Thereisanobstructioninahydraulic

hose.

3.Findandremovetheobstruction.

4.Ahydraulichoseiskinked.4.Replacethekinkedhose.

5.Theauxiliaryvalveonthetractionunit

isnotopening.

5.Repairthevalve.

6.Ahydraulicvalveorthedrivemotoris

damaged.

6.ContactyourAuthorizedService

Dealer.

7.Thereisanobstructioninthecultivator

(eg,rockorroot).

7.Findandremovetheobstruction.

8.Thedrivechainisloose.8.Adjustthechaintension.

Thecultivatordoesnotoperate.

9.Thedrivechainisbroken.9.Repairorreplacethechain.

15

Notes:

Notes:

DeclarationofIncorporation

ModelNo.SerialNo.ProductDescriptionInvoiceDescriptionGeneralDescriptionDirective

23102319000001andUpSoilCultivator,Compact

ToolCarrierSOILCULTIVATORCompactToolCarrier2006/42/EC

RelevanttechnicaldocumentationhasbeencompiledasrequiredperPartBofAnnexVIIof2006/42/EC.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedToromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Certied:AuthorizedRepresentative:

MarcelDutrieux

ManagerEuropeanProductIntegrity

ToroEuropeNV

Nijverheidsstraat5

2260Oevel

Belgium

JoeHager

Sr.EngineeringManager

8111LyndaleAve.South

Bloomington,MN55420,USA

March7,2019

EEA/UKPrivacyNotice

Toro’sUseofYourPersonalInformation

TheToroCompany(“Toro”)respectsyourprivacy.Whenyoupurchaseourproducts,wemaycollectcertainpersonalinformationaboutyou,eitherdirectly

fromyouorthroughyourlocalT orocompanyordealer.Torousesthisinformationtofullcontractualobligations-suchastoregisteryourwarranty,

processyourwarrantyclaimortocontactyouintheeventofaproductrecall-andforlegitimatebusinesspurposes-suchastogaugecustomer

satisfaction,improveourproductsorprovideyouwithproductinformationwhichmaybeofinterest.T oromayshareyourinformationwithoursubsidiaries,

afliates,dealersorotherbusinesspartnersinconnectiontheseactivities.Wemayalsodisclosepersonalinformationwhenrequiredbylaworin

connectionwiththesale,purchaseormergerofabusiness.Wewillneversellyourpersonalinformationtoanyothercompanyformarketingpurposes.

RetentionofyourPersonalInformation

Torowillkeepyourpersonalinformationaslongasitisrelevantfortheabovepurposesandinaccordancewithlegalrequirements.Formoreinformation

aboutapplicableretentionperiodspleasecontact[email protected].

Toro’sCommitmenttoSecurity

YourpersonalinformationmaybeprocessedintheUSoranothercountrywhichmayhavelessstrictdataprotectionlawsthanyourcountryofresidence.

Wheneverwetransferyourinformationoutsideofyourcountryofresidence,wewilltakelegallyrequiredstepstoensurethatappropriatesafeguardsare

inplacetoprotectyourinformationandtomakesureitistreatedsecurely.

AccessandCorrection

Youmayhavetherighttocorrectorreviewyourpersonaldata,orobjecttoorrestricttheprocessingofyourdata.Todoso,pleasecontactusbyemail

at[email protected].IfyouhaveconcernsaboutthewayinwhichT orohashandledyourinformation,weencourageyoutoraisethisdirectlywithus.

PleasenotethatEuropeanresidentshavetherighttocomplaintoyourDataProtectionAuthority.

374-0282RevC

CaliforniaProposition65WarningInformation

Whatisthiswarning?

Youmayseeaproductforsalethathasawarninglabellikethefollowing:

WARNING:CancerandReproductiveHarm—www.p65Warnings.ca.gov.

WhatisProp65?

Prop65appliestoanycompanyoperatinginCalifornia,sellingproductsinCalifornia,ormanufacturingproductsthatmaybesoldinorbroughtinto

California.ItmandatesthattheGovernorofCaliforniamaintainandpublishalistofchemicalsknowntocausecancer,birthdefects,and/orother

reproductiveharm.Thelist,whichisupdatedannually,includeshundredsofchemicalsfoundinmanyeverydayitems.ThepurposeofProp65isto

informthepublicaboutexposuretothesechemicals.

Prop65doesnotbanthesaleofproductscontainingthesechemicalsbutinsteadrequireswarningsonanyproduct,productpackaging,orliteraturewith

theproduct.Moreover,aProp65warningdoesnotmeanthataproductisinviolationofanyproductsafetystandardsorrequirements.Infact,the

CaliforniagovernmenthasclariedthataProp65warning“isnotthesameasaregulatorydecisionthataproductis‘safe’or‘unsafe.’”Manyofthese

chemicalshavebeenusedineverydayproductsforyearswithoutdocumentedharm.Formoreinformation,gotohttps://oag.ca.gov/prop65/faqs-view-all.

AProp65warningmeansthatacompanyhaseither(1)evaluatedtheexposureandhasconcludedthatitexceedsthe“nosignicantrisklevel”;or(2)

haschosentoprovideawarningbasedonitsunderstandingaboutthepresenceofalistedchemicalwithoutattemptingtoevaluatetheexposure.

Doesthislawapplyeverywhere?

Prop65warningsarerequiredunderCalifornialawonly.ThesewarningsareseenthroughoutCaliforniainawiderangeofsettings,includingbutnot

limitedtorestaurants,grocerystores,hotels,schools,andhospitals,andonawidevarietyofproducts.Additionally,someonlineandmailorder

retailersprovideProp65warningsontheirwebsitesorincatalogs.

HowdotheCaliforniawarningscomparetofederallimits?

Prop65standardsareoftenmorestringentthanfederalandinternationalstandards.TherearevarioussubstancesthatrequireaProp65warning

atlevelsthatarefarlowerthanfederalactionlimits.Forexample,theProp65standardforwarningsforleadis0.5μg/day,whichiswellbelow

thefederalandinternationalstandards.

Whydon’tallsimilarproductscarrythewarning?

•ProductssoldinCaliforniarequireProp65labellingwhilesimilarproductssoldelsewheredonot.

•AcompanyinvolvedinaProp65lawsuitreachingasettlementmayberequiredtouseProp65warningsforitsproducts,butothercompanies

makingsimilarproductsmayhavenosuchrequirement.

•TheenforcementofProp65isinconsistent.

•CompaniesmayelectnottoprovidewarningsbecausetheyconcludethattheyarenotrequiredtodosounderProp65;alackofwarningsfora

productdoesnotmeanthattheproductisfreeoflistedchemicalsatsimilarlevels.

WhydoesToroincludethiswarning?

Torohaschosentoprovideconsumerswithasmuchinformationaspossiblesothattheycanmakeinformeddecisionsabouttheproductstheybuyand

use.T oroprovideswarningsincertaincasesbasedonitsknowledgeofthepresenceofoneormorelistedchemicalswithoutevaluatingthelevelof

exposure,asnotallthelistedchemicalsprovideexposurelimitrequirements.WhiletheexposurefromToroproductsmaybenegligibleorwellwithinthe

“nosignicantrisk”range,outofanabundanceofcaution,T orohaselectedtoprovidetheProp65warnings.Moreover,ifT orodoesnotprovidethese

warnings,itcouldbesuedbytheStateofCaliforniaorbyprivatepartiesseekingtoenforceProp65andsubjecttosubstantialpenalties.

RevA

This manual suits for next models

1

Table of contents

Other Toro Tiller manuals

Toro

Toro 29518 User manual

Toro

Toro GREENS AERATOR 09120 User manual

Toro

Toro 23515 User manual

Toro

Toro 23102 User manual

Toro

Toro 58601 User manual

Toro

Toro 33513 User manual

Toro

Toro Dingo 22445 User manual

Toro

Toro 09802 HydroJect 3010 User manual

Toro

Toro 09802 HydroJect 3010 User manual

Toro

Toro 9801 User manual